Heating from a wood stove in Russia, rich in forests, was for a long time the only way to heat a home. More recently, alternatives have appeared - gas or electric heating, each with its own advantages, which, however, have begun to decline rapidly due to the continuous increase in energy tariffs. Today, many owners have begun to consider water heating in a private home from a wood-burning stove as a practical option for heating a country house, which has additional benefits.

Traditions combine perfectly with technology Source kelohouse.ru

Advantages and disadvantages of stove heating

Traditional stove heating is preferred by many rural residents because it has time-tested advantages:

- Autonomy . The house does not need to be connected to additional communications, which is always expensive and troublesome. The operation of the system is based on the principle of natural circulation.

- Savings during installation . Equipment for a furnace connected to water heating is cheaper than for other heating systems.

- Availability of fuel . Firewood is a natural, abundant and cheap fuel throughout much of the country. There are combined furnaces that allow the use of coal, peat briquettes, and coke.

- Savings during operation . Some stoves (long-burning designs) can significantly reduce wood consumption.

- Environmentally friendly . Burning natural fuels does not harm the environment.

- Aesthetics . Modern wood stoves can become a significant interior detail.

Autonomy of operation is an important feature of a wood-burning stove Source heaating.ru

Along with the undoubted advantages, stove heating also has some disadvantages:

- Relatively low efficiency . The efficiency (coefficient of performance) of the furnace will always be lower than the efficiency of a gas or diesel boiler. Significant losses of thermal energy occur through the chimney.

- Constant service . For the system to operate smoothly, constant human supervision is required; It is impossible to establish automatic operation; you need to monitor the fuel supply and waste disposal.

- Slow and uneven heating of rooms . The stove will only warm up the room where it is installed; in the far corners of a spacious house it will be noticeably colder

- Usage skills . Maintaining the combustion process in a firebox is more difficult than in a boiler.

- Place . It is necessary to allocate a place to store a supply of firewood.

- Fire hazard . Individual parts of the structure need careful insulation (which is especially important if the building is wooden). Another difficulty is that combustion cannot be stopped instantly.

You will have to find a place to store firewood Source pinterest.com

See also: Catalog of companies that specialize in the installation of fireplaces and stoves.

Types of stoves for heating a country house and other buildings

Compact, highly efficient devices with a beautiful design are very popular among the population. Manufacturers are trying to satisfy the demand for this type of equipment, so they are developing entire lines of devices that have a diverse set of adjustments. Thanks to the wide range, everyone can choose the model that best suits their needs.

Wood burning stoves

Such products, profitable from an economic point of view, will not only become a highlight of the interior of the room, but will also last for a long period of time. Ignition and heating of buildings (even quite voluminous and large in area) occurs in the shortest possible time. Some units on the market are additionally equipped with a hob. The latter quality makes the devices universal.

The process of servicing the unit will not cause difficulties even for an inexperienced stove operator - the ash can be removed while the fireplace is operating. However, with all the positive properties of the device, it also has negative aspects:

- Heat is not distributed well enough - the air masses at the top of the room are much warmer than at the bottom.

- The rapid formation of soot deposits in the chimney is a phenomenon due to abundant condensation of excessively hot smoke. With regular use, pipes need to be cleaned of deposits between seasons.

Ovens with built-in hob

This auxiliary function of the heater is pleasantly combined with its reliability and operating efficiency. Thanks to the huge variety of options, the device will fit into any interior design and can even become its main accent. It is easy to install, easy to operate and maintain. Manufacturers recommend using only high-quality wood as fuel. If this rule is neglected, the efficiency of the device decreases. Difficulties may also arise when it is necessary to reduce the temperature of the steel plane. When choosing equipment, take this fact into account and give preference to the one that is equipped with additional doors to reduce the temperature. Food cooked on such a surface has a special aroma and taste.

Additional Pros and Cons of a Water Loop System

The design of the water circuit makes it possible to distribute heat more evenly throughout the home. Stove heating, supplemented with a water circuit system, is characterized by improved parameters and additional advantages:

- Productivity . A system with a water circuit is capable of efficiently warming up large areas of housing. Due to its high specific heat capacity, water absorbs and releases significant amounts of energy, with little loss during transportation.

- Size . The water circuit has small dimensions, unlike, for example, the air ducts of an air-convection system, which often remain visible.

- Multitasking . A stove for heating a house with water heating can easily cope with several tasks: maintaining a comfortable air temperature in the rooms, heating water for domestic needs and cooking.

