During repairs, improvement of a house or cottage, the owner may have difficulty choosing suitable pipes. Emergency situations occur when an old pipeline leaks and there is a risk of flooding. To get rid of such problems, new high-quality communications should be established. In the modern market, metal-plastic pipes for heating are in great demand.

Assembly

In general, there are few subtleties in installing heating with metal-plastic:

- It is best to wrap threaded connections with a steel pipe using plumbing linen with quick-drying paint

(for example, NC). In this case, the flax does not rot or fade; - You can cut metal-polymer pipes with a grinder with any cutting wheel or a hacksaw for metal. I already wrote above about the need for calibration, deburring and chamfering;

- A jumper

is required in front of ball valves or throttles that cut off the radiator . Otherwise, you will begin to regulate the permeability of the entire riser. In an apartment building, neighbors will not hesitate to pay you a visit and protest this technical solution in unparliamentary terms;

- When tightening the nut on the compression fitting, hold its body with a second wrench to prevent disruption of previously installed connections;

- Turns are made using corners, not bending the pipe. With a large bend radius, the liner will look sloppy; with a small radius, you are likely to break the aluminum core of the pipe;

- To connect the liner to the radiator, use American ones

. They will allow you to quickly disconnect the heating device if necessary.

In the photo there is an American woman on the radiator connection.

Tools and materials for laying pipes

Laying metal-polymer systems requires a minimum of devices and materials, but it is better to choose high-quality devices and pipes.

Pipeline installation accessories

To create a structure made of metal-plastic, a very modest set of tools is enough: a pipe cutter, a simple pipe bender, press pliers, a sliding and spanner wrench.

To install a metal-plastic system with your own hands, you need a minimum of tools, which can be purchased in a set or separately from a construction supermarket.

To separate measured sections of pipe from the coil, it is advisable to stock up on a pipe cutter designed for cutting metal-plastic pipes. Since metal-plastic is a fairly malleable material, it can be cut with a hacksaw or even a sharp knife.

However, ideal perpendicularity of the lines, without which it is difficult to obtain a tight connection, can only be achieved by using a special cutter.

Different types of wrenches are important for installing and assembling threaded connections on pipeline fittings. If absolutely necessary, you can get by with one spanner, but for comfortable work it is better to use two spanners and one adjustable wrench.

A gauge is an important tool for creating an accurate and tight connection between a pipe and a fitting: it allows you to center the cut plane and chamfer the inside of the product.

The pipe bender allows you to change the configuration of the element, so you can save on corner fittings

It is especially important to have this tool if the design involves a large number of angular mates

Before starting work, we advise you to familiarize yourself with the rules and specifics of crimping metal-plastic pipes.

What materials will be needed?

To lay the pipeline, it is important to stock up on the following components:

- pipes (coils, measured sections);

- various fitting options (bends, tees, corners), with the help of which individual sections of pipes are transformed into a single system;

- fastening elements - dismountable clamps and clips, with the help of which metal-plastic structures are fixed to supporting surfaces, most often on the wall.

It is important to select all the necessary materials and tools in advance so that you can carry out all the work smoothly. This article will introduce you to the range of metal-plastic products for pipeline assembly.

This article will introduce you to the range of metal-plastic products for pipeline assembly.

Date: September 25, 2022

The use of metal-plastic pipes in autonomous and central heating systems

The use of metal-plastic pipes for the installation of heating networks allows you to save time, effort and money and equip a pipeline that has all the positive qualities of metal and plastic.

To obtain such a result, you must, first of all, understand the differences in the operation of central heating and individual heating:

- In a central heating system, a powerful heat-generating device heats a large volume of water. The heated coolant enters houses and apartments at a temperature of 40 to 95 degrees, but with preventive measures, the water supplied to the pipes can have a temperature of up to 150 degrees. The pressure is usually in the range of 4-5 atmospheres, but since an extensive and branched heating network is serviced, water hammers occur in the pipeline - pressure surges when it exceeds the norm by 2-3 times. For metal-plastic, 95 degrees is the operating temperature limit, and water hammer is a threat of instantaneous destruction of the walls, especially at corners and nodes. Therefore, the installation of metal-plastic pipes in rooms receiving coolant from a centralized system is undesirable. However, the above problems can be solved by equipping the pipeline with pressure stabilizers and temperature regulators.

- A small volume of coolant circulates in an autonomous system; temperature and pressure can be adjusted directly on the heat-generating device. Therefore, in houses, apartments, commercial and other buildings with individual heating, metal-plastic can be used without restrictions.

We recommend that you read: Sealing a chimney using heat-resistant sealant

No. 5. Type of plastic in the inner and outer layer

The following types of plastic are used for the production of metal-plastic pipes :

- cross-linked polyethylene PEX and linear polyethylene PE-RT. They provide pipes with maximum strength, reliability and resistance to various types of loads. Such products better withstand mechanical stress, temperature and pressure changes in the system, and have a long service life. To install a hot water supply or heating system, it is better to take just such pipes;

- low-pressure polyethylene (in the marking of pipes it can be designated by abbreviations such as PEHD, PE-RS, PE or HDPE) is also used in the production of metal-plastic pipes, but significantly narrows the scope of their use. This polymer is not able to withstand temperatures above +750C, therefore it is used exclusively for transporting cold water. In addition, it wears out quickly when exposed to direct ultraviolet rays, so it is advisable to protect the pipes from sunlight. Pipes made of low-density polyethylene are cheaper, but if operating conditions are observed, they can last for decades.

