I would like to insulate the veranda, but I don’t have a lot of money. Insulate walls and floors.

Can be insulated with cardboard. Since a low budget is implied, other materials must be affordable; there is no point in using expensive membranes and other modern materials. Let's say the veranda is made in the form of a frame sheathed inside and out. We remove the casing, preferably from the outside. Then we fill the inner space with layers of cardboard. Cardboard can be different, thick, like book covers and corrugated cardboard, which is used as containers. It can also be laminated and covered with film. Laminated cardboard needs to be attached with a laminated layer towards the room to be insulated, nailed to the inner lining, I don’t suggest a stapler, it’s expensive. Tape the joints between the sheets with tape. This layer will be a kind of vapor barrier that will protect the main layer from being moistened by moisture coming from a warm room. The inside is filled with corrugated cardboard, and the joints between the sheets should be staggered, overlapping the next row. If the space is large, then it makes sense to nail the slats after laying out several rows so that the entire cake is compressed and the sheets do not dangle inside. The last, outer layer also needs to be made of laminated thick cardboard with the joints taped. This will be a windbreak. All that remains is to return the outer casing to its place.

In anticipation of the onset of the cold season, the search for the optimal option for home insulation becomes especially important, and the most popular method of insulation is the use of kraft paper. The effectiveness of Kraft liner thermal insulation has been repeatedly confirmed both by experts who have conducted special studies and by home owners who have appreciated the advantages of this method. For those who are wondering how kraft paper is used and what it is, we will try to understand the features of this insulation.

What it is?

Kraft paper is a high-strength material based on wood processed using kraft pulping. Most people are familiar with it as a packaging material, which has become especially popular for packaging eco-friendly gifts and souvenirs - bags, wrapping paper and envelopes. This paper is also used for making all kinds of stationery.

Another area of use of this material is the production of durable products for packaging various products - bags, boxes, etc. The characteristics of cellulose allow its use in cases where high levels of strength, wear resistance and reliability are required from the material, therefore paper insulation is widely used for thermal insulation of buildings for various purposes, including residential buildings.

There are many ways of thermal insulation using kraft liner. Using paper with reflective foil helps achieve high efficiency. This option prevents the passage of thermal radiation and is used to insulate walls, roofs, etc. Another area of its use is paper flooring: such a photo can also be found on the Internet.

Underfoot

Earth, turf and peat are natural insulation materials that have been used in house construction since time immemorial. The traditional dwellings of the northern peoples were huts with a base of poles, covered with layers of peat or turf. Such houses were indispensable in conditions of strong winds. Until now, in Iceland, buildings are dug into the slopes of hills or covered with earth on the sides so that the house ends up on a small hillock.

In many Russian villages, until the middle of the 20th century, huts were still insulated using earthen, sand or peat piles. They were built using wattle or timber, creating a box around the house into which earth was poured or peat or turf was laid in layers. Since ancient times, turf has also been used for roof insulation: it was laid in several layers on a multilayer birch bark substrate. In villages, soil was often poured over the ceilings for warmth, and the houses themselves were buried. The warmth of the earth allows you to increase the air temperature in the house by 1-2 degrees Celsius.

How it's done. There are several options: the house can be deepened into a natural or artificial hill, you can create a multi-layer wall with cavities for filling with earth or dried peat, you can build the wall itself from bags of earth or cover an existing one with bags of soil. The main condition for installing such insulation: all building structures that can rot upon contact with the ground must be insulated from it with a moisture-proof layer (plastic film, bitumen roll material or even birch bark plates). Let's say you decide to insulate a small house the size of 3x4 m and 3 m high. With a bag width of 40 cm, only one wall will need about 4.8 m 3 of soil weighing 13 tons.

