Home » Gas heating » What to do if the pressure in the heating system drops?

Installing a heating structure in a house is as necessary as installing electricity. In winter, you want to be warm and comfortable in your own home.

One of the most popular heating systems is gas double-circuit, which provides both heat and hot water. Thus, with minimal effort on your part and with a fairly modest budget, you will provide your home with everything you need.

But at the same time, a problem often arises with a drop in pressure in the system or its increase. Below we will consider the main reasons for the increase in pressure in the heating system and how to eliminate them.

Heating system pressure

Why doesn’t the circulation pump press through the heating system?

You are here: >> Do-it-yourself radiator heating >> Designing home heating >> There is no coolant circulation in the heating system - what are the reasons?

If there is no circulation of coolant in the heating system, then there is nothing to talk about any comfortable living in the house in winter. Because no matter how much you heat up the boiler, the radiators will still be cold.

However, you need to think about this not when the system “worked, worked and suddenly stopped,” but at the design stage, i.e. now.

In this article we will deal with the problems that lead to poor coolant circulation.

Causes of poor coolant circulation

There may be no coolant circulation in the heating system for the following reasons:

- insufficient power of the circulation pump (or pumps, if there are more than one). For this reason, the coolant simply does not reach the radiators furthest from the boiler, so they are cold (or slightly warm, which still doesn’t make it any easier). There are several articles and videos on how to select the power of a circulation pump in the section on heating calculations;

- check valves are not installed. Usually their absence is “painful” for complex systems with several circuits. Check valves are used to ensure that the coolant moves along the desired circuit and in the desired direction (read more below);

- system contamination. It happens that the pipes are clogged along the entire diameter - what kind of circulation is there! There is only one way to treat this: replacing the pipes. This is exactly the case when the best treatment is prevention. And “prevention” should be carried out at the stage of installation of the pipeline and radiators. First, make sure that no debris gets inside the pipes. To do this, after first making sure that there is nothing inside, we close the ends of the pipes with something before installation. For example, it is convenient to use simple plastic bags. Secondly, there may be debris in the radiators. Even new ones! So we check and get rid of it;

- pipe diameter is too small. Small pipe diameter - high hydraulic resistance - the pump is not able to “push” the coolant throughout the pipeline - there is no circulation in the heating system (well, or it is so bad that it’s the same as if it doesn’t exist). Again, at the design stage it is necessary to calculate the hydraulic resistance;

- accumulation of air in the system (airing). Air, of course, is not garbage, but air pockets will also prevent the coolant from circulating freely. Air locks may appear due to violations of the rules for installing the heating system. Getting rid of air is simple - install an automatic air vent at the highest point of the system and Mayevsky valves on the radiators.

Coolant circulation in a combined (branched) heating system

Let's start analyzing the coolant circulation with a complex system - then you will understand simple circuits without problems.

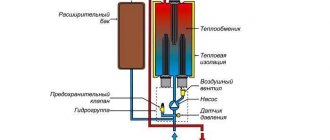

Here is a diagram of such a heating system:

It has three circuits:

1) boiler - radiators - boiler;

2) boiler - collector - water heated floor - boiler;

3) boiler - indirect heating boiler - boiler.

Firstly, it is necessary to have circulation pumps (H) for each circuit. But this is not enough.

For the system to work as we want: the boiler is separate, the radiators are separate, we need check valves (K):

Without check valves, let’s say we turned on the boiler, but the radiators “out of the blue” began to heat up (and it’s summer, we just needed hot water in the water supply).

Cause? The coolant went not only to the boiler circuit, which we now need, but also to the radiator circuits.

And all because we saved on check valves, which would not allow coolant to pass where it was not needed, but would allow each circuit to operate independently of the others.

Even if we have a system without boilers and not a combined one (radiators + water heated floor), but “only” branched with several pumps, then we install check valves on each branch, the price of which is definitely less than reworking the system.

Coarse filter

As mentioned above, one of the reasons that there is no coolant circulation may be the accumulation of debris in the pipeline. To completely avoid this, again, we don’t save on pennies, but install a coarse filter in front of each device:

Using a filter, catching dirt is easier than correcting the consequences of clogged pipelines or boiler heat exchangers.

The filter needs to be cleaned regularly. And this is very simple to do: close the valves before and after the filter - unscrew the plug (1) on the filter - remove and rinse the mesh under the tap - put it in place and tighten the plug. All. Not like changing pipes

Causes of air in the heating system

When solving the problem of how to remove air from a heating system, it is useful to study the reasons that cause airing, the main ones being:

- Incorrect installation. In order for water to flow into the boiler with natural circulation, it is necessary to maintain a constant slope when laying pipes. Failure to comply with this condition leads to the appearance of air jams in curved sections.

