A home heating boiler using solid fuel and electricity is designed to heat buildings without centralized heating. It is convenient because energy consumption is regulated independently.

A combined heating boiler is needed to heat buildings.

What are solid fuel and electric boilers?

All combined models are divided according to the following parameters:

- number of circuits;

- supported fuel types;

- type of combustion chamber.

Scope of application

The range of use of the units is small; they are mainly purchased for heating houses where there is no other heating, as well as in saunas or baths.

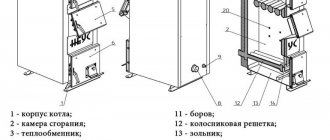

Combination boiler design

All heat generators consist of:

- steel body painted with heat-resistant paint;

- combustion chambers;

- heat exchanger;

- smoke exhaust systems;

- an ash pit separated from the firebox by grates;

- protective, adjustment, control and measuring instruments (these include pressure gauges, temperature sensor, drain pipe, pressure relief valve, gate lock, heat limiter).

Solid fuel boiler design.

Specifications

Basic data includes:

- Thermal power during operation.

- Electrical energy consumed.

- Weight, dimensions.

Principle of operation

The operation of combined units consists of the following stages:

- Fuel is added to the combustion chamber and ignited. After which the water is heated, its temperature is regulated by a thermostat. At this stage, the heating elements do not work.

- After burning a batch of wood or coal, the water begins to cool. When the minimum value is reached, the sensor is triggered and the heaters are turned on.

- If you add a new portion of fuel, the device operates without electricity.

Heat exchanger material

Since the thermal efficiency of a heat generator is decisive for the entire heating system, manufacturers use materials with high thermal conductivity to manufacture heat exchangers. Typically this is steel and cast iron for solid fuel installations, and copper and aluminum for gas installations. In modern combined units, especially those with a dual-circuit layout, heat exchangers made of cast iron, steel or non-ferrous metals or their alloys can be used simultaneously.

Prices for Kentatsu combi boilers

Kentatsu combi boilers

Advantages of combi boilers

Benefits include:

- Cheap fuel. Wood waste is used.

- Economical.

- A reliable automation system that controls the operation of the unit in the absence of a person.

- The coolant heats up quickly, and the loss coefficient is minimal.

- There is no need to heat at night, because... The heating elements automatically turn on and provide a continuous heating process.

- Multi-fuel models provide for the use of firewood, coal and peat.

- The service life is 20 years.

The advantages of combined boilers include efficiency.

Disadvantages of equipment

Disadvantages of heating devices:

- High price.

- Large dimensions. The devices are made only floor-standing due to the wood-burning firebox. They will need a separate room.

- The need to install a chimney and forced ventilation.

- Large mass of cast iron firebox.

- The equipment will require a foundation or concrete pad.

- The power limit of the heating element is no higher than 30 kW.

- A complex device that increases the complexity of installation and the cost of repairs.

Multi-fuel boilers and electrical installations - which is better?

To buy suitable equipment, you need to focus on the following criteria:

- Place of installation (house or apartment).

- Area of heated premises.

Electrical appliances are small in size and are hung on the wall to save space. They do not require a special room, chimney, or hood, because... they do not emit harmful substances into the atmosphere. Disadvantages include high energy consumption, the need to install separate wiring, and energy dependence. Such units are recommended for use in apartments or as a backup system.

Multi-fuel boilers are small in size.

Multi-fuel devices are convenient because they support different raw materials:

- firewood;

- coal;

- peat;

- wood waste;

The presence of a heating element will protect you in the absence of solid fuel.

In any case, when choosing which is better - an electric boiler or a solid fuel boiler, each user decides based on his needs.

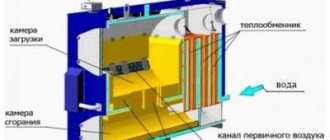

Principle of operation

The operating principle of stoves operating on wood and electricity is based on the possibility of automatically turning on electric heating elements when the temperature drops (after solid fuel burns out). This happens as follows:

- Kindling and heating of the stove is carried out using firewood. Since the firebox is located at the bottom of the device, it transfers heat from the burning wood to the upper part of the device - to the heat exchanger. An increase in coolant temperature is detected by a sensor installed in the system line;

- when the temperature begins to drop due to fuel burning, the electrical circuit is automatically closed and electric heaters are connected to operation;

- from this moment on, the specified coolant temperature parameters are maintained by the heating elements, based on the readings of the air or water sensor;

- when loading the next batch of solid fuel, the electrical part is automatically switched off, as the coolant is heated

- already from the side of the combustion chamber.

This transition from wood heating to electric heating and vice versa ensures continuous heating of water in the heat exchanger, which allows you to maintain the optimal temperature in the house around the clock.

Wood and electric stoves come in two types:

- single-circuit - connected to the heating system and used only for heating;

- double-circuit - designed to heat the coolant in the heating system and hot water for domestic needs.