This design consists of several main parts:

Cardboard as insulation

Cardboard insulation has been used for quite a long time: this material is used to insulate walls, floors and attic spaces. This material is most often associated with packaging: a corrugated cardboard box can provide reliable protection for products. Due to its affordable price, it is also popular for performing thermal insulation work. Corrugated cardboard as an independent thermal insulation can solve the problem of insulation when laid in a sufficiently thick layer - it is recommended to make a layer of at least 5-10 centimeters.

The thermal insulation properties of corrugated cardboard are ensured by the structure of this material, and the ease of its use allows all work to be carried out in the shortest possible time. Using insulation boards impregnated with special compounds, you can ensure good moisture resistance and protect the insulation from rodents.

Mineral wool for insulating a frame house

Mineral wool, produced in the form of slabs or rolls, has been very popular recently. It is worth noting that basalt wool in slabs is in greater demand than in rolls.

Mineral wool has good thermal insulation properties. Not flammable. But cotton wool contains formaldehyde, which is harmful to human health. Mineral wool fibers, like fiberglass, are carcinogenic.

For this reason, when insulating internal walls with this insulation, it is necessary to use vapor barrier membranes (in addition to the main purpose), so that small grains of mineral wool do not scatter throughout the room.

When laying mineral wool, it is imperative to use additional means to protect the face and other exposed parts of the body. On top of mineral wool, you can attach not only a vapor barrier film, but also simple polyethylene. The seams are taped.

A significant disadvantage of cotton insulation is the fear of moisture. When the insulation is moistened by 2-3%, its thermal insulation properties are reduced by 50%. Therefore, it is imperative to use a vapor barrier. As a rule, after 25-30 years, mineral wool needs to be replaced.

Advantages and disadvantages

The active use of kraft paper is due to a number of its undoubted advantages, including:

- Environmental Safety . This is an environmentally friendly material that does not emit harmful substances. Thanks to this, it is safe for human health and the environment.

- Affordable price. The low cost of this insulation allows thermal insulation to be performed at the lowest cost.

- Ease of installation . The insulation can be easily placed even in hard-to-reach places: it is easily attached to various structures using a construction stapler, self-tapping screws, etc.

Types of equipment for do-it-yourself penoizol basic equipment

The production of insulation can be established in any room, but it is recommended to do this directly at the work site in order to save on transportation.

To make the unit you will need:

- Foam pump.

- Foam generator.

- Solution pump.

- Electricity.

- Compressor.

Equipment for the production of insulation today on the construction market is presented from different manufacturers. The models differ in their characteristics and cost. The average price of the device is 35,000 rubles. Experts recommend giving preference to installations that are manufactured in Russia or Ukraine.

Conclusion

Using kraft paper as insulation has both positive and negative sides. The undoubted advantages of this insulation are the low cost of the material and the ability to perform insulation quickly and easily. In addition, given the growing attention to the problem of environmental safety, choosing kraft paper is the best option in terms of ecology: such insulation does not emit harmful substances.

The topic of our article is paper insulation. No, do not rush to cover the walls of your house with old “Roman newspapers”: paper in its pure form is too afraid of moisture, and its density is too high for an insulating material.

However, it is still possible to use cellulose for thermal insulation.

Let's hope that more civilized methods of insulation will be found.

OSB on the inside of the wall

The installation of OSB on the inside of the wall was caused by the following reasons:

- Giving additional rigidity to the frame

- The basis for applying an additional layer of ecowool with a wet adhesive layer

- additional vapor barrier

This solution was invented even before the house was built.

But now, in fact, I would do it differently. Instead of OSB3, I would buy a simple 12mm isoplaat, which is not windproof but heat-insulating. Why? Firstly, because in fact even one external 12mm isoplaat gave the house sufficient rigidity. Secondly, this solution is more harmonious when using ecowool as insulation. Thirdly, for my volume, the increase in price would be meager. But what’s done is done. The plates were fastened horizontally, in a “chessboard” pattern. For fastening, 30mm galvanized screw nails were used, simply because I had a significant amount of them left over from somewhere.

Many materials that either have a porous structure or in their mass form many cavities that retain air can serve as insulation. Where to look for them?