- Violation of tightness. If defects appear in the heating circuit pipeline in the form of various types of cracks and depressurization of threaded, soldered, and compression connections, air penetrates through them, leading to airing of the entire system.

- Incorrect installation of air vents. Air removal from the heating system of a private house is usually carried out using air vents in heating radiators (Mayevsky taps), on distribution manifolds for underfloor heating and at the highest point of the heating circuit. If these conditions are not fully met, the likelihood of airing the system increases significantly.

- Malfunction of air vents. The coolant may contain products of decomposition (oxidation) of metal components, expired antifreeze or metal salts. The presence of solid suspended particles in the system leads to clogging of the inlet openings, channels of air valves of air vents and makes their normal functioning impossible.

- Failure to comply with the rules for filling coolant. One of the reasons why the heating system in a private home becomes airy is that it is not properly prepared for operation. When filling radiator heating circuits and underfloor heating systems with coolant, simple rules should be followed, otherwise violation of them will lead to the formation of air locks.

- After repair work. One of the reasons why the heating system will vent is air getting into the pipeline after repair or preventive maintenance of individual components. For example, if a circulation pump is removed, redirecting the coolant through a parallel bypass, after installing it in its original position, a problem will arise with the presence of air inside the housing.

- When replenishing the coolant volume. After pouring an additional amount of working fluid into the circuit, the likelihood of airing the pipeline increases due to the fact that the liquid contains a high percentage of dissolved air.

Heating system diagrams

The layout of the heating system depends on several criteria:

- method of connecting batteries to supply risers. There are one-pipe and two-pipe systems;

- the location of the line that supplies hot water. You need to choose between upper and lower wiring;

- line laying schemes: dead-end system or associated movement of water in routes;

- risers can be located horizontally or vertically.

What is the difference between forced and natural circulation?

Forced movement of the coolant implies the circulation of liquid along the line due to the working force of the pump. The natural system does not require the use of any equipment; here the coolant moves due to the difference in the weight of the hot and already cooled liquid.

Single-pipe circuit: how to regulate the temperature?

To ensure the same temperature in rooms on different floors, the surface of heating devices on the lower floor should be slightly larger than on the upper floors. The liquid that is hot and cooled in the upper heating devices enters the lower radiators.

In a single-pipe system, there can be two versions of fluid movement: in the first case, part goes to the battery, the other part goes further along the riser to the lower radiators.

In the second case, the entire coolant passes through each device, starting from the top. The peculiarity of this wiring is that the batteries on the lower floors receive only cooled coolant.

And if in the first option you can regulate the temperature in the rooms using taps, then in the second you cannot use them, since this will lead to a decrease in the supply of coolant to all subsequent radiators. In addition, completely shutting off the tap will stop the circulation of liquid in the system.

When installing a single-pipe system, it is better to choose a wiring that makes it possible to regulate the water supply to each battery. This will allow you to adjust the temperature in individual rooms and make the heating system more flexible, and therefore more efficient.

Since a single-pipe system can only be top-mounted, its installation is only possible in buildings with an attic. This is where the supply pipeline should be located. The main disadvantage is that heating can only be started throughout the entire house at once. The main advantages of the system are ease of installation and lower cost.

Methods for eliminating air locks from heating systems

There are two main types of heating systems - open gravity (gravity) and closed (forced).

In the first option, the working fluid rises through the pipes from the boiler upward by gravity due to its lower density compared to the colder environment. In this case, a certain amount of liquid collects in an expansion tank placed at the highest point of the heating circuit.

In the closed version, a sealed expansion tank with an elastic membrane is used, which houses the coolant that increases in volume when heated.

Open circuit deflation

Gravity systems with an open expansion tank are used in radiator heating; when installing them, the main task is to correctly maintain the angle of inclination of the pipes. From the vertical section of the pipeline extending from the boiler, the pipes are directed to the radiator heaters, passing through which the working fluid flows back into the boiler along a return line laid with a certain slope.

Obviously, in a gravity heating circuit there is an open expansion tank for unobstructed air outlet. Due to this, if installed correctly, problems with airing in gravity structures occur quite rarely.

If installation rules are violated and airing occurs, you will have to solve the problem of how to remove the air lock from the heating system if it is not operating efficiently. To do this, check the correctness of the slopes and straightness of the pipeline; the main method of eliminating traffic jams is to dismantle the incorrectly laid section and reinstall it in the correct position.

Also, when the coolant passes through the batteries, aired zones may appear inside them, so each heat exchanger must also have exhaust valves (Mayevsky taps). With their help, air pockets are removed from the heating system by bleeding air in the upper part of the radiators furthest from the supply and return pipelines.