Specifications

Practice shows that metal-plastic pipes with an outer diameter of 16 and 20 mm are in greatest demand. The wall thicknesses of such pipes are, respectively, 2.0 and 2.25 mm. The thickness of the aluminum layer in them is 0.2 and 0.24 mm. The pressure created in the pipe will be determined by its diameter, wall thickness, and the temperature of the fluid passing through it.

Let's look at an example. If you raise the water temperature to 95 °C, the pipe can withstand pressure up to 10 atm, and if the water has a temperature of 25 °C, then the pressure can be raised to 25 atm (1 atm is equal to approximately 105 Pa). Metal-plastic pipes are also designed for higher temperatures (up to 110 °C), but for a short period of time.

Having learned to decipher the markings of metal-plastic pipes, the consumer will be able to independently find out the information necessary to put them into operation. Regardless of additional designations that may be included in the marking, manufacturers must indicate:

- what is the name of the company that produced this product;

— availability of a certificate of conformity;

— marking of the polyethylene used;

- letter designation of the method of cross-linking polyethylene (for example, a - by the pyroxide method, b - using silane);

— the diameter and wall thickness of the pipe must be indicated. They can be indicated in both mm and inches (1 inch = 25.4 mm);

— the nominal pressure calculated for a medium temperature of +20 °C must be indicated;

- followed by an icon indicating or prohibiting the use of a pipe for passing drinking water;

- then, the last inscription is usually associated with the product batch number and the date of its manufacture.

What is taken into account when choosing pipe diameter

Heat generator power. It is taken as a basis and determined individually for each building. What does the owner focus on when purchasing a boiler?

For the total area of all heated premises. This is exactly what the manager at the point of sale will definitely clarify if the buyer has questions about this item.

Coolant speed. If it is less than 0.25 m/sec, then there is a risk of airing the system and causing traffic jams on the highway. Exceeding the value of 1.5 is fraught with “noise” in the highway.

This is especially noticeable when the pipes are metal, and even laid in an open way. But in any case, the movement of the coolant along the route will be clearly audible.

Practice has proven that for a private building (with an autonomous heating circuit) you should focus on an indicator in the range from 0.3 to 0.7. This is the optimal value for any system.

Circuit configuration. In private houses, when installing it, as a rule (regardless of the circuit), all the “threads” are connected to the collector. Each of them is “loaded” with a certain number of radiators.

There is no point in purchasing pipes of the same diameter for all lines, given that the larger the cross-section of the workpiece, the higher the price of 1 running meter.

Pipe diameter. The outer one does not play a special role, since products made from different materials have differences in wall thickness. This parameter only indicates the ease of fastening the product. The internal diameter is about the throughput of the route. It is he who is decisive.

Pipe diameters are usually indicated in inches. For us, this is an unusual (non-metric) system, so you should know the rules for converting quantities. The ratio of inches to centimeters is ½.54 (or 25.4 mm). Pipe material – metal-plastic, steel, PP, PE.

Specifics of the structure. First of all, this relates to the effectiveness of its thermal insulation - what materials it is assembled from, what method is used, and so on.

Selection principle

The set of advantages for both types is quite large. Therefore, when choosing, you should take into account the place where the pipe will pass, so that the characteristics of the material do not affect ease of use:

Polypropylene or metal-plastic pipes

- A metal-plastic pipe “sweats” almost the same as a steel pipe. Sweating structures are not suitable for all rooms.

- Polypropylene is lighter in weight.

- The level of heat resistance of metal-plastic is much higher (up to 110 0C). Therefore, it is good for installing heating, underfloor heating, and hot water supply.

- Metal-plastic is flexible. With pipes in a polymer sheath made of polyethylene, you can install water supply without using corner fittings, simply by bending them.

- Metal-plastic and polypropylene pipes have low resistance to thermal deformation compared to metals, but this indicator is much higher for metal-plastic.

- When installing polypropylene pipes for heating and hot water, compensation loops should be provided due to changes in the size of the pipeline when heated.

For urban pipelines, the response to water hammer during system checks and pressure drops is very important

Polypropylene ones burst in one place and form a leak, while metal-plastic ones delaminate over a fairly large period, although they can withstand much greater loads, this is especially important for supplying hot water and heating. Therefore, when eliminating a leak and replacing part of the water supply system in metal-plastic, you will have to change a larger piece

Types of plastic pipes

Related video: Which pipe is better - PPR, polyethylene or metal-plastic?

Publications on the topic

How and with what to solder plastic pipes

Features of insulation of sewer pipes

Simple and affordable methods for connecting pipes without welding

Review of manufacturers and prices

Metal-plastic products are manufactured in many countries: Russia, Germany, Italy, China, Turkey and so on. The modern market is constantly growing, so manufacturers have to withstand fierce competition. The main goal of companies is to create truly high-quality products that meet all requirements.

When choosing communications, price is of considerable importance, especially if you plan to equip long-distance highways. Metal-plastic pipes for heating can have different prices per meter, which are indicated on the website of the manufacturer or official dealer.

It must be taken into account that the final figure is formed based on the quality of the product and the popularity of the brand that produces the product. For this reason, there are products on the market at prices starting from 600 rubles per meter. Of course, this is an inflated cost, because you can buy pipes for 50 rubles.

Among the available companies, it is worth highlighting Aquapipe and LTM from Turkey and China, respectively. Despite the relatively low cost, the products are of decent quality and meet all standards.

Metal-plastic pipes for heating, price per meter in rubles:

- Valtec - from 70;

- Fado - from 102;

- Golan - from 175;

- Henco - from 35;

- Kermi - from 78;

- Polvax - from 70;

- Rehau - from 165.

