Interruptions in hot water and preventive shutdowns have led many to install water heaters in their apartments. It turned out that heating water is cheaper than using the services of public utilities. Despite this, there are also disadvantages - equipment is prone to breakdowns, which often occur due to poor quality water. Will a boiler filter help? Do I need to install it? You will find the answer in our article.

Do I need a filter for a water heater?

The quality of tap water directly affects the life of the heater, especially if it is constantly in use. The water must be “soft” and meet the following requirements:

- Transparency.

- No unpleasant odors.

- Minimum content of metal salts, hydrogen sulfide.

- No bacteria.

Achieving such indicators is not easy. Water often contains heavy magnesium and calcium salts: settling on the boiler elements, they reduce thermal conductivity. As a result:

- A large amount of electricity is wasted.

- The water takes a long time to heat up.

- The contents become cloudy.

- The heating element burns out.

When hard water is heated, scale is produced - at first a small deposit. If it is not removed at this stage, then the heating element is covered with limestone.

If you are not in the mood to buy a filter or you do not have the opportunity, you must carry out the following procedures:

- Regular inspection of the internal elements of the tank.

- Cleaning the walls and heating elements.

- Replacing the magnesium anode.

Then you will do this more and more often: you will not only waste your time and effort, but also spend money on cleaning products. Just imagine, at least once every six months you will need:

- Drain the water from the tank.

- Dismantle the heating element by disassembling the fastenings.

- Remove the housing cover and clean the walls from plaque, clean the heater.

In this case, there is a risk of damage to one of the parts. Isn't it easier to improve water quality than to endure such consequences?

Softening methods

Softening liquid from an autonomous source or water supply is carried out in several ways:

Thermal methods (freezing and boiling)

The appearance of scale on the heating element of the kettle and its walls after boiling hard water.

To remove the hardness of water from wells, a thermal method is used. After boiling, the bicarbonates decompose. Sediment remains on the walls of the dish, but the liquid becomes softer. This is a simple method for home use. At the same time, it allows you to get rid of dangerous bacteria and microorganisms.

Freezing also helps reduce salt concentrations. Ice formation occurs gradually, the liquid that remains around it will have many impurities. It needs to be drained. After thawing you will get soft moisture. Both methods allow you to purify a limited amount of fluid consumed.

Chemical reagents

Technical water softening filter with polyphosphate

To soften water, chemical additives are used in the form of tablets, powders, and concentrates. They are placed in washing machines and dishwashers. When dissolved, the reagents soften the liquid. They are not added to drinking water. For these purposes, available means are used: soda, vinegar, citric acid. Baking soda is added during cooking at the rate of 1 tsp. for 3 liters of water. The acidified liquid is recommended for washing hair and removing scale. All chemicals are used in strict dosages.

Types of filters and operating principle

There are three groups based on the type of cleaning:

- Deep. They are mounted up to the water meter and trap small debris: dirt, sand, pieces of rust. The part needs to be cleaned periodically.

- Thin . Purify water from harmful impurities. Can be woven or mineral. When the substance darkens, the user understands that it is time to replace the cartridge.

- Biological . These devices are multi-stage. Perform several functions simultaneously: cleanses from dirt, salts, chlorine, viruses and bacteria.

How to determine the need for cleaning

Gas boiler cleaning

Boiler manufacturers recommend servicing equipment once every 1 to 2 years. But the need for cleaning may arise more often, since it all depends on the operating conditions and the specific model. Most often, the heat exchanger needs unscheduled maintenance.

But you shouldn’t disassemble the boiler on schedule just because it’s time for cleaning. In order not to take unnecessary actions, it is important to know the signs of clogging of internal parts and systems:

- slow heating;

- loss of power;

- increased gas consumption;

- pops when igniting;

- constantly working burner;

- extraneous noise during water movement;

- uncharacteristic odors from the boiler;

- difficult ignition;

- reduction of pressure in the water circuit;

- incorrect sensor readings;

- no reverse thrust.

Which filter is better to choose?

To make your task easier, we have compiled a selection of filters that users have responded well to. Now you can choose which product to install to protect against scale.

Svod-AS

The reagent contained in the flask is called “food grade”. It does not allow scale to crystallize, so it does not settle on surfaces. In addition, the action of the reagent allows you to remove already deposited plaque.

Suitable for hardness level: up to 34.

- Operates at 105 degrees.

- After purification, the water becomes potable and complies with GOST. Can be safely used for household purposes.

- Easy to install.

- Replacing the filler is easy.

For example, the Svod-AS 10/250 model is designed for 42,000 liters. Connects to ½" thread. Usually installed on a tee.

The Vault 5/100 model has a resource of 15,000 liters, and the pipe diameter is ¾ inch.

Geyser 1 PF

Installed in front of the water heater.

Works on the basis of polyphosphate salt. Dissolving in water, polyphosphate binds impurity ions so that they do not precipitate. The transparent flask allows you to monitor the amount of salt inside.

Why doesn't hot water flow through the column?

1. Clogged filter at the entrance to the water chamber of the block tap. 2. The mixer aerator mesh is clogged with large particles. 3. Scale in the heat exchanger of the gas water heater.

Removing scale and cleaning components is carried out as part of on-site service by professional technicians. If you need help in solving various problems, we are at your service. Leave a request for repair of a geyser via the electronic form and find out the cost of services.

