When installing a water heated floor, a different number of structural elements are used, which are mandatory, or without which the system does not work correctly and not optimally. These also include a mixing group for heated floors. Why is this element needed and is it possible to build a mixing unit for a heated floor with your own hands? Let's look at these questions in more detail.

general information

It is no secret that the problem of uneven heat distribution in a room often causes a lot of trouble for owners. To get rid of this unpleasant phenomenon and create a comfortable temperature regime, you need to introduce a special device into the heating system - a thermal power regulator or a three-way valve.

The mechanism ensures recirculation of the coolant fluid by mixing a certain amount of cooled treatment with the main current. Currently, tees are installed in hot water supply systems, heating circuits and plumbing systems.

In most cases, three-way valves are installed in heating systems with many components and circuits, which is necessary to stabilize the temperature in all radiators. The use of the device allows you to control the flow of coolant, distributing it to different parts of the room (for example, in the kitchen, garage and living rooms). Among the main advantages of the invention are:

- compact and ergonomic dimensions;

- multifunctionality;

- ease of installation, operation and maintenance;

- high tightness;

- long service life;

- ease of switching between operating modes.

In addition to the advantages, tees also have disadvantages. These include the likelihood of valve jamming if operating rules are not followed and rapid wear of inexpensive products.

This video will tell you how to install a three-way valve correctly:

How to choose a valve for a heated floor?

The popularity of water floors, which are increasingly used for heating private houses and country cottages, has given impetus to the emergence of a huge selection of models on the market. But here the question arises: which three-way valve to install on the heated floor, which manufacturer to choose. After all, the abundance of goods makes shopping difficult. When selecting a device, experts recommend deciding in advance what type of device is needed—two- or three-way. Then select the manufacturer:

- Valtec. The company presents Russian-Italian products on the market. Their main advantage is a budget price with excellent physical and technical qualities. The manufacturer provides a 7-year warranty on the purchased three-way valve for heated floors with a thermostat. The products are supplied with quality certificates, technical data sheets, installation recommendations and a warranty card.

- Esbe. The Swedish company offers high-quality underfloor heating taps made from innovative materials. The devices are maximally resistant to operating conditions, reliable and visually attractive. When purchasing Swedish devices, it is recommended to carefully consider the technical characteristics of the equipment. There is a small chance that the parameters will not match. The cranes are supplied with certificates and warranty cards, the service life is over 5 years.

- Honeywell. The thermostatic mixing valve for underfloor heating from the American company Honeywell is distinguished by its high technology and excellent design. The main advantages of its products are practicality and simplified installation. The design is designed in such a way as to make installation of the equipment as easy as possible. Errors are excluded. The company is proud of its innovative developments, which it implements in the manufacture of devices. This makes them more efficient and reliable, but also more expensive.

From the listed manufacturers, consumers buy time-tested three-way valves for underfloor heating. But you shouldn’t rely only on the quality of the equipment, because even the most stable and reliable device will not be able to protect the system if it is installed incorrectly. In this case, the choice should also be based on the throughput of the unit. This parameter should be clarified in the technical documentation for the equipment. When designing a system for auxiliary heating of air masses from below the room, its power, throughput, heat loss, etc. must be calculated.

Design features

The faucet looks like a tee with a T-shaped arrangement of tubes. For this reason, plumbers began to call it a tee. As for the design of the mechanism, it includes:

- A sealed metal case that is reliably protected from moisture penetration, corrosive processes and other negative influences. The material used to make the body is cast iron, bronze, steel or brass.

- A valve with several passage channels of different shapes.

- Three openings (outlet, with hot and cold water supply).

Three-way valves may differ in some additional characteristics.

The tee may also differ in a number of additional properties, which are indicated on its packaging. Depending on the type of shutter mounted in the mechanism, conical, cylindrical or spherical products are distinguished. The fastening principle can be flanged, coupling, welded or end-fitting. The mechanism is controlled manually, by a drive system or by an electronic controller. As for the shape of the plug, it comes in three types - S, T, L.

Advantages of heated floors with mixer

A heated floor with a mixing unit has many advantages compared to other heating systems.

Comfort

It is possible due to the supply of heat energy due to radiation, but not convection. In addition, the floor surface and the room are heated evenly. There are no cold bridges or hot radiators in the rooms. All this creates a comfortable and healthy atmosphere, therefore there is no dust. The surface always remains dry and does not create an environment for mold, mites and other harmful microorganisms.

Warm floor with mixer

Economic benefit

Depending on the location of the tubes and the functioning of the heating system, you can save on heating the room. It has been established that residential apartments consume 30% less electrical energy, provided that the ceiling has a standard height. Thus, the consumption of energy resources can reach 50%.

Safety

This is important for rooms where people are constantly present. The operation of a heated floor allows you to avoid burns and other manifestations that may occur when using radiators or convectors

Hygiene

The water floor system with mixer allows for proper disinfection of the finish coating. The floor can be cleaned with various detergents and water. This heating system is ideal for rooms with specific hygiene requirements. For example, a water floor with a mixing unit is suitable for kindergartens and hospitals.

Warm floors - comfort and convenience

Principle of operation

To start the mechanism, you need to connect two pipes for supplying cold and hot water. To successfully connect, you should study the diagram of a three-way valve, which shows various arrows and guides. The hot water that comes from the boiler is the main coolant, and the cold water is the remaining waste.

Systems may differ in position and method

Between both openings with inlets to the flows there is a valve that regulates the water supply. Depending on the position and connection method, the system can:

- mix two streams of water into one;

- divide one line into two outputs.

Many people mistakenly think that the tee blocks the water channels that are connected to it, but this is not the case. The purpose of the mechanism is only to redirect the fluid from inlet to outlet.

In a simple configuration, the radiator is connected to the boiler in a series or parallel manner. It is impossible to adjust each element individually, since only the temperature of the liquid in the boiler tank changes.

If there is a desire to regulate each battery, the system must be equipped with a bypass, as well as a regulating needle valve, which will allow you to regulate the volume of liquid passing through it.

