You purchased a lot of equipment for your home, and you have a large amount of foam left over from packaging. What can you make from polystyrene foam with your own hands? Don't rush to take it to the garbage disposal.

Expanded polystyrene or polystyrene foam can be used to make various crafts for the garden and apartment. In this article you will learn many examples for using leftover foam.

What can be made from old coins. How to use old coins.

What to sew from old jeans? DIY crafts from jeans.

What can be done from old tiles. 16 ideas

Main characteristics

- thermal conductivity is low (the extruder has the same thermal conductivity as other types of polystyrene foam, but the extruder is more expensive)

- durability (up to 60 years does not lose properties when the temperature changes from -40 to +40 °C throughout the year)

- moisture resistance

- it does not create an environment favorable for the development of mold and similar “life” (can only occur on the joint surface of, for example, wood)

- minimal harmfulness (it is allowed to be used in the food industry (packaging));

- a light weight

- noise insulation (3 cm thickness reduces noise up to 25 dB)

- fire resistance (we can only talk about it when it comes to fire-resistant varieties; you also need to know that in the production of fire-resistant types, a larger amount of carbon dioxide is used and if the combustion process takes place directly, then the release of this gas will be greater and it will burn, although the temperature it has a high temperature of +490 °C)

- vapor permeability (similar to wood such as oak)

- tensile strength is at least 20 MPa

- resistance to alcohols and ethers, but is easily destroyed when exposed to solvents

- does not withstand ultraviolet radiation (when using slabs, they must be covered with a protective layer of primer and painted)

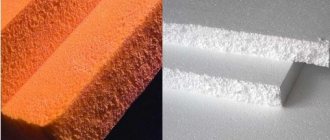

Expanded polystyrene is mistakenly called polystyrene foam in everyday life. Let's look at the main differences between the characteristics:

- absorbs water and vapor

- visually they can be distinguished (it has a uniform structure, and the foam has large granules)

- density higher than foam

- mechanical strength

For children

Guys are a separate category that requires special attention and care. Therefore, if possible, make several foam toys with them.

It could be a bright fish that has come to visit...

A cat purring tenderly in the sun...

A boat happily plowing the waters of the pond...

A little imagination and your child will be happy and cheerful.

Advantages

If all installation rules are followed, liquid foam will last more than 50 years without defects. Other arguments in favor of insulation such as Liquid Penoplast:

- Fire safety;

- adhesion (bonds, connection) with solid materials (concrete, stone);

- natural composition, safe for human health;

- fire resistance;

- reasonable price;

- wide range of permissible temperatures;

- static dimensions, no swelling after hardening;

- low consumption over large areas;

- minimizing the risk of surface damage by microorganisms or insects.

The material does not require preliminary thorough preparation of the surface, which significantly reduces time and money costs. To apply foam with your own hands, you will need a hose (diameter of at least 30 mm). With its help, the substance reaches the most inaccessible places. Insulation using the “old-fashioned” method (using foam rubber) has long since sunk into oblivion due to its ineffectiveness.

Interesting fact: the quality indicators of vapor permeability make it possible to successfully use liquid foam to protect wood coverings, walls, and facades.

Useful crafts for home

DIY foam crafts can be not only decoration, but also quite functional things.

Snow Queen's Castle

To assemble the castle, you need to cut identical cubes from foam plastic, approximately 2x2 Washing machine. Cardboard is used for the base. You need to draw markings on the cardboard: fence, towers and other details. The towers are assembled in a circle, the foam cubes are glued to the cardboard at the same distance. The gap must be at least 1 Washing machine. The second row is made of “bricks”, placing them not on top of each other, but shifting them.

It is necessary that the edges of the cube stick to the two bottom ones, leaving an empty space in the middle.

This is done row by row until the tower reaches 7-10 Washing machines in height. Separately, in the same way, the upper part of the towers is assembled. It should be narrower than the bottom, so the rows are reduced by 1 cube. The upper part is carefully glued to the lower part. For the roof, take blue cardboard and make a cone out of it. Carefully glue it onto the foam building.