Rice. 4 Operating principle of different types of air vents

Installation of air vents

One of the main methods for solving the problem of how to remove an air lock from a heating system is the use of special air vent devices. Their principle of operation is to collect lighter air than the liquid from the pipes in a barrel-shaped chamber of the housing. A float is placed inside the air outlet barrel, connected to a drain valve - if there is an excess of air, it drops, the valve opens and releases the flow to the outside.

Air vents are most often installed in the following places:

- At the highest point. Since air is lighter than water, it tends to rise up through the pipes, leading to their airing, so a drain valve must be installed at the highest point.

- On heat exchange devices. Heat exchange radiators have a complex shape and various connection methods; if a plug appears in them, it will not be possible to expel air from the heating system through a coolant flow without special drain devices. Therefore, every modern radiator must have drain valves in the form of Mayevsky taps.

Air vents are also mounted on heated towel rails of complex design, placing them in the upper part.

Rice. 5 Locations of air vents

- On the commutator comb and hydraulic arrow. For wiring winding and extended contours of heated floors and radiator batteries, special combs and hydraulic arrows with a complex design are used. Typically, air vents are installed in the upper part of such units, with the help of which you can ventilate distribution combs, hydraulic arrow housings and heating pipelines for heated floors.

- Safety devices. A standard safety group is installed in the piping of many household boilers - a unit consisting of an air vent, a pressure gauge and a drain valve.

The emergency device is usually located at the outlet of the pipeline in the upper part of the boiler.

It should be noted that there are two main types of air vents - manually operated (Mayevsky taps) and automatic (there are designs for batteries), the latter do not require opening the drain valve mechanically.

Rice. 6 Separator and sludge separation devices - operating principle and design

Coolant heating

The standard coolant temperature in the heating circuit does not exceed 70 °C - a higher value leads to increased heat losses and reduced injury safety.

Since the working environment expands when heated, this effect can be used to more effectively solve the problem of how to remove air from the heating system. To do this, the coolant is heated to a temperature not exceeding 100 °C, after which the removal (displacement) of air pockets occurs with greater efficiency.

Mechanical or automatic replenishment - which one to choose?

The make-up valve can be mechanically or automatically controlled. The first option is installed where small heating systems operate. In them, as a rule, any surges in the operating pressure of the coolant are regulated using membrane tanks. And the easiest way to compensate for the loss of water volume is to manually open the supply tap in a cold water supply. The main inconvenience of this option is the need for experience to perform the described operations, as well as the possession of certain technical knowledge and skills.

Note! In this case, you will have to independently control the pressure inside the closed heating system. An excessive increase in the volume of coolant can lead to an emergency situation

Automatic make-up valves are installed in large branched systems. They are often included in the heating boiler package, becoming part of its automation. Installation of such a device does not cause any particular difficulties. But its implementation makes the entire scheme volatile. And this must be taken into account when choosing one or another type of technical unit.

Operating principle of automatic valve

Auto make-up valve

The operating principle of the automatic valve is extremely simple. The operating parameters are pre-configured. Water losses are programmed in advance - the lowest pressure indicators are set. If the volume of coolant drops, say, by 10%, the valve is activated and starts the pump. The latter pumps the required volume of liquid from the cold water supply line. When replenishment occurs, the valve is activated again and shuts off the supply automatically.

The described device is easy to install. First, a measuring pressure gauge or any other electrical contact sensor is installed on the cold water supply line, which allows you to regulate the pressure in two directions. One of its groups is adjusted to lower operating pressure. This is where the intermediate relay or contactor is installed. When the volume of hot water drops inside a closed circuit, it turns on a mechanism that starts the suction pump. The second group turns off all these links when the water volumes are replenished. An electric valve—a valve with an electric motor—can be used as an actuator.

Note! When using an automatic make-up valve, the heating system independently controls the pressure and also independently calculates the compensating volume of water. This is the main advantage of this technical unit

When is it necessary to organize make-up using a bypass circuit?

Automatic recharge of systems and its efficiency

As a rule, all closed heating systems can function effectively only with high operating pressure of the coolant. But the deciding factor here is also the temperature of the hot water.

As it increases, the thermal expansion of some technical components increases. It can be compensated by installing an expanzomat - a hydraulic accumulator capable of accumulating hydraulic energy when there is an excess of it and releasing it when there is a shortage. It must be connected using a bypass circuit. Read how to do this here.

