For comfortable living in a house, high-quality, durable and reliable thermal insulation of the roof is necessary - regardless of its structural features and external conditions. Let's consider what types of material are used to insulate a roof from the inside, what requirements are placed on it when choosing it, what types of roofs exist, what are the features of their thermal insulation, and also what stages the technology of laying the material consists of.

Roof insulation from the inside Source build-blog.ru

Roof insulation

In addition, if the roof is insulated, thoroughly waterproofed and provided with effective ventilation, this will allow, in addition to effective energy saving, to expand the living area of the room due to the resulting attic, which can be made as cozy and comfortable as all other rooms.

If the roof is located above a non-residential attic and consists of rafters, sheathing and roofing, then insulation is not always necessary. The attic is continuously ventilated, and the temperature and humidity in it are almost the same as the outside air. In such houses, the main thing is to carefully insulate the attic floor.

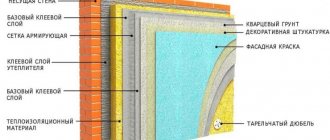

But if under-roof thermal insulation is installed, the temperature and humidity of the air inside the attic floor differ significantly from the air outside. Moisture rises along with the warm air and comes into contact with the colder, lower surface of the roof. This causes condensation to form on it. Also, moisture can penetrate into the roof elements, which is facilitated by inaccurate laying of the vapor-proof layer on the inner surface of the insulation, insufficient overlap of the vapor barrier strips, their loose fit to the walls and pipes, accidental ruptures, etc. Therefore, first of all, when insulating the roof, you need to take care of the device reliable vapor barrier located on the interior side. On the roof side, the insulation is protected by a layer of waterproofing laid along the rafters or a special flooring.

Such protection of an insulated roof on both sides is quite reliable, but sometimes this is not enough. It is necessary to provide a way to remove moisture that accidentally gets into the insulation. This effect is achieved by air circulation in cavities, one of which is located between the roof and the under-roof waterproofing, and the other is located between the under-roof layer and the thermal insulation layer. In order for outside air to freely enter these cavities and be removed from them just as easily, it is necessary to install vents in the roof overhang and in the upper part of the roof. To ensure free movement of air between the roof and the under-roof waterproofing, lay counter battens along the rafters. Their thickness determines the size of the air cavity. Air enters this cavity through holes located in the side overhangs of the roof.

How to avoid the problem of high humidity

After thermal insulation work, the humidity inside the room may increase, which negatively affects the microclimate. There are several reasons for this.

- Insulated structures have gaps or cracks, which means their integrity is compromised. Therefore, before starting work, it is necessary to carefully check all the bases and eliminate all existing defects in advance.

- There is no vapor barrier layer or it is damaged. In this case, moisture does not leave the room, but accumulates in the insulating material. Therefore, it is imperative to use a vapor barrier film, gluing the joints of the sheets with a tape specially designed for this.

- The system of natural and forced ventilation of the room was broken. For example, during the renovation, the ventilation holes were moved or blocked, the shaft was blocked, and metal-plastic windows were installed. All of the above actions lead to a decrease in air circulation due to excessive tightness of the structure, so it is necessary to periodically ventilate the room or take care of installing supply and exhaust ventilation.

Video description

In this video, see an example of how the floor of a cold attic is insulated:

Almost all of the above materials are suitable for this. The only thing you need to pay attention to is fire safety. For example, in houses with stove heating, at the point of contact between the pipe and the ceiling, it is better to use non-flammable insulation - mineral wool or penoplex.

Insulated attic

In a private house there is often a need to have insulated non-residential premises. The space between the roofing system and the ceiling is sometimes the best solution to this problem. In this case, similar methods used for the option with attic insulation are suitable. Both slopes and gables need to be insulated. The only difference is in the choice of materials. For the attic, the requirements are somewhat relaxed - since the premises are non-residential.

Flat roof

Insulating a flat roof from the inside is quite problematic. Basically, this procedure is performed externally. However, if the roof is already erected, there is no choice. In this case, dense slab materials are suitable, allowing them to be fastened from bottom to top using special fasteners. As an option, you can use spray foam insulation.

Insulation of pitched roofs

You can insulate a roof with a frame made of rafter systems in one of four ways: by laying insulation between the rafters, on the rafters, under the rafters, or in a combined way. In most cases, thermal insulation is carried out in the simplest way - by laying thermal insulation material between the rafters.