By analogy, a fence is assembled. It is not necessary to make it an even square; you can place round “pillars” in the corners. The courtyard inside is decorated with old cut-up DVDs and deer figurines, which are also cut out of foam.

Easy disposal of polystyrene foam at home

Imitation brick on the wall

A brick wall is a fashionable way to visually change the space in a room and add originality to your home decor. For this purpose, various panels are sold, both made of solid materials and foam plastic, and simple wallpaper with a suitable print. It will be cheaper to make foam bricks yourself.

- stationery knife;

- foam sheets with a thickness of no more than 1.5 Washing machine;

- pencil;

- ceiling tile adhesive;

- laser level.

Important note: the walls must be smooth.

Don't throw away the foam

If there are noticeable waves and holes on the surface, you should not glue the brick. It will highlight all the irregularities, they will become even more noticeable. To make it easier to cut out bricks, you can make a template from cardboard, which you then simply trace on foam plastic without making markings each time. Usually the size of decorative bricks is 25x6 Washing machine.

The first stage is cutting the bricks. When the required amount is cut out, you can add texture: cut a chamfer on all sides, make the surface rough. A metal brush can be useful here; it is used to press on the brick and make grooves. You can also imitate pits and chips with a soldering iron.

Before gluing the brick, the walls must be treated as before painting. Old wallpaper is removed, the surface is washed and degreased. Using a laser level, markings are made on the wall so that the rows of bricks are even. You should start work from the lower right corner of the wall.

The seam between bricks should not exceed 1 Washing machine in width. When the wall is completely ready, the bricks need 24 hours to stick to the wall more tightly. After this, they are painted with water-based paint.

Characteristics and properties

Expanded polystyrene is designed to retain heat. This happens due to compressed small balls containing air. They form a solid air cushion, similar to foam, which is why the material has a similar name.

The density of the material ranges from 0.028 to 0.034 watt meter per Kelvin. The indicator depends on weather conditions. Scientists proved in 2014 that mold fungi are not able to live on this insulation.

Each type has its own vapor conductivity. For example, extruded does not allow steam to pass through at all, but foamed - from 0.019 to 0.015 kg per m/h/Pascal. The difference appears due to the fact that the second type is obtained by cutting from a whole block into slabs of the required thickness. Therefore, air penetrates through the broken structure of the balls.

Moisture absorption works on the same principle as vapor barrier. Solid polystyrene foam will absorb a maximum of 0.4 percent of water, thinner ones can absorb ten times more - 4%. Due to its dense structure, extruded is considered strong, approximately 0.4 to 1 kg per square cm.

Due to the presence of antiperspirants in the composition, polystyrene foam will last for many years without losing its advantages. Based on all of the listed properties, solid polystyrene foam is significantly better than foamed polystyrene. He almost ousted his competitor from the market and became the most popular.

Our address

222721, Minsk region Dzerzhinsky district, ag. Dvorishche, industrial building with administrative and administrative buildings, 6

© 2013–2017, Private Enterprise "TM-StroyPlast" 222721, Minsk region, Dzerzhinsky district, ag. Dvorishche, industrial building with administrative and administrative buildings, 6

Sources:

https://m-strana.ru/articles/penopolistirol-chto-eto-za-material/ https://stoksovet.ru/dom/penoplast.html https://handsmake.ru/podelki-iz-penoplasta.html https://varjag.net/chto-mozhno-sdelat-iz-ostatkov-upakovochnogo-penoplasta/ https://www.plast.by/novosti/chto-mozhno-sdelat-iz-penoplasta.html

What is polystyrene foam or expanded polystyrene?

First you need to understand what polystyrene foam is and how it behaves under various influences. And understand whether polystyrene foam is harmful to health?

Expanded polystyrene is a gas-filled material. They are made by steam heating polystyrene granules. These granules are first filled with gas. The gas used is different: in ordinary polystyrene foam, natural gas is used, in fire-resistant foam, carbon dioxide is used. When heated, the gas expands, and the granules increase many times in size (15 - 30 times the original).