The purpose of the bypass is to maintain the overall resistance of the installation to prevent malfunction of the pump. Unfortunately, this approach is expensive and complex to install, so it is not very popular.

Operating efficiency and final efficiency indicators may depend on the location of the valve. If it is half open, then the outgoing water flow will have an average temperature. If the valve is fully open, the temperature will reach its maximum. When it is completely closed, only cold water flows out.

Elements and components

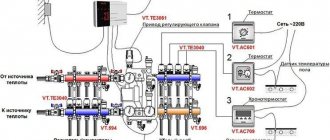

To create all the described schemes, a certain amount of shut-off and control valves and components are used. Some elements are mandatory, such as a circulation pump, while others are used if necessary. In general, most manufactured units use:

- circulation pump of the required capacity;

- control valve (2 or 3 way) with thermal head or thermostatic valve;

- supply and return thermometers (optional);

- bypass, balancing and shut-off valves;

- Ball Valves;

- air vents.

The main elements are control valves and a pump, the operation of which allows the coolant to be obtained at the required temperature in the required quantity.

Valves and taps

The water mixing unit for a heated floor necessarily includes valve taps. Let's look at the features and scope of some of them:

A 3-way valve is a device that is used to mix, separate, or switch flows of water or other coolant among themselves. When applied to mixing units, their main task is to create a mixture with the required temperature for supplying underfloor heating to the network using the hot flow from the boiler and the cooled coolant from the return pipeline.

3-way valve with thermal head.

A two-way valve is capable of changing the coolant flow from one source. That is, when using it, the flow is regulated. When the valve cross-section is reduced, the volume of coolant passing through it decreases, and the amount of water required for pump operation is taken from another pipeline.

2 way valve.

Any of the valves described is simply a locking mechanism, the regulation of which is possible by certain methods. The simplest is manual, when the flow is blocked using a valve. But this is practically not used for mixing units in heated floors, since the autonomy of such a system is questionable.

Most often, thermal heads are used, which automatically regulate the degree of valve opening depending on the readings of a temperature sensor, which is attached to the supply or return pipeline. It is also possible to use servos.

There are also thermostatic three-way valves, to which two branches with different temperatures are connected and from which coolant leaves at a pre-selected temperature. In such a valve, temperature regulation is carried out by sensors built into the body of the device. Unlike a remote sensor, as in thermal heads with a 3-way valve.

Thermostatic three way valve

When choosing either a 3-way or a 2-way valve, it is important to have an idea of such characteristics as capacity (Kvs, Kv). It means what maximum coolant flow is capable of passing through the valve in the fully open position at a pressure drop of 1 bar. Kvs of the valve is standardized and is indicated in the characteristics - 1.0, 1.6, 2.5, 4.0, 6.3, 10...

In general, Kvs depends on the fluid flow and pressure drop across the valve. To do this, use the formula Kvs=G-√dp, where dp is the root of the pressure drop across the valve, G is the water flow.

As an example, we can say that for a heated floor with an area of approximately 50 m² with a pressure loss of about 8 kPa, a valve with Kvs 1.6 is usually sufficient. With a similar system of 150 m² and 10 kPa, the use of a three-way valve with Kvs 4.0 is already necessary.

Pump

A mandatory element of the mixing unit is a pump group for a heated floor, which is selected in such a way as to ensure the supply of the calculated amount of coolant to the heated floor. When choosing, the pressure loss in the longest heated floor loop is also taken into account. Losses depend on the length of the branch, the presence of taps and valves, turns and other elements that create resistance to the movement of the coolant. For calculations, it is convenient to use special programs that are developed by manufacturers of heated floors or use formulas from reference books.

The calculation of the coolant in the heated floor circuit can be calculated using the following formula:

Q=3600⋅P/s⋅(tп-to), where P is the power of all underfloor heating loops; c – heat capacity (for the coolant – water, it is 4.2 kJ/kg); tп and to – calculated temperature of the supply and return pipelines. Typically, the difference should not exceed 10 °C.

For example, at a temperature of the supply and return pipelines of 35 and 25 °C, and a system power of 8 kW, the coolant flow will be: G=3600⋅8/4.2⋅(10) = 685 l/h (0.685 m³/h).

Based on the found flow rate and pre-calculated pressure losses in the network using pump nomograms, we select the model of the required performance.

Pump selection according to the nomogram.

To take into account pressure losses, it is necessary to carry out a hydraulic calculation of the heated floor. To do this, many parameters are taken into account - the length of the loops, the diameter, the number and characteristics of all local resistances (branches, valves, turns, etc.). To simplify the calculation, many manufacturers provide special programs.

Total losses include:

- Pressure loss in the pipeline. They depend on the length of the longest loop of the heated floor, the speed of water movement in it and the diameter and material of the pipe. Above we found the total coolant flow rate passing through the pump. The amount in each loop may vary depending on manifold characteristics, control valve settings, etc., but a value of 0.04 l/min can be used as a rough estimate. That is, if you have a branch 50 m long, then the flow rate for it should be approximately 2 l/min. Using this value and the pressure loss per meter of the pipeline used, we find the total pressure loss in the loop. Specific pressure losses per 1 meter of pipeline are determined according to the loss nomogram for a specific pipe, which can be found in the documentation for the product. If a specific loss of 1 Pa is indicated for a pipe, then at 50 m there will be 50 Pa. In the same way, we take into account the losses on each section of the direct pipeline included in the most loaded loop.

- Pressure loss at each resistance of the design section. They are found by the formula dP=S⋅(V²/2) ⋅r. Where dP is the pressure loss at all local resistances, S is the sum of the local resistance coefficients, V is the coolant velocity, r is the coolant density. The local resistance coefficient for each fitting is indicated in its documentation or in the reference literature. You need to take into account all valves, tees, and other elements.

Total pressure losses consist of the sum of losses in pipelines and local resistances. After all these parameters are calculated for a specific network, the total losses will be found, which serve as the basis for choosing a pump. It must be borne in mind that several units are used for pressure, each of which can be indicated in the nomogram, and sometimes several at once, for example, kilopascals (kPa), meters of water column (N). If necessary, they can be converted using the formula - 1 meter of water column = 9.8 kPa.