Even well-known brands offer affordable prices for their products. It should be borne in mind that the price also depends on the diameter of the product.

Prices for metal-plastic pipes

metal-plastic pipes

Installation

Connecting metal-plastic heating pipes can be done in 2 ways:

Using a compression fitting

The outer part of the pipe is clamped by a collet (O-ring) into which a fitting is inserted (the fitting and collet are equipped with special projections that make the connection reliable). A special nut is screwed onto the outside of the fitting, thereby ensuring a strong connection.

It is important not to overtighten the nut.

The advantages of such connections include the relatively low cost of the fittings, as well as the possibility of their dismantling and reuse (for example, for maintenance of this part of the heating system).

Crimp connection

The disadvantages include the fact that if such connections are installed in a private house, then after several months the nut may loosen. This is due to the cyclical operation of the boiler in a private house (the boiler turns on and off every 2-3 hours). Such cyclicality is absent in apartment buildings, where the heating is turned on once in the fall and turned off once in the spring.

Fittings for metal-plastic.

The fact is that the fitting and the metal-plastic pipe for heating have different thermal expansions, and with high cyclical operation of the boiler, this leads to wear of the sealing rubber, as a result of which the nut becomes loose. In this regard, in order to avoid leaks, the fittings must be periodically checked and, if necessary, tightened.

Important! During the circulation of coolant through the heating circuit, a metal-plastic pipe, like any other, expands. If the connection is not made well, there are cases when the pipe, expanding, may simply fly out of the fitting

At the height of the heating season, this situation will cause a lot of trouble for the home owners. Moreover, an emergency can occur at a time when no one is in the house.

To install the compression fitting, you will need the following:

- Pipe;

- Fitting;

- Scissors for cutting pipes (pipe cutter);

- Pipe bender is a special device for bending a pipe;

Valtec calibrator for metal-polymer and polymer pipes. 16-20-26, with chamfering knives.

- Chamfering device (calibrator). Once the correct size pipe is cut, it must be calibrated (before inserting it into the fitting). For this, a so-called tee is used, onto which a pipe is placed and turned several times in different directions. The protrusions on the tee will chamfer at an angle of 30°, after which the part can be freely put on the fitting. It is recommended to keep the pipe with the hole down to avoid cut parts getting inside the pipe;

- Wrench and gas wrench.

Important! If you do not remove the chamfer, the O-rings may break when putting the pipe on the fitting fitting.

Using a press fitting

Durable, maintenance-free connection. To create it, you need a special press, with which the sleeve is pressed into the surface of the pipe. The press has special nozzles with ring protrusions that make the connection reliable.

Crimping

Advice! Many people refuse crimping only because there are no press pliers. Today, almost every plumbing store provides tools for rental. The rental cost is about 300-400 rubles/day + a deposit is required.

Valtec VTm.293 manual radial press jaws. Weight without attachments – 4.76 kg. Cost – 9400 rub.

In addition to increased reliability and tightness, press fittings have a beautiful aesthetic appearance, so many people lay metal-plastic pipes for heating externally, without fear of spoiling the interior of the room.

The disadvantages of press fittings include their high cost compared to compression fittings. And also the fact that the connection obtained in this way is not detachable. It is no longer possible to twist such a fitting.

Tools for working with metal-plastic pipes

To install the fitting you will need:

- Pipe;

- Fitting;

- Scissors for cutting pipes (pipe cutter);

- Pipe bender;

- Manual or electric press pliers;

Important! When installing a metal-plastic pipeline on a wall, the distance between the fasteners should not exceed 0.5 m. If you ignore this recommendation and make the gap larger, this may lead to sagging of the pipe during operation, which in turn will disrupt the hydraulic characteristics of the heating system

Fitting

This is the name given to the pipeline elements with which pipes are connected and branched. Despite the plasticity of the material, one-piece fittings are produced, with the help of which complex structures are fastened. At the moment, metal-plastic connecting elements are widespread, since in most cases this modern material is used to create heating systems. All fittings are classified according to the method of fixation.

Detachable

This type of connecting elements is used by many professionals. Its advantage is that in the event of a breakthrough in the system, it is not necessary to dismantle part of the communication for replacement. Fittings provide a more reliable connection compared to soldering or welding.

This is explained by the linear expansion of the material: when heated or cooled, it accordingly increases in volume or returns to its original state. If soldering was used, then these properties of the system can become the main problem, because the likelihood of violating the integrity of the joint increases. By working with fittings, such situations can be avoided.

Due to the fact that these connecting elements are reusable, they are called detachable. The key structural part is the collet, which looks like an O-ring. It is through this element that the required level of tightness is achieved. In addition to the collet, the fitting design includes a ferrule ring and the body itself, which is made of brass.

Press fitting

It is used indoors, since the elements do not withstand frost well, which significantly reduces the service life of the fittings. Installation outdoors may cause an emergency on the pipeline section. To install such a structure, a special tool is used - pliers, with which the ends of the pipes are compressed. Press fittings are produced monolithic. Their design consists of a body, a fitting and a sleeve with a gasket.

One point needs to be taken into account - press fittings are a disposable connecting element, therefore they are most often used when installing a “warm floor” system and laying communications in the walls.

To connect pipes where the pressure can reach 10 bar, these fittings are used, because they are made of durable material. As experts assure, if you follow the installation rules, the connecting element can last about 50 years.