If nothing restrains the expansion of granules, then the result is a crumbly material that is used in filling frameless furniture, packaging, and construction. To obtain solid forms of polystyrene foam, foaming is carried out in a closed form of the desired configuration. This is how flat sheets of insulation, embossed decorative products, boxes for packaging household appliances and much more are obtained.

The resulting material has a number of very advantageous qualities:

- high thermal insulation;

- high durability;

- low water absorption;

- low vapor absorption;

- biological stability;

- unattractive to rodents and parasites.

Polyfoam is an inexpensive, very light, practically non-moisture-absorbing material with low thermal conductivity. It is resistant to rot and biocontamination, durable, can take any shape and be elastic, but hard enough to hold its shape.

Thanks to this, expanded polystyrene has become widely used in many areas:

- In ammunition for safety (both military and civilian). In helmets, knee pads, and elbow pads, polystyrene foam is used as a shock-absorbing material and insulation.

- For the production of disposable tableware. Containers for hot food and cups for drinks are widely used.

- As packaging material. Expanded polystyrene protects fragile items well during transportation. It can be used both in bulk and in the form of pressed forms of the desired profile.

- For the manufacture of children's toys and child safety products.

- For frameless furniture (poufs, bean bag chairs).

- When making blanks for handicrafts and creativity.

- For the manufacture of decorative elements of the interior and garden decoration (fake stones, garden figures)

- In some countries (Japan, Finland, Norway, Canada, USA), polystyrene foam is used in road work to protect soil from freezing, reduce the vertical load on soils prone to subsidence, create artificial unevenness, etc. In Russia, polystyrene foam is not used for this purpose .

- For interior and exterior finishing. Various decorative elements of facades, ceiling tiles, imitation stucco molding and much more are made from expanded polystyrene.

- In the production of polystyrene foam, concrete and polystyrene foam blocks for the construction of walls in low-rise construction.

- For the manufacture of various heat-insulating and sound-insulating materials.

We advise you to study - User ratings of ovens for electric and gas models

Polystyrene foam packaging

Making balls

Let's take a closer look at the manufacturing process of this sought-after part. The foam prepared for work should be no thinner than the diameter of the future ball. If only sheets with a smaller thickness are available, you will have to glue them together along the plane. For work, we will make two devices from a polypropylene pipe, the internal diameter of which will determine the size of the ball. Let's cut two pieces of pipe with a length approximately equal to three times its diameter. We cut the first pipe in half lengthwise and leave one half. We cover its inner surface with sandpaper. The second pipe will be used to cut out a starting cylindrical blank from foam. For faster work, the wall of one edge of this pipe can be chamfered. Having pointed the pipe onto the foam , we begin to simultaneously scroll the pipe and press it into the sheet material. The output will be a foam cylinder. We turn it into a ball by treating it with sandpaper, which was glued inside the first device.

Ready-made balls are well suited for making Christmas tree decorations, flowers, snowmen, and other decorative items and toys. Using the proposed devices, you can also make hemispheres and oval blanks. To decorate the balls, whatever is at hand is suitable: paints, colored satin ribbons, decorative cords, beads, colored paper.

The influence of polystyrene foam on human health

Questions about whether polystyrene foam is harmful to health or not have worried consumers almost from the very beginning of its use. Each new finishing and building material based on foam plastic caused a renewal of these disputes.

Proponents of the use of expanded polystyrene cite the research of scientists - chemists, physicists and materials scientists - as a safety argument. Expanded polystyrene, without external influences on it, practically does not interact with the environment.

Its molecular structure is very stable. The experiments described above show that under normal human conditions, polystyrene foam does not emit any harmful substances. Actually, it does not release any substances.

Might be interesting

Opponents of the use of expanded polystyrene claim the possibility of styrene release. Even if not under ordinary, but under extreme conditions. Extreme conditions refer to exposure to high temperatures. Indeed, when burned, polystyrene foam, like many other substances, releases a large amount of toxic substances, among which styrene is considered especially toxic.

