Modern gas boilers have automation that turns off the equipment when a malfunction occurs. The user can look at the error code on the information panel and identify the cause of the failure. Displays are installed in almost all Baxi gas boilers for ease of use. The manufacturer produces many different models, so you can choose equipment based on your capabilities and requirements.

Gas boilers, like other equipment, fail. Using the error code, you can identify the cause of the failure. Baxi gas equipment can be installed in any room. Boilers are suitable not only for residential buildings, but also for industrial ones. The room in which the boiler will be installed must comply with all safety standards and regulations. Do not forget about good ventilation in the boiler room, which is necessary for the normal operation of gas equipment.

Error e10

The most common error in Baxi gas boilers is e10. Due to incorrect operation of the sensor, which controls the circulation of the coolant in the heating system and the operation of the pumping equipment, this error code may appear. When the coolant pressure drops to a critical level, the automation may operate. In addition, the problem may arise due to lack of contact between the board and the pressure switch. This reason is the most popular when error e10 appears in Baxi gas boilers. Also, if the pump does not operate correctly, an error may occur. If the filter system or heat exchanger is clogged, code e10 may also appear.

Installation features

Baksi devices use gas as a coolant, and despite all its undeniable advantages, it is dangerous. Gas boilers require a professional approach. The slightest error in installation can lead to very negative consequences. Installation of the device should only be carried out by highly qualified specialists. List of problems that DIY work can lead to:

- Freezing of the device in the winter season.

- The occurrence of an explosion.

- Fire.

- Penetration of carbon monoxide into residential areas.

Of course, modern gas devices have a high-quality protection system, but even “smart” automation is not always able to cope with problems that arose due to unprofessional intervention. If we talk about a less serious outcome of the matter, the most common problem with self-installation is the incorrect operation of the equipment. For example, the device may not turn on and display error codes, despite the fact that the device is fully operational.

Baksi boilers are energy-dependent units. They are not able to function without being connected to the mains. The connection rules are quite simple and are no different from the requirements for installing a standard electrical device. The device is connected to a 220 V network; grounding is required.

Of course, if there is no grounding, the boiler will not turn on with a “bang” sound, but this may negatively affect the operation of the equipment. Quite often, the boiler displays error codes due to simple connection errors. If at the moment it is not possible to ground, you should purchase a stabilizer with galvanic isolation.

In addition to the need for grounding, there are other features when installing equipment. It is very important to follow these recommendations:

- In order for the boiler to function properly, the pressure must be 170-250 V. At a lower voltage, the equipment will turn off, and at a higher voltage, the varistor will burn out.

- The sinusoid should flow without disturbances. Such devices react very negatively to voltage surges. Professionals advise installing additional voltage stabilizers. When installing gas boilers, there is no need to use UPS devices.

- The connection must be made through a separate machine.

- If the model is phase-dependent, it is necessary to maintain the correspondence of phase and zero.

Troubleshooting error e10 Baxi

Let's look at the most common reasons why error e10 appears:

- The minimum pressure switch is inoperative.

- Reduced water pressure in the heating circuit.

- Lack of contact between the sensor and the control board.

First of all, it is recommended to check the pressure gauge data. There should be an arrow in the green zone. Most often, you can eliminate the error by filling the heating system with coolant using a make-up tap.

If after this the error does not disappear or appears after several hours or days, then this is a good reason for concern. Most likely, the error appeared due to a coolant leak. The leak may be in the primary heat exchanger, make-up valve, emergency relief valve, heating system, or damaged gaskets and seals. Leaks can be diagnosed by visually inspecting all connections and hydraulic components.

Error code E35

A fairly common heating equipment recently is the Baksi gas boiler. Error E10 (how to fix it was mentioned above) is not the only malfunction that sometimes accompanies the operation of such devices. If you encounter error code E35, then the problem may be expressed in the flame control sensor. This unit is necessary to signal the presence of flame before opening the valves.

The reasons why the control sensor did not work can be very diverse, but the most likely of them is moisture and condensation on the electronic board; the problem may also be a stray flame. If we are talking about an electronic board, then you need to look for it in the boiler itself. But if these assumptions are not confirmed, then the reason should be sought in the persistent flame that remains after the equipment is turned off. The manufacturer emphasizes that this problem may be due to insufficient valve tightness. But most often this error resolves itself; to do this, you just need to try to reboot the boiler.

