Boiler room in the garage: is this option possible? This question interests many owners of this utility room. In principle, it can be resolved positively, because modern boilers, if all requirements are met, are considered safe; their installation is allowed even in basements and attics. Another thing is that amateur performance should not be allowed, but standard equipment should be used. Otherwise, such installations can lead to big trouble. In addition, most types of boiler rooms are installed if permitted by the relevant organizations.

Which furnace gas industry will accept without complaints: 11 recommendations to avoid problems with connection

Why is the boiler room actually a furnace room, how to design it and what to equip it with

Heating the house from the main house is the cherished dream of many country residents. The “heart” of such a home is the room where the gas boiler is installed. What requirements do gas services place on a boiler room? And how to design a furnace so that it is approved by the gas industry? We have selected key recommendations from the new Code of Practice and will tell you about them in this material.

What materials and equipment should be in the furnace room?

Everything is written in the Code of Rules:

- The wall-mounted gas boiler in the combustion chamber must be located at least 20 mm from the walls (back and side) made of fireproof materials.

- Walls made of non-combustible materials must additionally be insulated with non-combustible materials that do not support combustion and the spread of flame. In this case, the boiler is located at a distance of 30 mm from the wall. The insulation should extend beyond the dimensions of the equipment by 100 mm on the sides and 0.7 m on top.

- If a gas boiler is placed on a wooden floor, it must be insulated with fireproof materials. The fire resistance limit of the material is at least 45 minutes. The floor insulation must protrude beyond the dimensions of the equipment body by at least 100 mm. Install the equipment in the furnace so that there is easy access to it for operation and repair.

How should a furnace room with a gas boiler be ventilated?

The dimensions of the exhaust and supply channels are determined by calculation based on the following parameters:

- Ventilation of the combustion chamber occurs naturally.

- The hood should provide three air exchanges in the room in 1 hour.

- The inflow is equal to the exhaust volume + the air required for gas combustion.

In which direction should the door from the furnace open?

The door from the room where the gas boiler is installed must open outward.

What size window should be installed in the furnace room?

The window in the furnace room is made on the basis that the glazing area, and not the entire window with frame, is at least 0.03 square meters. m per 1 cubic meter of room volume. Moreover, the window design must meet the requirements set out in GOST R 56288 “Easily removable window structures with double-glazed windows for buildings”

. In short, the window, in the event of a gas explosion in the furnace and exposure to a blast wave, must, under the influence of pressure, open outward. For example, a sash rotates around its axis, or a double-glazed window, or a frame with a double-glazed window moves and falls out.

Where should gas boilers not be placed?

It is not allowed to install gas-using equipment in bathrooms and toilets.

Is it possible to install a gas boiler in the basement?

First, let's define the terms: “basement” and “ground floor.” So,

- Basement floor

- a floor where the floor level of the premises is below the planning level of the ground by no more than half the height of the room. - Basement floor

- a floor where the floor level of the premises is below the planning level of the ground by more than half the height of the room.

SP 402.1325800.2018 states that heat generators running on natural gas can be placed in the basement and basement floors of residential buildings.

Is it possible to install a gas boiler in the kitchen if there is already a gas stove there?

In the kitchen, you can install a gas stove, and hang a modern gas boiler on the wall, for example, a condensing boiler, which goes well with low-temperature heating systems - liquid heated floors. But there are a number of important limitations:

- If the kitchen has a two-burner gas stove and a gas boiler with a closed combustion chamber

, the volume of the room must be at least 8 m³, with a ceiling height of at least 2.2 m. - If a four-burner gas stove is installed in the kitchen, you must admit, this is what is done in most cases, and a gas boiler with a closed combustion chamber is installed, then the volume of the room must be at least 15 m³.

- If there is a gas stove in the kitchen and a gas boiler with an open combustion chamber hanging

, then another 6 m³ is added to the above-mentioned room volumes.

The kitchen should be ventilated using an exhaust system through a window with a window. If the kitchen has a door, then a gap of at least 0.02 square meters is made between it and the floor for air flow. m.

The volume of the combustion chamber must be at least 15 m³, right?

SP 402.1325800.2018 contains clause 5.5. In short, it says - the volume of the combustion chamber must be at least 15 m³, with a ceiling height of no less than 2.5 m.