Effect of styrene on humans:

- dizziness;

- irritation of the mucous membranes of the eyes;

- high concentrations lead to lung damage and even fatal poisoning;

- the functioning of the kidneys, liver, and hematopoietic system is disrupted;

- oncology.

The flammability of the initially created polystyrene foam was quite high. At temperatures above 210 °C, the foam was able to independently support surface combustion and spread fire. That is why fire retardants (substances that inhibit ignition and flame spread) are now used for the production of construction and finishing polystyrene foam.

Thanks to this, it was possible to reduce flammability and increase the ignition temperature to 440 °C. In addition, most modern polystyrene foam products do not allow flames to spread and do not support spontaneous combustion.

It must be said that, like many other substances that are dangerous in large doses, but harmless in small doses, styrene is naturally found in many products that we use every day - coffee, tea, cinnamon, cheese, strawberries and so on.

Melting polystyrene foam

The harm of expanded polystyrene to human health may also be associated not so much with the qualities of the material, but with its improper use in finishing. Expanded polystyrene is a very popular thermal insulator, but at the same time it does not allow steam and moisture to pass through. It happens that people, out of ignorance or out of economy, insulate the walls between the apartment and the street from the inside with sheets of expanded polystyrene.

This situation is serious because the moisture in the warm home air collides with the cold wall directly under the foam and condenses there. The wall on the concrete surface is constantly wet, which will inevitably lead to the development of fungus and black mold, the spores of which are a dangerous allergen. Black mold can trigger the development of asthma, chronic bronchitis and other diseases.

Volumetric (relief) plaster

Such design works create imitation of any textures or clearly traced images on the walls of rooms. Foam plastic is excellent for making voluminous parts or elements with a large area. A part of any complexity is cut out of sheet material along the contour. After processing and adjustment in place, it is mounted on the wall surface using an adhesive solution. All the work is done much faster, because there is no need to make bulk elements from the solution in several stages and wait until the previous layer sets and dries. In addition, foam parts are very light and after reinforcement, another layer of mortar or plaster can be applied to them.

What to choose for the balcony: polystyrene foam or other materials?

- Styrofoam. The most popular material for insulating loggias and balconies. It differs from others in its availability, good technical characteristics and low cost. Also, it is easy to install.

- Penofol. It is often used as a vapor and waterproofing material and a base for thermal insulation. It is a layer of foamed polyethylene, which is covered with foil on one or both sides. It is lightweight and thin, and is available in rolls.

- Extruded polystyrene foam (Penoplex). It is an orange-colored slab that has a low thermal conductivity coefficient and a long service life (up to 40 years). Tolerates high humidity well. It has higher strength and cost compared to other materials.

- Mineral wool. It is as widespread as polystyrene foam. It has good technical characteristics, is resistant to fire and is of natural origin. However, when insulating a balcony and other building elements, it requires high-quality vapor and waterproofing.

If you need high-quality insulation of a loggia or balcony, and there are no plans to spend large sums of money, then using polystyrene foam is the best option.

Cooler bag

Let’s exploit the material’s ability to perfectly prevent heat transfer. This is a very important property for a mobile refrigerator. We determine the dimensions of the sealed box and cut out the side walls, bottom and lid of the future product from sheet foam or its sections. A sharp knife (preferably a construction knife) with a thin blade and a hacksaw with a fine blade tooth are suitable for cutting.

The cut parts are adjusted and glued together - the main thermal box is ready. The characteristics can be improved by covering the inner surface with insulation with a reflective foil surface, for example, penofol. For the finished product, we sew a protective case-bag with handles, and you can get ready for a picnic.

Your mini-fridge will maintain a stable temperature for several hours, especially in tandem with dry ice poured inside. The device is effective and, if necessary, does not allow hot products placed in it to cool down. A similar product, although larger, assembled inside a large box on the balcony, is perfect for storing vegetables until the first light frost.

Types of foam

Divided into the following types:

- polystyrene;

- polyethylene;

- polyvinyl chloride;

- polyurethane.

