Author: Yuriy Fedorovich Kolesnikov, thermal power engineer

The stove is built once, but it needs to be heated all the time, on the one hand. On the other hand, the design of the furnace is largely, if not completely, determined by the type of fuel used. And its availability significantly depends on the reserves of local resources in the region. So the stove is bursting with fuel.

Modern heating technology makes it possible to burn everything that, in principle, can burn, and some of what, in principle, cannot burn, to carbon dioxide, water and ash. This is not just a joke. What can you expect from combustion of fuel in a furnace? And how simple and effective can a stove be using such and such or such types of fuel? It depends on its properties:

- Physical state – solid, liquid, gaseous;

- Specific calorific value, or heat of combustion;

- Unit cost;

- Combustion rates;

- Combustion temperatures;

- Ability to water;

- Ash content;

- Contents of higher organic compounds;

- Sulfur content;

- Activities.

Solid, liquid or gas?

Mini-boiler room diagram

Upon careful consideration (for which, unfortunately, there is no room here), in terms of the totality of qualities, natural gas and liquid fuels so far turn out to be the best. But it’s better not to try to make a stove for them yourself: without industrial equipment and well-established technology, even an experienced heating engineer will not undertake this. More precisely, he won’t take it on, knowing what’s what.

And there is a nuance: since this fuel gives off heat almost instantly, you can’t get by with just one stove. Combustion also requires a complex set of equipment. For an example, see Fig. scheme of a house mini-boiler room. This costs a lot, and it turns out to be economically (and environmentally) justified for households with a living area of more than 120-150 square meters. m.

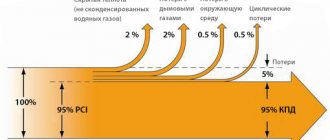

Note: The efficiency of even a small gas or oil boiler with automation reaches 90% or more. Almost all losses in centralized boiler houses occur in pipelines.

A homemade stove can heat and supply hot water up to 60-100 square meters. m. residential. More - the complexity of the work and costs increase so much that it turns out to be cheaper and easier to install a double-circuit gas boiler. If, of course, there is a gas supply. In this case, you need to focus on the lowest of the indicated values; with bottled gas – to the highest level.

An exception is a pyrolysis (more precisely, gas generator) furnace using waste or dark heating oil. It is easy to do it yourself, subject to safety conditions. But the heated area is up to 40-60 square meters. m, heat extraction for hot water supply is difficult, and the installation of a full-flow water heating circuit is hardly possible. Those. scope of application: garage, cottage, small residential building, provided that the stove is in an extension.

Note: Pyrolysis oil is not a fuel for pyrolysis furnaces. It is a product of rapid (50-30 s) oxygen-free pyrolysis of wood waste at a temperature of about 600 degrees. Pyrolysis oil is quite heavily watered and has an acidic reaction, i.e. chemically aggressive components in its composition and contains up to 2% or more sulfur. It is burned in industrial boilers and furnaces using a special burner.

Firewood

Nothing compares to a real wood fire - such an alluring and desirable crackling of wood in the fireplace is only possible with real logs.

But to know how to heat a fireplace with wood correctly, let’s look at the important points in using wood:

- Storage - it is very important to follow the rules for storing firewood. Only dry wood is suitable for burning! They are darker in color and often dotted with cracks. It is best to use logs that have been drying for at least 1 year. And no firewood from trees that have just been cut down or have been soaked in rain or snow.

- Size - select firewood for stacking in the same size. The length of the log should ideally be ¾ of the combustion hole. The optimal thickness of firewood for long burning is from 6 to 10 cm.

- Stacking firewood - for burning a fireplace and stove, it is better to stack firewood horizontally. This means that the logs are laid horizontally in the firebox with an interval of 1 cm. The height of a single stack should not be higher than 30 cm.