Roof insulation between rafters

The insulation with this method of insulation must be continuous, gaps are not allowed. This also applies to areas adjacent to walls, pipes and windows that are built into the roof plane. This approach is explained by the fact that any place where thermal insulation is interrupted leads to the formation of a cold bridge. Also, in insufficiently insulated places, condensation may occur due to temperature differences, which will gradually destroy the entire structure. It must be remembered that the attic always brings greater heat loss than other floors, since its entire surface is in contact with the street. Since heat escapes not only through the slopes, but also through the gables, it is necessary to insulate the entire roof contour.

For example, an uninsulated gable wall connecting to the roof structure can cause a problem. When insulating walls, Mauerlats are usually not insulated. When thermal insulation of a roof slope is carried out, it is also quite often brought only to the level of the Mauerlat. Thanks to this, a powerful cold bridge appears, along which heat leaves the room. To avoid such a negative phenomenon, you need to wrap the insulation of the attic slopes onto the Mauerlat to the place where the insulation of the outer wall reaches.

We do decorative finishing of the attic

Of course, finishing and insulating the attic should take into account how you intend to use this room in the future. The most common occurrence is that a living room is being built on the attic floor: a children's room or a bedroom. In general, there are also exceptions here. Many people turn to specialists if they don’t know how to decorate an attic

Finishing the attic with wood

It is enough to think about the best way to decorate the attic, and many options will immediately appear. First of all, wood comes to mind - after all, load-bearing roof structures are traditionally made from wood.

- Wood for finishing the attic is excellent in that additional thermal insulation will be created. In addition, indoors you will get a good local climate, saturated with the pleasant smell of wood. No finishing can compete with this;

- In finishing work, clapboard boards are most often used - this option is perfect for cladding an attic.

There are 5 types of board profiles, as well as a number of standard sizes. Installation is done in different ways;

- The board on the surface can be placed both vertically and horizontally - but this is not limited to this. Often the lining is laid in a circle, diagonally, in a herringbone pattern. This is how various pictures are made, due to which the monotonous surface becomes more interesting;

- Lining, as a finishing material for the attic, is not bad in the sense that the place can be zoned - just any zone is painted in a certain color;

- There are other solutions for finishing the attic with wood. For example, wood panels. They can be made either from solid wood or in the form of slatted panels made of lining;

- There is also MDF, with a special coating of bamboo or wood. As an economical option, veneered, laminated fiberboard panels are often used. Wood panels are successfully used not only for finishing walls, but also for arranging suspended ceilings;

- Finishing the attic with MDF panels is done when the room will be used as an office or home gym. This cladding is not usually done in bedrooms - the interior in this case will look very official. Therefore, it is customary to make compositions with other finishing variations - with decorative plaster, wallpaper, painting. Finishing the attic with wood is an extremely successful solution

Not so long ago, construction stores began to sell fresh finishing materials - wood wallpaper. This is a set of panels made from profiled wood parts that are glued to a base.

Coniferous wood is used to produce this wallpaper. The thickness of the product is no more than 20 mm, and the width is 120 cm. The length of wood wallpaper is 200-600 cm.

These panels are attached to the wall in the same way as ordinary wallpaper - with their help you can perfectly and quickly finish the finish “under the tree” in any room.Decorate with ceiling beams

Ceiling beams can become a complete decoration of the attic interior. Depending on the roof structure, these beams can be full-fledged load-bearing beams, and not at all hollow false beams, which are often found in the interiors of the first floors. In addition:

- Rafters can also perform this function - but for this they need to be properly decorated. This is truly extremely original and beautiful - just look at a few examples in the photo.

When people talk about the attic, ceiling beams will never be superfluous when decorating. Decorative finishing of the walls can be extremely ordinary - beam structures will “draw” attention to themselves. It is especially great when they are made in a contrasting color relative to other surfaces. In such an interior, ceiling lamps of a unique design can play a huge role - if they are in harmony with the beams.

Plasterboard structures

As mentioned above, there is nothing in the attic space that could become an obstacle to the implementation of any structure - be it arches, columns, partitions or suspended ceilings.

The main rule here is that there should be plenty of space for everything - this is extremely important. Any element can be used to divide the room into zones.