What to do if you have low blood pressure

For high-quality operation of the heating system, in which the coolant circulates normally and does not overheat, a pressure that corresponds to the norm is necessary. In order to monitor this indicator, a special pressure control sensor is installed. In addition, you can independently check the indicators using a mechanical pressure gauge.

New users often encounter this problem, so you should follow these steps:

- Check the readings on the mechanical pressure gauge. If the arrow is not in the green zone, but in the red, then you need to move on to the next point.

- In different models, the make-up valve is located in different places. It is usually located near the pressure gauge and at the entrance to the water pipe equipment. If you cannot find the feed tap, its location can be found in the instructions for the Baxi gas boiler. The make-up valve can be black or red with a square cross-section, or black and blue with a round cross-section.

- Through the make-up tap, it is necessary to fill the heating system to the required level. You can open the tap counterclockwise; you can usually hear the sound of water entering the gas boiler. After you hear the noise, you no longer need to turn it, but just watch the pressure gauge needle. When the arrow moves to the green zone and is above the 1 bar mark, you need to close the tap clockwise.

- Once the pressure in the heating boiler is at normal levels, error e10 should disappear and the equipment will automatically begin to operate.

In a closed heating system, pressure may often drop due to coolant leakage. Typically, pressure loss occurs once every 6-12 months. It is often not recommended to feed a gas boiler, as this has a bad effect on the heat exchanger and, consequently, reduces its service life. The cost of this element is quite high and amounts to about 40% of the total cost of a gas boiler. Tap water contains various impurities of minerals and salts, which at high temperatures are deposited on the walls of the heat exchanger. Consequently, the cross-country ability and efficiency of the element are reduced.

Main characteristics

Baxi equipment can be installed in buildings of any purpose. It is perfect for both city apartments and large private houses. However, the room in which the device will be installed must meet several criteria:

- Its area must be at least 15 cubic meters.

- The ceiling height is at least 2.2 meters.

- Availability of high-quality ventilation.

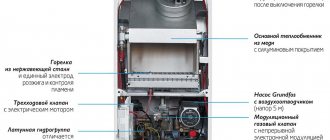

These parameters can be ignored if the choice was made in favor of a boiler with a closed combustion chamber. Such a device is a real mini-boiler room that meets all the necessary criteria and does not harm the environment.

The Baksi company produces many models of heating equipment and can offer units of various capacities. In Russia, the following boiler models are in great demand: Main Four 240 °F (Main For 240f), Eco Four (Ecofor), Luna (Moon).

The pressure is normal, but the gas boiler shows error e10

Using a pressure switch, the pressure is controlled by the heating boiler control board. This device does not measure pressure, but determines the value. The sensor has 2 contacts and 2 positions. If the pressure in the gas boiler is less than 0.45 bar, then the contacts are open, but if it is more, they are closed. To check the serviceability of the sensor, the resistance at the contacts is measured. In order to do this, you need to turn off the power to the gas boiler, then remove the wires from the sensor and check the resistance with a multimeter. If the readings do not meet the requirements, the sensor must be replaced.

It is not recommended to exclude the sensor from the security system by permanently closing the contacts.

Troubleshooting instructions

If you purchased a Baxi boiler, error E10 may become a reality for you. Therefore, before starting to operate such equipment, it is necessary to understand the main types of problems. They are indicated by codes that can be divided into two groups, namely: the equipment goes into standby mode or completely blocks the operation of the device.

In the latter case, the problem can be solved by simply rebooting the unit. Such an error indicates that serious problems have arisen that can create dangerous situations for human life and health. That is why such a failure should be treated with special attention. Among them, the lack of traction, lack of fuel supply, and overheating of the device should be highlighted. If you purchased a Baxi boiler, error E10 can resolve itself. However, without human intervention such an outcome is unlikely. But if this happens, then it can be argued that the automation turned on the device on its own.

The expansion tank is faulty with error e10

Almost all models of Baxi gas boilers are equipped with an expansion tank, which is necessary to compensate for the expansion of the coolant during heating. This device consists of two metal panels that are separated by a rubber membrane. One part contains coolant, and the other contains nitrogen or air. When filled, the air chamber has a pressure of 0.8 bar. It may happen that the pressure in the expansion tank will be more or less than the nominal one, therefore, the heating system will not work correctly: the pressure of the hydraulic system will decrease or increase and error e10 will appear.

Using a special valve, you can check the pressure of the expansion tank, and also adjust it by pumping air with a car pump.