Crimping

The main advantage of this type of connection is ease of installation, so each owner can do the installation with their own hands. But you need to take into account that such fittings are short-lived, since their design uses a rubber seal. The element itself is quite expensive and cannot be monolithic (installed into the wall).

Crimping parts have optimal technical characteristics suitable for arranging water pipelines. You don't need to use special tools to make a reliable and durable connection.

The use of metal-plastic pipes in autonomous and central heating systems

The use of metal-plastic pipes for the installation of heating networks allows you to save time, effort and money and equip a pipeline that has all the positive qualities of metal and plastic.

To obtain such a result, you must, first of all, understand the differences in the operation of central heating and individual heating:

- In a central heating system, a powerful heat-generating device heats a large volume of water. The heated coolant enters houses and apartments at a temperature of 40 to 95 degrees, but with preventive measures, the water supplied to the pipes can have a temperature of up to 150 degrees. The pressure is usually in the range of 4-5 atmospheres, but since an extensive and branched heating network is serviced, water hammers occur in the pipeline - pressure surges when it exceeds the norm by 2-3 times. For metal-plastic, 95 degrees is the operating temperature limit, and water hammer is a threat of instantaneous destruction of the walls, especially at corners and nodes. Therefore, the installation of metal-plastic pipes in rooms receiving coolant from a centralized system is undesirable. However, the above problems can be solved by equipping the pipeline with pressure stabilizers and temperature regulators.

- A small volume of coolant circulates in an autonomous system; temperature and pressure can be adjusted directly on the heat-generating device. Therefore, in houses, apartments, commercial and other buildings with individual heating, metal-plastic can be used without restrictions.

We recommend that you read: Welded air ducts made of black steel

General requirements for the operation of pipeline systems

During operation of pipe products made of metal-plastic, the following requirements must be observed:

- Heat sources with a heating temperature higher than +150 ºC should not be placed in close proximity to metal-plastic heating pipes.

- In case of fire, use sand to extinguish.

- Periodically inspect the joints of parts and, if necessary, tighten detachable connections.

- Do not use metal-plastic pipes for external communications; system wiring in unheated rooms must be protected from heat loss.

No. 8. Metal-plastic pipes for heating

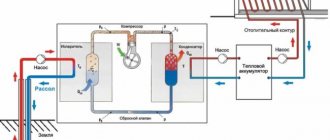

In centralized heating systems, the pressure can rise to 4 atm, in autonomous ones it rarely exceeds 1-1.5 atm. The coolant temperature is about +70 0 C, sometimes it rises to +90 0 C (if you use, then this parameter can easily be adjusted). This once again convinces us that metal-plastic pipes can be used to organize a heating system.

The only limitation

, which is present in this case, is the need to maintain positive temperatures in the house. The linear expansion of such pipes is minimal, so if the water in them freezes, the metal-plastic will tear. That is why it is used to organize heating in constantly heated rooms.

If used where overheating of the coolant is possible, it is better to install a heat accumulator, otherwise with frequent temperature increases above +100 0 C the pipes may leak.

No. 1. Performance

Of course, some of the performance qualities of metal-plastic pipes may differ depending on the materials used in production and their thickness, but most products currently sold have the following characteristics:

- maximum water temperature inside the pipe +950C;

- at a temperature of about +950C, the maximum pressure that the pipe can withstand is 10 atm;

- at water temperatures up to +250C, the maximum operating pressure can reach 25 atm;

- the pipe can withstand a short-term increase in the temperature inside it up to +110...+1300C.

Fittings for installation of heating systems based on polypropylene pipes

For the installation of a heating system based on polypropylene pipes, the following products are used:

- Couplings. Couplings are available: straight, transitional, with steel threads (both internal and external). They are designed both for connecting pipes by soldering, and for connecting steel or metal-plastic pipes to polypropylene pipes. They are also suitable for connecting shut-off valves and heating devices.

- Transition couplings.

- Taps and valves. They also come with or without metal threads. They are installed on heating devices, as well as main circuits, so that they can be turned off for repairs and preventive maintenance.

- Crosses and tees. Similarly, like couplings, they can have soldered or combined connection threads. Required for connecting multiple pipes.

- Corners. Used to connect pipes at right angles.

- Plugs. Used to close temporarily unused connections.

Before you start purchasing fittings, you need to make a drawing of the entire system indicating all its elements, their sizes, diameters. Only in this case can you accurately determine how many and what connections you need to buy.

Types of installation of heating systems in a private home are:

- Single circuit system. In this arrangement, all radiators are connected in series. In this case, the total length of the pipes and the number of connecting elements required is minimal. There is one big drawback in such a system - the further “along the pipe” the radiator is installed, the less it will heat up. Therefore, the heating of rooms in the house will be uneven.

- Double circuit. This system is the most popular. Each radiator is connected to two circuits: “supply” and “return”. Thanks to parallel connection, each radiator has the same heating temperature.

- Multi-circuit. With this system, the room has several heating circuits, which are connected using a heating manifold. With such a system, it is possible to regulate the supply of coolant to each circuit, thanks to which energy resources can be used more optimally. This system requires a large number of pipes and connections.

- The design of heating systems for a private home should be carried out by specialists. Otherwise, there is a high probability of building a system that will not meet the requirements of the heated room.

Polypropylene or metal-plastic - subtleties of choice

When choosing a heating system, homeowners are guided by the price of materials and the cost of installation work, which together gives the total cost. This factor plays an important role, which is quite natural given the current income of citizens. In this regard, PPR is better than metal-plastic, since it will cost at least half as much. If you take high-quality materials produced by well-known brands, then metal-plastic will cost three times more.