Polystyrene

There are two ways to produce this type of foam:

Pressless. This variety is familiar to every person

When buying home appliances, you can pay attention to the fact that they are packaged in foam plastic, consisting of small balls fastened together. It is very fragile and can be crushed and broken by hand.

Press

But this type will be much more difficult to crumble. The granules of such foam are more tightly bonded to each other. The production technology is much more complex and more expensive than that of the non-press type, so it is much less common.

There is such a variety as extruded foam; it is practically no different from non-pressed foam.

Polystyrene types of foam have one significant disadvantage - high hygroscopicity.

Water vapor enters the cavities that are located between the “balls” and granules.

We advise you to study - Advantages and disadvantages of houses made of timber

This material “does not breathe”, so the steam does not escape anywhere and when exposed to sub-zero temperatures it can freeze, destroying the structure.

Even in the absence of exposure to cold, the accumulated steam worsens the thermal insulation properties of the foam and increases the humidity in the room.

Extruded foam plastic does not have such disadvantages, since it is homogeneous in its structure. It is common in the production of disposable cutlery, tableware, and food packaging.

As for the durability of polystyrene foam, we can say that for non-pressed foam it will range from 10 to 35 years. Extrusion will last much longer, about 50-70 years. Of course, the service life directly depends on the manufacturer of the material and the impact of destructive factors at the installation site.

Polyurethane

One example of polyurethane foam is foam rubber. It has a porous structure, good air and steam permeability, and high elasticity. It is used in furniture production, both as upholstery and as a filler.

Based on it, many household items are made. It is highly flammable and releases hazardous substances that are more toxic than polystyrene foams. The reason for this is hydrocyanic acid in the composition. It is extremely short-lived, turns yellow and is destroyed when exposed to external factors such as ultraviolet radiation.

Polyvinyl chloride

Polyvinyl chloride itself is a thermoplastic polymer that contains up to 56.8% bound chlorine, which makes it difficult to burn. It can be produced using both press and non-press methods. Its properties are similar to extruded polyethylene foam.

It contains no toxic substances. When burning, polyvinyl chloride foam extinguishes on its own.

It is highly elastic, but can corrode metal structures next to which it is located.

Polyethylene

It occurs quite often in everyday life. It looks like a translucent film consisting of air pimples.

It is used for wrapping fragile items and easily damaged equipment and does an excellent job of protecting against damage.

Polyethylene foam is very elastic and has different thicknesses, from a few millimeters to several centimeters. It is similar in strength to extruded polystyrene foam, but its distinctive feature is its non-toxicity. It is considered an environmentally friendly material with a long service life. Flammable.

Advantages and disadvantages

Now it’s worth considering what the advantages of one and the other materials are. After all, each of them was invented for a reason and is in demand among consumers.

Styrofoam

The main positive qualities of polystyrene foam include:

- Using it as wall insulation both inside and outside the building.

- Its relatively low price is why it is in demand among consumers.

- The material is quite moisture resistant.

- Has little weight.

- Easy to use and install. In addition, it is easy to cut using a knife or other cutting object.

- Good insulation for foundations.

- Polystyrene foam can be cut at various angles, and any shapes can be cut out of it.

- The material can be painted and plastered.

Polystyrene foam is a good insulation material for foundations.

The disadvantages of the material include:

- The thickness of the material used should not exceed 3 cm.

- To better attach the material to the wall, it must be perforated, for example, with a needle roller.

- It is necessary to take care of the fireproof coating for the material.

- When installing foam sheets, it must be completely coated with glue.

- When leveling the sheet, it is necessary to use a moisture-proof putty.

It can be seen that the material has both positive and negative sides. Therefore, before purchasing, you need to weigh the pros and cons so as not to get into trouble.

Expanded polystyrene

Its main advantages are:

- It does not transmit heat well, meaning it remains indoors.

- It does not allow moisture to pass through well, which means that even if the material is exposed to rain for several hours, it will remain dry.

- Despite its artificial origin, it allows the house or any other structure to breathe.

- Not subject to rotting.

- Not affected by fungus.