And now in more detail:

- The final finishing of attics lined with plasterboard may look like a surface that has been painted with acrylic paint or covered with wallpaper. Often, attic spaces have a good height - this is exactly what almost all modern apartments located in high-rise buildings lack;

- Often the height is even hidden - since suspended plasterboard ceilings can have several levels and have a distance from the base surface of more than 12 cm;

- If you pay attention to design projects, you can often find suspended ceilings in the attic.

For example, a good living room interior will turn out if plasterboard walls are mixed with a glossy stretch ceiling made in a milky color. A similar solution will also emphasize the natural lighting of the attic, which is usually extremely good;

Someone uses plasterboard to decorate the attic and gets excellent results

That is why, when asked about which colors look best when finishing an attic, almost everyone says unequivocally: light colors should be used.

From time to time, only certain interior elements are made dark. A popular method of decorating walls can be called a solution when their surface is, as it were, a continuation of the ceiling. It all looks like this: a bed can be placed with its end facing the wall. A strip of wallpaper with a thick pattern is glued along its headboard. Usually the pattern contrasts extremely well with the light surface - thanks to this, the room visually stretches in height. The attic floor can be extremely cozy

Selection of thermal insulation material for roof insulation

The most popular materials for thermal insulation of roofs are mineral fiber mats, polystyrene foam and polyurethane foam boards, which have a thermal conductivity of 0.35 - 0.40 W/m × K.

When choosing a material, you should pay attention to ensure that it does not shrink or sag under the pressure of its own weight. If this happens, cold bridges may appear. This effect is often observed when using low-density fiberglass materials.

Mauerlat is a special beam that holds the roof rafters. It is designed to evenly distribute the load from the weight of the roof onto the walls of the house. Thanks to it, the roof lasts a long time and does not collapse under the weight of snow in winter.

Expanded polystyrene is only partially suitable for insulating pitched roofs: when using it, it is necessary to carry out a number of fire-fighting measures, which include fire-retardant impregnation of wooden structures, installation of fire-retardant layers, etc. The most appropriate material is hydrophobized slabs made of basalt rocks and laminated with foil or fiberglass. They are ideally suited for thermal insulation of unloaded roof structures. You should also pay attention to the fact that all selected materials are accompanied by hygiene certificates.

Video description

Watch this video on how to properly insulate an attic:

Advice! When choosing a way to properly insulate an attic from the inside with your own hands, you must take into account that the air in a living space is always saturated with moisture. Therefore, the material must be installed so that wooden rafters and sheathing do not accumulate dampness and during further operation are not subject to destruction from biological factors (rot, mold, fungus).

Non-residential premises

The unheated space between the horizontal floor (ceiling) and the roofing system serves as a kind of barrier that prevents heat from escaping from the lower living space. However, in the middle zone and in the northern regions this is clearly not enough. Full insulation is required. In this case, there is no need to insulate the slopes - it is enough to thermally insulate the ceiling itself.

Do-it-yourself roof insulation step-by-step instructions

First, waterproofing is done. The film is rolled out horizontally in the direction from the eaves to the ridge of the roof with an overlap. On the film, the places of such overlap are indicated by a special strip, and its magnitude directly depends on the slope of the roof. If the slope is up to 21%, the overlap must be at least 20 cm, at 22 - 30% it is 15 cm, and for a slope greater than 31% an overlap of 10 cm is required. The waterproofing film is attached using a construction stapler or galvanized nails with a wide head. Overlapping areas must be insulated with special adhesive tape.

It is advisable to roll out the film so that the overlaps fall on wooden structures (counter battens, rafters, spacer bars). If the lathing was impregnated with a special antiseptic, you should make sure that the impregnation has completely dried before laying the film.

The waterproofing layer at the eaves and roof overhang above the gable should protrude beyond the wall line by at least 2 cm, and at the ends of the roof extend onto the end boards. At the eaves, it runs directly along the rafters and is secured with a special adhesive tape.

When laying perforated film, you must ensure that the perforation “looks” outward. Otherwise, it will allow moisture to pass into the roof and prevent steam from escaping from the inside. The film always has inscriptions indicating its front (outer) side.

The film must be laid, leaving a sag between the rafters equal to 20 mm. It is necessary in order to eliminate possible film tension and rupture due to a decrease in its size due to the cold. It is desirable that the distance between the rafters be no more than 1.2 m.