Calorific value and cost

The formal content of this paragraph does not require any special explanation: kilocalories or joules. We can only remind you that 1 kcal = 4.3 kJ. That is, if the calorific value is 10,000 kcal/kg, then in joules it will be 43,000 kJ/kg or 43 MJ/kg for solid fuel. For gaseous - kilocalories or kilo/mega joules per cubic meter. For liquid references they give either per kilogram or per liter/cubic meter.

The heat of combustion of commonly used types of fuel ranges from 1800 kcal/kg (waste wood: alder, broom, rotten damp brushwood) to almost 11,000 kcal/kg (polyethylene and other organic polymers), which in megajoules will be from 7.74 MJ/kg to 47.14 MJ/kg for polyethylene.

Here a nuance is already revealed: you can completely burn everything, but the price per kilogram is different! Therefore we do this:

- We carry out thermotechnical calculations of the heating power of the room.

- We give it a reserve of 10-20% for hot water supply.

- In addition to what we received, we give an additional 50% reserve for abnormal cold weather.

- DIVIDE the resulting value by the efficiency of the selected furnace.

- Based on the obtained required thermal power of the furnace and the specific calorific value of the fuel, we determine its mass/volume consumption.

- By multiplying the consumption by the cost, we get the specific cost of heating.

- We repeat the procedure for different stoves and fuels until we reach a minimum price.

Note: heating devices with an efficiency less than the threshold 70% can not be considered. Even if we personally view ecology as purple on the yellow side, if there are no additional taxes and fines elsewhere, there will be. Necessarily.

What shouldn't you light a fireplace with?

- in coniferous wood is resin, which releases a lot of soot when burned. During combustion, so-called micro-explosions occur due to the resin and coals can jump out of the fireplace. If your fireplace is closed with a glass decorative door, you should also not spoil it with resin and soot from pine needles. The second reason is the formation of a large amount of soot, which clogs the chimney and can become a problem over time. Therefore, give preference to “smokeless” wood species - birch, aspen, alder, etc.

- Garbage - everything that burns in the fireplace affects the microclimate in the room. If you use painted boards, plastic or polyethylene to burn your fireplace, heavy chemical compounds will seep through the walls of the stove and enter the indoor air. For garbage, the place for garbage is exclusively in a bucket, but not in the fireplace.

- Wet fuel – Wet wood should only be used to fuel a fireplace as a last resort. Wood oversaturated with moisture is a source of large amounts of soot, smoke and soot. Decide for yourself whether you want all this to remain on the walls of your chimney.

Burning rate

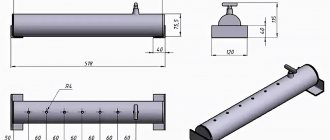

In homemade stoves without complex automation, there is a clear correspondence: the faster the fuel burns, the lower the efficiency of the stove can be achieved and the more complex its design becomes. The reason is simple: without technological tricks inaccessible to the DIYer, it is difficult to capture a large amount of heat released at once and direct it into the room, or into a water heater, before it flies out into the chimney. Therefore, it only makes sense to make a homemade stove using slow-burning fuel - solid fuel, oil, oil sludge, etc. Or a slow-burning oven, where the combustion process is artificially slowed down.

In terms of combustion speed, coal stands out among solid fuels. It is very uneven as it burns. At first, when gasification occurs, the flame rages. And then, when pure carbon (amorphous carbon, coke) remains, slow smoldering begins. But making a stove with high efficiency in both combustion modes is not so easy.

Coal furnace firebox

Today, coal is a rather rare type of fuel for heating a private home. It differs from other types of fireplace fuel in that maximum heat transfer does not occur during combustion. and during smoldering. But in order for your fireplace to serve you as long as possible, it is important to know how to properly burn a fireplace with coal.

To do this, you must meet 4 conditions:

- Clean the fireplace from ash in a timely manner.

- The combustion hole must be covered.

- Until the fire breaks out, the ash door must be kept open.