Automatic valves

It was mentioned above that 3-way valves can be operated manually using a stem, which is located on one side of the valve and is equipped with a turning handle or nut. But this method of control is not entirely convenient.

As you know, the power of the heating circuit is adjusted taking into account the return temperature , so the manual method can only determine the proportion of mixing water with different lines. Changing the final temperature may take too long, and the distribution of thermal potential is uneven.

Because of this feature, automatic valves that operate on the basis of servo drives or special hydrodynamic and pneumatic heads have recently become very popular. These elements are capable of instantly changing the current three-way valve configurations, taking into account the outlet temperature.

Automatic valves are easy to use, therefore they are more popular than manual ones.

According to the principle of operation, the electric drive is similar to manual control, but it operates without human intervention, but on the basis of an electronic control unit. The unit itself is a power unit that rotates the rod and changes its position taking into account the signal.

Almost all three-way valves support the installation of a servo drive, but it is advisable to buy special designs that are small in size and designed for electric drives.

After receiving the required values, a signal to action is sent to the servo drive, then it begins to change the location of the rod or rotate the ball inside the tee. Uninterrupted and high-quality operation of the system is ensured by the operation of the electronic control unit. The absence of this node makes the installation useless.

Servo drives have many advantages. Their main advantage is the ability to automate the entire operation of the heating system and deprive yourself of additional hassle. If you connect a node with a Smart Home system, this will also allow you to control the heating directly from your smartphone.

The best manufacturers

Due to the fact that three-way valves are quite popular in the modern heating equipment market, they are in great demand.

Therefore, after you decide which valve is right for you, research the best manufacturers in order to choose exactly the valve that will serve you for a long time.

Let's look at the best manufacturers of 3-way valves on the thermal equipment market.

- ESBE - if you do not have the opportunity to buy an expensive valve, then the ESBE manufacturer is exactly what you need. I have a fairly low price for the product, the manufacturer is responsible for the quality and ease of installation.

- NAVIEN - for a very long period of time, this manufacturer has been occupying the first position in the list of leaders in the production of thermal equipment, including 3-way valves. Buyers have only positive feedback because of the reliability and durability of the products. The manufacturer does not skimp on materials and carefully checks each product.

- DANFOSS - products from this manufacturer are especially popular among customers due to their particularly precise adjustment and stability.

- IVAR - this manufacturer is famous for the same good reliability as all others, but it has valves in its arsenal not only for heating systems, but also for cooling systems.

- HERZ - this manufacturer is No. 1 in the modern heating products market. Herz captivates customers with its reliability and huge product functionality. The range of goods is quite large, which cannot but please the consumer. Even a beginner can understand Herz products.

Areas of application

Modern valves are in wide demand and are actively used in various areas of human activity. They are often installed in modern heating mains, which require constant adjustment of proportions when mixing different coolant flows. For such purposes, it is customary to use electromagnetic devices or models with a thermal head.

As for domestic use, in this case it is enough to purchase a thermostatic mixing device that will allow you to regulate the temperature of the coolant. It is supplied both to the underfloor heating piping system and to heating radiators. And if the household device is equipped with automatic control, then changing the temperature in the room will be much easier.

Alternative options

If the room area does not exceed 10 m2, then the temperature can be adjusted using simple valves. You only need two devices - for supply and return. If you need to increase the temperature, just unscrew the valve more, and vice versa, by tightening the tap, you can reduce the temperature of the coolant. However, unlike a thermostatic three-way mixing valve for underfloor heating, the valve must be closed manually. And it is quite difficult to obtain accurate data - everything is determined only experimentally.

The thermostatic valve can be purchased not only three-way, but also two-way. Such a device is installed in addition to a conventional valve on one side. In this case, there will be no need for manual regulation - it will be carried out automatically.

Buying a crane

When purchasing a three-way valve, you need to consider several features and selection criteria. First of all, you need to do the following:

- Measure the diameter of the pipes of the common line to which the tee will be connected. The optimal figures are 20-40 millimeters, but there are also non-standard situations when you have to purchase special adapters for an individual size.

- Understand the pipeline capacity in heating circuits. To do this, you need to carry out a simple calculation and determine how much liquid each pipe can pass through, as well as what period of time this process takes.

- Find out if it is possible to additionally connect a servo drive, which will make the system automatic. This option is especially in demand for rooms with heated floors.

When purchasing a 3 way valve, it is important to take some measurements

Also, when purchasing a tee, it would not hurt to carefully study its other characteristics. In most cases, they are indicated on the box with the product. If it is difficult for an inexperienced buyer to understand various terms and official data, then it is better for him to seek help from consultants.

Rules for installing a three-way valve

- The installation site must be freely accessible.

- The “tee” is installed with the lever up or sideways (outward). The control lever should move freely in the desired direction.

- Markings in the form of arrows on the device body will tell you how to correctly connect it to the system. The arrows indicate in which direction the flow will move.

- If the quality of the coolant is low, it is advisable to install a filter in front of the three-way mixer.

- In the heating circuit, a “tee” is installed in front of the circulation pump.

- The threaded connection must be sealed with flax fiber and treated with a sealant.

- When connecting for welding, it is necessary to avoid the formation of scale inside the line.

Installation and operation

To ensure successful installation of a three-way valve, it is important to follow the drawings and step-by-step instructions. also need to pay attention to several nuances of the upcoming installation:

To properly install a three way valve, it is important to follow the drawings and step-by-step instructions

- On the body of the tee there is a special diagram with arrows that show in detail the direction of water flow. Its presence significantly simplifies installation work and allows you to quickly and accurately connect important components.

- When welding metal mechanisms, the temperature flow in the joint area must not be allowed to exceed +100°C. It is important to ensure that scale or dirt does not penetrate the system, otherwise this can lead to irreparable consequences.

- To install the tee, you need to choose a place that will be easy to reach for repairs or maintenance. If the tap has to pass insufficiently high-quality liquid, it is recommended to additionally equip it with filter units.