If you are not confident in your abilities and cannot identify the exact cause of this error, then it is better to contact an experienced specialist who will do his job efficiently.

If the cause of error e10 is incorrectly installed, there can be negative consequences. In our store you can buy spare parts for gas boilers inexpensively in Moscow.

Error E10 boiler Baxi Leave

Most of the recommendations for troubleshooting heating equipment in the manufacturer's instructions boil down to one thing: contact a service workshop. Error e10 for Baxi boilers is common, and the method for solving the problem is not difficult. The article explains in detail what the user should do when the 10th fault code appears.

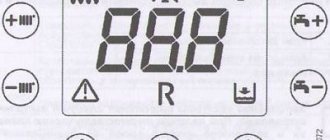

Error E10 on the Baxi control panel

Decoding

Error E10 is generated by the electronic unit of the Baxi boiler when the OB pressure switch is triggered . Occurs when the pressure in the heating circuit drops below a critical value (0.5 bar) . The relay contacts open, and the automatic protection system stops the unit upon an emergency signal. Knowing this, it is not difficult to understand the method for eliminating error e10.

Check the readings of the control device

If the boiler pressure gauge needle leaves the green sector (turns to red), bring the coolant volume to normal . The feed tap of any version of Baksi is located at the bottom of the heating installation, next to the connection pipe for the cold water pipe. It opens counterclockwise until the characteristic noise of incoming liquid appears. At the same time, the pressure is monitored using the Baksi boiler pressure gauge. When the arrow moves to the green zone (˃1 bar), error e10 will disappear , the tap must be closed: the unit will start on its own.

Check the pressure gauge on the Baxi boiler

On a note! The pressure in the “cold” system when filled from cold water should be 0.5 bar less than in the expansion tank.

Master's advice

Loop Condition Assessment

Pressure drop in a closed system , error E10 is caused by a leak. By inspecting the facility, it is easy to identify the problem area of the highway by wet spots on the floor. Particular attention should be paid to the joints. With regular hydraulic shocks, this is where the depressurization of the circuit occurs. Pipes, radiators, and equipment included in the heating circuit are subject to inspection.

A pipe is leaking in the heating system. Leaking in places of shut-off valves (taps, valves, plugs)

If error e10 of the Baksi boiler appears infrequently (once every few months), but regularly, the leak is insignificant. A difficult case - a microcrack cannot be detected by inspection. Small droplets of liquid flowing from it do not have time to fall to the floor - they evaporate. To determine the location of the defect, you need to wait until the pipes and radiators cool down. After some time, a stain will appear under the damaged area.

Keep an eye on the connections in the heating system [always]

Pressure switch testing

If filling the system does not remove the E10 error, then its probable cause is the pressure switch . The sensor in Baksi boilers is initially set to 0.45 bar. When the pressure in the heating circuit increases, its contacts close and the board receives a switch-on permission signal. Accordingly, a drop in pressure leads to a break in the circuit, and error E10 is issued, blocking the operation of the boiler in emergency mode.

Pressure switch in gas boiler baxi

- Eliminating a fault code begins with the simplest action - checking the signal line. Unreliable contact, break, short circuit - the causes of error e10. Such defects are determined visually: for inspection, unscrew the mounting screws and fold back the bottom panel of the Baxi boiler. A poor connection is caused by oxidation of the lamellas, so it is worth removing the plug from the sockets, assessing the condition and firmly installing it in place again.

- The second stage is sensor diagnostics. To check, the voltage is removed from the Baksi boiler, the wires are disconnected from the pressure switch, and the contacts are tested with a multimeter. After bringing the coolant level to normal, they must be closed (R = 0): under the pressure of the liquid, the membrane presses on the moving group, the signal circuit is closed.

On a note! On thematic forums there are recommendations from “experts” regarding the elimination of error E10: bypass the pressure sensor. The code will disappear, but there is no need to talk about the safe operation of Baksi after such a “repair”. A pressure switch excluded from the protection circuit will not react if the coolant volume critically decreases. As a result, overheating, failure of the heat exchanger and other structural parts. The cost of the device is about 20% of the price of the boiler. There is little benefit, since the problem is not completely solved. But the consequences are unpredictable, including significant material costs to eliminate them.

Checking the expansion tank

Users forget about it, but it is this special tank that often causes error e10. The cavity of the tank is divided into 2 compartments, one is filled with nitrogen or air under pressure in the range of 0.8–1.2 bar.