Is it true that a ceiling height of 2.5 m is required for a gas boiler?

Due to changes in SNiPs and Codes of Regulations of different editions and different years, confusion arises as to what the height of the ceilings in the furnace room should be. Let's turn to SP 402.1325800.2018. It states that the ceiling height in a separate room where a gas heat generator is installed must be no less than 2.5 m, provided that the boiler is operated with an open combustion chamber

.

Gas boiler room, boiler room and furnace room, are they the same thing?

Many are accustomed to calling the premises in private residential buildings where gas heat generators are installed - boiler rooms or boiler rooms. This is not entirely correct. A boiler room is, most often, a separate facility where engineering equipment is located, which generates heat for multi-storey residential buildings and complexes, as well as commercial and industrial buildings. Boiler rooms are subject to more stringent requirements than conventional furnaces.

for cottages.

The combustion room is an individual room where there is a gas heat generator that produces heat for a private home.

SP 402.1325800.2018 has the following description: a heat generator room is a separate non-residential premises where a boiler and additional engineering equipment are installed. Therefore, below, we will call the boiler room the furnace room.

Types of heating devices

Heating gas is used in the following ways:

- Full heating with boiler. It heats the water circulating through the pipes. Gas service workers themselves must connect the system to the main wire. To do this, you will need to sign the relevant documents and pay the price for the insert.

- Boiler for heating air. Heating in this case is carried out using a heat gun. With this method, the gas burns out in a burner, and heat fills the room through a fan.

Gun for organizing garage heating

- Condensing boiler - economical heating of a garage space. The efficiency is approximately 10% greater compared to conventional gas ones.

The first method is the most difficult, since it takes time to collect, prepare documentation, create a project, and install heating. In addition, you should select, buy, and install a boiler.

For the second method, no special equipment is needed; it is enough to use liquefied gas from a cylinder.

Gas-burner

A burner is an easy way to heat a garage; it is the most affordable method that helps maintain a comfortable temperature in a small room. The burner is easy to operate and meets heating needs even in winter.

There is no need for a chimney under the burner, because during operation it does not release harmful impurities into the space. But a constant supply of fresh air is important.

The burner is an infrared heater, so the heating does not spread in a narrow direction. This is extremely convenient if you need to stay warm and quickly warm up your work area. For uniform heat distribution, you will need to wait about 30 minutes - depending on the power of the device. Fuel consumption (in this situation, gas) is minimal. One cylinder is enough for several days of operation of the device.

Article on the topic: How to draw a garage project

Gas-burner

Do not leave the burner on unattended. In other cases, this is a simple, accessible and economical method.

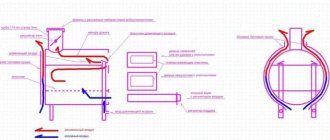

Gas gun

A good heating method is using a gas gun. You just need to choose the right power of the device, this will allow you to maintain highly efficient heating.

The principle of operation of the gun is similar to the operation of a hair dryer. The basis of the device is a fan, the degree of heating is changed by a thermostat located on the body. The fan helps create a directed flow of air passing through the heating element. The heated air flows out, and the gun absorbs a new portion to warm up.

For garages, it is better to purchase a mobile cannon with wheels so that you can always move it to the right place. When using, please note that the device should not be constantly turned on. The garage only warms up to the desired temperature, then the gun is turned off. An important advantage of the device is its efficiency, because only 500 ml of liquefied gas is consumed per hour.

For maximum efficiency of the device, it is important to decide on the choice of a model that is suitable in terms of power. The performance of the device is calculated: 1.4 kW of power for every 10 square meters of room area, if the ceiling height is approximately 2.5 m. Typically, 3 kW of power is enough for a standard garage.

If there are often frosts in your region of residence, you should buy a gun with a capacity of 5 kW. The disadvantage of the device is poor environmental friendliness, because during combustion it releases toxins into the environment.

Gas heater

A heater that runs on bottled or natural gas can be mobile or stationary. Mobile devices are small in size and benefit from their local heating. Stationary devices can operate from the main wire or from a cylinder.

There are no special devices designed only for garages. You should choose taking into account the available assortment. For a garage space, 4 different types of gas heaters are suitable.