- The method of fixing the product can be either vertical or horizontal. This does not affect work efficiency in any way. As for the valve, it is installed directly in front of the circulation pump.

In order for the tee to function for a long time, reliably and efficiently, it is necessary to take into account the operating rules and maintain it on time. The service life of the device depends on proper and correct use.

Changing operating modes of heated floors

The thermostat is an effective solution for monitoring the water temperature in the heating circuit. This method is inexpensive and accessible to almost every owner. The boiler heats the water to 90 degrees, and water should flow to the floors at a temperature twice as low.

The desired degree can be achieved thanks to the thermostatic head:

- The supply of hot water is short-term - the water fills the pipeline, the supply ends until it cools to an acceptable temperature;

- Constant water supply with the addition of cool coolant from the return pipe.

Periodic short-term supply

With a short-term water supply, the system works in a small space - a bathroom, ceramic floor in the toilet, shower room and other places. At the supply point there is a valve with two strokes, a remote-type floor sensor and a thermal head.

As soon as the circuit is filled with coolant, the sensor is triggered and the flow is blocked by the valve. After some time, the screed will cool down, the valve will open again and hot water will fill the system. This circuit is economical and can replace the mixer unit.

For heated floors, special thermal heads from the RTL series have been developed, without an external sensor. They are installed on the return line to maintain the set water temperature without depending on the heating of the floors. By installing this model of thermostat, the automation changes the threshold heat values (no more than 40 degrees Celsius).

The installation feature is installation in an exclusively horizontal position. Experts from Moscow do not recommend setting the water level in the floors lower than the temperature in the room.

Periodic short-term injections of water into the circuit allow you to maintain stable movement along the coolant circuit without overheating the system.

Constant coolant supply

A constant supply of water requires the installation of a three-way valve in the system, complemented by a floor sensor and a thermal head. Using a tee, a connection is made from the return to the third stroke of the mixing unit. The direct water supply must always be open, so the valve must be installed professionally and correctly.

Experts recommend installing the thermal head on a three-way valve using a locking type axle box. When the sensor heats up, the valve stem moves and a gap is formed inside. This gap receives cool water from the return line.

This sequence of work allows the coolant to stably enter the circuit, while the temperature remains within acceptable limits. Due to the continuity of the flow, the floor covering quickly heats up to 28 degrees Celsius and remains comfortable for the owner, and the circuit does not overheat.

Pipes and screed will last longer due to the absence of excessively high temperatures. The addition of cold coolant is important for heating large rooms where a comfortable temperature is needed.

Useful tips

Before starting the heating system, you must make sure that the three-way valve and other components are in full working order, do not need repair or replacement, and also meet operational requirements. It is not recommended to install a tee on a pipeline with a pipe diameter of 40 millimeters or more. When operating in a hot environment, the valve must be opened with extreme caution, otherwise there is a risk of hydraulic valve failure.

The best material for a three-way valve is brass.

Experts recommend placing control devices or a turning handle with a rod so that they are freely accessible. When choosing a suitable faucet model, it is advisable to give preference to products made of brass. They are characterized by a long service life and resistance to all kinds of influences.

As for the control method, the best option would be a product with pneumatic control. Before making a choice and buying a tee, it is better to consult with a specialist, talk about the possible pros and cons of the available models, and also read reviews about them on thematic forums.

Among the huge variety of shut-off valves that are used on the heating system, there is a rather rarely used element - a three-way valve for heating with a thermostat. It is similar in shape to a tee, but it is designed for completely different functions. How a three-way valve with a servo drive works and why it is needed will be discussed in this article.

Three-way mixing valve with thermal head

The valve with thermostat guarantees the practicality and efficiency of the system. Three-way heating valves are designed to regulate heat flow, which ensures indoor comfort and economical use.

Before proceeding with the design of the heating system, a thermal calculation is performed. Based on its results, the appropriate power and type of heating devices are selected that can maintain the optimal temperature in the room.

The area of the room is taken into account, and then possible heat losses are analyzed. Based on this, the performance of the heating system necessary to create a comfortable microclimate in the rooms is calculated. After that, a heat balance is compiled for all rooms.

However, these calculations are made under specific conditions, which may change during operation.

- The factors affecting the operation of the radiator are different:

- temperature changes outside;

- solar Activity;

- wind force;

- the presence of household appliances that generate heat.

As a result, the calculated temperature balance is disrupted and the room becomes hot. However, it is impossible to remove parts of the radiator from the room or muffle thermal radiation. Thus, there is a need to manage the energy generated by heating devices in order to maintain a comfortable microclimate in the room.

- There are two ways to regulate the energy released by the radiator:

- Qualitative change in the properties of the radiator.

- Quantitative regulation of heat generated.

- In both cases, manipulations with the liquid circulating through the pipes are necessary.

In cases where you cannot influence the temperature of the water supplied to the radiator, you can regulate its quantity. For this you need to buy three-way valves for heating with a thermostat.

These devices make it possible to limit the amount of water passing through the radiator, and as a result, with the same radiator area, more or less heat will flow into the room, of course, within limits limited by the power of the system.

Three-way mixing valve with thermostat

A three-way valve for the heating system and a temperature controller installed on the radiator can be used separately, however, in autonomous heating systems of modern apartments and private cottages, a combined method is often used to increase efficiency.

Thus, it is advisable to purchase a three-way valve for heating with a thermostat.

It is important to consider that the operating principle of a three-way mixing valve allows you to increase or decrease the radiator temperature only within established limits. These limits are dictated by the technical characteristics of the heating device, namely, the value of its maximum heat transfer, and depend on each specific radiator.

Operating principle of three-way valve

A three-way mixing valve is installed in those sections of the pipeline where it is necessary to divide the main coolant flow into 2 circuits:

- with variable hydraulic mode;

- with constant.

Often a constant flow is necessary for those who are supplied with high quality coolant and in specified volumes. Its adjustment corresponds to quality indicators. Regarding the variable flow, it is used for objects where quality indicators are not key. Here the quantity coefficient indicator plays an important role. In other words, the supply of warm fluid in this case is carried out according to the required quantity.