- Durable. Can last about 50 years.

- The material is good to use as a sound insulator. Because it has a homogeneous structure that muffles and absorbs sounds.

The disadvantages of this material include:

- Price. This material is not the cheapest. This is why many consumers buy polystyrene foam.

- This material is destroyed under the influence of certain solvents.

- Expanded polystyrene is susceptible to destruction by rodents. It is quite easy for them to build passages and houses in the material.

- Just like polystyrene foam, polystyrene foam is a flammable material. Therefore, it is necessary to take care of safety. Cover it with a special solution.

It can be seen that the positive aspects of expanded polystyrene are quite attractive, in some cases even better than those of polystyrene foam. However, the main and sometimes decisive disadvantage is the high price of the material.

Designer interior items

Smooth, durable and lightweight foam sheets are good stretchers for various volumetric compositions, decorative panels, and modular paintings. They draw on their surface, place large photographs, and create compositions of different textures from fabrics and other materials. From sheet foam you can make a designer dial for a wall clock, which will be a harmonious continuation of the surrounding environment. The clock mechanism can be easily transferred to a fashionable dial from an old or specially purchased inexpensive watch.

Polystyrene foam is an excellent material for making signs, three-dimensional letters, and logos. Three-dimensional letters made from foam plastic are cheaper than those made from other materials.

How do foam products affect the environment?

Of course, such a proliferation of material and its daily participation in human life makes one wonder: is polystyrene foam harmful or safe?

Manufacturers declare that one of the most important performance qualities that polystyrene foam possesses is environmental friendliness. But their interest is quite understandable. That is why, when determining whether polystyrene foam actually harms the environment, it is better to turn to scientific research.

Expanded polystyrene under a microscope

The environmental friendliness of any material is determined by its own impact on the environment, the impact under certain conditions and when interacting with other substances.

Moreover, it is necessary to consider both the immediate impact and the long-term one. Here are the main influencing factors:

- Expanded polystyrene practically does not absorb water and does not interact with it at all. Therefore, its use, for example, in finishing and insulating facades, is not only effective, but also safe. It follows from this that ceiling tiles made of foam plastic, if not heated, pose no harm.

- Expanded polystyrene does not oxidize when exposed to air and does not decompose when exposed to ultraviolet radiation. These qualities allow polystyrene foam to be disposed of in a household waste dump, rather than at a specialized chemical site.

- Expanded polystyrene is not dissolved by any substances that it might come into contact with in a household waste dump. Solvents for it are acetone, original styrene, aromatic and chlorinated hydrocarbons. These substances are not (or at least should not be) found in household waste dumps.

- Expanded polystyrene is a very durable material. Cyclic stability tests with annual temperature changes in the range from -40 ° C to +40 ° C with exposure of the material to ultraviolet radiation and water showed that even after 80 cycles (which corresponds to 80 years), the structure of polystyrene foam remained unchanged.

- Temperature extremes are not typical for polystyrene foam use conditions, but have also been studied. When heated without an open flame source, even polystyrene foam not treated with fire-fighting substances begins to collapse only at 300 °C, and with an open flame - at 210 °C. The impact of low temperatures can not be taken into account at all, since destruction occurs only superficially, and even then at -310 °C.

We advise you to study - Children's bunk bed made of wood - design and assembly instructions

Unfortunately, the bulk of used polystyrene foam is disposed of in household waste landfills. When buried, polystyrene foam is practically harmless to the environment, since it does not interact with water and air, but it does not decompose.

The situation is complicated by the fact that the collection and processing of polystyrene foam is not economically profitable today. During processing, expanded polystyrene can be used to produce polystyrene, however, the cost of this process is comparable to the production of polystyrene from primary raw materials, but requires a more complex organization of the process.

Another way to process expanded polystyrene is to grind it for use in the production of concrete - expanded polystyrene blocks, filler for heat-insulating mixtures and similar materials. This is a promising area of recycling that offers hope for reducing landfills.