Industrial production and crazy hands

It’s worth clarifying right away: the idea of using paper for insulation is not new. Ecowool, one of the fairly popular insulation materials, consists almost entirely of cellulose and is made from recycled waste paper. We will devote a separate article to its properties.

However, along with the industrial production of ecowool, insulation with cardboard and paper is also practiced without their additional processing; As an option, insulation boards are made independently. We will also pay attention to this use of cellulose.

No processing

Kraft paper

Let's start by getting to know one fairly popular type of cellulose product.

Kraft paper is a very durable material that is made from long fibers of kraft pulp. Raw materials - wood; wood chips are boiled in an aqueous solution of sodium sulfide and some other substances.

It’s interesting: the process is extremely technological, since it allows the use of wood of any species. In addition, the chemicals used are recovered and can be reused. Yeast, soap, turpentine, rosin, methyl alcohol and many other useful products are obtained from by-products.

Everyone is familiar with kraft paper in this capacity.

How is thin and thick kraft paper useful in terms of insulation?

Of course, not as a thermal insulation material.

- The classic design of a frame house is a frame made of timber, sheathed inside and outside with clapboard, OSB or plywood . The space between the outer and inner skins is filled with insulation. It is often used mineral wool, polystyrene foam and other modern materials for insulation; The heat-insulating material is protected from blowing and moisture saturation by special polymer films. This scheme has two disadvantages:

- The materials used are of artificial origin and often continue to saturate the air in the house for many years with phenolic resins, styrene or fine mineral fibers that irritate the eyes and respiratory organs.

- They are by no means cheap.

Roof cladding technology

Quite often, instead of the ceiling, and sometimes together with the ceiling, the roof of a frame house is also insulated with mineral wool.

This is done when the attic space is heated or residential. The technology will be practically no different from ceiling insulation. The only exception is that a waterproofing material must be stretched over the insulation, which protects the insulation from the external aggressive environment.

Like the ceiling, it will be much more convenient to insulate the roof from the outside, since installing wool from the inside is inconvenient, and the material tends to spill onto the face and head. When the rafter system is installed, a vapor barrier layer must be hemmed underneath, onto which sheathing material, plywood or boards are also placed.

Sheets of insulation are laid outside, following all the same rules as in the case of other parts of the frame house. A waterproofing membrane is placed on top of the insulation, which should already be filled with sheathing and roofing material.

The roof can be insulated from the inside , but only if it is completely assembled. This process will be less convenient, since you will have to come up with some additional temporary fastenings.

Self-production of cellulose boards

Is it possible to make more convenient paper insulation with your own hands?

Yes, you can make some kind of thin and dense insulation from waste paper. Whether the result is worth your time is debatable; however it is possible.

Here is a description of the production process.

- The paper is shredded and poured into a barrel. The smaller the fragments, the better the result. Then it is soaked for a day or two. Water should completely fill the paper.

- After this time, water is added to the barrel at the rate of 20 liters per kilogram of waste paper.

- An oil emulsion is made in a separate container: 100 grams of machine oil and water are taken per 200-liter barrel. The mixture is whipped with a mixer and added to the barrel: it will make the material hydrophobic.

- Add 100 grams of soda ash to the barrel (it will reduce the ability of the insulation to ignite) and 20 grams of boric acid (an antiseptic).

- Beat the mixture thoroughly. This can be done with an improvised mixer: three pieces of 4 mm wire are clamped into the drill chuck; then the last 15 centimeters of each segment are bent radially.

- After 5-7 days of settling, the mixture is whipped again. It should become as homogeneous as possible: in this case, the density of the insulation will be minimal, and the yield of useful volume will be maximum.

- We are constructing a mold for the future insulation board. Overall dimensions are arbitrary (you can focus on 50x100 centimeters). The bottom is a mesh on a solid base that allows water to pass through, or simply polyethylene pierced in several places with an awl and laid out on flat sand.