Note! One of the elements of shut-off valves is an analogue of the device that we are talking about in this article, which is called a two-way valve. What makes it different? It differs from the three-way one in the principle of its operation. The fact is that one of the elements of its design, the rod, cannot block the flow of liquid, which has constant hydraulic parameters.

The rod is constantly open, it is adjusted to a certain volume of liquid. Based on this, users have the opportunity to obtain the required volume, both in terms of quantity and quality. In general, this device cannot stop the flow of fluid for a network with a constant hydraulic flow. But it is capable of blocking a variable flow, which makes it possible to regulate the pressure/flow.

You can create one three-way valve by connecting a pair of two-way valves. But they must work in reverse mode, that is, when one opens, the other must close.

A three-way valve for underfloor heating or other purposes operates with the following sequence:

- hot water flows to the collector, which is one of the elements of the heated floor;

- the degree of heating of the liquid is determined as it passes through the thermomixing valve;

- in the case when the temperature exceeds the set level, a passage opens from where the cooled liquid flows;

- both streams mix internally;

- Once the temperature drops to the set limit, the cold water passage is closed.

The disadvantages of three-way valves include the likelihood of sudden temperature changes that can occur when heated water is started, which can have a negative impact on the condition of the pipeline during mixing.

The three-way thermostatic mixing valve is used to:

- if necessary, redirect flows from different pipelines;

- mix flows of diametrically different temperatures to obtain a flow of a set temperature;

- dynamically control the direction of flows to obtain a flow with a constantly set temperature;

- in a plumbing system, this is obtaining a flow with a given stable temperature;

- in a heating system, this means obtaining a separate mixing unit with a consistently constant circulation temperature.

The need for mixing units in a heated floor system

When installing water heating using radiators or other high-temperature equipment, the coolant can be supplied to them at almost any temperature that the boiler is capable of producing. But the situation with warm floors is radically different. According to building codes and common sense, there is a limit to the maximum floor surface temperature. Excess of which makes the operation of the system uncomfortable and even dangerous.

For example, according to SNiP 41-01-2003 “Heating, ventilation and air conditioning” the maximum temperature of the floor in which the built-in heating system is used cannot exceed:

- 26 °C for rooms with constant occupancy;

- 31 °C for occupied rooms and some areas of indoor swimming pools;

- 23 °C for preschool institutions.

These restrictions make it difficult to use a boiler without a mixing unit for underfloor heating. Since without it, the coolant will inevitably raise the temperature of the heated floor above the limit value. And the coolant temperature can reach levels above 80 °C.

The mixing unit for the heated floor in this case allows the coolant to be supplied to the pipes at the optimal temperature. Is its use essential and is it possible to get out of the situation without it?

Mandatory use of mixing units

As we have already determined, the main purpose of the mixing unit is to maintain the water temperature in the system at the required level. To do this, part of the water from the boiler with an increased temperature is taken and mixed with a certain amount of water from the “return” until the required level is reached, which allows the optimal floor temperature to be achieved.

If you exclude the pumping and mixing unit for a heated floor from the diagram, then it is necessary to maintain the temperature in another way. Alternatively, it is possible to use a low-temperature boiler, which is capable of providing a supply water temperature of around 35-38 °C to maintain the required floor heating. Most often, electric boilers are recommended for these purposes. Water heat pumps also operate in this mode.

Scheme of a heated floor without a mixing unit.

It should also be borne in mind that a heated floor without a mixing unit is almost impossible to use with a combination of floor and radiator heating, since for radiators the temperature must be high enough to ensure optimal heat transfer. If underfloor heating is used as the main source, then if a good boiler with suitable characteristics is used, the mixing unit may not be used.

So, if the need for a mixing unit is not in question, what should you do in this case? You can use a factory-made product that is designed and tested for trouble-free operation, but the main disadvantage of such systems is their high cost.

As an option, you can use a homemade mixing unit for heated floors. Its main advantage is a significantly lower price. On average, such a unit is 3-4 times cheaper than a factory-made one, but questions arise in its calculation and selection of elements. After all, if the selection is incorrect, the heated floor will work unevenly or its operation will be significantly difficult.

How to create a mixing unit with your own hands? In general, the main tasks when posing the question in this way boil down to the following points:

- choose the layout and design of the mixing unit;

- select the necessary elements;

- calculate pump performance and characteristics of other products;

- mount the unit.

The principles of installation are no different from creating a heating network. The main attention should be paid to calculations, selection of circuits and selection of equipment. This is what we will focus on next.

Types of valves for heating

Without further introduction, let's say that the device comes in two types, which differ in the principle of operation. It happens:

The principle of operation of the device is clear from its name. The design of the mixing device has two outputs and inputs. This is necessary in order to mix different flows of liquid to reduce its temperature. By the way, this is the best option for setting the required mode for a “warm floor”.

The process of adjusting the temperature is quite simple. You only need to know what the current temperature of the incoming liquid streams is in order to accurately calculate the required proportions of each stream in such a way as to obtain the required output indicators. By the way, if installed correctly, this control device can also work to separate the flow.

A dividing valve divides one flow into two, so it has one inlet and two outlets. This device is used mainly for separating the hot flow in domestic hot water systems. Although quite often it can be found in the piping of air heaters.

In appearance, both options are quite similar to each other. But when examining the drawing, where the devices are shown in section, you can see the main differences. In the mixing device, the stem has one ball valve. It is located in the center and blocks the main passage.

The rod of the separating devices is equipped with two such valves installed at the outlets. They work as follows: one of them is pressed against the saddle, closing the passage, while the other opens the second passage.

The control method of modern models is:

The most commonly used device is a manual control method; in appearance it is similar to a ball valve, but has three outlet pipes. But models with electrical control have automatic control, which is used mainly in private homes. Its job is to distribute heat. For example, the user can adjust the temperature regime in the rooms, and the coolant will flow according to how far the room is from the heating device. As an option, you can attach it to a warm floor.

Three-way valves, like other devices, are divided according to the pressure in the system and the diameter of the inlet. All this is determined by the regulatory acts of GOST. And if these requirements are not met, this can be regarded as a gross violation, especially in cases where it concerns the pressure indicator inside the line.