Selecting a combi boiler

To purchase suitable heating equipment, you need to consider the following parameters:

- Type of energy carrier.

- Dimensions.

- Technical characteristics (power).

- Efficiency

- Number of circuits.

- Firebox dimensions. This parameter affects how often it loads.

Possibility of connecting a water circuit

The combined equipment has a special structure, due to which the coolant quickly heats up. In addition, a boiler is connected to the units. Some models provide for the connection of a “warm floor” system, which will allow additional heating of the premises.

A boiler can be connected to the combined equipment.

Heat exchanger material

This device is considered an important design element, because heats the water to the required parameters. When choosing heating equipment, you should pay attention to the material from which the heat exchanger is made:

- Steel is most often used because... this metal is easy to process and has a low cost. Such devices are resistant to high temperatures and do not deform during operation. The advantages of steel heat exchangers include maintainability, low weight, and low cost.

- Cast iron is used only in floor-standing models. Such devices are resistant to high temperatures and have a long service life. Disadvantages include the need for cleaning, large weight and size, which complicates replacement.

- An alloy of aluminum with silicon (silumin) is resistant to aggressive environments. This type of heat exchanger is used in floor-standing equipment. The disadvantage is sensitivity to the composition of water, which affects the protective layer. Therefore, only filtered liquid can be used.

- Copper is considered the best material, because... It is lightweight, corrosion resistant and durable. The main disadvantage is the high cost.

Required power

This parameter is considered the most important, because a weak boiler will not provide a comfortable temperature, and if the power is exceeded, fuel consumption increases and water can boil, which reduces the service life of the equipment. So, to heat 10 m², 1 kW of heat energy is used. It is recommended to make allowances for the height of the rooms, the number of storeys of the building and the thickness of the walls and leave a reserve of 0.5 kW.

Boiler power is an important parameter.

Type of solid fuel

There are many types of consumables for combined equipment:

- Firewood. Their heat transfer depends on humidity and wood type.

- Pellets are granules with a diameter of 8 mm and a length of up to 5 cm. They are produced by pressing waste wood, straw, corn, etc. They are highly effective and popular in European countries.

- Fuel briquettes (eurowood). Made from wood processing waste under pressure at a temperature of +260°C. This creates durable bars that are similar in texture to firewood.

- Coal. Has high calorific value. Disadvantages include ash content and environmental pollution.

- Peat. It is formed by rotting plants at high humidity in swampy areas in the absence of oxygen. The main advantages are simple storage conditions and affordable price.

Availability of safety valve

When choosing solid fuel boilers, it is important to pay attention to the safety device.

Its main function is to ensure safe operation and eliminate accidents that occur when water overheats and pressure increases.

Fuel chamber size

The devices are available with various parameters. The frequency of filling depends on the dimensions of the firebox. In small chambers you have to add fuel more often, and this is inconvenient, especially at night.

The size of the fuel chamber varies.

Dimensions and weight of the boiler

The combined appliance is large in size and weight due to the firebox, which is often made of cast iron. Therefore, it is worth determining the installation location in advance.

Features of operation

To light the stove, you can use wood chips or splinters. They need to be placed in the combustion chamber and set on fire. After the fire has flared up, larger firewood is laid. The air dampers should be open at this moment; you can close them after the fire has engulfed the logs.

Heating a room with an electric wood stove, regardless of where exactly it is located, can be potentially dangerous. Therefore, there are safety precautions during operation designed to reduce dangerous situations to a minimum:

- a metal sheet must be laid on the floor in front of the combustion door;

- Grounding must be connected to the device body;

- Clean the chimney in a timely manner.

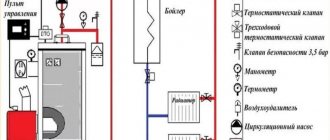

Requirements for installation of a combi boiler

Such units are considered dangerous equipment, so their placement must comply with the required standards.

Room

The following rules are established for the location:

- The walls in the boiler room must be made of non-combustible materials.

- The boiler is located 300 mm from the walls.

- Dry room.

- Cement screed under the unit.

- It is prohibited to place flammable materials near the boiler.

- It is necessary to install a metal sheet in front of the firebox to prevent fires from sparks or dropped fuel.

Chimney

A combined heating system requires the installation of a pipe to remove harmful substances. For stable combustion you need good draft, for this the chimney is installed higher than the roof. Its diameter must be no less than that of the boiler pipe. A hermetically sealed connection at the joints is necessary to avoid smoke in the room. In the cold season, it is recommended to insulate the chimney.

A combined heating system requires the installation of a chimney.

Circuit

The universal device provides for the operation of a heating element, so it is better to make a separate wiring for it that will withstand the existing power.

The connection of the unit must be carried out by certified specialists.

Where is the best place to install?

A wood-burning and electric stove must be installed in a room with a normal level of humidity, the walls of which are lined with non-combustible materials. The choice of location is determined depending on the decoupling scheme of the heating system.