- You can burn a fireplace with coal only if the stove has a grate. And since coal combustion requires a large amount of air, the height of the grate is important. To prevent steel burning, you may need to replace steel grates with cast iron ones.

- Both stone and brown coal are suitable for burning the fireplace. We recommend choosing a type of coal with a combustion temperature of up to 1500 degrees.

Combustion temperature

This is a double-edged sword. One end - the higher the temperature, the easier it is to achieve complete combustion and high efficiency. On the other hand, again, it becomes more difficult to extract and direct where the heat is needed; due to the large temperature gradient, it tends to fly out into the chimney. Therefore, the design of the furnace becomes more complicated. In addition, high combustion temperatures require expensive heat-resistant materials.

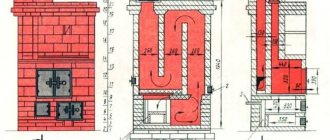

In general, the lower the combustion temperature, the simpler and more efficient the stove is. Clumsy homemade designs that smolder at 600 degrees (slow burning stoves) can give an efficiency of more than 85%. It is difficult to achieve an efficiency of more than 75% from a wood/coal stove (800-900 degrees) in an amateur design, and it often turns out that the structure proudly presented in the video burned out or cracked before the end of the heating season.

Note: the maximum combustion temperature achievable in home-made designs is approximately 1100 degrees; These are pyrolysis and gas generator furnaces. Above - without special steels and refractories, it will only withstand a few test fireboxes.

Is it effective to heat a fireplace with wood briquettes?

Wood briquettes are the most convenient and effective way to fire a fireplace and stove in the house today. This type of fuel is often called Eurowood, and lighting a fireplace with ordinary wood is gradually becoming a thing of the past. This is how a new type of firebox appears with the already familiar name - Euro-firewood.

Eurofirewood is pressed firewood in the form of briquettes. This type of fuel has many advantages compared to conventional wooden firewood:

- During the combustion process, wood briquettes provide heat transfer 30-50% more than conventional firewood.

- Eurofirewood consists of pressed wood or peat of a certain moisture content. It is the humidity indicator that determines the quality of firewood combustion - in briquettes the humidity does not exceed 11%, which means the flame is more uniform and does not spark.

- One full load of wood briquettes will burn for about 2 hours. Peat briquettes up to 4 hours.

Water cut

The watering of the fuel takes away heat not only and not so much to the evaporation of water. At high temperatures, in the presence of a catalyst - carbon - even more energy is spent on the chemical reduction of water and the combination of the released oxygen with atmospheric nitrogen. The water content of fuel as a percentage by weight is designated as W.

The ability of fuel to absorb moisture firstly reduces its calorific value. For firewood, it doubles or more when the humidity increases from 20% to 50%. Watered liquid fuel can also be explosive. And barely wet brown coal ignites spontaneously, which is why it is not transported from mining sites; thermal power plants using brown coal are built near mining quarries.

A furnace operating on wet liquid fuel must be equipped with a special burner and fuel preparation system. Solid fuel - a complex smoke path in which the reduced components and oxidized nitrogen do not cool down before they decompose to the original ones and give back heat.

What is the best way to light a fireplace?

How to heat a fireplace in a house so that it is practical and aesthetically pleasing? The choice of fuel determines the height of the flame, burning time, heat transfer and, oddly enough, the amount of soot and type of firebox over time.

Therefore, we will consider the most common types of fuel for stoves and fireplaces in Belarus from all sides:

- firewood

- coal

- gas

- fuel briquettes

- wood pellets

- biofuel

Firewood and coal - good old classics that are best left in memories? Life is becoming more expensive and today it is important to think not only about aesthetics, but also about heat indicators and the duration of fuel burning in the fireplace. And firewood is far from the best fuel option for a stove and fireplace. Technologies do not stand still, and today zealous owners choose long-burning Eurowood for heating their stoves and fireplaces. Simply put, compressed wood fuel: briquettes and pellets (granules).