Design and principle of operation

To understand what the thermo-mixing three-way valve of the most common saddle type consists of and how it works, you should study the diagram below. Inside the brass body with three nozzles, 3 chambers are arranged using the casting method, the passages between which are blocked by poppet valves. They are fixed on one axis - a rod coming out of the body on the fourth side.

In a 3-way mixing tap, the outlet pipe (from where the mixed water comes) is always open, the remaining 2 fittings are alternately closed with a thermal head

The operating principle is as follows: when you press the rod, the passage for one flow will begin to open and gradually close for another, resulting in water of the required temperature in the mixing chamber of the valve. It leaves the brass body of the element through the third pipe. The force of pressing on the rod is adjusted by a thermal head with an external temperature sensor installed in accordance with.

The whole process is worth explaining in more detail:

- Imagine that an insufficiently heated coolant comes from the hot water side. Then the mechanism passes it further, and the third pipe is closed. The remote sensor is filled with a heat-sensitive liquid and is connected through a capillary tube to a reservoir (bellows) inside the thermal head.

- When the sensor heats up, this liquid expands, its volume in the tube and bellows increases, as a result of which the latter begins to press on the three-way valve rod. The moment of pressing is determined by the adjustment on the scale of the thermostatic head, set to the required temperature.

- After this, cold water from the third pipe is mixed into the flow of heated water and the temperature of the water at the outlet of the thermal valve remains unchanged, although heating of the coolant at the inlet continues.

- If the incoming water continues to heat up above normal, then to maintain the set outlet temperature, the thermostatic valve can completely close the inlet and open the side flow. In this case, the rod lowers to its lowest position.

- As soon as the sensor detects cooling of the coolant, the head slightly releases the stem, the valve seat on the hot side opens and the addition of heated water begins.

If we are talking about a dividing valve, the principle of its operation is almost the same, only when you press the rod, one flow begins to divide into two. But in the switching element, the direction of movement is changed by the electric drive, which is described in detail in the video:

Watch this video on YouTube

Where is this device used?

The three-way valve, whose operating principle was discussed earlier, is used quite widely. For example, such varieties as an electromagnetic device or a device with a thermal head can easily be found in modern highways, where adjustment of proportions is necessary when mixing two separated liquid flows, but the volume or power should not be reduced.

In everyday life, the most popular is the thermostatic mixing device, which, as mentioned earlier, helps regulate the temperature of the coolant. It can be supplied both to the underfloor heating pipeline and to heating radiators. And if the valve is equipped with automatic control, then temperature control will be carried out without any problems.

Note! Using a three-pass heating system to balance temperature changes is beneficial not only in terms of creating convenience and comfortable conditions, but also saves your money.

The bottom line is that by regulating the temperature of the coolant at the “return” of the heating device, you can quite significantly reduce the volume of fuel consumed, and in addition, the efficiency of the system itself will increase. On some systems, installing a valve is simply necessary. For example, in a “warm floor” system, this device prevents the floor covering from overheating higher than necessary for comfortable conditions, thereby relieving users of unpleasant sensations.

Regulating devices of this kind are also used in water supply systems in order to obtain a permanent flow at the desired temperature. The most common example is a regular faucet, which allows you to regulate the water temperature by opening and closing valves.

Mixing unit diagrams

The design of the heating floor mixing unit is designed in such a way as to correctly obtain the coolant at the required temperature. All existing modern schemes of mixing units are divided into two large groups:

- parallel;

- consistent.

This separation takes place according to the flow pattern of the coolant. How are both types different?

Parallel

The parallel circuit of the mixing unit for a heated floor is designed in such a way that after mixing, water of the required temperature is supplied not only to the heated floor itself, but also to the circuit of the heating device. This imposes special features on the functioning. Since part of the prepared coolant does not enter the underfloor heating network, it is necessary to use a pump with higher capacity.

Parallel circuit.

Consecutive

To operate a series circuit, a pump of lower capacity is required than when using the same parallel circuit. This is due to the fact that after mixing, the entire prepared volume of coolant circulates directly in the heated floor circuit. In general, this scheme is more suitable and is most often used in modern conditions.

Sequential circuit.

To understand the difference between each scheme, you can familiarize yourself with the drawings.

Selection criteria when purchasing

You need to remember that when purchasing, be sure to pay attention to the technical characteristics of the device, which include the following:

- Diameter of connection to the heating main. Most often, this parameter ranges from 2 to 4 centimeters, although most of it depends on the characteristics of the system. If you cannot find a device of the required diameter, then you need to use a special adapter.

- Possibility of mounting a servo drive on the device to ensure its automatic operation. This is especially important when the valve is planned to be installed on a warm water floor system.

- Finally, there is the pipeline capacity. This concept refers to the volume of liquid that can pass through it in a certain time.

There are many manufacturers of three-way valves on the domestic market. The choice of one model or another depends, first of all, on:

- type of mechanism (and let us remember, it can be mechanical or electrical);

- areas of use (DHW, cold water, “warm floor”, heating).

The most popular device is rightfully considered Esbe - a Swedish valve from a company that has existed for more than a hundred years. This is a reliable, high-quality and durable product that has proven itself in many areas. A combination of European quality and modern technology.

Another popular model is the American Honeywell - a true brainchild of high technology. Simple operation, convenience and comfort, compactness and reliability - these are the distinctive features of these valves.

Finally, relatively “young” but promising devices are valves from the Valtec line - the result of joint cooperation between engineers from Italy and Russia. All products are of high quality and are sold with a seven-year warranty. They differ in that they have a very affordable price.

Installation of a warm water floor

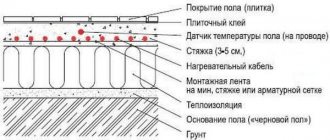

Any warm water floor system consists of such basic elements as pipes, as well as technology for their fixation. Typically, two methods are used:

- Dry method, using wood and polystyrene, which form the base on which the pipes are laid. To ensure that the heat is distributed more evenly, the pipes are also laid evenly, in grooves specially provided for this. After this, hard material, such as plywood, OSB, gypsum fiber board, etc., is laid on top of the pipes. A solid base is used for laying flooring of any origin.