The next stage is laying insulation. At the junction of the wall insulation and the roof slope, you need to try to make sure that both of these layers fit very tightly to each other. Also, such places need to be additionally reinforced with reinforcing mesh and protected from rain. In a pitched roof, they are usually located under the eaves, which protects them from atmospheric moisture, and for a flat roof, protection is required using tin aprons and sealing polyurethane tape.

Then an anti-condensation film is laid. It must be laid out on the rafters in the direction from the eaves to the ridge of the roof. Laying is done with an overlap, the absorbent surface down, and then secured using staples of a construction stapler or galvanized nails with a wide head. The film must be laid with tension, avoiding sagging. It is advisable to reinforce the gluing area with a pressure strip. This is especially important if the roof slope is less than 30°. The bottom surface of the film should not come into contact with the insulation. To ensure ventilation, the distance between the insulation and the anti-condensation film should be about 40 - 60 mm.

If the vapor barrier film is foil, then it is laid with a reflective surface inside the room. The joints of such material are glued with special foil tape.

In those places where the film is adjacent to internal walls, chimneys, etc., you must pay attention to the nature of the surface to which it will be attached, since the connection must be airtight. To materials with a rough surface (unplaned wood), a vapor barrier film is glued using polyurethane, acrylic or synthetic glue. On such surfaces, you cannot use adhesive tape or polyurethane sealing tapes, since the tightness of the connection may be broken. If metal beams are used in the roof structure, then a vapor barrier is attached to them using glue or double-sided tape.

Vapor-proof films when used in living rooms lead to an increase in air humidity, disrupting the normal microclimate, so the room must be regularly ventilated.

After laying the film along the rafters, counter-lattice bars with a cross-section of 40 × 25 mm are nailed in increments of 100 - 150 mm using galvanized nails. On top of these bars, lathing is made for the roof covering.

If a diffusion membrane with high vapor permeability is used, it can be laid directly on the thermal insulation layer without leaving a bottom gap. In this case, an overlap of 20 mm should be made. In this case, only one ventilation gap will remain - the top one, located between the membrane and the sheathing and amounting to 30 - 40 mm. The membrane is laid after reading the manufacturer's instructions, turning the painted side towards the insulation and the back side out. It is mounted in the same way as the film: using galvanized nails with a wide head or staples from a construction stapler. The joints of the membrane strips must be connected with double-sided self-adhesive tape to protect them from capillary moisture.

You need to pay attention to the following: the width of the air gap located between the insulation and the under-roof waterproofing in all areas of the surface must be at least 2 cm.

In this case, it is necessary to ensure that the waterproofing material does not sag too much, which can interfere with normal air circulation. Therefore, sometimes waterproofing is laid over a continuous wooden flooring. To ensure air escape from the cavities located above and below the waterproofing layer, special tiles are installed near the ridge for ventilation or gaps are left when constructing the ridge itself.

The better to insulate

The materials used for roof insulation have clear quality parameters:

- Weight - in winter, whole snowdrifts can lie on the roofs, and the lighter the material, the less additional load on the rafter system when using it;

- Thermal conductivity coefficient per square meter of area: the lower the better;

- Thickness and density. This depends on the region of residence and operating conditions: it is clear that in Sochi and Siberia the requirements for these indicators are different.

- Environmental friendliness. The material must be safe for human health;

- Fire safety. In country houses, many fires start in the attic. The material must at least not support combustion;

Therefore, if, after painful deliberation about how to insulate the roof of a private house, a choice is made in favor of a budget material, but it is something like this:

Ax Consultant FORUMHOUSE

If it doesn't allow steam to pass through, your roof will rot. The mouse will find its way there, that’s all. And the stink is poisonous, especially when heated.

then you shouldn’t buy it even at the most attractive price - this is a bad economy.

It is vital that the material has a long lifespan - there are stories on FORUMHOUSE about replacing insulation without removing the roofing material, and this is always difficult and expensive.

KabykiFORUMHOUSE Member

It’s easier to go through the roof and not reinvent the wheel.

The material will retain its properties for many years if it is resistant to moisture, temperature changes, fungus and mold, and it is good if mice and birds are indifferent to it.

Here are the most popular materials for roof insulation:

- Mineral wool (glass wool, stone wool). It is produced both in mats and in rolls, it is elastic, holds its shape and fits well to the frame, so it can be mounted both along the rafters and between the rafters: the material is convenient for all installation work.