Activity

Fuel activity is a conditional parameter. It characterizes the ability of a fuel to ignite and burn on its own.

Fuel that ignites from a spark is considered extremely active, and the combustion zone immediately spreads over its entire surface. Highly active fuel requires ignition with a small amount of even more active fuel or with the help of a wick, but then in the open air it ignites quickly and over the entire surface. Medium active requires ignition with more active fuel and without additional measures (scrub, stir) or pressurization in the open air it does not burn completely. Combustion of low-level fuel can only take place in special devices after ignition.

The activity of a fuel depends little on its calorific value, but much more on its state of aggregation, boiling point (for liquid fuel) and degree of grinding (dispersity) for solid fuel. For example, gasoline and ethyl alcohol are extremely active at room temperature. In diesel fuel at room temperature, the torch goes out, but, sprayed by a nozzle, it flares up in the open air at 90 degrees. Wood in the form of firewood is moderately active, in the form of dry shavings it is highly active, and in the form of sawdust it is very weakly active.

Note: according to the specifications, the flash point of summer diesel fuel is 62 degrees. But this is in a closed crucible.

Biofuel for fireplaces

Biofuels are alcohol-based liquid fuels. The heat output of biofuel is much higher than that of wood fuel, but the cost of burning such a fireplace for 2-3 hours is comparable to a bottle of good wine.

Advantages of burning a fireplace with biofuel:

- even flame during combustion;

- soot and soot are not emitted;

- no smoke or smell.

And to add the crackling sound that we are used to hearing when burning wooden logs, biofuel with sea salt is produced, which creates a believable imitation.

A few words about the physics of combustion

Every schoolchild knows that the combustion process requires oxygen. And the more there is, the more intense the process will be. Accordingly, by changing the air concentration (more precisely, the oxygen concentration) you can influence the combustion rate. This is precisely what the creators of long-burning stoves took advantage of, the operating principle of which is to minimize air flow through built-in adjustment.

Fig. 1. Long-burning furnace NMK Sibir

Which fuel to choose

Coal is a chemical compound containing a number of hydrocarbons and impurities with a low combustion rate.

These substances are formed in the lower chamber of the boiler after combustion. This is slag and ash that needs to be regularly cleaned out of the ash pit. Moreover, each species, depending on geography and period of occurrence, contains a certain level of carbon. It is the age and the ratio of flammable and non-flammable components that determine the quality and grade of the solid fuel mineral. There are several types:

- The youngest of the subspecies is lingitis. It is a loose stone structure. It often crumbles and crumbles. Ineffective for heating houses. However, it is considered the cheapest and is used for energy production in thermal power plants.

- Anthracite is the variety that warmed up most deeply when buried. It is a transitional form from coal to graphite. The amount of carbon reaches 95%. The most effective among all varieties.

- Hard coal is the result of the transformation of bitumen masses. Divided into several grades depending on carbon content, from 75-95%. Humidity reaches 12-15%.

- The brown subspecies, unlike other varieties, is formed from peat and includes up to 70% carbon. It has a characteristic white color. Can be used as fuel or raw material. Also includes a large number of volatile compounds.

Different grades

Due to its minimal weight and significant carbon content, it is anthracite that has the maximum specific heat capacity. Indicators can reach 9 thousand Kcal/kg. Coal, due to its lower content of flammable substances and higher humidity, has up to 5.5 thousand kilocalories per kilogram. Brown has an even lower rate of 3 kcal/kg. Therefore, anthracite is considered the optimal choice.

How to reduce coal consumption

An increase in the rate of coal consumption, after several years of operation of the boiler, occurs quite often. The increase in costs is primarily due to clogging of the heat exchanger and chimney pipe with soot. It is recommended to completely clean the chimney and internal components of the boiler at least 2 times a year.