- Coolant quality . Water is a safe and affordable filler for the home circuit.

Visualization of a structure with a large firebox and a water circuit Source yandex.uz

The use of water has disadvantages due to its physical and chemical properties:

- High freezing point . If people live in a country cottage all year round, nothing threatens the water circuit. If your home sits empty during the winter, water can freeze, expand, and damage the system. A common solution is to drain the water (but then the corrosion of metal parts increases). An alternative option, the use of antifreeze, is not suitable for all systems and radiators and requires additional cash injections.

- Composition of water . If the water circulating through the system has a high salt content, scale forms on the internal parts and corrosion begins. Undesirable processes can be slowed down by adding special additives to the system. Arranging a closed system will also help extend the life of the water circuit.

The Dutch oven has high heat output and takes up little space. Source opalennia.com

Positive sides

The use of stoves for heating homes has a long history. They are still often used due to many advantages that are not available to modern heaters:

- complete autonomy and independence from external factors if there is a supply of fuel. To operate such heating there is no need for electricity, gas, or water;

- the cost of installing furnaces is several times lower than the cost of installing equipment for using other types of heating;

- the frequency of the process and the availability of firewood in some regions, coupled with its low price, make this type of heating economical.

If you have sufficient skills, it is possible to do stove heating for a private home yourself. In its design, most often there is no liquid coolant, which is used as water. This makes it possible to stop the combustion process for a long time and resume it at any time, regardless of any conditions. The last factor is most relevant for buildings with temporary presence of people, for example, for dachas and garden houses. However, water heating can be added if desired by installing pipes and radiators.

When constructing a furnace, there are various options available. At the stage of construction of the stove, you can make it in the form of a fireplace, provide in the design of stove beds, dryers, stoves, and build in tanks for heating water.

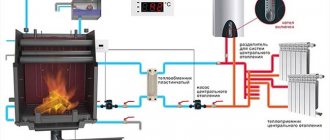

Water heating device

Water heating systems installed in modern buildings can be implemented in two ways. In the most common radiator system, rooms are heated thanks to all kinds of radiators (batteries). A less common type is a heated floor system. Here, the role of heating elements is performed by pipes located in the floor screed. The elements of any heating system with a water circuit include:

- Heat generator . A stove or fireplace with a heat exchanger that produces heat to heat the coolant.

- Heating circuit . A system of pipes through which water circulates. In a heated floor system, the pipes are also a heating element.

- Heating elements . The main heating of the rooms is carried out thanks to radiators; their design promotes maximum heat transfer.

- Expansion tank (open or membrane). It helps avoid damage to the system when pressure increases.

A stove with a water circuit in a house with an attic Source otopleniehouse.ru

- Circulation pump . Maintains water movement in the system at the proper level.

- Additional elements . Depending on the type of system, various control devices and security sensors are built into it. A variety of shut-off and control valves may also be present.

DIY pipe boiler

An iron boiler welded from a metal pipe has a very simple structure. Preparatory work in this case is limited only to the study of several drawings of these devices, as well as the acquisition of all required consumables.

Almost always, such boilers are made from a metal pipe of fairly large diameter. It is most convenient to take a diameter of approximately 500 mm; a length of no more than one meter would be quite suitable. Due to this, you can get a device that can create a comfortable temperature in a room, the volume of which is about 15 cubic meters or approximately 9 square meters.

To produce such a boiler it will not be possible to do without the following tools:

- Inverter or electric welding machine;

- Angle grinder or grinder;

- Metal cutting wheels for grinders.

Construction of a solid fuel boiler for a bathhouse

First prepare the pipe:

- At the first stage, three supports are made that will stand parallel to the surface of the earth at three different levels. To do this, you need to take three pieces of reinforcement, the diameter of which should be 14 mm and the length 3 cm. The first level is required in order to install the stove. The second one is placed depending on where the blower door will be located. The third is installed 20 cm from the top edge of the pipe;

- The bottom is a circle of the required dimensions, which is cut from a steel sheet whose thickness is at least 5 mm;

- For the grate, through which combustion products will fall, as well as the oxygen required to maintain combustion, a circle of sheet metal will be required. An already perforated sheet is taken or slots are made in it;

- The furnace lid acts as a support for the stones, so it is also made of sheet steel with a thickness of 5 mm. In the central part you need to cut a hole into which the chimney pipe is inserted;

- A slot is made in the lower part of the future boiler to install the door;

- Instead of a door, in some cases a box is installed through which fuel will be supplied to the boiler.