Advice. If you have a rather limited budget, then there is only one choice - to use PP-R pipelines and fittings for heating. But remember that welding must be done very carefully and efficiently. Corrections and alterations will increase the cost or take a lot of time if you solder PPR pipes yourself.

It is impossible not to touch upon the technical characteristics of metal-plastic and polypropylene. The most important are the operating maximum permissible pressure and water temperature in the pipeline. These parameters are interrelated, for example, a PP-R pipe will withstand a pressure of 10 Bar at a coolant temperature of 60 °C, and at 95 °C the pressure drops to 5.6 Bar. The higher the operating temperature, the shorter the service life of polypropylene, as shown in the table:

Note. Technical data taken from the website of a well-known Czech manufacturer of PP-R products sold under the WAVIN Ekoplastik brand.

For comparison, let’s take the equally famous Belgian brand Henco, which offers high-quality metal-plastic pipelines reinforced with a solid layer of aluminum. Its operating characteristics are as follows: at a temperature of 95 °C, the maximum operating pressure is 10 Bar, and for some modifications of pipes it is 16 Bar. The given technical characteristics should be taken into account when choosing a material. It is also important to understand where its operation will take place:

- heating a private house;

- centralized heating system for the apartment;

- boiler room;

- warm floor.

Polypropylene is not used for water heated floors, only metal-plastic or cross-linked polyethylene.

Although some manufacturers (Valtec, Ekoplastik) have begun to produce polypropylene pipes for heated floors, metal-plastic remains the leader in this area. It is better in all respects, including heat transfer. PPR heating circuits transfer heat worse “thanks” to the large thickness of the pipeline walls.

What is better for a private home

For radiator heating of small country houses, both plastics are suitable, although polypropylene is preferable in terms of price. In a small building the system is simple, the number of joints is small. If open laying of highways is planned, PPR will be a good solution. But we repeat the warning: high-quality installation is required.

Advice. If you decide to hire a team of performers, follow the advice of an expert and ask the foreman how they will solder connections in hard-to-reach places and withstand the heating time, checking the table:

Owners of cottages with several floors are recommended to turn their attention to metal-plastic. As a rule, such houses are built by developers with high requirements for the interior and the reliability of all engineering systems. Polypropylene manifolds and wiring will definitely not be able to meet these requirements due to difficulties with hidden gaskets. Metal-plastic can be safely installed under the floor and in other problem areas.

Polymers and central heating

The peculiarity of centralized heat supply is that the parameters of the coolant are unknown and can often reach maximum values. Despite this, many plumbers suggest that apartment owners install polypropylene for central heating, laying it in the grooves of the walls. Such solutions are risky; the material may not withstand a pressure drop or temperature jump and leak at the junction.

The optimal solution for an apartment is metal-plastic with press connections; PP-R is best installed on the water supply. Judge for yourself: apartment wiring cannot be called complicated or too long, so you won’t feel a big difference in price. But metal-plastic will give you reliability and durability, plus it can be hidden in a wall or floor, making the interior of the rooms more attractive.

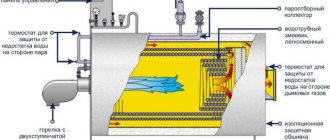

Boiler room wiring

The piping of boilers and other thermal power equipment can be done with either polypropylene or metal-plastic. But there is a peculiarity here - the presence of a large number of turns and connections. It is difficult to do the wiring yourself using any polymer pipes, except that in the boiler room there is 1 wall-mounted heat generator that works only for heating. But even here everything needs to be done beautifully so that the pipes do not run at random.

An example of a beautiful PP-R wiring, the manifold is also welded from polypropylene tees

If a solid fuel boiler is used to heat a private house, then you can use polymers for its piping, but be careful. This means that some areas will have to be made of metal, for example:

- a piece of pipe from the heat generator to the safety group, when it is installed separately;

- the area where a surface-mounted temperature sensor working with a three-way valve is attached to the return line.

There is an opinion that only pellet boilers can be wrapped with polypropylene, and wood-burning boilers can only be wrapped with metal. This is not true; in the event of an emergency overheating, boiling water will still have time to enter the heating system and melt the plastic pipes. Several meters of steel pipelines laid in the boiler room will not save you from this.

How to choose pipes for use in a central heating system

Nowadays there are many brands of metal-plastic pipes intended for space heating systems on sale.

However, choosing to advise a specific brand is not always correct; you should always pay attention to the technical characteristics of the product, that is, to the declared operating parameters of pressure and temperature in the system. It goes without saying that the higher the latter, the better.

The next question is what diameter of pipes to choose. Let's say right away that it should be larger than that of the same steel pipe that could be installed in this place. So, for risers, pipes with a diameter of 32 or 26 millimeters are taken, but 26 mm products can also be used for connections to radiators. The thing is that the marking of a steel pipe (DU) is a conditional diameter, which usually corresponds to the internal diameter. While for metal-plastic pipes the outer diameter is taken into account. This means that the useful cross-section of the latter is reduced taking into account the wall thickness.

Flaws

- High cost of fittings.

- The passage opening of the fittings is narrowed, which negatively affects the hydraulics of the heating system.

- When the coolant freezes, there is a high probability that the pipe will burst. Therefore, it is not recommended to use metal-plastic outdoors, even despite the fact that many manufacturers guarantee the product’s ability to withstand several cycles of water freezing.

Important! If the coil has just been brought indoors from the cold, then before you start unwinding, it should be allowed to sit (at a temperature of +10°C and above) for at least 5-6 hours and only after that you can start working.