Heater

The devices and functions of each are interconnected, because heating in them is carried out according to similar rules:

- first, gas is supplied to the combustion chamber;

- at this stage the gas is ignited using a piezoelectric element;

- fuel combustion products enter the chimney through a special pipe - this is how stationary models are designed;

- heat during combustion affects the heating element, heats it up; the heating element can be ceramic or steel.

Subsequently, the process differs depending on the type of device.

Gas convector

When there is no water in the garage, there is no possibility of connecting to the main line through which gas passes, then the best choice is heating through a convector. For a room of a standard area, just one convector is enough. It economically consumes gas from the cylinder, requiring less costs in contrast to the column or boiler.

Article on the topic: How to build a cellar in the garage yourself

During the installation process, you will only need to spend money on a good convector, because radiators and water pipes are not needed. It is better to mount these devices on a vertical wall that is not located adjacent to other buildings.

This placement will help create high-quality heating and safely place the cylinders outside the garage room on the street. The optimal solution is to install the cylinders in a special metal box near the wall, behind which the convector will hang. When all the walls are located adjacent to adjacent buildings, the solution is to place the box with cylinders inside the room, but as far as possible from electrical appliances. There must be holes made in it for ventilation.

A gas boiler

The efficiency of many modern boilers is close to 100%. These are economical devices. For example, a top class boiler is characterized by an efficiency of 94-96%. The efficiency of a middle class boiler is 70-90%. The cost of premium equipment is an order of magnitude higher than average.

Boiler

Professionals advise not to focus on price; you should not purchase the most affordable models, since the difference in price will quickly pay for itself during operation. A cheap boiler will need to be replaced after a couple of years or constantly spend money on repairs and constant maintenance. As a result, the total costs will be much higher in contrast to premium models.

The service life of boilers in the middle price segment is 10-15 years, but more expensive options will last at least twice as long.

The purchased model must be equipped with automatic control. Modern boilers are easy to use, they are completely safe, reliable, and are distinguished by the ability to set a comfortable temperature regime. You can choose even the smallest gas boiler, but it is still very powerful.

Requirements for the premises for installing a gas boiler

The premises in which the gas boiler will operate are specified in SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000 - these documents eliminate or minimize any emergency situations. Premises for placing gas boilers fall under the classification of fire and explosion hazards, therefore, when designing, planning, installing and setting up equipment for gas heating, all requirements for the premises for installing a gas boiler must be strictly observed.

General requirements for the installation of gas appliances

In the room intended for the installation of a gas boiler, according to the above standards, there must be good natural lighting: per 1 m 3 there must be at least 0.03 m 2 of window opening area (but not windows - partitions, frames and imposts are not taken into account). It is imperative to equip the room with a supply and exhaust ventilation system according to the following rules: the total volume of forward and reverse air flows per hour, multiplied by 3, is equal to the volume of the entire exhaust device. In addition to a window equipped with a window, a door with access to the street is installed in the room. The table shows the requirements for room volume:

For gas-fired units with a power of more than 6000 W, 0.2 m3 should be added for each extra unit of power.

Supervisory requirements for the premises for installing a gas boiler stipulate that the operation of any appliances for heating an apartment is permitted on each floor of a multi-storey building and in any room of the apartment. Kitchens in multi-storey buildings also meet these requirements, since they are already equipped with appropriate communications. The only condition is that the total thermal power of all devices for heating water and heating the apartment (boilers, boilers, heating elements, heating radiators, batteries or registers) should not exceed a total of 150 kW.

The ceiling height in the room is 2 meters or more. The room in which the gas boiler will be installed and operated must be separated from adjacent rooms by solid fire-resistant walls. Material for walls or partitions must have a fire resistance time limit of 0.75 hours (45 minutes). The boiler room must be designed so that in the event of an operational fire there is no possibility for the fire to spread throughout the apartment.

Gas boilers of the TLO brand, operating on the principle of natural coolant circulation, can be installed and should be operated only in the basement of the house or in the basement.

Requirements for heating with gas from cylinders

As an alternative, you can use bottled gas. Containers should be kept in a closed metal cabinet for storing gas cylinders.