Advantages and disadvantages

The open heating system has not yet lost its relevance, and recently it has even experienced a rebirth, and there are reasons for this. Many homeowners are concerned about the energy independence of their communications, and the open tank scheme allows this to be achieved. She has other advantages:

- Filling an open heating system and bleeding air is easier than in a closed one. There is no need to monitor the maximum pressure, and when filling, the air leaves the pipelines very quickly through the open expansion tank. All that remains is to ventilate the radiators;

- it’s easier to refill: again, pressure control is not required, and water can be added to the container even with a bucket;

- the operation of the system does not depend on the presence of leaks: here the operating pressure is very low, so as long as there is water in the heating network, it will function properly.

As usual, there were some drawbacks, due to which such systems began to be gradually replaced by closed-type circuits with a membrane expansion tank. Due to the direct contact of the coolant with atmospheric air, two processes occur in the container at once: natural evaporation of hot water and its saturation with oxygen. This leads to the following requirements:

- you need to monitor the water level in the tank and replenish it on time;

- Do not fill the heating network with antifreeze, which releases harmful substances when evaporated.

Oxygen saturation of the coolant leads to a decrease in the service life of steel parts of the boiler. For the above reasons, the open system has not been used in apartment buildings for a long time, although in the 60-70s of the Soviet era such practice took place in low-rise residential buildings. It is also undesirable to operate it with high-temperature heat sources when the coolant is close to the boiling point. The fact is that with increased pressure in a closed network, this threshold increases, and there is nowhere for water to evaporate. In an open system, the amount of water will quickly decrease, freeing up the entire volume of the expansion tank for air.

Natural circulation

Approximate system diagram

The main issue of the natural circulation system is the issue that determines the force of movement of the coolant to the heating devices and back to the boiler. The force of movement of the heated coolant appears due to the fact that the coolant is heated in a heat generator, whereas in heating devices this coolant cools down and is squeezed out by the heated coolant. In other words, the coolant, which has been heated in a heat generator to a certain temperature, has less mass than the coolant in a cold state.

So, water heated to the required temperature rises in a certain direction in the main riser and is distributed by piping to all heating devices, that is, radiators. After some time, the coolant in the radiators cools down, giving off its heat to the metal, which makes it heavier. Through specially installed return pipes, the cooled coolant is transported back to the heating boiler, where its mass displaces hot water from the heat generator.

This cycle of coolant movement in the heating system will be repeated until the heating boiler is operating, as a result of which the coolant will circulate through the pipe line. Heating systems with natural circulation have different pressure forces, which leads to different rates of circulation and heating of heating devices. The force of movement of the coolant in the heating system depends on the different densities and weights of the cold and hot coolant.

From this we can conclude that the pressure in the heating system and the force of water movement depend on the overall difference between the hot and cold coolant. In other words, the greater this difference, the greater the force of movement of the coolant in the heating system, in which the coolant circulates naturally. Among other things, the pressure in the heating system and the force of movement of the heated coolant depend on the height at which the heating device is located relative to the thermal energy generator.

As a rule, the coolant in a simple water-type heating system heats up to 95 degrees, while the cooled coolant has a temperature of no higher than 70 degrees. From such indicators it is possible to determine the total pressure in the heating system and the force of movement of the coolant to the upper and lower heating devices. In order to visually imagine the distribution between the upper and lower radiators in the heating system, it is necessary to draw some kind of diagram.

In the center we denote the heating boiler, from which there is wiring to the upper and lower radiators, which closes opposite the boiler itself. By drawing a line between the upper and lower heating devices (radiators), we get a temperature difference from 95 to 70 degrees. Next, we will consider the heating process.

System diagram

The heating boiler heats the coolant, in our case water, which, due to the resulting pressure, begins to move from one heating device to another. When the coolant crosses the line we have drawn and goes to the heating devices on the lower floor, its temperature will be significantly lower, and the coolant with a temperature of only 70 degrees will come out of the last radiator. When moving coolant from radiator to radiator, do not forget that part of the temperature is transferred to the pipes themselves, as a result of which the temperature of the coolant is constantly decreasing.

From this we can safely conclude that heating devices that are located above the system separation line will heat up more than those located on the lower floor.

All this leads to the fact that the use of this heating system for two-story houses is irrelevant, because the first floor will be constantly colder than the second. In addition, when using a two-pipe heating circuit, when the radiators are located below the boiler itself or at the same level with it, it is almost impossible to achieve proper coolant circulation without the use of auxiliary mechanisms.

For these obvious reasons, the location of the heating boiler should be such that the heating devices are located at a level above the boiler itself. To do this, heating boilers are placed in a small recess, and the heating system is raised slightly at a certain angle in order to achieve the proper pressure and proper natural circulation of the coolant. Standard single-pipe heating schemes do not have such obvious shortcomings.

