In order to simultaneously increase the temperature in the premises of a home to a comfortable level and at the same time reduce energy consumption for heating, it is necessary to perform high-quality thermal insulation. One of the best materials today is foamed polyglass. Let's look at what foam glass insulation is, what are its main characteristics and scope of application, what pros and cons it has, what types are found and what are the features of its installation.

Insulation of external basement walls with foam glass Source stroy-podskazka.ru

Foam glass - what is it, characteristics, application

An artificial thermal insulation material with a cellular air-foamed structure based on silicate glass is called foam glass. Despite the fact that it was first obtained almost a century ago, it became widely used as insulation only recently. The basis for this was a number of its practical properties, the main of which are high heat and sound insulation properties, a large margin of safety, minimal weight, fire safety and water resistance.

The production cycle of the material consists of the following main stages:

- Grinding of raw materials - pieces of silicate glass.

- Mechanical mixing of powder with gas-forming agents (mainly carbon).

- Laying the mixture into a mold or conveyor.

- Sent to the melting furnace.

- Heating up to 1000 °C.

- Melting the powder to a thick viscous mass.

- Emission of gas accompanied by foaming of the melt.

- Cooling of the heated mass.

- Formation into a finished product - blocks, slabs, granules.

Foam glass granules are poured into the cavities of frame walls Source tproekt.com

In essence, this foam glass is identical to standard household glass, with the only difference being that the first has a porous-cellular structure, and the second is a solid monolithic one.

Characteristics

Thermal insulation material of this type is distinguished by the following external features:

- The porosity of the structure is within 80-90%. In this case, the pore dimensions reach sizes from 1 to 10 mm.

- A variety of shades - green, cream, black - depending on the composition of the original components.

- Variability of release forms - blocks, slabs, granules, shaped products.

- A variety of installation methods on any surface - mortar, mechanical fasteners, glue, etc.

The technical properties of foam glass insulation are expressed by the following features:

- The minimum density is about 100-200 kg/m³, which guarantees a very low load on the foundation and structures.

- High compressive strength - 40-100 tons/m², thanks to which the material is successfully laid under powerful concrete screeds.

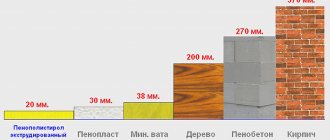

- Low thermal conductivity - 0.4-0.6 W/m*C, which is 1.5-2 times lower than that of wood.

Foam glass is harmless and allows you to insulate from the inside Source infradom.ru

See also: Catalog of companies that specialize in insulating houses

- The noise absorption coefficient sufficient for comfortable conditions is 50-100 dB per slab with a thickness of 100 mm.

- The volume of water absorption is no more than 2%. This characteristic makes foam glass almost completely water-repellent and absolutely impervious to steam.

- Inert to thermal changes and fire safety. The material does not burn, is not afraid of severe frosts and can withstand heating up to 300-500 °C in the standard version, and about 1000 °C with special additives. This allows it to be used in places with a high risk of fire spread.

- Resistance to aggressive substances and environmental safety.

One of the important practical features of foam glass insulation is the constancy of its insulating qualities throughout its entire service life, which reaches the time of operation of the structure itself.

Foam glass does not get wet and does not allow steam to pass through Source kti.by

Application

In everyday life, foam glass thermal insulation material is used in the following cases:

- For external or internal insulation of main walls of a house. The material is perfectly suited to silicate bases - concrete, brick, blocks - since it itself has a similar base, and therefore has the same coefficient of thermal expansion as them.

- For insulation and waterproofing of underground premises and structures - foundation, basement, basement, garage.

- Foam glass in the form of granules is widely used both as an additive to concrete mass to increase its thermal insulation properties, and as backfill in the cavities of frame walls, floors, ceilings, and roofs.

- For thermal insulation of heating and water supply lines, sewer lines - in the form of shaped products.

On a note! Foam glass granules in pure form or in composition with other bulk materials are widely used for landscaping local areas. For example, they can be used to make bedding on clayey and swampy soils, to arrange paths, to form the basis of greenhouses and greenhouses, and to insulate underground containers.