- Wet method, which involves laying the pipe system in a screed. The technology consists of several layers. The first layer is insulation with a pipe fixation system, the second layer represents the heating system itself, and the third layer is a screed. The floor covering is laid directly on the screed. It is advisable to provide a layer of waterproofing so as not to flood the neighbors below. For greater reliability, a reinforcing mesh can be installed in the screed. The entire system will be more reliable, since the reinforcement will prevent cracking of the screed, which, in turn, will protect the heating system from damage. You should not ignore the presence of a damper tape, which should be present around the perimeter of the room, as well as at the junctions of two circuits.

Neither one nor the other system can be called ideal, although laying pipes in a screed is considered a more optimal option, therefore, most people prefer this technology.

System selection

When choosing a system, it is necessary to analyze a number of factors. Dry systems are more expensive, but they allow you to operate them much faster. Their use is preferable for a number of reasons.

The first and main reason is the weight of the entire system. The heating system embedded in the screed is significant in weight, so not all structures are able to withstand such weight. The thickness of the screed can reach at least 6 cm, and this is a significant weight. In addition, tiles can be laid on the screed, which are not lightweight, especially if they are intended for laying on the floor. If you are not sure that the structure will withstand such a load, it is better to abandon the “wet” option, giving preference to the “dry” option.

The second reason is related to the maintainability of the system. Any system can fail at any time, no matter how well it is installed. Despite the fact that heated floors are laid without joints or connections, they sometimes burst due to the slightest defect or are damaged as a result of repair work or other manipulations. If a pipe in a screed bursts or is damaged, it is very difficult to repair it, since you will have to break the screed, and this is sometimes not easy. Naturally, after renovation, this place is considered the most susceptible to various mechanical loads.

Installation process of water heated floor

It is not recommended to turn on heated floors in a screed until the screed is completely dry, which is about 30 days.

If the screed is laid on a wooden floor, then this in itself is a real problem. A wooden base, and even under the influence of high temperature, and even more so if the technology is violated, will quickly become unusable, collapsing the entire system at any moment.

The reasons are quite significant, so in certain cases it is better to give preference to dry technologies, and if you solve the problem yourself, then such a technology may not be as expensive as it seems. The most expensive element is metal plates, but they are not difficult to make yourself. It is better if aluminum is used as the manufacturing material. The only problem is to bend the metal so that grooves are created for laying pipes.

An option for installing a heated floor system based on polystyrene, made using “dry” technology, is presented in the video.

Water heated floor on a wooden base - Part 2 - Laying the contours

Watch this video on YouTube

DIY valve installation

We present to your attention several schemes for installing a mixing valve.

A scheme that is used mainly in boiler rooms of heating systems that are connected to a hydraulic separator or to a free-flow collector. The pump, which is located in the second circuit, ensures the necessary circulation of the coolant.

Attention! In the case when the valve is planned to be directly connected to the coolant source on the bypass, which is connected to port B, then it will be necessary to install a valve with hydraulic resistance, which will be equivalent to the same resistance of this source.

If this is not done, then the coolant flow in the segment A-B will fluctuate depending on the movement of the rod. It is worth noting that this installation scheme provides for a possible interruption of coolant circulation through the source if the installation is made without a circulation pump or hydraulic separator in the main circuit.

Design and functionality of the device

Three-way valves (TC) differ in size and material: stainless steel and bronze. The body can be made of either metal or polymer material. Although the latter is not very popular.

Valve types

The design has 3 openings: an inlet and two outlets; inside there is a drive that controls the flows to obtain a given temperature.

Structurally, the product is designed to interrelate the action of a pair of two-way valves. The main difference is that TC does not stop the flow of the medium, but regulates its intensity. 3-way devices are divided into groups according to the adjustment system: “rod-seat” and “ball-socket”, and can be paired with a Hertz thermal head.

Control of the movement of the rod is usually carried out by an electromechanical type drive, and is used for installation in automatic control systems for thermal processes of the Proterm boiler and other modern solid fuel engines.

Valve design

The principle of operation of the heating system is based on mixing 2 temperature flows of the coolant on the supply and return, into a common flow, with a temperature indicator set by the user.

The medium in the internal cavity of the device moves from one pipe to another until its temperature changes to the desired size.

Simplified mixing elements with temperature lock

An autonomous three-way valve of a simplified type can be installed in simple heating systems of country houses, where heat is obtained from a TT boiler. To function, it does not require a thermal head with a temperature sensor, and there is no rod there.

The thermostatic element, which is installed inside the housing, is adjusted to a certain temperature of the coolant at the outlet, for example. 50 or 60 °C (must be marked on the body).

The mixing valve of this sample always maintains the set temperature of the coolant at the outlet; this setting does not change. This gives rise to positive and negative aspects when using such fittings:

- advantage - cheaper, unlike a unit with a thermal head. The difference is about 30%;

- disadvantage - there is no possibility of adjusting the heating of the exiting coolant. If the factory settings are set to 55°C, then it will constantly supply water at this temperature ±2°C;

- Before purchasing a valve of a simplified design, carefully study the documentation for the solid fuel boiler; it usually indicates the minimum return temperature.

A thermostatic three-way valve is a rather useful thing in the heating system of a private home, which makes it possible to efficiently use the heated liquid, and thereby save fuel. Moreover, this part allows you to increase the service life of solid fuel boilers, and also plays the role of a safety element. On the other hand, you should not sculpt the valve just anywhere; it is always better to consult with a specialist who is well versed in this.

Typically, warm water floors are installed in private households equipped with heating boilers. In this case, the heating scheme with heated floors involves connecting pipes with coolant through a manifold for heated floors with your own hands. First you need to lay the pipeline system and install the manifold cabinet (you can see how it looks in the photo).

How does the water mixing system work?