Pile of old foam plastic

It is too early to say what harm polystyrene actually causes or will cause to the environment. The material is very durable. Even the first mass-produced foam plastics, buried in landfills long ago, have not yet approached the threshold of decomposition.

The use of foam plastic for thermal insulation

Wall insulation

Polystyrene foam is widely used as insulation for external walls, and even owners of city apartments have begun to do this in the face of significant increases in energy prices.

The polystyrene foam is screwed to the facade of the building with dowels, then plastered, after laying a metal mesh on top of it.

Another common option is:

- Polystyrene foam is laid in the spaces between the sheathing bars, the cross-section of which corresponds to the thickness of the slabs

- Siding panels are attached to the sheathing with seams sealed with foam

Polystyrene foam is also widely used as insulation for walls inside an apartment.

Insulation of basements and plinths

When insulating basements, foundations and plinths with foam plastic, the low strength of this heat insulator should be taken into account. In winter, it will experience significant loads from freezing soil, which, if unprotected, will lead to its deformation or destruction. For this reason, a brick or concrete lining is constructed outside the thermal insulation layer of foam plastic.

Floor insulation

The environmental friendliness of polystyrene foam has led to its widespread use inside buildings. For example, it is often used as a thermal insulator in floor construction. The polystyrene foam is laid on top of the waterproofing layer, filling the seams with polyurethane foam or silicone sealant. Then a screed and a finished floor covering are laid on top of the slabs.

Methods of roof insulation

Thermal insulation of roofs using foam plastic is carried out using one of two technologies:

- Installation of a non-ventilated (warm) roof. With this method, the roof is covered with 70 mm thick foam plastic slabs, which are then filled with bitumen

- Installation of a ventilated (cold) roof. In this case, the foam is attached to the inside of the roofing so that there is a ventilated gap through which water vapor will be removed

Is foam plastic harmful as insulation?

A significant disadvantage of polystyrene foam is the high danger it poses in the event of a fire. Manufacturers and marketers position this material as non-flammable and point to its ability to self-extinguish, which is especially evident in the presence of a fire retardant additive. However, a material does not have to ignite to be dangerous in a fire.

As experience and numerous tests have shown, exposure to flame and high temperatures provokes thermal decomposition processes in foam plastic, as a result of which the air, even at a considerable distance from the fire site, is filled with a large amount of smoke, corresponding in toxicity to substances of the highest hazard class.

There are a large number of insulation materials for the home. If foam is not your thing, then you may want to consider other options. For example, Rockwool insulation, the technical characteristics of which make it possible to perfectly protect the house from heat loss. The structure of the material allows the walls to “breathe”, therefore, there will be no problems with rotting and fungus formation.

Rockwool insulation is essentially mineral wool. If you only need to insulate the ceiling, we recommend that you familiarize yourself with the process of insulating the ceiling with mineral wool here. You can install this material yourself.

Price

Here is the approximate price for polystyrene foam as insulation of various brands:

- PSB-S-15O (density - about 9 kg/cubic m): 1050 rub.

- PSB-S-25 (about 15 kg/cubic m): 1800 rub.

- PSB-S-25T (about 20 kg/cubic m): 2350 rub.

- PSB-S-35 Light (density - from 21 to 23 kg/cubic m): 2550 rub.

- PSB-S-35T (density - from 26 to 28 kg/cubic m): 3050 rub.

Users unanimously recognize the affordable price as the most important advantage of polystyrene foam. Forum participants rate the thermal insulation qualities of polystyrene foam quite highly.

But owners of private houses advise using this insulation only where there are no problems with mice. One of the users said that in the polystyrene foam he used to insulate the garage, these rodents made a whole system of passages, and their activity is accompanied by clearly audible sounds.

Wooden floor

- We prepare the surface and repair defects in the base.

- We lay waterproofing material. This may be plastic film or other waterproofing. The film should extend onto the walls. The joints between the film strips are overlapped. Everything is taped together.

- We lay the logs.

- We place foam boards between the joists with our own hands.

- We lay a vapor barrier membrane on top.

- We cover everything with reinforcing mesh.

- We make a concrete screed.