The entire structure is assembled at its final location following the following sequence of actions:

- At the first stage, a box is welded into the structure. If this work is already carried out directly in the bathhouse, then the box is placed in the boiler in such a way that it goes either into the dressing room or onto the street;

- A chimney pipe is welded into a pre-prepared hole. This work should be given as much attention as possible, since if even the slightest hole is left, combustion products will pass through it into the steam room and accumulate there. This can have a very negative impact on a person’s health;

- The structure is quite heavy, so it is necessary to build a foundation for it. The easiest way is to make a reinforced concrete slab. Instead, a concrete or reinforced concrete screed is suitable. Moreover, it is poured onto crushed stone, the layer of which must be at least 15 cm;

- The structure is placed on a prepared base, and stones are placed on the lid.

In principle, instead of a metal pipe, craftsmen often use a barrel of suitable sizes. Moreover, this structure can be built without the use of any power tools, except for a welding machine - all holes are cut out with a chisel or an ax. All other actions will be exactly the same as when working with a piece of pipe.

Boilers for saunas made of pipes with heaters

Operating principle of a water heating system

Such a system can work in two ways:

- Based on natural (gravitational) circulation of water . Natural circulation of water becomes possible due to the fact that the specific gravity of cold water is greater (it is heavier) than hot water. Such a significant difference allows cold water, which has given up heat and flows through the pipes to the heat exchanger, to displace hot water into the heating circuit. The main condition for organizing such a system: the entry point of cold water into the heat exchanger is designed below the exit points from the radiators. In order for the condition to be met, they try to place the heat exchanger as low as possible, often in the basement.

Diagram of a closed heating system with a storage boiler Source petrenco.com

- Based on forced water circulation . In private buildings with an area of more than 80-100 m2, the natural circulation system becomes ineffective - it takes a long time to warm up and is poorly regulated. The problem is solved by installing a circulation pump in front of the heat exchanger. It ensures constant movement of water along the circuit, allows you to flexibly regulate pressure and quickly increase or decrease the heating temperature. Depending on the model, the pump may have different dimensions, be integrated into the circuit differently and produce noise of varying degrees.

Material selection

Well-fired solid clay bricks are used to construct the furnace. It is possible to use ordinary building solid bricks made of clay, provided that the firebox is lined with refractory bricks. The masonry mortar is made from oily clay with the addition of fine sand.

The part of the chimney located above the roof level must be made of sand-lime brick with cement mortar. The temperature of the flue gases in this area of the chimney is already low, and exposure to heat and atmospheric moisture (as well as exposure to wind and precipitation) will quickly destroy the clay brick.

For the manufacture of doors, grates, and valves, finished cast iron products are used, produced at enterprises specializing in the production of such products.

About the features of furnaces with a water circuit (PVC)

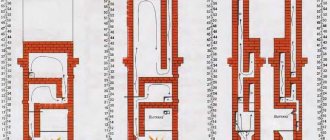

Wood-burning stoves for water heating at home can have different appearance, power characteristics and additional functionality. If they are installed not in a technical room (basement, boiler room), but in a residential area (kitchen, living room), its appearance also becomes important. A modern wood-burning stove can fit into any interior and become a decoration of the living room. Based on the material used, stoves are divided into three types:

- Brick.

- Metal (steel or cast iron is used).

- Combined (as a rule, a metal combustion chamber is framed by a brick body).

How to choose a heating device

If you intend to purchase equipment of this type, you need to decide on the following important nuances:

- How will the installation work - as the only source of heating or as an addition to a gas or electric boiler.

- Whether cooking is required - many models are equipped with this function.

- The volume of the heated room must be taken into account. The power, material of the firebox and its dimensions depend on this parameter.

- Location and battery life are also important factors.

- Availability of water connection.

Budget options made of steel are usually installed in country houses and garages. In buildings with large areas it is better to use cast iron units.

Video description

About the visualization of the stove project with a water circuit in the following video:

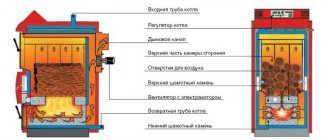

Wood stoves built into a water circuit can also be divided according to the method of burning fuel:

- Stoves with traditional firebox . Such stoves have a volumetric combustion chamber where a large amount of firewood is placed.

- Pyrolysis or gas generating units . These stoves have a special design, thanks to which the wood burns slowly. During combustion, flammable gas accumulates, which is then burned in a separate chamber.