Foam glass granules are used for backfilling under screed Source twimg.com

A little history

Foam glass was invented by the honored worker of technology and science Isaac Ilyich Kitaygorodsky. The professor specialized in glass production technology, because he considered it the material of the future. The professor's invention was improved by US specialists in the 40s. Initially, foam glass was used as a floating material. But it soon became clear that it demonstrates excellent heat and sound insulation properties, is easily glued together, and is easy to process. Therefore, it was decided to use it in construction.

Thus, in Canada a building appeared, created from concrete slabs with a layer made of cellular glass. This event happened back in 1946. The experiment was very successful. The material has received well-deserved recognition. But, to the great regret of the inventor, it did not gain popularity in Soviet countries, since the cost was high and the production technology had not been developed. It was manufactured in the USSR, but the quality of the product left much to be desired, which led to the closure of factories.

But currently the production of this product is in full swing!

Advantages and disadvantages

Foam glass insulation has the following number of advantages:

- Optimal practical characteristics.

- Preservation of thermal insulation properties and dimensions throughout the entire period of operation.

- Environmental Safety.

- Inertness to natural factors of destruction - microorganisms, insects, rodents, rust, etc.

- Durability.

- Ease of processing.

- Compatibility with all building materials.

- Easy to install.

- Fire safety.

- High sound absorption rates.

- Strength.

- Resistance to chemically active substances.

- Inert to temperature changes.

At the same time, foam glass as insulation has several disadvantages:

- High price. It is one of the most expensive thermal insulation materials, since the production technology involves high energy costs and the use of special installations.

- Minimal impact resistance. Under such loads, products are quickly damaged. This must be taken into account during transportation and installation, since after installation the thermal insulation layer, as a rule, is not subject to such factors.

To install foam glass slabs, special glue is required Source ytimg.com

- Vapor tightness. Contributes to the accumulation of dampness in the room and the formation of an unhealthy microclimate.

- Lack of aesthetics. After installation, additional finishing is required.

Advice! When laying material on a combustible substrate, such as wood, polycement adhesive is best suited. Since it has sufficient elasticity and adhesive ability.

Foam glass insulation technology

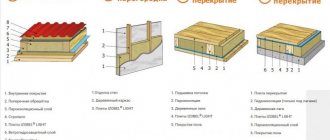

To guarantee high thermal insulation qualities of the material, it is necessary to follow the technology of its installation:

- To attach the slabs, it is recommended to use special glue, which must be applied to the back of the slab and the side walls. After which the glue should be evenly distributed over the surface of the sheet.

- If the surface has pits, bulges or other irregularities, the adhesive should be applied to the foam glass with slaps to obtain the most even base possible.

- When insulating a wooden base, it is recommended to secure the slabs with special dowels. Wood expands when exposed to moisture and temperature, so insulation must be installed mechanically.

- When installing the slab on a vertical surface, it is necessary to install the bottom strip using a building level. It is best to use a metal profile or rail as a strip.

- The first row of insulation should be mounted on a profile that will act as a support. After the glue has completely hardened, the support can be removed. However, it is best to remove it after the work is completely completed.

- When installing slabs on vertical or inclined surfaces, start from the bottom, and on horizontal surfaces, start from the far corner.

- The slabs should be laid close to each other with one row offset relative to the other. After applying and completely drying the glue, it is additionally recommended to strengthen the slabs with special dowels.

- It is recommended to install heat-insulating boards around windows and doors in one piece. On corner lines, connecting individual pieces of material to each other is not allowed.

Roof insulation with foam glass

Foam glass is a high-quality, modern and very lightweight material for thermal insulation of various surfaces. Proper adherence to installation technology will increase the efficiency of thermal insulation and extend the service life of the material.

Varieties

The insulating material of the type under consideration is divided into the following types according to the form of release:

- Plates or sheets of standard sizes.

- Blocks of various sizes.

- Molded products – for thermal insulation of pipes, fittings, adapters.

- Granules or crumbs.

Foam glass slabs and blocks are widely used in conjunction with other building materials, and serve as the main thermal insulator for walls, floors, partitions, ceilings, and roofs of various structures. Separate forms are used to insulate communications. Granular material, depending on the location of filling, conditions and purpose, is used for cavities and surfaces - both in pure form and in composition with other components:

- Gravel.

- Rubble.