To reduce coal consumption, you need to fire the boiler correctly. To reduce the amount of soot, add fuel in layers - firewood and coal. This installation will ensure maximum heat transfer. Coal consumption changes depending on the boiler efficiency. Consequently, the higher the efficiency, the lower the fuel costs.

Another way to reduce coal consumption is to burn only high-quality fuel. Cheap raw materials, brown coal, have a large percentage of underburned coal, quickly clog the chimney and heat exchanger and, as a result, are more expensive than anthracite.

Ash generation rate

The amount of combustion waste that will have to be cleaned from the furnace equipment depends on this indicator. It is calculated simply: the weight of the waste is divided by the burned mass. That is, if a kilogram of fuel was burned and 50 grams of ash was formed, then the ash content is 5%. In the tables, this indicator is denoted by the letter A. This indicator can be viewed in two ways. On the one hand, a large amount of waste creates certain economic difficulties, and on the other hand, ash is an excellent fertilizer, so waste can also be beneficial.

Pellets

Lighting a stove with pellets is the newest type of heating.

Pellets are cylindrical granules of the same size made from wood waste. In a good way, to effectively heat a room with pellets you need a special boiler. But to meet minimal needs, they can be used in a conventional wood-burning stove.

Advantages of pellet heating:

- — environmentally friendly fuel, contains no more than 3% ash;

- — granules do not contain dust and spores, are less susceptible to spontaneous combustion and do not cause allergies;

- — characterized by high dryness and greater density, which leads to high heat transfer;

- - ease of storage

The main disadvantage of pellets is their high price.

Types of solid fuel boilers

traditional fuels,

- The first type of boiler is called cast iron. It is designed to burn fuels such as coal and wood. Despite all its positive aspects, it is still dependent on people and energy supply. Wood in such a boiler usually burns for no more than 5 hours, which means fuel must be constantly added. Currently, domestic and foreign manufacturers produce such boilers, some of them are called KChM and Solida.

- The second type differs in many ways from the first and is called pyrolysis heating boilers. There are two combustion chambers, in one of which the fuel immersed in the boiler burns, and in the second the gas synthesis burns out. The main type of fuel is wood. It has a longer burning time than a cast iron boiler; here it is 10 hours. One of the most successful boilers of this type is called Dakon, made in the Czech Republic.

- Pellet boilers, the name comes from the word pellets (granulated wood). It is she who needs to heat the room using such boilers. It has a convenient additional advantage - it independently adds the required amount of fuel using an auger and ignites it. The burning time in this case depends on the boiler model and the capacity of its hopper. But there is also a significant drawback - you cannot burn anything except wood pellets in such a boiler.

- The most modern and popular type is long-burning boilers. Firewood, sawdust, coal, and peat can be used as fuel. They surpass their analogues in combustion time; with such a boiler no human intervention is needed for 2 days or more thanks to the latest top-down combustion system, this allows the fuel not to burn, but to smolder for a long time.

Solid fuel boilers are a good alternative to gas. If you live in a country house or your street is not gasified, a long-burning boiler using coal, wood and other fuels will perfectly heat a room of any size.

How to choose a solid fuel boiler

When choosing a boiler, you should pay attention to the following criteria:

- boiler design;

- principle of operation;

- power;

- type of raw materials used;

First of all, you should pay special attention to power. This is one of the most important criteria and the operation of the boiler depends on it, since not every model can cope with a home heating system that is too large

You need to check the power of the boiler with a specialist; he will compare criteria such as the area of the house, the climatic region and even the height of the ceilings. The approximate required power can be calculated independently based on the following rule: 1 kW of power is required for 10 square meters.

An error in choosing the boiler power can have a bad effect on the quality of heating. With a lower degree of heating, the room will be cold, and with a higher degree, the equipment may fail.