Diagnostics

We diagnose gas flow columns remotely, so the cost of this service for you is

0 Rubles

Call

We will charge 500 rubles for the call if the repair is refused, but this service costs

0 Rubles

Service

The cost of the technical work performed without the cost of the required spare parts varies.

From 900 rubles

Guarantee

Before leaving, our employees will issue a guarantee from our company for the work done for a period of time.

Up to 6 months

Descaling procedure

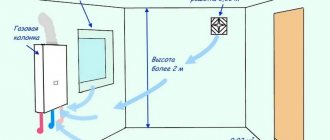

To flush the heat exchanger of a conventional gas water heater, you must first find the valves that shut off the flow of gas and water to the device, and then turn them.

At the same stage, it is recommended to obtain the operating instructions and refresh your memory about the device’s design, as well as the manufacturer’s recommendations. This will avoid mistakes during dismantling.

To disassemble the column, you will need the usual tools that any experienced craftsman has at his disposal:

- adjustable and pipe wrench;

- straight and Phillips screwdrivers;

- paronite gaskets;

- a hose at least half a meter long;

- a metal clamp to secure this hose.

The hose is connected to the outlet of the heat exchanger and lowered into the sink so that waste water with contaminants can be drained into the sewer. If this is not possible, you will also have to stock up on a large enough container to drain the water. The protective casing is removed from the column. Be careful not to break the control panel.

To clean the heat exchanger from scale, it is usually dismantled and then put back in place, sealing the threaded connections.

Now you need to remove the water filter, which is usually secured with a nut. The filter should then be washed and replaced. If the deposits prove to be too complex, it is recommended to use chemical cleaners to remove contaminants from the mesh. During the washing process, damage to the filter may be detected. In this case, it is better to replace it.

Now you need to disconnect the heat exchanger from the water pipes; usually in these places a regular threaded connection is used, which should simply be unscrewed. The heat exchanger is removed from its hinges and turned over. Some craftsmen advise placing it in a large enough container during cleaning so that aggressive chemicals do not leak onto the floor.

To properly rinse the heat exchanger, you can place it in a spacious container with a cleaning agent. Processing time depends on the instructions on the package

Suitable products can be used as a cleaner, for example, Antiscale. A regular 9% vinegar solution and other household compositions will also work. You can make a solution of citric acid: 100 g per liter of water.

Some have had positive experiences descaling with drinks like Pepsi-Cola or Sprite, which contain phosphoric acid. But you should not use vinegar essence for these purposes, it can corrode the walls of the pipes, and serious repairs will have to be carried out.

The heat exchanger is turned over and the cleaner is poured into it using a rubber bulb or a large syringe. Usually you need at least 500 ml of the substance, but no more than a liter. After this, vinegar or citric acid is left inside for about a quarter of an hour. When using industrial cleaners, it is recommended to follow the instructions.

Remove the protective casing from the gas water heater carefully so as not to damage the electronic control panel and other elements of the device.

At the end of cleaning, the solution is drained and the pipes are washed to remove accumulated dirt. To do this, the inlet of the heat exchanger is again connected to the water supply, and a container is placed at the outlet to collect dirty water.

Flushing is carried out until a clean stream appears. If there is serious contamination, a one-time cleaning procedure may not be enough; it will have to be repeated again, using a fresh portion of the cleaner.

Upon completion of work, it is necessary to reassemble the column in the reverse order. The heat exchanger is connected to the water supply. In this case, the threaded connections should be sealed and treated with graphite lubricant. All gaskets present at the installation sites must be immediately replaced with new ones.

Now you need to replace the washed coarse filter, put the casing on the device and again supply gas and water to the column by unscrewing the corresponding valves. All that remains is to perform a test run of water to make sure that the column is working properly.

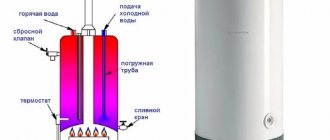

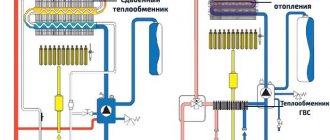

The simplest connection diagrams

The simplest connection diagram for a gas boiler involves direct connection of the boiler to the heating system. That is, the supply and return lines of the heating network are immediately connected to the boiler pipes. Of course, the above-described nuances are observed.

According to the requirements, such a scheme is suitable for simple heating systems. As a rule, they are found in apartments and small houses. In addition, it is only possible when using a boiler equipped with an expansion tank, a safety group and a circulation pump.

If the heating system in the house is complex, that is, it includes high- and low-temperature elements (the first are radiators, the second are represented by heated floors and heated towel rails), then to “consistency” the movement of the coolant in the house, the circuit must be supplemented with a hydraulic separator. It will smooth out the influence of some contours on others.

One of the requirements for creating such a scheme in a house is to install a separate circulation pump for each circuit of the heating system. That is, they include their own pump in the heated floor, and their own in the distribution of pipes and radiators.

Aquarus 5B

Designed to prevent scale in boilers with a tank volume of no more than 50 liters. Very easy to connect, the liquid is purified with an innovative substance, with high efficiency and absolute safety for the user.

Filter Aquarus 5B

Its advantage is to prevent noise during operation of the heating device. Reduces the amount of chlorine and harmful metals, and can extend the life of the device.