A special feature of any PVC is a heat exchanger, which can be made in the form of a coil, radiator or boiler. The size and type of device is affected by the volume of the firebox; At the same time, the design of the heat exchanger determines the efficiency of the furnace. Based on the organization of the heat exchanger, furnaces are divided into three groups:

- The heat exchanger is built into the firebox and is a simple chamber (water boiler) made of sheet steel or a pipe system. This method reduces the capacity of the firebox; There is also a risk of damage (leakage or explosion if overheated).

The pyrolysis furnace is characterized by high efficiency and economy Source pechivdom.ru

- The heat exchanger is placed around the perimeter of the combustion chamber or in the chimney duct (then called a tubular flat register), which increases the efficiency of the system. Such PVCs are more technologically advanced, more expensive and are not suitable for use in gravity systems. If power outages are possible, the circulation pump will require autonomous power.

- Pyrolysis furnaces , where the heat exchanger is located next to chambers filled with hot gas. The furnace equipment is characterized by a complex structure and the highest efficiency; energy is effectively absorbed by the coolant (water), and the smoke from the furnace comes out barely warm. For the full operation of pyrolysis structures, the quality of workmanship and the steel used are important.

Operating principle

Devices with long fuel combustion, when compared with conventional traditional designs, are more economical and efficient. This is due to the peculiarities of their functioning. For such units, one fill of fuel lasts much longer. To understand how a slow-burning stove for a home differs from a classic firebox, it is necessary to consider their components in more detail.

The process during which wood burns slowly is called pyrolysis. To describe this in simple terms, they say that there is “active smoldering” of the fuel in the combustion chamber, since a minimum oxygen concentration is ensured there. Under such conditions, a fairly large volume of pyrolysis gas is released, which has enormous energy potential.

After the wood is placed in the stove, ignition is performed. The damper plays a significant role in this procedure. While the wood is burning, the door is required to be open, then, after 35-45 minutes, when the house warms up, it is closed. The first step is to heat the unit and dry the wood. Then heat transfer begins and the release of a flammable gas mixture. The latter goes into a special afterburning chamber, where it burns. Thus, the stored fuel burns out, doubling the efficiency, while minimizing the consumption of firewood. In long-burning stoves for the home, all combustion products of wood briquettes are emitted directly through the chimney into the atmosphere.

Brick PVC - operating features

Often, water heating is combined not only with a fireplace or a modern wood-burning stove. For many, the best option would be to install a classic brick stove as a source of thermal energy. By properly expanding the capabilities of a brick oven using a water circuit, you can efficiently heat not only the nearest living rooms, but also the entire building. To increase the efficiency of a brick kiln, various designs of heat exchangers have been developed (coils and registers act as them). The operation of such a system in suburban housing has features, which include:

- Arrangement . To build a high-quality stove and then install water heating, you will need highly qualified craftsmen.

- Size . A large traditional Russian stove takes up a lot of usable space and does not fit in every kitchen. An alternative for modest-sized rooms would be a Dutch or Swedish brick oven. Such designs are characterized by smaller sizes, but full functionality.

Heat exchanger installation diagram Source ogon.guru

- Improved efficiency . The maximum efficiency of the furnace does not reach 50%; half of the heat (and money) disappears irretrievably in the pipe. The design of a full-fledged water heating system allows you to increase this parameter to 80-85%, which is comparable to the characteristics of industrial boilers operating on solid fuels.

- Inertia . Unlike electric boilers, it will take some time to heat up a system connected to a brick oven.

- Care . Burning wood leaves behind ash and dust. The room in which the brick oven is located will have to be cleaned frequently and thoroughly.

- Security requirements . Improper operation of a brick stove for a home with water heating poses a threat not only to fire, but also to carbon monoxide poisoning.

An excursion into the past of gas furnaces

Nowadays, it is already very difficult to determine when a gas stove was made in the form that is familiar and familiar to us. Thanks to scientific and technological techniques, innovations and numerous improvements, this type of household appliances has a wide variety of designs - from simple inexpensive models to examples of almost cosmic aesthetics.

Whatever the stove is - traditional, using wood and coal or modern, gas, it has been and remains a center of family well-being, synonymous with coziness, comfortable warmth, and your own home. For the first time, the idea of using gas for domestic stove needs found industrial implementation in Great Britain, where in the mid-thirties of the last century one of the factories put gas stoves into production.