Press pliers, calibrator, pipe cutting shears.

Do-it-yourself heating in a private house from polypropylene pipes

The main components of heating are a heat generator, pipes and heating devices. The rest of the equipment ensures the system operates under various loads. Equipping the system with additional elements depends on the size of the house and the modification of the selected boiler. The specified operating parameters of the unit are ensured by a safety group, an expansion tank with an overflow pipe, a supercharger and a pressure control device.

If the circulation pump is not built into the boiler circuit, then the blower is installed on the return line of the pipeline, in the immediate vicinity of the heat generator. The installation location of the closed type expansion tank for heating is in front of the circulation pump. The safety group is mounted on the supply line near the boiler.

How to connect with clamp fittings

For high-quality assembly of a metal-plastic pipe system, it is necessary to use not only the highest quality materials, but also professional tools. If you try to make do with cheaper materials, it will be quite difficult to ensure that there are no leaks. As a result, the system will not withstand even several years of operation. High quality tools and good use of them are the key to reliable assembly.

To work with communications you will definitely need:

- Shears for pipes made of metal-plastic or plastic

- Shaver for shaping the seat and chamfering

- Open-end wrenches in assortment

Old-style shavers were used not only to chamfer, but also to calibrate pipes. However, because of this, the fittings, even in the highest quality pipes, were not tight enough, not providing the necessary reliability of the connection. Modern tools only remove the chamfer and give the desired shape to the contour.

If installed incorrectly, after two to three years of use, the pressed fittings have to be tightened due to leaks. When installing heating, the following points must be taken into account:

- For cutting, you need scissors suitable for pipes of a certain diameter. After using any type of hacksaw, rough edges remain on the cutting line. Even after cleaning it is impossible to obtain a completely flat surface. Scissors leave an even and smooth cut

- Before installing the fastener, you must remove the chamfer. Otherwise, the sealing gaskets on the shanks may break. New types of shaver should also be used

- When installing a collet seal, you need to carefully monitor the behavior of the collet. If the joint is pinched, this ring can be squeezed into the gap between the contour and the nut. As a result, the ring will pinch the thread

It is not recommended to save on materials or rush, then the quality of the heating circuit will ensure its long-term and reliable operation. In the future, when using the system, mechanical loads should be avoided. This is especially true if there are children in the house.

The advantage of using metal-plastic is ease of installation. But to achieve a certain level of quality, you need to hire professional performers or purchase high-end instruments, which are quite expensive. But if you do not do this, you will have to regularly, before each heating season, devote time to inspecting, repairing and adjusting the system.

Advantages over others

Metal-plastic pipes are especially durable and efficient. When wondering where to buy metal-plastic pipes for heating, you must remember that you need to pay attention to the main positive qualities of the product provided by each manufacturer:

- Metal-plastic pipes are not subject to corrosion, deposits and blockages do not form on them. The smooth inner surface is not subject to oxidative processes. The material does not change its state, and the composition of the transferred liquid does not change throughout its entire service life.

- Resistance to aggressive environments on the outer layer.

- The formation of silt and growth in the inner part of the pipe are excluded even after 10 years of operation.

- Easy to use. Installation of metal-plastic pipes is considered one of the simplest, since they are quickly attached without causing difficulties, bend easily, and are highly resistant to damage during installation. Their light weight is noted, which helps speed up the work on fixing pipes.

- Wear resistance. The inner surface is very durable and therefore does not deform even at high speeds of movement of the working medium.

- Efficiency. Polymer materials used in the production of metal-plastic pipes have a much lower thermal conductivity coefficient than metals, so heat loss is minimized.

- Small number of connections. The elasticity and flexibility of the pipes is characterized by the highest rates, therefore, to avoid corners and irregularities on the surface, the use of additional fittings will not be required, which significantly increases the reliability of the entire system.

- During the installation of metal-plastic pipes, a minimal amount of waste is generated.

- Heating pipes are sold in coils, so the consumer can measure the necessary parameters of the material in advance, and the seller will cut the footage specified by the buyer.

- A standard set of tools is required. Without additional processing or restrictions, the pipes can be placed under the screed, that is, after installation, they can be filled with concrete.

- Repairs can be carried out without the use of professional pipe bending and welding equipment, so the owner, having the necessary knowledge, will be able to carry out repair work independently.

- Low price. The purchase of equipment and labor costs for workers cost a small amount, since the cost of the raw material and the time spent on installation are small.

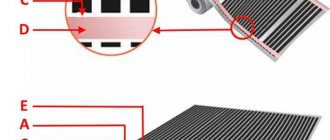

Design features

The technical characteristics of metal-plastic pipes for heating are based on the use of polymer materials. For their production, cross-linked polyethylene is used. But since it does not have the required degree of rigidity, an additional layer of foil is installed to give the products the required properties.

The technology for creating metal-plastic pipes allows them to be produced with different diameters. For this, an extrusion method is used, which consists of attaching an internal and external polyethylene layer to an aluminum base. A special adhesive composition is used as a binding component.

The inner layer has high strength, heat resistance, it does not oxidize, and salts do not accumulate on its surface. Due to the fact that the central element of the design is aluminum, these pipe products are hydraulically resistant. Since the metal is protected on both sides by polymer, it is not affected by negative external influences.

If you lay a heating system from metal-plastic pipes, then with high-quality assembly it will last a long period.