- Materials based on foamed polystyrene (foam plastic, extruded polystyrene foam). These are rigid slabs of standard sizes; gaps may remain or form over time between them and the rafters, so it is better to install them along the rafters.

RostikaParticipant FORUMHOUSE

The wood dries, and the rafters are made of wood. Elastic basalt insulation, which was initially set aside, copes with this, but polystyrene foam, etc. – easily lags behind the rafters, forming direct heat releases into the atmosphere.

These slabs are very light, which allows them to be mounted without lathing or reinforcing the frame.

- Rigid polyurethane foam in foam. This material is applied directly to the inner surface of the roof slope using a special installation that foams the liquid with air or carbon dioxide.

Sometimes, for reasons of economy, people want to insulate their roofs with materials that are different in composition and quality. This can be done, but the vapor permeability of each material must be taken into account.

RostikaFORUMHOUSE participant

The top layer should have greater ability to release steam and heat. That is, if you decide to use polystyrene foam, then lay it down, and basalt insulation or glass wool on it.

Insulating the roof from inside the house

When laying thermal insulation material below the rafters, most often the under-roof waterproofing is installed from above, along the rafters, without making a solid wooden sheathing, because the ventilation gap in any case will be large - almost the entire thickness of the rafters. The disadvantage of this method of roof insulation is the reduction in the volume of the attic.

Selecting material for roof insulation

As insulation, you can use the same materials as when installing thermal insulation between the rafters: glass wool and mineral fiber mats, polystyrene foam and polyurethane foam boards. The thickness of the thermal insulation material should not be less than 100 mm, but at the same time it cannot exceed the thickness of the rafters.

Do-it-yourself roof insulation

The first stage when performing insulation work is waterproofing. As mentioned above, in this case it is laid on top directly along the rafters. Attach the waterproofing film using construction staples or galvanized nails with wide heads.

If the room is not heated or the attic is cold, a vapor barrier is not required. It is enough to lay only the waterproofing layer.

At the second stage of work, thermal insulation material is laid. Laying is carried out below the rafters. The material is secured using a construction stapler. A vapor barrier film is installed on top of the thermal insulation layer.

The final stage is installation of the internal cladding. Sheets of plasterboard, plywood and lining are suitable as building materials here. The cladding is attached using galvanized nails equipped with wide heads or self-tapping screws. In order for the finishing to be of high quality, you need to ensure that the heads of the nails or screws are recessed into the facing material. Before performing the final finishing, the recesses from screws or nails are puttied. Then you can stick wallpaper onto the drywall or plywood.

Roof insulation from above

Thermal insulation of the roof above the rafters will qualitatively protect most of its structural elements from precipitation and temperature changes. In this case, the insulation is laid on solid wooden sheathing. This method is also interesting because it provides the opportunity to use open rafters when decorating the interior of the attic.

But a problem immediately arises - where and how to attach the waterproofing material? The modern market offers thermal insulation panels with already provided waterproofing. In this case, you need one level of air circulation located between the thermal insulation material and the roof. The air cavity is created by means of a counter-lattice, in which the slats are laid parallel to the rafters. A necessary condition for the high-quality functioning of such thermal insulation is the installation of a good vapor-proof layer on the inside of the roof.

The advantages of this roof insulation scheme are the minimal risk of cold bridges, constant temperature and humidity of all structural elements, which eliminates the possibility of thermal deformation of materials; the most effective sound insulation compared to other constructive methods; maximum use of the entire internal space of the attic floor.

Disadvantages - the difficulty of performing insulation work on a roof with a complex shape, high requirements for under-roofing films, and the impossibility of carrying out installation work in bad weather conditions.

Preparing for work

At the preparatory stage, special attention is paid to:

- Checking the condition of the existing layers of the cake and structures, if necessary, updating, strengthening, antiseptic treatment or building up.

- Cleaning and drying the base, ventilating or warming the room.

- Protection from fire or transfer of previously laid electrical communications.

- Calculation, delivery and acclimatization of insulation, preparation of other materials and tools.

Roof insulation from inside and outside

You can use a combined roof thermal insulation scheme - two-layer insulation. With this method, one part of the thermal insulation material is laid between the rafters, and the other under them.

Roof insulation material:

When laying insulation between and above the rafters, mineral or glass wool of normal density can be used for the main thermal insulation layer. The top layer must have high shear strength. Fiberboard or basalt slabs are suitable for it. When laying the top slabs, it is necessary to completely cover the rafters to prevent the formation of cold bridges.