General connection diagram

An asbestos board is placed under the device, which simultaneously serves as a leveling layer and protects the floor covering from fire. The room must be equipped with high-quality supply and exhaust ventilation and a chimney. Special requirements apply to the electrical network in the room:

- the brand and cross-section of the electrical wire must correspond to the maximum current consumed by the furnace;

- It is recommended to connect the unit to the network via a differential relay, which will operate if there is a current leak of 30 mA;

- devices with a power of 2 - 5 kW are usually designed for a supply voltage of 220 V and are connected to a regular single-phase power line at home. More powerful stoves are produced for a voltage of 380 V; to connect them, a three-core cable is required.

Well-known manufacturers of solid fuel and electric boilers

There are many manufacturers of equipment for private homes that produce various models.

“Teplodar Cooper Praktik 14”

Model 2022 with 14 kW. The heating area is 140 m². Combined type - solid fuel, built-in heating elements. Suitable for any system.

“Teplodar Cooper Praktik 14” heats 140 m².

“Karakan 16TPEV 3”

A powerful long-burning boiler is designed for heating rooms up to 160 m². Made from 3 mm sheet steel. The device has 2 circuits and runs on the following types of fuel:

- firewood;

- wood waste;

- peat;

- coal;

- electricity.

The second circuit is designed to heat water for domestic needs. There is a hob on the top panel.

“Teplodar Cooper OVK 18”

A solid fuel boiler with a heating element heats rooms with an area of 100 m² to 180 m². The upper part is the cooking surface. Connection is made on the right and left sides. It is possible to install a gas burner. A 2 year warranty is provided.

“Teplodar Kupper OVK 18” is a solid fuel boiler.

For heating a smaller room, a “Kupper OVK 10” boiler is suitable.

Lamborghini Calor el DB DN EVO 32

The heat generator works with gas or diesel burners. The body is made of cast iron with steel elements. These boilers are reliable and easy to operate. The advantages include:

- low fuel consumption;

- stylish design;

- compactness.

- The kit includes additional Lamborghini burners of the EKO, FIRE, EM series.

Ferroli Atlas EVO 47

A single-circuit boiler with a floor-mounted forced-air burner has a cast-iron heat exchanger. The model is equipped with digital control. Runs on gas and diesel fuel. There is a liquid freeze protection function.

Ferroli Atlas EVO 47 is a single-circuit boiler.

Buderus Logano G125

The floor-standing electric boiler is made of cast iron and operates on liquid fuel. Available in 25 kW, 32 kW and 40 kW power outputs. The burner is set at the factory, so it works immediately after switching on. A boiler connection is provided.

“Evan Warmos TT 18”

A modern solid fuel device has an improved design that ensures safe surface temperatures, low weight and good thermal power.

“Evan Warmos TT 18” is a solid fuel device.

ACV Delta Pro S 25

The device runs on gas and liquid fuel. The model is equipped with an indirect heating system using “tank in tank” technology. The equipment has a large heat exchange surface area.

Prices: summary table

| Manufacturer and model | Heat exchanger material | Number of circuits | Efficiency, % | price, rub. |

| Teplodar Kupper OK 15 | steel | single-circuit | 78 | 26 900-36 200 |

| Viadrus Hercules U22 D-4 | cast iron | single-circuit | 80 | 83 000-90 500 |

| Roda Brenner Classic BCR-04 | cast iron | single-circuit | 80 | 53 000-55 000 |

| HEPHAESTUS VPR KSTGV-20 | steel | double-circuit | 80 | 23 500-26 400 |

| Karakan 20 TEGV | steel | double-circuit | 75 | 28 500-31 000 |

Reviews of combination boilers

Tatyana, 60 years old, Bataysk

My husband built a 2-story house on a summer cottage. There is a small fireplace on the 2nd floor, but it is not enough to heat the entire building. It's cold on the 1st floor. Then we bought a boiler. Since there is no gas supply or central heating to the house, and there are rare interruptions in electricity, we had to buy a combined type.

The most affordable boiler for us turned out to be a solid fuel boiler with heating element. There were no problems with the installation, because... We had a small extension to the house that was suitable for a boiler room. We are satisfied with the operation of the boiler; the heating elements turn on at night, so there is no need to get up and add firewood. I also regulate the temperature and electricity consumption myself.

Anatoly, 38 years old, Pskov

I was skeptical about combined models due to their high cost and large dimensions. But my brother only recommended this type. I liked it because of the possibility of using waste wood or coal. And when you are too lazy to heat, the electric heating turns on. Now I plan to install a “warm floor”.

Evgeniy, 39 years old, Rostov

I have had a solid fuel boiler for 10 years. During all this time there were no breakdowns, I am satisfied with the quality of the material. He equipped a boiler room especially for him. The area of my house is 85 m², it is fully heated. Since my wife and I have 3 children, we connected the heated floor. I'm happy with everything.