The modern market of construction and finishing materials offers a huge number of insulation materials that differ in characteristics and performance properties. Polyurethane insulation Polynor is the most effective modern material used for thermal insulation of a home.

Polynor thermal insulation is a new product on the Russian construction market. It is a sprayed polyurethane foam that has excellent sound and heat insulation characteristics due to its composition, which is 90% air.

At the same time, it is extremely easy to install, which puts it an order of magnitude higher than other thermal insulation materials.

You will also be interested in reading the reviews about Polynor, which are at the end of the article.

Material advantages

Unlike similar insulation materials, liquid insulation has the following advantages:

- efficiency;

The energy saving coefficient when insulation is carried out with Polinor is higher than that of the so popular mineral wool.

- profitability;

For fastening, there is no need for the construction of an additional frame or the use of hydro- and vapor barrier materials, and there is also no need for special devices and costs for delivery to the repair site.

- ease of installation;

One person can spray the material. Its application does not require labor-intensive preparatory work, surface leveling, etc.

- minimum consumption;

The question of how much insulation is needed can be easily answered. One liter of liquid is enough to create a four-centimeter insulating layer on a surface area of 1 sq.m.

At the same time, the cost of such insulation is noticeably lower than the same mineral wool, which will require many additional materials (vapor barrier, waterproofing, sheathing, fastenings, etc.)

- excellent adhesion to any type of material;

- biostability and lack of condensation.

Along with a large number of advantages of Polinor insulation, it also has some disadvantages:

- negative influence of sunlight on it;

- deteriorates under constant exposure to water;

- when applied, requires a temperature of +15 to + 25 degrees;

- dangerous to the eyes and respiratory system (use of a respirator and safety glasses is required).

Recommendations for applying insulation

The insulation has all-season use, the main thing is that the temperature of the cylinder during application is within +18 - +35 degrees.

At lower or too high temperatures, the insulation loses its properties. Therefore, the cylinder must be kept in a warm room. To install the polynore, a special gun is required. Before applying the insulation, a nozzle is put on it, which comes complete with the balloon heat insulator. The shape of the nozzle ensures uniform spraying of foam over the surface and also allows you to control the consumption of material. To insulate the ceiling, it is best to use a corner nozzle, which is sold separately. The 3D insulation kit comes with two types of attachments: white and blue. The first is intended for spraying on vertical surfaces, the second - on horizontal and inclined surfaces.

After applying the insulation, a dense film forms on the surface within 4 minutes. Complete polymerization occurs within one hour.

20 minutes after spraying, the thermal insulation layer increases by 20%, so the manufacturer does not recommend applying a layer of more than 4 cm at a time. The second layer can be sprayed only after the previous one has completely dried, after about 20 minutes.

Polinor can be applied both under plaster and under cladding with any finishing material. In the first case, the insulation is simply sprayed onto the prepared base. In the second, it is necessary to build a frame of wooden beams in advance, the cells of which are then filled with a heat insulator.

Basic properties of the material

Sprayed insulation Polinor. Its characteristics demonstrate excellent technical properties that exceed the properties of other materials:

| Parameter | Meaning |

| Density | 18-28 kg/m3 |

| Water absorption by volume | 0.02 |

| Coefficient of thermal conductivity | 0.023-0.025 W/mK |

| Temperature | From -25 to +120 °C |

| Coating thickness | 25-60 mm |

| Probable service life | 35 years |

| Polymerization rate at t=20 °C | 40 min |

| Complete drying time | Up to 3 days |

| Failure due to compression, shear. | Missing up to 50% |

| Flammability group | G3 |

Scope of application

The description of the insulation presents us with a modern, almost universal material, which has a fairly wide application as a finishing and insulating material, in particular:

- for facades for finishing;

- for foundations and attics;

- for balconies;

- for insulation of internal walls of a building, partitions in various buildings;

- to isolate communication systems;

- in vehicles with isothermal functions.