- Sand.

Kinds

Today there are two types of foam glass - granular and block.

In addition, there are three types of granular insulation:

- foam glass gravel;

- foam glass crushed stone;

- foam glass sand.

There are also three types of block insulation:

- slabs (foam glass sheets);

- blocks;

- shells (shaped foam glass).

If we compare the thermal properties of granulated and block glass, of course, gravel, crushed stone and sand are inferior to slabs, shells and blocks. But, nevertheless, granular insulation is more popular due to its relatively low price.

Video description

Video about what foam glass is:

The main difference between granular material and blocks and sheets is its lower price. Thanks to this, granules are used more often.

Note! On the building materials market you can find a cheap analogue made on the basis of liquid glass. The material has a porous structure, and its composition is more related to adhesives. Naturally, its quality is in many ways inferior to the original. Its only comparative advantage is its 2-3 times lower cost.

Price

The cost of foam glass is steep. Prices, of course, vary, as they depend on many factors, but on average you can buy blocks by paying $120–400 per cubic meter. You can purchase slabs and shells by paying $110–350, and you can get a granular version by spending $35–100 per cubic meter.

What can we say? Insulation with foam glass is a very dubious and costly undertaking, since the material has a lot of serious drawbacks, and, in addition, is incredibly expensive. But, as they say, the master is the master. Maybe it’s not for nothing that they call it the raw material of the future. To buy or not to buy? That is the question! The choice is yours, dear readers.

Warmth and comfort to your home, dear friends! See you on other blog pages!

Wisdom quote: Reading is the best teaching (A.S. Pushkin).

Installation features

Due to the fact that foam glass is a universal insulating material, it is used for structures made of any material. In general, installation is carried out using the following technology:

- The surface is cleaned and leveled if necessary.

- On the side attached to the wall, the slab or block is treated with special glue or cement mortar.

- Next, the material is pressed against the wall.

- Once the adhesive base has hardened, the outer surface of the heat-insulating layer is plastered or puttied.

Important! Despite the high compressive strength, the structure of the material is quite fragile. Therefore, in order to avoid violation of the thermal insulation properties, blocks and slabs only need to be glued, and not screwed onto dowels or screws.

Advantages

The advantages of foam glass include:

- Non-erosiveness . There are no soluble elements in foam glass. Nothing in it can be washed away by water.

- Immune to temperature fluctuations . Expanded foam “takes root” without problems in climate zones with the most extreme temperatures. In terms of its resistance to different temperatures, foam glass insulation can be compared with traditional materials from which load-bearing structures are made (steel, concrete, silicate and ceramic bricks). This is a guarantee that when installed on such a structure with foam glass, everything will be in order.

- No sagging or shrinkage due to good strength.

- You can use foam glass almost forever. Recent studies have shown that foam glass, which was used to insulate a municipal building in Pittsburgh, America, back in 1952, is fully serviceable after 65 years!

- Water leakage through foam glass is absolutely impossible, since it consists of closed cells. Even frozen water (which can damage granite and basalt) does not cause any harm to foam glass.

- The material does not oxidize , since it contains only higher oxides.

- Easy to install . Foam glass can do without complex fastenings, which often allow cold to pass through or become very hot and deformed.

- Foam glass can be reused after dismantling.

- High environmental friendliness makes it possible to use foam glass in the food industry, in bathhouses, swimming pools and cafes.

Briefly about the main thing

Foam glass insulation is a porous material based on silicate glass. It is produced by simultaneous melting and foaming of raw materials. Among its main characteristics are low density, lightness, compressive strength, 2 times lower thermal conductivity than wood, good sound absorption, water repellency, fire safety, inertness to thermal changes and resistance to chemically active substances.

It is used for insulation of floors, walls, roofs, partitions on any basis, as well as communication systems. Available in the form of blocks, slabs, shaped products and granules.

Main advantages:

- Preservation of properties throughout the entire period of operation.

- Environmental friendliness, fire safety, resistance to destruction factors.

- Ease of processing and installation, durability.

- Compatibility with any materials, chemical inertness, heat resistance.

Disadvantages include high price, low impact strength, visual unattractiveness and the inability to provide a healthy indoor climate. When choosing, it is necessary to take into account the thickness of the material layer that is suitable for the conditions and features of the insulated structure. Installation is carried out in accordance with the rules of technology.