Ecowool

At the beginning of the article, we mentioned the insulation industrially produced from cellulose - ecowool. Let's get acquainted with it: after all, the raw materials for its production are the same cardboard and paper.

What it is

Appearance – gray flakes.

The full composition looks like this:

- Cellulose – 81 percent.

- Antiseptic (boric acid) – 12 percent.

- Boron (fire retardant) – 7 percent.

The insulation does not contain harmful substances; the fibers are non-volatile and even if accidentally contacted with mucous membranes cause much less irritation than mineral wool fibers.

The photo shows Ecowool cellulose insulation.

Thermal insulation qualities correspond to the degree of thermal insulation provided by basalt wool.

Important: when moistened, ecowool retains these qualities. All types of mineral wool insulation, once damp, begin to conduct heat much better.

The material does not cake and does not shrink. It has very moderate breathability, which is a definite plus: the insulation will not be blown through by wind and drafts. But vapor permeability is high, which is also good: dampness will not linger in the thickness of insulated walls and ceilings, causing accelerated destruction of load-bearing structures.

The material is chemically inert. In contact with steel load-bearing elements, it will not cause accelerated corrosion.

With all this set of advantages, the cost of a cubic meter of finished insulation when working on horizontal surfaces is about 700 rubles. On verticals, a high packing density and special equipment are used, so a cubic meter of insulation is more expensive - about 1,300 rubles.

Application

How to use ecowool if we are planning to insulate a loggia or cottage walls?

There are three ways to use it.

- Ecowool fluffed with a mixer can be poured between beams or floor joists.

- It can be supplied to the wall or subfloor through any opening using an air compressor. In this case, the insulation fills the smallest grooves in the thickness of the wall.

- Finally, wet installation is applied to ceilings and walls. Moistened ecowool is sprayed onto them and sticks tightly: the notorious lignin binds the flakes to the surface and to each other.

Insulation with ecowool using the wet method.

The latter method, as already mentioned, requires special equipment.

How to insulate a frame house for winter living?

In order to live comfortably in a frame structure and in winter, the material used for insulation must have the following qualities:

- Environmental friendliness - insulation should not contain substances that can cause harm to health.

- Fire resistance - the material should not ignite, and in the event of a fire, emit a large amount of smoke.

- A small thermal conductivity coefficient is optimal if the winter insulation in a frame house is within 100-150 mm.

- Strength and tightness - the insulation must tightly fill the gaps of the frame.

- Easy installation of thermal insulation.

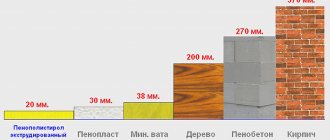

To insulate a frame house, it is customary to choose between polystyrene foam, extruded polystyrene foam, mineral wool, basalt wool and polyurethane foam.

Let's look at the advantages and disadvantages of each.

Styrofoam

The material is considered the warmest, but is less suitable than others for insulating frame houses. Features of use:

- Polystyrene foam is rigid slabs, they are laid on a flat wall. For a frame house, this insulation option is only suitable if the surface is perfectly flat, otherwise cold air will leak through the gaps.

- The material should not be placed near fire sources.

- It does not allow moisture to pass through and requires the installation of reliable waterproofing and vapor barriers.

- light weight, which makes the installation process simple;

- does not lose its properties due to temperature changes.

Extruded polystyrene foam

This is a high-quality material with good thermal insulation properties. Made from granulated polystyrene and foaming agent.

- Low water absorption. This indicator remains unchanged even at high humidity.

- No additional waterproofing required.

- Strength.

- Low flammability.

- Can be used at temperatures from -50 to +75 degrees.

- Environmentally friendly and harmless to health.

- You can install it yourself.

- Low vapor barrier. To improve the indicator, installation of ventilation is required.

- High price.

- Installation of an additional frame on which the material will be attached.

- Application of a special composition to polystyrene foam to protect against UV rays.