As you can see, the application is wide. And this is understandable, since the heat insulator has good performance properties, fits perfectly on any surface, is very flexible and is not subject to destruction, even if a crack appears on the surface. The material is non-toxic and perfectly absorbs sound and vibration waves.

Release form

Sprayed insulation has been known since 2013. It is a one-component self-expanding mixture with a closed-cell structure.

In construction stores, this thermal insulation is sold in cylinders similar to conventional foam for a gun.

It is applied in the same way as construction foam. According to reviews, one cylinder is enough for a 5-centimeter layer of insulation over an area of one square meter. The manufacturer's instructions state that the service life, in the absence of exposure to negative factors, will be at least 35 years.

Precautionary measures

Despite the safety of the Polinor composition, it is recommended to observe the following precautions when performing insulation measures.

• When the composition is released from the cylinder, there is an increased concentration of the chemical components of the insulator, which can cause irritation of the mucous membranes of the eyes, respiratory organs, and skin. Therefore, work should be carried out in special clothing, safety glasses, a mask or a respirator.

• Do not spray the contents of the cylinder near an open flame. The presence of gas may cause a fire. It is also prohibited to combine installation with smoking cigarettes.

• In the room where thermal protection is installed, you need to open windows and doors to organize good air ventilation.

In general, working with polyurethane foam insulator Polinor, produced in cylinders, is characterized by simplicity and uncomplicated application techniques, which is confirmed by user reviews.

Installation features

Cylinders with insulation must be kept in a warm room until they are used. This is an important point, since negative temperatures can have a bad effect on the characteristics of foam insulation.

The thermal insulation mixture can be applied both to a clean surface and to the sheathing, it all depends on the chosen method of finishing the room. It adheres well to almost any materials. Spraying is easy, even with the hands of a non-professional.

In addition to the walls and facades themselves, Polynor foam can easily be used for thermal insulation of various communication pipes, well caissons and complex construction sites.

Before applying any insulation, including Polynor spray insulation, the surface is thoroughly cleaned of dirt and debris. If defects or damage to the surface are found, they should be repaired. A crack in the wall, for example, cannot affect the insulation in any way, but it may well spread under the insulation layer. Therefore, it is better to immediately begin repairing it using glue and cement composition.

Then the insulated surface is thoroughly degreased with special compounds. This must be done due to the fact that Polinor insulation does not adhere well to an oily surface.

Then spraying is carried out with an aerosol gun, to which is attached a nozzle for controlling the consumption of material and the supply of foam.

How to spray thermal insulation

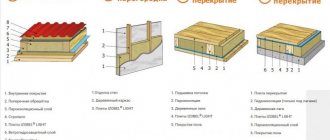

Foam insulation is easy to apply , which does not require the involvement of significant labor or the use of complex installations or units. The use of such materials is allowed on vertical, horizontal and inclined surfaces (floors, walls, ceilings, partitions), as well as structures with complex shapes (decorative finishing, plumbing fixtures).

Even one person can apply insulation in cylinders. The lightweight cylinder can be carried, lifted and operated without noticeable effort. The volume of material consumed is calculated based on the available number of containers (1 cylinder = 1 sq. m of insulation).

Regardless of the surface area, time of year and other factors, the order of applying thermal insulation material is approximately as follows:

- Clean the base from dirt, remove dust and moisture accumulation.

- Repair damage to surfaces made of brick, concrete or wood to prevent further destruction of the base and insulation.

- Degrease the substrate with acetone or an available solvent to remove oil stains and improve adhesion.

- Prepare the gun for Polynor insulation by fixing the spray gun and removing the protective cover. Shake the container well before use. Before use, it is recommended to store the container at temperatures not lower than +18−30 ºC.

Polynor balloon insulation is equipped with a universal nozzle for controlling material consumption through the dosage of force on the handle. During the application of foam, the container must be shaken periodically to ensure better spraying. It should be borne in mind that before it hardens, sprayed thermal insulation remains harmful to health, so it is imperative to work in protective clothing, gloves, and goggles.