To locate it, you need to choose a place as far as possible from heating devices and flammable appliances.

Gas cylinders in action: a quick and easy option, even taking into account the fact that you have to buy gas cylinder equipment, a reducer and shut-off valves

You cannot install a module with cylinders at floor level, because in this case it will not be possible to notice a gas leak in time and solve the problem.

Installation of a gas wall-mounted boiler - kitchen requirements

- Ceiling - 2 meters and above.

- The total volume of the kitchen is more than 7.5 m3, ventilation is equipped, a window is installed and there is a door opening onto the balcony.

- For air exchange, it is necessary to install a grille at the bottom of the wall or door that opens into the next room; the area of the grille is at least 0.02 m2.

If the kitchen in the apartment does not meet the requirements of SNiP, then gas heating equipment can be installed and operated only with the permission of the gas supervision authority.

It is strictly forbidden to install more than 2 heating devices or more than 2 boilers in one room if the volume of the room is less than 7.5 m3

The existing rules for installing a gas boiler in a private house largely repeat the requirements for boilers that operate in apartments in multi-storey buildings. The differences are caused only by the fact that often in a private house a separate room or building is allocated for heating equipment, which is subject to additional requirements listed below.

Rules for installing a floor-standing gas boiler

- In a house under construction, it is necessary to plan a separate room for installing a gas-fired boiler. The room should have a natural flow of air through a grille in the door or through a hole in the wall.

- A separate hole must be made for supply and exhaust ventilation - it must be located under the ceiling.

- A hole in the wall for the chimney pipe, a hole below the chimney for a soot brush (for cleaning the chimney pipe), which is made below the main chimney by 20-30 cm.

- The chimney is made airtight so that smoke and carbon dioxide do not flow back into the room. To ensure tightness, a smaller diameter pipe is installed inside the large chimney pipe, through which gas combustion products are discharged.

- The room intended for installation and operation of a gas boiler must be spacious and provide easy access and operation, maintenance and repair of the boiler. The floor in the furnace room must be made of non-combustible materials - concrete screed, natural stone, paving stones. The furnace room must be connected to the water supply for the operation of the water heating device, and be equipped with a sewerage system.

- The area of the room for the boiler is 4 m2, the height of the ceilings in the room is at least 2.5 m2.

- The outer door must be 80 cm wide.

- The top of the chimney should be higher than the roof. The cross-section of the chimney pipe must be larger than the diameter of the boiler outlet.

- To supply power, the boiler room must be equipped with an electrical panel with grounding.

- The gas line is brought into the room in advance. A separate valve must be installed for each gas appliance.

- The walls of the boiler room are plastered - it is strictly prohibited to decorate the walls with flammable materials (MDF, fiberboard, plastic).

Attached boiler room to the house

The need to install a heating system for private housing construction arises for every owner. Not everyone knows the requirements of regulatory documents and how to attach a boiler room to a house. Correct installation of which will ensure the safe use of any type of fuel. A popular option is the construction of a boiler room adjacent to one wall directly to the house.

Main requirements of heating devices

The maximum number of heating devices in one room is no more than two. The chimney and supply and exhaust ventilation must be equipped taking into account the features and power parameters of the unit.

Brick and concrete are the best components for building walls. The floor covering on top is covered with a sheet of metal or can remain concrete. A frequently used method is laying porcelain tiles on the floor. The walls are covered with non-combustible mineral plaster or tiles. The door leaf is manufactured taking into account fire safety requirements.

Technical documentation determines the dimensions of the building. In this case, free space should be provided near the unit in the attached boiler room for the most convenient maintenance of the boiler during operation.

Selecting the energy carrier to use

It is very important to decide in advance what fuel the unit will run on. Taking into account the choice of boiler mainly determines how to properly install and equip the room. Mainly 4 types of energy carriers are used:

Having selected the desired model, you can begin preliminary work.

Features of premises for electric boilers

The most optimal heating unit from the point of view of safety is the electric one, which does not emit harmful combustion products. For this type of fuel, you do not need to install a ventilation system. The advantages include efficiency up to 99%, noiselessness and simple installation. Electric boilers are unpretentious in terms of maintenance.