Rules for installation of metal-polymer structures

When laying metal-plastic systems, it is important to be guided by the following provisions:

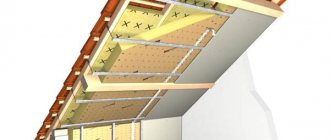

When laying hidden pipelines from this material, it is important to provide removable shields (hatches) that are free of sharp protrusions. They provide access to compression fittings. It is important to lay systems through building structures using sleeves whose internal diameter is 0.5-1 cm larger than that of the pipe. The gap that forms between the elements must be filled with soft, non-flammable material that allows the pipe to move in the longitudinal direction. When laying metal-plastic plumbing or heating systems, it is important to avoid damage to the surface of the elements, including scratches or cuts

To unpack the bay, it is better to avoid sharp objects and mark the structure with a pencil or marker. Installation of the structure can be carried out using a support or suspension, which are usually present in the range of manufacturers of metal-polymer pipes. They help to attach products to the wall, while metal parts are installed with spacers made of soft material.

The gap that forms between the elements must be filled with soft, non-flammable material that allows the pipe to move in the longitudinal direction. When laying metal-plastic plumbing or heating systems, it is important to avoid damage to the surface of the elements, including scratches or cuts. To unpack the bay, it is better to avoid sharp objects and mark the structure with a pencil or marker. Installation of the structure can be carried out using a support or suspension, which are usually present in the range of manufacturers of metal-polymer pipes

They help to attach products to the wall, while metal parts are installed with spacers made of soft material.

All stages of operations must be carried out carefully and carefully, since metal-plastic elements are sensitive to ultraviolet radiation and mechanical damage. External installation of such structures is appropriate only in places where there are no such factors.

Installation process

As we said above, most negative reviews about metal-plastic pipelines are associated with errors made during installation of the system. Therefore, before starting the actual installation, you need to study the manufacturers’ recommendations and read the instructions for installing the heating circuit from the products in question.

Before installation begins, a diagram of the future highway is drawn up. The location of the threads and other necessary components is placed on the house plan. After this, they calculate the volumes of materials that will be required to solve the problem.

The step-by-step installation looks like this:

- A piece of pipe is cut off with scissors.

- The calibrator is used to align the inlet pipe for connection to the fitting.

- The press fitting is mounted and clamped using crimping pliers.

If you have purchased high-quality metal-plastic pipes, it is permissible to use a spring pipe bender. In this case, the minimum bending radius must be carefully observed. It directly depends on the cross-sectional index of the product.

Useful tips for soldering polypropylene heating pipes

Important tips and tricks to follow:

- When the pipeline passes through a wall, it is necessary to provide for the presence of steel sleeves. They will protect polypropylene from mechanical damage.

- On straight sections of pipelines longer than 5 meters, it is necessary to provide expansion joints.

- When soldering stopcocks and valves, it is necessary to think through their position in advance so that they have free and full movement. This is a very common mistake for beginners.

- Don't forget about the clip brackets that will support the welded pipes. They should be installed in advance.

- If you are not sure of the quality of the welded seam, it is better to cut it off and redo it. Carrying out work on a finished system in the event of a leak will be problematic.

- When joining heated elements, it is necessary to take into account the joining marks on the parts. After connection, their position can be adjusted by 1-2 mm.

Installation of heating from PP pipes

Heating installation

Installation of a heating system that uses polypropylene heating pipes does not require serious physical effort or time.

In this case, the following requirements for tools and parts must be observed:

- Installation work must be carried out at a temperature of at least 5°;

- Before work, ensure that the material is free of contamination and damage;

- Do not expose elements made of polypropylene to open fire;

- Threading is not allowed on polypropylene elements;

- Polyfusion welding is performed using an electric welding machine with nozzles;

Scissors for cutting PP pipes

Special scissors are used to cut pipes.

Compensator

You should also talk about a rather important detail that is part of the heating system made of polypropylene pipes - the compensator. The main function of the compensator is to compensate for the thermal expansion of the PP pipe

It should be remembered that using a compensator can be dangerous for the entire heating system.

Installing the compensator in the position shown in the figure above leads to the accumulation of air in its upper part, which will lead to the cessation of water circulation in the system and its irreparable breakdown.

Therefore, the compensator should only be installed with the hinge facing downwards to avoid air trapping.

Before starting installation, the welding machine should be heated to a temperature of 270° in order to obtain a homogeneous, high-quality seam.

The main stages of installation of a heating system made of polypropylene pipes

- First of all, measure and cut the required length of the pipe. In the case of welding a foil pipe, the middle and top layers are removed (the size of the removed layer is equal to the insertion depth of the fitting);

- The end of the pipe is cleaned of burrs;

- A marker marks the depth of complete insertion of the fitting. To prevent narrowing of the passage, leave a 1-mm gap between the end and the protrusion of the fitting;

- Using a marker, mark on the surfaces of the pipe and fitting the place where they are connected to each other;

- The pipe and fitting are placed on the welding machine and both parts are heated simultaneously;

- After sufficient heating of the elements, they are connected to each other in accordance with pre-made marks. In this case, it is necessary to control distortions in the radial and axial directions;

- Cooling of the seam lasts from 10 to 30 seconds, which makes it possible, if necessary, to make minor corrections to the connection;

- The connection of the remaining pipe components is carried out similarly. It is advisable to determine the order of their connection in advance, which can significantly speed up the work.

