Specifics of the technique

Water heating equipment operates using the energy of methane combustion. Performance often depends on the type of device. The devices are divided into 2 types based on their operating principle and design.

Cumulative

In a boiler, water accumulates in a reservoir (tank). Gas burners heat the bottom, creating heat transfer. Air is needed for the normal process. The spent oxygen leaves through a special pipe located inside the container.

Storage devices heat the entire volume of water in the tank to the temperature specified in the settings. If the temperature drops, the equipment is de-energized. The user sets the parameters once, and the equipment independently modulates the flame and controls the flow.

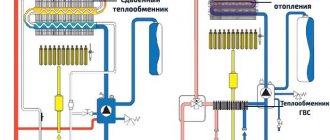

Sectional view of a gas storage device Source progasmarket.ru

What determines the efficiency of a boiler?

The main indicator of the efficiency of a boiler is its efficiency - efficiency factor. The average efficiency of various models is in the range of 90-94%. Much greater efficiency, more than 100%, is achieved by condensation heat generators, which use condensate that is formed during gas combustion to heat the coolant.

The type of combustion chamber - open or closed - also affects efficiency. In a closed combustion chamber, the gas burns completely, and a minimal amount of carbon monoxide enters the air. The correct choice of power is also an important factor in the efficiency of the boiler. If you install a boiler that is too powerful, it will turn on and off at very short intervals, and as a result, it will consume more gas.

If the power is insufficient, the heat generator will wear out, which will significantly reduce its service life. Economical operation of the boiler will be ensured by automation, which will respond to changes in room temperature. And, most importantly, insulating the house, because no matter how economical your boiler is, heating the street will bring everything to naught.

Video about a homemade gas boiler:

How to remake a column

It is technically possible to implement the idea, but the design needs to be redesigned. The flow heater has sensors that regulate the pressure and superheat of the water. In order for the liquid to constantly flow into the pipes, you need to connect a circulating pump. A hydraulic arrow is added to the structure, and pure oxygen is provided into the room.

Why is the method dangerous?

The disadvantages of heating with a gas water heater are related to the specifics of the technology. The flow apparatus is intended for domestic heating of water, but not for operation in a heating system. The equipment will not function as a boiler. With a constant supply of hot liquid, the plastic parts at the entrance to the device very quickly fail.

Why the method is dangerous Source yanashla.com

Water heating for a dacha from a gas water heater.

I came across a faulty gas water heater, which they wanted to simply throw in the trash.

After some manipulation it was restored and I decided to use it somewhere.

I came across a faulty gas water heater, which they wanted to simply throw in the trash.

After some manipulation it was restored and I decided to use it somewhere.

I already have hot water in the garden and decided to make a heating boiler out of it for the spring and autumn. But the main problem of the gas water heater is its high productivity and high gas consumption, which did not suit me. Therefore, I decided to remake it.

Initially, it was planned to install a 12-volt car Gazelle pump, 2 cooling radiators from a VAZ with original fans, but after going to the store this idea faded into the background.

All my friends know that I come up with all sorts of unusual crafts, so before throwing something away, they offer to take it away. So I got 2 air evaporators from a refrigeration unit with 220 volt fans, so it was decided to do the heating at 220 volts. The pump came in handy from the Indesit washing machine.

To reduce gas consumption, I decided to install 2 Chinese-made gas burners and dismantle the original one. The jets in the burners are drilled out with a 1 mm drill.

Regulators and shut-off valves are 2 valves from the freon filling cylinder. Here you can install an additional 220-volt fan in the case to improve traction. Just in case of an “emergency,” all fans and the pump were turned on through a 500-watt uninterruptible power supply from the computer.

The result is a burner block like this.

A freon cylinder was used as an expansion tank. Installed above heating radiators and gas water heaters. The geyser and heating radiators are on the same level. If desired, you can embed an electric heating element into it.

Washing machine pump. Water is pumped into the radiator of the gas water heater. The result is the movement of water: expander-pump-gas water heater-heating radiator-expander. That is, a sequential circuit.

In total, I needed to heat 28 sq.m., an area; in terms of productivity, the heating turned out to be 5 kilowatts, that is, for 50 sq.m. Therefore, after my radiators warmed up, I turned off one of the 2 burners with a valve, and depending on the temperature in the house, if it got hot, I turned off the fans.

The valves open from the bottom, I didn’t put the handles on the body, I’m happy with it anyway, I light the gas with a household gas lighter for gas stoves.

I haven’t tested this system in winter, since in the summer I have to remove everything and take it to the garage. Therefore, there is no photo of the complete heating assembly. Theoretically, if you additionally install 2 more burners and fill in “anti-freeze” or antifreeze instead of water, the heating will not fail. And in terms of gas consumption, in comparison with a gas boiler or gas water heater, the savings are decent!

Making and installing a chimney with your own hands

The rules for installing outlet channels are the same for speakers of any type and year of manufacture.