Requirements for solid fuel modifications

Low explosion hazard does not require significant requirements for the attached boiler room for burning wood, coal and other solid components. The distance between the equipment and the walls must be at least 10 cm. To prevent fire from hot particles falling on the floor, it is necessary to lay a metal sheet in front of the firebox.

The surface of the walls and floors is finished with non-combustible materials. To install windows, a universal formula is used, derived from practical research: for 1 kW of unit power, 8 sq. cm window area.

Boiler rooms with gas heating appliances

The use of gas fuel, the most popular among private home owners, requires the fulfillment of a significant number of requirements.

It is necessary to properly attach a gas boiler room to your house due to the high explosiveness of the energy carrier used. It is especially important to pay attention to the following points:

Preparatory stage

Even at the project development stage, it is important to provide for the conditions of the regulations under which the facility will be built. The main recommendations of these documents include:

The hood must pump at least 3 times the volume of air per hour in comparison with the sum of the volumes of air mass consumed during combustion and the room itself.

Specifics of constructing an extension for wooden buildings

For objects of this type, there is a strict sequence of various stages that must be followed without fail:

Moydodyr for the bathroom Leroy Merlin

Start of installation work

First of all, you should install a grounding loop, which is required by the rules of regulatory documentation. The most popular and simplest method is the use of 4 metal pipes. They are evenly located along the entire perimeter of the structure. To connect the pipes to each other, they are tied with corners and then welded. The connection to the house is carried out with 12 mm rods.

It is prohibited to attach load-bearing walls of a building to existing ones. The extension to the house is made with separate independent structural elements. During the construction process, the installation of an input sleeve is provided if the use of gas is planned for fuel. Any pipe stump with dimensions of 100x100 mm is secured in the wall with expanded clay concrete.

To ensure the supply of fresh air through the hood, a hole of appropriate size is made. With natural air supply from the street, the window area parameters must meet the following requirements - for 1 kW of power at least 8 sq. cm, and when connecting from adjacent rooms - 30 sq. cm per unit power. A ban on installing forced ventilation applies to gas boiler houses, which must be insulated.

Arrangement of ceilings

We should not forget about the special function of the ceiling, which will protect the boiler room from the danger of explosion in an emergency. Under such circumstances, the ceiling acts as a valve, therefore, its design should be as light as possible.

Fears that such a ceiling will be cold are untrue. Insulation will be provided by a sheathed structure. This will require boards with a thickness of 30 mm. A layer of bituminized paper is laid on top of the filing. And ordinary sawdust is used as thermal insulation. 4mm heat-saving material is attached to the ceiling from the inside. The final stage is installation of the sheathing. Next we level the floor and plaster the walls.

Application of finishing materials

A few simple tips will help you avoid problems when operating your equipment:

Compliance with all rules and requirements contributes to the serviceability of any unit and ensures the safe residence of the owners.

Rules for installing wall-mounted gas boilers in an apartment

Typically, in an apartment, a gas boiler is installed in the kitchen, since it already has a gas line, water supply and sewerage. That is, a priori, all requirements for the installation of gas equipment have already been met - all that remains is to connect the boiler. This state of affairs automatically reduces the cost of laying utilities and energy resources. It is prohibited to install a gas boiler in rooms with high humidity - in a bathroom, laundry room, etc.

There are several additional requirements for wall-mounted boilers:

- The wall or partition for hanging the boiler must be able to support it - equipment cannot be hung on a plasterboard or other light partition.

- If the wall is decorated with flammable materials (wallpaper, vinyl, plastic, MDF, fiberboard), then a 3 mm thick gasket of non-flammable material is installed between the gas wall-mounted boiler and the wall. In this case, the boiler must be secured with special hardware that ensures a distance from the boiler body to the wall of at least 4-5 cm.

- The minimum distance from the boiler to the ceiling and walls of the room is 0.5 meters. The distance from the boiler to the floor is 0.8 meters.

Before installing and starting up gas equipment, you must obtain all relevant documents. The main condition when installing a boiler in a private house that runs on gas is that an agreement on connecting the gas main is first concluded, and a project for the installation of gas equipment and gasification of the house is drawn up. These documents are developed and approved by the gas supplier in the region.