Knowing how polypropylene heating pipes are installed, you don’t have to worry about the efficiency and reliability of the heating system. In addition, you can be sure that the use of a heating system made of polypropylene pipes will provide a cozy and warm atmosphere in the house for many years.

conclusions

General conclusions can be drawn as follows: if you use high-quality materials and have “direct” hands, metal-plastic pipes can be used for heating. Moreover, even with their shortcomings, they behave better than steel in heating systems. But this is true only for high-quality “branded” materials and for systems in which the coolant does not heat up above 95°C. With centralized heating, such temperatures simply cannot exist, so metal-plastic can be safely used. With individual heating, there can be no problems with automatically controlled boilers: you can set the temperature of the coolant in them. And if so, then set it to 85-90°C and reinforced polypropylene (PP or PP) and metal-plastic (MP) will feel great.

It will be more difficult with plastic pipes in systems with solid fuel boilers: if overheating protection is not installed, the coolant may be above 95°C. Some super-high-quality MP and PP pipes tolerate infrequent exceedings of the limit. But it is precisely “tolerated” and “infrequent”. To equalize the temperature in the system with a solid fuel boiler, you need to install heat accumulators. They absorb “excess” heat in maximum combustion mode, and then release the accumulated heat when the boiler goes out. With such a device, in this case you can install plastic.

Heating system diagrams

Select the optimal pipe layout for self-installation of polypropylene heating. In the future, you will receive recommendations for connecting individual elements and place them in accordance with the chosen plan.

Single-pipe scheme

Single-pipe scheme

The simplest method of arranging a heating system. In accordance with this wiring method, each battery installed further from the heating unit will heat up to a lower temperature compared to the previously installed battery.

This method makes it possible to reduce the consumption of materials for the arrangement of the heating system. However, the heating efficiency will be low, because The temperature distribution with such pipe routing is uneven.

In view of this, you should try to refrain from a single-pipe pipe routing scheme.

Collector circuit

Collector circuit

To equip a heating system according to this scheme, you will have to spend more materials, however, the basic operational properties of such heating will be much higher.

Heat distribution throughout the rooms will be fairly uniform and high quality.

Two-pipe system

Two-pipe system

The most optimal method of arranging a heating system. The pipes are laid into the floor or into the walls of the house around the perimeter. Two-pipe heating is best suited for heating a home. Therefore, experts recommend giving preference to this particular pipe routing option.

Comparison with analogues

If we consider heavy all-metal communications, then metal-plastic pipes for heating systems are in a more advantageous position, firstly, due to their low weight, and secondly, due to their resistance to aggressive environments, in particular, to the formation of corrosion. Additionally, these factors are the reason why metal-plastic pipes of different sizes for heating systems are much easier to install, since it becomes possible to work without anyone’s help.

Watch the video and compare with analogues:

https://youtube.com/watch?v=7j6sJra-Dqc

Even if someone points out the need to clean such products as a disadvantage, the counterargument on this issue is the short duration and simplicity of this operation. To connect individual sections of the pipeline, it is enough to have at your disposal a special soldering iron for this material.

Installation of a heating system with metal-plastic pipes

Metal-plastic products are connected using three types of fittings:

- - detachable (threaded or collet) - the connection can be disassembled and then reassembled;

- - conditionally detachable (compression - can be disassembled, but during assembly it is necessary to replace the crimp ring);

- - one-piece (press) - requires an expensive press, can be embedded in walls or floors.

Required tools for installation

- — scissors (pipe cutter);

- — calibrator;

- — pipe bender (internal or external spring);

- - adjustable wrenches;

- - Teflon or fum tape (for sealing threaded connections).

When assembling, you must follow some rules

- — open laying is carried out after finishing work;

- — the ambient temperature should not be less than +5°C;

- — it is better to cut the material with a special tool;

- — when bending, fracture of the internal aluminum layer is not allowed;

- — the pipeline is attached to the surfaces using clips;

- — during installation it is necessary to leave a reserve for thermal expansion;

- — when using threaded connections, care must be taken not to pinch the material when tightening the nut.

Before installation, you need to cut the sections in accordance with the diagram. If you don't have a pipe cutter, you can use a hacksaw, but the edge may end up uneven. Then, using a calibrator, the ends are returned to a round shape.

To bend the elements, use a pipe bender or a spring. The spring can be external or internal. The use of a tool prevents the aluminum from breaking at the bend. If the bending radius is less than 7 diameters, it is better to use a fitting.

Heating system made of metal-plastic pipes with compression fittings. To create compression connections, no special tools are required. You can purchase a variety of fittings - adapters, angles, tees, crosses. All of them are equipped with a fitting with an O-ring, a union nut and a clamping ring. The pipe must be put on the fitting, the clamping ring must be installed and the union nut must be screwed on.

How to identify a fake

When installing pipelines, it is very important to use high-quality pipes, which will allow the system to last for decades. Counterfeits are simply not able to withstand the existing loads; after 2-3 years they can leak. In addition, in low-quality products, the aluminum layer deteriorates over time, which can also become a problem.

A few tips to help you spot a fake:

- The pipes must be accompanied by a certificate. Of course, if there are documents, this does not mean that the product is 100% high quality, but if they are not there, this is a reason to think about it. If the supplier is conscientious, he must attach to each batch a corresponding document indicating the originality of the products.

- Visual characteristics. The marking and appearance of the pipe must be the same as indicated on the manufacturer’s website. You need to be vigilant when purchasing products.

- Pipe cut quality. If the aluminum is butt welded, everything is fine, but if the seam is made “overlapping,” the product is of low quality. You also need to pay attention to the thickness of the aluminum - it should be identical throughout the entire diameter. The same applies to the outer and inner layers.

By adhering to these rules, the likelihood of buying counterfeit goods can be minimized. The key to the efficiency of a heating system is properly installed high-quality pipes.