Mixing system for several rooms

Relatively speaking, the mixing unit for a heated floor works like this:

The hot liquid reaches the underfloor heating manifold and is stopped using a safety valve if its temperature is too high. The pressure triggers the damper and begins to supply cooled liquid from the return (which has already passed through the circuit and cooled down). As soon as the temperature becomes optimal, the valve closes back. There are several ways to organize water mixing, which we will discuss below.

Also, often the collector unit not only maintains the optimal temperature level, but also increases the pressure in the circuit to improve circulation.

It usually consists of the following elements:

- The safety valve we described above. It turns on mixing if the temperature gets too hot.

- A circulation pump that increases water pressure and makes heating even.

In addition, the unit may also include a bypass - to protect against overloads, valves for draining water and air vents. Depending on your requirements, its assembly can be done in several ways.

The mixing unit is always installed before the heated floor contour, but the location of its attachment can be different: directly in the room, in the boiler room or another room in the manifold cabinet.

The main difference between mixing units and each other is the valves used in them. The most popular are two- and three-way valves.

Two way valve

Two way supply valve

Also, such a valve is often called a supply valve. It has a thermal head with a liquid sensor that constantly checks the supplied water. If necessary, it cuts off the supply of hot liquid from the boiler.

As a result, water from the return line is constantly supplied for mixing, and when it cools down, a hot portion is added by a valve. Thus, the warm floor of an apartment or house does not overheat and its service life increases. This option has a small throughput, so the adjustment occurs smoothly, without sudden jumps.

Most craftsmen prefer to install this type of mixing, but to use it, the heating area should not exceed 200 square meters.

Three-way valve

This type combines the functions of a bypass valve and a bypass balancing valve. Its main difference is the mixing of hot coolant inside it with cooled return fluid. They are often equipped with servos that control thermostatic devices and weather controllers.

Inside this valve there is a damper, which is installed in the area between the supply and return pipes. By adjusting the position of the damper, the ratio of the supplied water changes.

Three way mixing valve

This type of connection is considered more universal and is well suited for large systems with a large number of circuits and the use of weather controllers.

It is also worth talking about the disadvantages of this connection scheme. It is possible that, following a signal from the thermostat, the valve will fully open and allow 95 degree water into the circuit. In a heated floor system, sudden changes in temperature and pressure are unacceptable; heated floor pipes can simply burst.

The second disadvantage is the large capacity of the three-way valve. That is, even a slight shift in temperature can change dramatically.

Outdoor temperature sensors

Connection together with an outdoor temperature sensor

Weather-dependent sensors automatically adjust the temperature to suit weather conditions. For example, during a sudden cold snap, they give a command to increase the floor temperature.

The valve rotates a maximum of 90 degrees. The controller divides them into 20 segments of 4.5 degrees each and checks the supplied temperature every 20 seconds. If the actual temperature does not correspond to the optimal temperature, the valve is turned 1 notch. In addition, some species may reduce water supply when no one is home.

Of course, this can be done manually, and tighten the valve each time, but it will be difficult to set the optimal heating mode each time.

Collector connection diagram

The order of work is as follows:

- The collector box is mounted in a place that is convenient for access and at the same time so that it does not interfere. Pipes supplying heated water and return are connected to the cabinet. But before this, shut-off valves should be installed on the collector.

- In order to control the temperature and pressure in the system, a thermometer and a pressure gauge are placed in close proximity to the valves.

- To connect pipes connected to the manifold, compression fittings are used using a threaded connection.

- If it is necessary to combine pipes with different diameters, adapters or universal fittings are used, taking into account the connection diagram for the heated floor.

The simplest scheme for connecting a heated floor is as follows: one of the collectors connects the pipes supplying water, and the second - the return flow of the already cooled coolant (pro

Rules for operating a three-way valve

The “tee” installed in the system requires periodic inspection for wear and leaks. If a leak is detected, you can try tightening the threaded connection. If the leak cannot be eliminated, the mixer will have to be disassembled. Very often it is the O-rings that wear out. Replacing them and cleaning the elements from scale extends the life of the device.

To reduce the wear of the device, it must be periodically lubricated with a special plumbing product.

Common mistakes and problems when installing a three-way valve

Errors made when installing a “tee” not only shorten its service life, but also negatively affect the operation of the entire pipeline:

- Incorrect connection of pipes increases hydraulic resistance.

- The use of models with fluoroplastic seals in systems with operating temperatures above 150 °C will require replacing the three-way mixer after 2-3 months.

- Installation in a hard-to-reach location will complicate preventive maintenance procedures.

Expert advice

- During installation, the brass body is easily damaged. To prevent this, it is better to place a thick fabric gasket under the wrench.

- To install a three-way valve on plastic pipes, special adapters are needed.

- Instead of a “tee”, you can use 2 conventional two-way valves. They must work according to a reverse pattern: when one opens, the other closes.

Mixing types: series and parallel

When all circuits are closed, a bypass with a bypass valve helps supply the pump with flow. The bypass valve is mechanically adjusted to the required pressure, under the influence of which it will begin to function. This option has a significant drawback - the temperature of the coolant at the outlet will be similar to that of the water entering the system (pro

Tips for choosing

The selection of a thermostat model for a water floor depends on several circumstances: the volume of the building, boiler connection, floor covering, environmental climate, availability of additional or main heating systems.

Purchase criteria:

- Price. The most profitable varieties are mechanical type products. They perform better and are almost impossible to damage due to carelessness. Such thermostats are suitable for those who have children.

- Multifunctionality. Electronic products are excellent at controlling heat in rooms.

- Programmability. This criterion allows us to provide the most comfortable conditions in every room of the house.

Mechanical thermostat: operating principle

If the air space in the room is heated to the required level, the working sphere in the bellows expands under the influence of heat, which causes the hydraulic cylinder to straighten. The rod, combined with the bellows, rushes forward, exerting pressure on the hydraulic valve, pressing it closely against the through hole. In this case, the supply of coolant to the battery (heating) stops.

After the remaining media in the heating battery has cooled, the mixture (or gas) in the thermoelement is compressed, causing its walls to shrink, which leads to the opening of the valve. The heated coolant enters the system, then the course of action begins all over again.