Price range in different regions of Russia

It is no secret that the cost of services differs depending on the territory. Taking into account this factor in general, and the convenience of the location of the facilities, residents of different parts of the country receive bills with a 10-fold difference in figures.

Collecting documentation and obtaining technical specifications will cost from 8 to 50 thousand rubles. The gasification project will be completed for 3-20 thousand. Each meter of wiring from the main pipe will cost 2-5 thousand rubles.

The insert alone costs up to 10-15 thousand in national currency. You will have to pay 1-2 thousand rubles for an inspector to come out and assess the readiness of the equipment. - quite a bit against the general background.

Boiler room in the garage

Requirements for the premises of a gas boiler room in a house or cottage (excerpts from regulatory documents)

GENERAL PROVISIONS (BOILER BURNER ROOM)

1 Automated heat generators of full factory readiness with a coolant temperature of water up to 115 ° C and a coolant pressure of up to 1.0 MPa of domestic or foreign production, having permission for use in the prescribed manner, should be accepted as sources of thermal energy.

2 The placement of heating units is provided: - in the kitchen with a power of the heating unit for heating up to 60 kW inclusive, regardless of the presence of a gas stove and gas water heater; — in a separate room on any floor (including the basement or basement) with a total power for heating and hot water supply systems of up to 150 kW inclusive; - in a separate room on the first, ground or basement floor, as well as in a room attached to a residential building, with their total capacity for the heating and hot water supply system up to 350 kW inclusive.

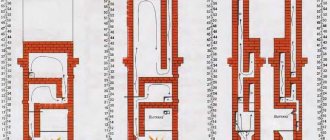

PLANNING AND CONSTRUCTION SOLUTIONS OF THE BOILER ROOM

1 When placing a gas stove, instantaneous water heater for hot water supply and a heating unit for heating with a power of up to 60 kW in the kitchen, the kitchen room must meet the following requirements: - height of at least 2.5 m; — the volume of the boiler room is at least 15 m3 plus 0.2 m3 per 1 kW of power of the thermal unit for heating; - in the kitchen, ventilation should be provided at the rate of - exhaust in the volume of 3 times the air exchange of the room per hour, inflow in the volume of the hood plus the amount of air for gas combustion; - the kitchen must have a window with a window. For air flow, a grille or gap with a clear cross-section of at least 0.025 m2 should be provided at the bottom of the door.

2 When placing thermal units with a total power of up to 150 kW in a separate room located on any floor of a residential building, the room must meet the following requirements: - height of at least 2.5 m; — the volume and area of the room are designed based on the conditions for convenient maintenance of thermal units and auxiliary equipment, but not less than 15 m3; - the room must be separated from adjacent rooms by enclosing walls with a fire resistance limit of 0.75 hours, and the limit of fire spread throughout the structure is zero; - natural lighting - based on glazing 0.03 m2 per 1 m3 of room volume; - ventilation in the room must be provided at the rate of - exhaust in the volume of 3 times the air exchange of the room per hour, inflow in the volume of the exhaust plus the amount of air for gas combustion;

3 When placing thermal units with a total power of up to 350 kW in a separate room on the ground floor, in the basement or basement of a residential building, the room must meet the following requirements: - height of at least 2.5 m; — the boiler room must be separated from adjacent rooms by enclosing walls with a fire resistance limit of 0.75 hours, and the limit of fire spread throughout the structure is zero; - natural lighting - based on glazing 0.03 m2 per 1 m3 of room volume; - ventilation in the room must be provided at the rate of - exhaust in the volume of 3 times the air exchange of the room per hour, inflow in the volume of the exhaust plus the amount of air for gas combustion; — the volume and area of the room are designed based on the conditions for convenient maintenance of thermal units and auxiliary equipment.

4 When placing thermal units with a total thermal power of up to 350 kW in an extension to residential buildings, the extension room must meet the following requirements: - the extension must be located at the blank part of the building wall with a horizontal distance from window and door openings of at least 1 m; - the wall of the extension should not be connected to the wall of the residential building; — the enclosing walls and structures of the extension must have a fire resistance limit of 0.75 hours, and the limit of fire spread throughout the structure is zero; — the height of the boiler room is at least 2.5 m; — the volume and area of the boiler room are designed based on the conditions for convenient maintenance of heat generators and auxiliary equipment; - natural lighting - based on glazing 0.03 m2 per 1 m3 of room volume; - ventilation in the room must be provided at the rate of - exhaust in the volume of 3 times the air exchange of the room per hour, inflow in the volume of the exhaust plus the amount of air for gas combustion.