Flaws

Of course, every raw material has its negative aspects. Foam glass is no exception. Before purchasing material, you need to carefully study the negative aspects.

- High price. The production of raw materials requires innovative high-tech equipment, which leads to its rise in price. And also the production of foam glass requires high energy costs.

- Fragility. The raw material, despite its strength, is very fragile, which leads to cracking if installation recommendations are ignored.

- Lack of steam conductivity. Foam glass, as was said, is not subject to the destructive effects of biological factors, but the surface under it is easily damaged.

- Fear of alkalis and hydrofluoric acid. Cellular glass, like an aspen leaf, trembles at the “sight” of alkalis and hydrofluoric acid, since they are capable of destroying it.

- Heaviness. The raw materials are relatively heavy, which negatively affects the building structure.

- Durability. Of course, a long service life is a plus. But the materials used to construct the facility are unlikely to last more than 100 years. This means that the structure must be repaired periodically, and cellular glass is not intended to be reused. Which exit? Replacing insulation.

- Low impact strength. Cellular glass does not withstand even light impacts. Mechanical influence is the “death” of the material. Of course, if the insulation is in the structure, it is not afraid of impacts. He is afraid of them during transportation, unloading and installation.

- Impossibility of “reanimation”. If the glass is damaged, it can be taken to a landfill. It is impossible to glue or cover up the cracks.

Properties played a cruel joke on cellular glass, turning a huge number of advantages into disadvantages.

Pellet production

[ads-pc-4]

The manufacturing technology of granular foam glass is somewhat different. After cleaning and sorting the raw materials, they undergo the following processing:

- Melting at high temperatures;

- Pouring into rounded billets;

- Foaming in a rotary kiln;

- Cooling and firing of finished granules.

Granulated foam glass is 15 times larger in volume than the raw material taken. You should also distinguish insulation from liquid glass, which is produced at lower temperatures by quickly removing water and gaseous substances. Liquid glass is not an insulator and is unstable even when exposed to water.

Advantages

Many of the advantages of insulation come from glass, while some are unique due to the combination of gas capsules and glass cells.

- Duration of operation - manufacturers indicate service life of up to one hundred years without deformation, even with temperature changes. Changes in dimensions and shrinkage are not typical for the material; the operating temperature range is from +350 to -250 °C.

- The versatility of the material for insulation purposes, as it is suitable for insulating pipes, roofs, walls, foundations, as well as for insulating buildings with a high fire hazard.

- Resistance to open fire and makes it possible to use the material in fire-hazardous objects, since at high temperatures the material will melt rather than burn.

- The sound insulation properties of the 10 cm thick material are able to cope with the roar of a tractor without letting sound into the building.

- Foam glass is easy to install and resembles the technology of laying foam concrete. It is easy to cut with a hacksaw, it is light in weight - 150 kg per cubic meter.

- The safety of foam glass in sanitary terms is another advantage, since its environment is unsuitable for the proliferation of microorganisms, it does not emit toxic volatile substances and can be used for insulation of children's institutions and hospitals.

These qualities make foam glass a new generation of insulation, with high ergonomics and safety, since environmental friendliness is the motto of construction over the last decade.

Manufacturers

The first samples of the material were made in Russia, but today it is produced in different countries. The most popular following manufacturers:

- SAITAX is one of the largest foam glass manufacturing companies in Russia. The company's products are used for insulation of administrative buildings and government facilities.

- Pittsburgh Corning is an American insulation manufacturer with a half-century history of development. The company's facilities are also located in Russia. The insulation is sold under the FOAMGLASS brand and is used in both civil and industrial construction.

- Gomelsteklo is a Belarusian company of international level that supplies insulating materials to many countries around the world. Certificates and data sheets of materials are publicly available.

- ZSTM – Plant of construction thermal insulation materials, located in Ukraine. The plant produces insulating materials produced using unique technologies developed in research centers. At the moment, block and tile products are produced.

Pay attention to the history of the manufacturer, reviews about it and the availability of certificates - then the high cost will not become an obstacle and will pay off by reducing the cost of heating and air conditioning equipment in the house.