Before starting work, it is recommended to consult with specialists. It should be remembered that the connection of the speaker can only be carried out by employees of a certified service.

What materials are best to make it from?

You cannot save money on installing a chimney for a water heater. Firstly, cheap products quickly become unusable. Secondly, they do not differ in the performance required for effective removal of combustion products.

It is advisable to focus on materials that meet the following criteria:

- strength;

- corrosion resistance;

- waterproof;

- fire resistance;

- durability;

- flexibility and elasticity.

Most of all, a double stainless steel pipe with basalt wool insulation meets these requirements.

Drawing and diagrams

Schemes are drawn up on a personal computer or worked out on paper. Preliminary measurements of walls, ceilings and roofs are made.

The drawing is made to scale in order to be able to accurately determine the design’s compliance with SNiP requirements. In addition, according to the scheme, the calculation of the necessary materials for the manufacture of a channel for removing smoke from a water heating column is carried out.

Size calculation

When making calculations, it is necessary to take into account that for water heaters with a vertical pipe it is necessary to provide at least 250 cm of vertical channel.

In addition, the following nuances must be taken into account:

- the diameter of the chimney is not less than the cross-section of the pipe;

- the number of corners is no more than three;

- the total length of horizontal sections is no more than 300 cm;

- a slight slope to the sides of the column is required;

- the permissible slope when walking around building elements is 30 °.

It is not allowed to lead the chimney into a shaft intended for ventilation. This is fraught with an emergency or poisoning of the residents of the house.

Installation features

When laying a channel in concrete slabs, care must be taken not to weaken their load-bearing capacity. To make through holes, you need to use a diamond bit with a diameter slightly larger than that of the chimney. The remaining cracks are filled with fireproof clay and plastered.

In a wooden house, an opening is made in the ceiling, the edges of which are located from the outer walls of the pipe at a distance of 38-40 cm. After this, the hole is closed with asbestos slabs, and the void is filled with insulation.

If a coaxial pipe is installed, it should be made as short as possible. Otherwise, the turbine will not be able to pump air efficiently.

It is advisable to route the chimney through the wall along the shortest route.

How to hide pipes?

Don’t forget that there are communications running towards the column that will also need to be hidden. Be sure to check out our article “5 Ways to Hide a Gas Pipe.”

Briefly:

- paint the pipes, it’s effective and inexpensive;

- disguise the pipe as a roof rail;

- use hanging furniture to hide communications;

- make a box and run pipes there;

- as a last resort, move the pipes with the help of a gas service.

Building regulations

Installation of chimneys is carried out in accordance with the requirements set out in SNiP 2.04.05–91. They determine the height, cross-section, channel capacity and installation rules.

Fire safety requirements for chimneys

Channels are allowed to be installed inside buildings made of brick and concrete. When laying in wooden houses, a heat-insulating gasket with a width of at least 40 cm is required.

The basic rules for installing a branch pipeline are set out in the table:

| № | Installation location | Distance to object (cm) |

| 1 | Below from the inlet | 250 |

| 2 | Near the inlet | 30 |

| 3 | Above the ground surface | 220 |

| 4 | Above the window opening | 25 |

| 5 | Under the window opening | 25 |

| 6 | Along a wooden wall | 30 |

| 7 | Along a concrete wall | 10 |

| 8 | Above a flat roof | 150 |

Every 200 cm, the pipeline must be attached to the load-bearing wall with metal clamps. The minimum length of the channel to create good draft is at least 500 cm. If this is not possible, a fan must be installed.

Traction force

The quality of combustion of blue fuel and the rate of carbon monoxide removal depend on this indicator. According to current standards, it should be at least 1.5 cubic meters per hour with a flow speed of 18-20 meters per second.

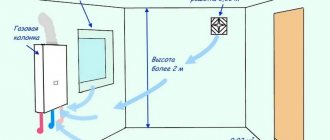

The flow of air for intake into the open combustion chamber is provided from supply ventilation openings or from adjacent rooms.

If the doors to the room are kept closed, then a ventilation opening with an area of 0.2 square meters or more is installed under them or in them.

Maintenance and cleaning

According to SNiP requirements, exhaust ducts must be inspected and serviced twice a year.

The following points are checked:

- clogging;

- soot thickness;

- integrity of the walls;

- state of traction.

If deviations from the norm are detected, the chimney is partially disassembled, cleaned, repaired or damaged areas are replaced.

Frequent errors and problems during installation

Inexperienced craftsmen make the following mistakes when installing chimneys:

- installation near fire-hazardous objects;

- arrangement of channels with nets to protect against debris and insects (draft is reduced);

- ignoring the insertion of glasses for condensate;

- lack of air flow from outside;

- incorrect calculations of the cross-section and height of the pipe;

- lack of thermal insulation in areas passing through cold zones.

Before putting the chimney into operation, it is necessary to check it for stability and tightness.