Statistics on the use of household appliances in the United States during this period show that coal-burning household stoves were the most popular. This can be explained by the only reason - coal, as an energy material, was much cheaper and was more widely used in everyday life. However, gradually gas production technologies began to make it possible to produce it in sufficient volumes and use it not only for industrial purposes, but also for numerous domestic needs.

PVC installation

If in a country cottage it is planned to install water heating from a brick stove (wood-burning), the heat exchanger is designed individually, for a specific stove. Such a device is practically beyond repair, so for installation a specialist stove specialist is hired who can professionally perform all the work:

- Make a heat exchanger and double check its quality - before and after installation.

- Install the heat exchanger at the required stage (after completing the foundation), then continue laying, observing certain rules. When installing the heat exchanger, compensation gaps are left, leaving 1-1.5 cm to the walls of the combustion chamber. Gaps that take into account thermal expansion are also needed when installing pipes.

- When installing a heat exchanger with pipes and for insulation, use exclusively heat-resistant seals .

Steel pipes for the manufacture of a heat exchanger Source 36doors.ru

Installation of the device

Installing a long-burning wood-burning stove is not particularly difficult. A flat surface and proper organization of the chimney are sufficient. The latter may pose some difficulties. It is important that the diameter of the heater pipe clearly coincides with the smoker pipe. The connection must be completely sealed. If combustion products are discharged through a wall, then the passage must be insulated with non-combustible materials. Due to the large mass of the heater, measures to transport it to the place of operation are carried out with the help of assistants.

Recommendations for placing heating system elements

Elements of the heating system can hardly be called decoration of a modern interior. Only pipes that look organic in some industrial interiors can fit this definition. In general, building codes and architectural principles recommend placing parts in areas that are hidden but accessible for repair and maintenance. When placing, they are guided by the following rules:

- The heat generator is placed in an isolated room with heating and good ventilation. The circulation pump must operate under the same conditions. Small boilers (with a power of up to 30 kW) can be installed in the kitchen, hallway, basement or warm heated extension. Stoves intended for residential premises are installed taking into account fire safety rules.

- The place for an open type expansion tank is in the attic ; supply and collection pipelines tend to be located along the main wall structures.

Compliance with operating rules helps the smooth operation of the system Source yandex.ru

- The main riser runs openly in the corners of the living quarters ; in the attic it is covered with thermal insulation.

- Radiators are installed openly under window openings . They participate in room circulation, heating the cold air coming from the windows. Attempts to decorate radiators with decorative screens are undesirable, since they reduce the thermal efficiency of the system.

Safety measures when converting heating stoves to gas

In many cities, the conversion of heating stoves in residential and public buildings to gas fuel is becoming quite widespread. Safety rules allow such a transfer of stoves if they are equipped with standard gas burners with an automatic safety system that turns off the gas when the flame goes out or the draft in the chimney is disrupted.

When switching to gas, small holes are made in the dampers (dampers) of heating stoves for constant ventilation of the stoves and their chimneys. This requirement reduces the thermal efficiency of the furnaces, but is necessary for safety reasons.

To prevent accidents when using gas heating stoves, automatic devices must be used. Among such devices for gas burners of heating furnaces, the most widely used in recent years has been the safety automatics developed by the Giproniigaz Institute. This automation consists of a thermocouple, an electromagnetic valve and an igniter-draft sensor. As long as the thermocouple is heated by the gas pilot flame, the valve, powered by the thermocouple current, keeps the gas passage to the main burner open. When the gas goes out or the draft in the chimney is disrupted, the gas pipeline to the burner is closed by an electromagnetic valve.

The draft sensor is an igniter in the form of a perforated tube, at one closed end of which, going into the room, there are two holes. If there is draft, the gas entering through the solenoid valve into the igniter normally exits through the fire holes into the firebox of the furnace and burns, heating the thermocouple and igniting the gas on the main burner. If the draft is disrupted, a backwater of combustion products is created in the firebox of the furnace, and they prevent the gas from escaping through the fire holes of the igniter. Gas begins to escape through the holes at the end of the pilot tube located on the room side. The thermocouple cools and the solenoid valve turns off the gas to the main burner. Since the gas consumption by the igniter is insignificant, and the response time of the solenoid valve when cooling the thermocouple is no more than 15-20 seconds, the flow of gas into the room through the igniter - draft sensor does not pose any danger, especially since it most often automatically ignites when the draft sensor is activated .

Currently, burners of the GK-17 type for heating furnaces with safety automatics are produced by the Giproniigaz Institute in Saratov.