Read our article: Which insulation is better to use

Do-it-yourself roof insulation

First, the waterproofing material is laid, it is secured using a construction stapler or galvanized nails with wide heads. Then insulation is laid under and between the rafters. The inner layer of insulation is laid between the cross beams, completely covering the rafters. The thickness of the timber should be equal to the thickness of the heat-insulating layer.

A vapor barrier layer can be laid between layers of insulation, but then to prevent the accumulation of condensation on the film, the inner layer of thermal insulation must have a thermal resistance of no more than 20% of the main one.

It is permissible to lay a vapor barrier on top of the inner layer of insulation, but with this method the risk of damage to the film during the installation of interior decoration of the room, installation of electrical wiring and lighting devices increases.

Briefly about the main thing

There are several options for how to insulate an attic roof using available insulation materials:

- expanded polystyrene;

- stone wool;

- penoplex;

- polyurethane foam;

- ecowool;

- penoizol;

- expanded clay;

- sawdust.

Each method has its own characteristics, pros, cons and purpose. In addition to the attic insulation method, there are other options for roof insulation - a warm attic, only the ceiling and flat blood.

When choosing an insulating material, it is necessary to take into account thermal conductivity, sound insulation capabilities, toxicity, flammability, density, structural stability and specific gravity. Insulation can be done on your own according to the instructions, but it is better to seek help from professionals.

How to insulate a flat roof

Thermal insulation of a flat roof differs from the insulation of a pitched roof in that it can be performed not only from the inside, but also from the outside of the building. But in this case, you will have to spend more time and money on its insulation. To avoid unnecessary expenses, it is better to first insulate the roof from the outside, and after use for one year, insulate it from the inside.

Insulating a flat roof from the outside

It often turns out that external roof insulation alone is enough, and insulation from the inside is not needed.

What material to choose for insulating a flat roof.

For insulation of ventilated attic roofs, polystyrene foam with a density of 12–15 kg/m², as well as mineral wool with a density of 20–35 kg/m², are suitable. If the roofless roof will serve as a terrace, then a more solid insulating material will be required. Expanded polystyrene with a density of at least 20 kg/m² or mineral wool with a density of 150 – 220 kg/m² is suitable. The best option for this case is extruded polystyrene foam, which has high water resistance. In any case, the thickness of the thermal insulation layer must be at least 150 mm, and the insulation itself is carried out in two layers to reduce the risk of cold bridges.

When cutting and installing mineral wool slabs, be sure to wear gloves and loose-fitting protective clothing, safety glasses and a dust respirator. The workplace must be well ventilated. Upon completion of work, you should thoroughly wash your hands and take a shower.

The best material for external roof insulation is slabs made of basalt mineral wool, which are characterized by durability, high vapor permeability, low thermal conductivity, good fire safety, and excellent resistance to mechanical loads.

Selection of tools

If you ask a professional roofer what tools you need to have to insulate the roof, he will probably answer that a knife, a hammer, a clear head and skillful hands. Essentially, this is the case, but there are subtleties and secrets that not everyone wants to divulge.

Roofing tools

The most important detail and, accordingly, the trick is choosing a knife . If you take a regular mounting knife, you will be able to work, but throughout the entire time you will suffer from unevenly cutting off pieces of insulation. Such a construction tool has a blade that is too short and is unable to cut through a thick layer of heat-insulating material. In addition to all this, a standard knife will quickly become dull on polystyrene foam or mineral wool.

If you don’t have a knife, then you can use improvised means for cutting - a hacksaw for wood or a wide kitchen bread cleaver with a lumpy sharpening.

The ideal option would be to purchase a special professional long knife . It is made taking into account the requirements placed on it - made of carbon steel with a length of 35 cm and a comfortable handle made of high-quality plastic.

Professional knife

In addition to a good cutting tool, you will definitely need a hammer, a screwdriver, self-tapping screws of different lengths, a long strong cord, reliable protective clothing, glasses to preserve your vision and a respirator.

It would also be a good idea to listen to the following recommendations:

- the place where thermal insulation materials are to be cut must be well ventilated;

- carefully protect your hands, head area and, especially, the respiratory tract with your eyes - they are most susceptible to damage from flying fibers;

- after work, immediately take a shower, thoroughly washing your hands, face and other areas of the skin;

- before cutting, make sure that the size is correct - the pieces should fit freely between the rafters, without falling out or being squeezed;

- It is advisable to cut mineral wool across the fibers - this minimizes the release of flying particles.