Boiler installation location

separate room. separate boiler room

Three important rules when choosing a boiler installation location:

Ventilated area. If additional gas is used as fuel, a slight leak may occur. If the installation is done correctly, there is no need to be afraid of leaks, but if they accumulate for a long time, there is a high probability of poisoning. Deep cellar. Not the easiest option for installing a boiler, but still, if the house has the opportunity to install it at a depth of 2 - 3 meters from the heating radiator, this would be an ideal option

Thanks to this installation, no additional circulation is needed, you don’t need to use circulation pumps, but if the installation option is only in the house, circulation is required, if it is missing or installed incorrectly, carbon monoxide can leak, it is impossible to determine its presence in the room without special devices, and you can be poisoned by it easily. Chimney. It is important to provide the necessary draft. If these calculations are incorrect, the boiler power may be reduced and combustion products may enter the room.

The installation of the chimney must be carried out by a specialist, since it is easy to make a mistake in this difficult task and lose heat.

If all rules are followed, the solid fuel boiler will work properly for many years.

How to melt correctly

The algorithm of actions looks like this:

- It is required to place sheets of dry paper at the bottom of the firebox. Then, a small layer of wood chips, logs, preferably fruit varieties. To speed up the combustion, it is necessary to arrange them in a pyramid.

- Set the paper on fire. Then close the door, but leave the ventilation hole open. Due to which you can regulate the rate of combustion of firewood. Moreover, depending on the volume of oxygen, the fuel will burn faster or slower.

- After complete combustion of the wood, you need to place a layer of small coal, up to 15 cm, on the resulting pile of ash.

- When it burns sufficiently, you can pour a larger mineral on top in the form of a pillow. The height can reach 60 cm. Before doing this, be sure to move the hot stones apart so that the coal does not bake.

If you use fuel of insufficient quality, coking may occur. Therefore, if you are not sure of the quality of the purchased raw material, put it in the form of a sandwich, mixing it with firewood. Several layers of logs, successively mixed with stone, make it possible to sufficiently warm up the installation and release heat into the premises.

How to use solid fuel units correctly?

The operating principle of a solid fuel boiler is known, and the issue of choosing the type of coal has been resolved. All that remains is to learn how to properly light the stove. There are several simple rules that everyone who chooses the described installations for organizing heating of a country house must learn.

Let's look at all these points in more detail.

Preparing the stove for lighting

If the stove in a country house is used occasionally, before starting its operation, for safety reasons, it is necessary to exclude the presence of cracks inside the masonry.

Why are they dangerous? Through them, combustion products and carbon monoxide can enter the room, which must be removed outside using drafts. If such a defect is discovered, it must be eliminated before kindling by covering the cracks with a mixture of clay and sand. Otherwise, when heated, the cracks may increase in size even more. And this will lead to dangerous situations.

When inspecting the stove from the outside, we remove flammable objects away from it and clean it inside. We remove the ash and slag with a shovel, freeing the internal compartment. It is advisable to wipe the inner walls of the firebox with a dry cloth. If this is not done, then during kindling the dust will begin to burn, filling the room with an unpleasant odor.

The coal stove needs to be lit several times a day. The duration of one fire should not exceed two hours. For loading, it is better to use well-dried medium-fraction coal.

Do not use household waste or flammable liquids such as gasoline or kerosene to ignite coal. Do not leave the stove unattended while it is burning. This rule must be observed especially strictly if there are small children or animals in the house.

How to properly melt coal?

The stove must be lit as follows:

- First, we place sheets of newspaper or any other dry paper on the bottom of the firebox. On top of it we place a layer of small wood chips. And on them we stack small firewood, for example, birch logs. To make them burn faster, they need to be folded in the form of a well or a small hut.

- Set fire to the paper. We close the oven door and open the ash pan. Using it, it is easy to control the intensity of fuel combustion. The stronger the air flow, the faster the stack of firewood burns out.

- After the firewood has completely burned out and only a pile of smoldering ash remains, you need to lay a 15-centimeter layer of fine coal directly on it.