Non-compliance with this value is reflected in the correct operation of the system, as a result, error e10 is displayed: possibly due to a crack in the body, rupture of rubber goods or its adhesion to the wall of the vessel (if the tank has not been used for a long time). The defect can be determined by examining the “pear” by removing it from the tank.

Membrane models RB cannot be repaired - only replaced. If the air pressure in the tank compartment is low, bring it to normal using a car pump.

Board diagnostics

This is the last probable reason for the appearance of error e10 in the Baksi boiler. You cannot do it on your own, no matter what home-grown experts say. This is the case when you need to contact a service center. On-site repair consists of replacing the module and does not require much time. Full electronics testing is carried out on a bench in the workshop.

Source: https://fixbroken.ru/oshibka-e10-kotla-baksi/

How to run self-diagnosis

A special launch of self-diagnosis of the Baxi boiler is impossible, since this system turns on immediately with the unit and operates in continuous mode. The system is formed by a network of sensors located in all main components of the boiler.

They constantly monitor the situation and give a signal immediately if any failures or failures of any element occur . It is sent to the control board, which reacts to changes in sensor readings by generating an error code displayed on the boiler display and blocks the operation of the device until the problem is resolved.

IMPORTANT!

The presence of a self-diagnosis system is a great advantage of the equipment, since it makes it possible to avoid serious accidents, allowing you to protect an expensive installation from destruction or failure. The owner of the installation is spared the need to constantly check the condition of the boiler; smart and advanced automation does everything for him .

E98 baksi. Expensive board replacement?

We believe that there is no need to rush to buy a new board. An error found by the self-diagnosis system indicates that the malfunction is not emergency and most likely the board can be repaired by replacing the faulty component.

In any case, to identify a malfunction, you will need to diagnose the board itself, and to carry out subsequent repairs, you will need special equipment and appropriate qualifications, diagrams, and spare parts.

We have all the necessary equipment and spare parts for repairing electronic boards; the accumulated experience allows us to quickly carry out repairs, and this is especially true in cases where a board malfunction occurred during the heating season. Remanufactured boards are available for the most common BAXI boiler models (mainfour, ecofour). In our catalog you can see prices for baxi boards.

Other errors 97 and 99 can occur for the same reasons, but the likelihood of damage to board components is small and they are less common.

Errors E25 and 26

In some cases, the Baksi boiler displays an E10 error, but if you notice a code on the display that is different from this one, then you need to consider the causes of the problem more seriously. For example, error E25 may be indicated by exceeding the maximum temperature. The manufacturer himself says this. In this case, you need to pay attention to the heating circuit temperature sensor. But first you should check the pump, as well as the cleanliness of the filters, clogging of which in the heating system can lead to insufficient coolant circulation.

If error E25 occurs, the pumping equipment may simply be blocked. But there is also the possibility that the heating system is partially or completely aired. The last action, when all of the above assumptions are excluded, is to check the temperature sensor. It may fail. If you also chose the Baksi boiler, error E10 (what to do to eliminate it was described above), of course, may occur. However, not only this code indicates some problems in the operation of the device. Sometimes error E26 also occurs. True, it is much less common compared to all the others. This code is associated with a temperature sensor failure. If the device produces this designation, then you can be sure that the temperature has risen above 20 °C.

Additional Information

To prevent breakdowns and errors from appearing, you must follow certain rules . It is important to take the following into account:

- For the system to work well, you need 170-250 V. If the voltage is lower, the device will turn off, but if the voltage is higher, the varistor will burn out.

- Gas boilers are very sensitive to power surges. Experts strongly recommend purchasing additional devices to stabilize it.

- To connect you need to create a separate functionality.

- If a phase-dependent type of boiler is used, you need to ensure that the phase coincides with zero.

Baksi heating systems are excellent equipment for the home. When operating, it is very important to follow the instructions and follow the recommendations given by the manufacturer. In case of problems, problems should be resolved in a timely manner. In case of serious damage, there is no need to try to restore the operation of the unit with your own hands; it is best to contact a professional.

In this video you will learn how to repair boilers:

Valve clicks

Gas valve clicks can be observed for various reasons - from a weak contact on the relay, to a difference in gas pressure in the main line and the boiler valve system. In each case, solving the problem requires its own actions.

Restore the gas valve relay contact group, adjust the minimum and maximum gas pressure, check the inlet reducer setting. All this work must be carried out by specialists from the service center; it is extremely dangerous to interfere with the operation of gas equipment on your own .