What to consider when building a garage?

It is also worth considering that the garage will quickly fill up with all sorts of useful things - tools for gardening, children's bicycles, a lawn mower, a trailer, as well as a huge number of others, without which life will lose all meaning. Of course, many will want to get a workbench with a decent set of tools. Well, when all this fits in the garage, there will probably simply be no room left for the car. That is why it makes sense to get a garage for two cars or a garage with an additional utility unit. Moreover, it is desirable that the entrance to the garage does not open from the house. Yes, it is attractive and convenient to get into the garage in windy October weather without even going outside. But very often frame garages are saturated with such not very pleasant odors as the aromas of fuel, paint, exhaust gases or simply gasoline. Well, every time you open the door from the house to the garage, part of this aroma will spread throughout the house. Not a very pleasant prospect, is it? In addition, when the doors are opened, some of the heat from the frame house goes into the garage, which is also not always good.

It would also be better to forget about the garage located in the basement. Of course, this looks very good on projects - there is no need to allocate extra space for construction, and the garage will not spoil the surrounding landscape. But when the snow melts and after rain, the garage will literally flood. And nothing can be done about it. In addition, in winter the descent to the garage is often covered with ice. In such a situation, you can only pull the car out of the garage with the help of a tractor or at least a winch. Is it worth experiencing such problems? Wouldn't it be easier to just build an above ground garage?

Types of boilers

First, it’s worth considering what types of boilers there are.

- Gas boilers - it is advisable to purchase when in the utility room there is a possibility of diverting a pipe from the gas main. This fuel is considered the most budget-friendly. The heat carrier is a liquid that is heated by the boiler. Heating is provided by the convection method using a fan.

- Electric boilers - it is advisable to install them in a room where the coolant is heated by electricity. The operating principle of such a device is that the liquid in the heat exchanger is heated thanks to electric heating elements.

The essence of the problem

At its core, any garage is a utility room (usually detached) of a warehouse type, but containing a car and substances belonging to the flammable category. These circumstances give rise to increased requirements for fire safety. Naturally, the question arises: is it even possible to place a boiler room in a garage?

When solving this issue, you should understand what a boiler room is and why it is installed. It is possible to set several tasks. Most often, the concept of a garage boiler room means a boiler for heating only the room itself, but sometimes a boiler room in a garage functions as a source of coolant for heating a private home. If in the first case a small standard boiler of various types is used, then in the second case fairly large areas and special permission are needed.

In any case, a garage with a boiler room is not prohibited by regulatory documents. At the same time, it must meet all technical and fire safety requirements. The need to draw up a project and coordinate it with the relevant organizations depends on the type and power of the equipment, the type of fuel consumed and the connection to centralized highways.

Choosing the “right” gas boiler

You can purchase a suitable gas boiler yourself. It is worth paying special attention to each component of the equipment. In particular, this applies to the body material itself, the chimney (if there is one), as well as the ignition system. In addition, you need to find out which gas connection option is available.

The most popular devices are boilers made of cast iron and steel. If you choose between the two, preference should be given to the latter, since cast iron is considered a rather heavy metal. A convenient boiler is one that has an electric igniter installed.

Particular attention should be paid to the chimney. Since combustion products are aggressive, this part must be made of durable material. Alloy steel is considered the ideal option. However, there is equipment where there is no chimney as such (the device is equipped with fans).

Procedure for obtaining technical specifications

Technical conditions for gas supply to the garage will be issued by the gas service at the location of the facility.

Application form for obtaining technical conditions for gasification: you can apply for a facility being designed, under construction or put into operation

The owner of the premises should submit the application itself for drawing up the contract, as well as the following documentation:

- land ownership documents;

- identification card or official document confirming the authority of the representative;

- topographic plan of the territory with the building;

- registration certificate;

- consent of the gas distribution company;

- garage plan along with smoke and ventilation ducts.

Upon delivery, the customer receives pressure parameters at the point of connection to the gas network, the minimum and maximum gas use per unit of time, a description of the system features and the permissible gas consumption.