Professional advice and customer reviews

Over several years of use, Polinor insulation has already managed to win admirers. Many professionals who have been using polyurethane foam for a long time have given their preference to the new product. It is noted that it is extremely easy to install, fits perfectly on any surface and has good characteristics during operation. Thermal insulation occurs quickly and at a high level.

It is also noted that the material is extremely toxic, so you should take precautions and protect yourself with special suits, gloves, respirators and goggles. If foam gets on the surface of the skin, rinse it thoroughly and consult a doctor.

Also, consumer reviews note that Polinor insulation is quite expensive in cost, but this factor should not be decisive when choosing insulation. The speed of application and excellent characteristics will allow you to save significantly on heating the room in the future.

The material is extremely toxic, so precautions should be taken

Professionals also often prefer this material. Its light structure and ease of application can significantly reduce the time and money spent on installing insulation.

Comparison of Polinor insulation with Penoizol

Experienced builders and finishers have already dubbed Polinor insulation a complete replacement for liquid polyurethane foam. At the same time, the final price for surface insulation will be significantly lower than when using polyurethane foam. In addition, when installing polyurethane foam, it is necessary to use special equipment that must be transported, incurring additional financial losses. Using insulation in cylinders, everything is much simpler.

Experienced builders and finishers have already dubbed the foam insulation in Polynor cylinders a complete replacement for liquid polyurethane foam.

Among the characteristics are excellent vapor barrier. An analogue of polynor polyurethane foam, it transmits steam worse and condenses moisture, unlike insulation in cans. This is especially important when insulating wooden houses.

Economic justification for the use of Polinor

If we compare the costs of laying conventional polyurethane foam and POLYNOR thermal insulation, then many factors speak in favor of the latter.

Firstly, its use can significantly save money on paying for the work of the installation team: this insulation is easily applied independently, and there is no need for knowledge of construction and technical basics.

Based on market prices in 2014, surface treatment with an area of about 100 square meters. it cost about 50 thousand rubles. These costs are similar to the costs of insulating a structure using mineral wool or expanded polystyrene. And if we compare the one-component effective heat insulator POLYNOR with a two-component mixture in the form of polyurethane foam, then the latter will cost almost one and a half times more.

The approximate cost of 1 cylinder of polyurethane sprayer POLYNOR with a volume similar to polyurethane foams is currently approximately 450 rubles. The modern Russian market is saturated with a lot of offers for the sale of Polinor, so you can always find the most acceptable price for yourself and discuss favorable delivery conditions.

Indoor insulation Polinor is packaged in an economical container, which is why purchasing more material than necessary is practically impossible, but there are no problems in re-ordering it. Please note that the standard package contains 12 cylinders with the mixture.

Reviews

Those who have used this insulation system have shared their opinions. Read the reviews on forums and construction sites that we have collected:

Airat

I read reviews about Polynor. I decided to try it myself too. The base was insulated with PP. I wanted to seal the seams with Polinor. It was sprayed well, the yield of material from the cylinder was almost 100%. But it is important to pay attention to the expiration date. I blew out one balloon, then went to buy a second one in another store. I used half of it, and then some kind of sludge started to appear. I took a closer look, and it was already past the expiration date. So you need to pay attention to this. But overall, I’m happy!

Natalia

It was necessary to insulate the loggia. I decided to look through the Polynor reviews on the forums. I liked it. I bought it from Leroy, received instructions and applied it myself to 12 squares. I'm happy with the result. At the end of autumn, being on the loggia is as comfortable as being in the apartment itself. The only thing is that when spraying, foam particles fly in the air, so you need to cover everything.

Sergey

The apartment is on the first floor. I decided to insulate the floor from the basement so that the cold wouldn’t pull in from below so much. I've heard about spray-on insulation. I googled reviews about Polinor insulation and decided to try it. In about 3 hours I foamed the entire required area (about 36 sq.m.). I liked everything, I just need to ventilate it, otherwise I might collapse from the stench. It is difficult to ventilate a basement, so the speed of work was a big plus.

After using Polynor insulation, you can leave your feedback in the comments below.