Cutting mineral wool

Do-it-yourself insulation of a flat roof

External insulation of a flat roof includes the installation of a vapor barrier layer, laying thermal insulation, waterproofing, and then a roll covering. The final layer is the laying of bulk material.

Before starting work, you need to clean the roof surface from debris, dust, and level it. Then install a vapor barrier as described above. After this, glue the insulation boards using cold mastic or special glue. The slabs are laid with a semi-overlapping seam, which ensures uniformity of the coating. It is permissible to lay several layers of slabs staggered and glue them with tape. This method of installation will prevent the occurrence of cold bridges.

Next, waterproofing is laid. The fire method of gluing a waterproofing carpet is often used: a cement-sand screed is laid on the slabs in a layer of at least 3 cm. After laying it, you need to wait until the concrete gains the necessary strength, then clean the surface from sagging and dirt. The waterproofing layer is glued using short-term exposure to fire. The gluing method is described in great detail on the packaging of the material. As a result of exposure to fire, the insulation does not lose its properties. After this, a rolled roof covering is laid and expanded clay or other similar material is poured.

Insulating a flat roof from the inside

There are times when it is necessary to insulate the roof from the inside. The most acceptable way of internal insulation of a flat roof is from the ceiling.

The main thing is to choose a fire-resistant material. The thermal insulation process is not difficult, but the placement of lighting fixtures will need to be redesigned.

What material to choose for insulating a flat roof from the inside

For this method of thermal insulation, fire-resistant polystyrene foam boards such as PSB-S-25 or PSB-S-35, with a thickness of 25 mm, are suitable. They meet all fire safety requirements.

Stages of work

First, strips made of soft wood must be screwed to the ceiling every 40 cm. The first is attached along one of the walls, which is perpendicular to the beams of the supporting structure. The second is mounted along the opposite wall. After this, glue the expanded polystyrene slab flush to the first plank, using special glue or mastic. Then the next plank is screwed in the same way and the second heat-insulating board is glued, etc. The laying of planks and heat-insulating boards is alternated. When the insulation layer is completely laid out, a plastic film is attached to the entire ceiling area. Decorative panels are then nailed to the slats. Galvanized nails are suitable for fastening.

Read our article: Roof insulation from the inside

Types of insulation

The most common method is to install a layer of insulation between the rafters and cover it with sheet materials. This “pie” is the most advantageous from any point of view, since the use of loose insulation materials such as expanded clay in this case is problematic. Expanded clay can be used for flat surfaces with a slight slope, which is very rare.

Note!

The most commonly used materials are mineral wool (in slabs), polystyrene foam and polyurethane foam (spraying) . They perform their functions properly, are inexpensive and light in weight . In addition, mineral wool and expanded polystyrene have sufficient rigidity for fastening from the inside, which is valuable when insulating a finished roof.

These materials are only part of the “pie”; it is necessary to have hydro- and vapor barrier layers that do not allow moisture (condensation) to be absorbed and allows the “pie” to breathe, i.e. ventilate. Without these functions, the insulation may begin to mold , accumulate water, and eventually ruin the rafters, which is fraught with undesirable consequences.

Since the insulation layer is sheathed on the inside with plywood, chipboard, plasterboard or other sheet materials, destructive processes will be noticed only when they cause serious damage. Therefore, the technology for assembling the “pie” should not be neglected.

How to properly ventilate a roof

- The area of exhaust and supply openings must be determined taking into account certain parameters, which include the volume and concentration of removed vapors, etc., which in practice is not always possible to do. Therefore, they usually use existing empirical findings. 2. The height of the ventilation gap between the base of the roof and the insulation must be at least 5 cm. It directly depends on the length and angle of inclination of the roof slopes. 3. The flow of air is organized both along the entire eaves and in local places - with the help of ventilation grilles that cut into the lining of the eaves overhang. 4. The total area of exhaust ventilation openings installed only at the highest point of the roof must be no less than the area of the supply openings for each slope. Exhaust devices are ventilation hoods for hipped roofs, ventilation ridges, roof aerators, etc. You can use both ready-made (store-bought) devices and those made by yourself. https://www.youtube.com/watch?time_continue=3&v=uzNCsJO2k6w