The owner of a garage with specifications in hand has the right to go to court if he is denied connection. The decision is usually made in favor of the plaintiff. The opportunity to go to court is also used in case of refusal to issue technical specifications.

Setting up a boiler room in the garage

Next, we suggest finding out how to organize a boiler room in a garage.

Layout of accommodation

It is better to install a gas boiler in a separate building, the area of which is at least four square meters. There is also a requirement for ceilings - they must be more than two meters. As for the width of the door, its size should be 80 centimeters and above. In addition, the room should be ventilated and have a window that would provide natural light in the room during the day.

It is recommended to build a boiler room at a relative distance from a residential building for several reasons. Firstly, so that the noise from work does not disturb the household. Secondly, the boiler room is a fire hazardous facility .

Preparatory work

First of all, the walls in the garage need to be finished with heat-resistant material. If it is necessary to install a chimney, the pipe is installed above the level of the garage roof, approximately one meter. In addition, it is worth considering how many bends are present on the pipe. So, the lower this figure, the better, since otherwise the substances that are released during combustion will settle on the sections. As a rule, to equip a chimney, a pipe with a diameter of 130 millimeters is taken.

The area of the roof where the connection to the chimney occurs must be protected with fire-resistant material. Take something like galvanized steel.

Ventilation arrangement

To ensure the safe operation of a boiler room in a garage on your own site, you will need to ensure there is a good ventilation system that can cope with the removal of harmful gases from the room.

For these purposes, the owner must correctly calculate the required fan performance.

Fan power is calculated using the following formula:

- M – fan power;

- S – building area;

- H – building height.

This formula includes the fact that the air in the room is renewed on average in 12 hours, and the minimum power reserve of the equipment is estimated at 30%.

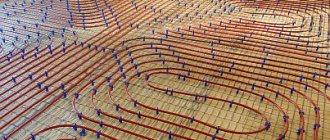

Installation of a heating boiler in a garage

For garages, wall-mounted or floor-mounted boilers are often purchased. The equipment is installed on a brick (concrete) stand.

Do not forget that before installation work the walls are treated with a material that is resistant to fire.

The boiler is fixed horizontally and vertically. Walls and other objects in the room should be 30-50 centimeters away from the device.

Connecting the device to gas and water

After the installation work is completed, the boiler is connected to gas and water supply. Water is supplied to equipment standing on the floor from above or to the side. In the version with a wall-mounted boiler, communications are connected to the transverse side.

Also, the remaining components of the device must be installed. In that situation, if there is no need to purchase an electric pump for the room, the pipes are laid with an inclination of five millimeters (per meter of length). Otherwise, there will be difficulties with circulation in the heating.

Features of garage gasification

According to SNiP 2.04.08-87 “Gas supply” in clause 6.32, gas equipment can be placed in buildings located separately from residential buildings or adjacent to them. Owners obtain permission from design organizations.

The authorized structure takes into account the availability of a gas line for the implementation of such intentions, and geographical factors of the area. The same criteria apply to rooms in individual buildings as for living rooms. The feasibility of projects and calculations depends on the gas operating specialized company.

In case of problems with conventional gasification, there is an option with an autonomous supply from a gas holder; this is an ideal solution for a garage remote from main pipes

The connecting branch to a non-residential premises or a building under construction is installed according to an individual project based on an agreement between the owner of the property and the gas service. The active process starts after the customer receives technical specifications (TS).

In this sense, the procedure is as follows:

- Submit a request for the preparation of technical specifications.

- Get TU.

- Draw up a written application for the agreement on accession to communications.

- Sign the document to connect.

- Obtain a warrant to put a non-residential building into operation.

- Sign the act of connection to gas communications.

The operational features of garage premises and their compatibility with gas appliances raise the need for regulation and standardization.

Garage owners install gas boilers, stoves, burners, gas heat guns, but this may be hampered by the small size of the buildings, the lack of windows and other rooms besides the main one.

The principle of operation of a gas heat gun is to take in air and warm it up, so that the room will be evenly filled with warm air

You should not strive to gain access to the main pipe in any case, because there are also alternatives with cylinders and tanks for autonomous gasification.