Causes of pressure drop

One of the most common reasons for this situation is power outages or a complete shutdown. Thus, the system stops working, and accordingly the pressure sensors tend to zero.

To prevent this, you can use alternative power sources. If the electricity disappears for a short time, then you just have to wait for it to come back.

Tip: Do not leave your heating system idle for long periods of time, as the radiators may defrost and require expensive repairs.

To prevent this from happening, you need to perform a few simple manipulations that will restore the system :

- Check the structure for leaks (the pressure always drops if there is a coolant leak. In this case, you can solve the problem yourself by wiping the joint with a paper napkin).

- The settings of the expansion tank have been reset (if a leak is not detected, then problems with the tank are most likely).

Advice: It is the expansion tank that is responsible for the process of stabilizing pressure in the heating system. It prevents pressure from rising and falling.

Leak in the heating system

The fact is that when heated, water slightly increases in size (by 3.7% ), thereby creating additional pressure in the system. The excess resulting from heating rises into the tank and is released from it if the temperature of the coolant drops.

How can you understand that the reason why the heating system does not press through is the expansion tank? It's pretty simple. When water is heated, the pressure can rise, resulting in an emergency reduction in pressure in the tank through a special valve.

Accordingly, after cooling the coolant, the pressure is at a level that is lower than necessary. In order to adjust the expansion tank, you should pay attention to its technical characteristics - the required pressure level is indicated there. And then the pressure in the heating system is adjusted according to simple instructions :

- completely turn off the system taps on both the supply and return circuits;

- Using the boiler drain fitting, drain the water completely;

- Using the nipple, we release all the air from the expansion tank;

- Using a connected car pump, raise the pressure in the expansion tank to 1.5 bar . At the same time, you should not worry if water flows out of the fitting;

- we deflate again;

- If a hose from the boiler is connected to the tank, disconnect it. This will allow the remaining water to drain out. After complete removal of the coolant, the hose should be reconnected;

- Using a car pump, we again raise the pressure in the tank to the level recommended by the instructions;

- close the fitting through which the water was drained;

- open the taps and fill the systems with water.

The principle of operation of the expansion tank

After all these manipulations, you can turn on the boiler. If everything is done correctly, the pressure gauge needle will be within the zone that is colored green - the pressure in the system is normal and you should no longer know what it’s like when the pressure in the heating system jumps.

How do open systems differ from closed systems?

Any hydraulic heating system can be represented as a complex of heating equipment and heating devices, combined in a certain order into one whole using pipes.

In heating systems, an expansion tank is installed, since the heated coolant increases in volume. If the tank communicates with outside atmospheric air, then the heating system is called open. By isolating the expansion tank from interaction with atmospheric air, a closed-type heating system is obtained. In open systems, the coolant evaporates, so you have to monitor the water level in the tank and top it up when the need arises. In closed systems. equipped with membrane-type expansion tanks, this problem does not arise.

Installation of a heating system, including a boiler, an open expansion tank, radiators, shut-off valves, air vents, a circulation pump providing forced circulation of the coolant

Signs of airing

Airing leads to inefficient operation of the heating system, as a result of which unnecessary resources are spent on heating the coolant. This leads to unjustified financial expenses and can significantly affect the family budget during the cold season. Signals if the heating system is airy are the following:

- No heating of heat exchangers. Air in the heating circuit in the form of a plug prevents the coolant from passing through the pipes, as a result of which it does not flow to the radiators or into the underfloor heating pipeline. If air gets into the supply pipes, the radiators and floors remain cold when the boiler is operating at full power.

- Uneven heating of radiators. If there is air in the heating radiators, one of its parts will have a lower temperature, which can be easily determined by touching the surface of the sections with your palm.

- Increased noise. The movement of coolant in a pipeline circuit with air pockets is often accompanied by noise, which causes the movement of microbubbles.

- Vibrations. An increased concentration of air in the coolant leads to an acceleration of oxidative processes due to the oxygen contained in it, accompanied by the decomposition of metals with the formation of salts and carbon dioxide. Periodic emissions of insoluble metal oxides and carbon dioxide into the coolant can cause vibration processes in pipes.

Rice. 2 Air-filled radiators in a thermal imager

Consequences of cold return

Circuit for heating return

Sometimes, with an incorrectly designed design, the return flow in the heating system is cold. As practice shows, the fact that the room does not receive enough heat with a cold return is half the trouble. The fact is that at different supply and return temperatures, condensation may form on the walls of the boiler, which, when interacting with carbon dioxide released during fuel combustion, forms acid. It can also damage the boiler much ahead of time.

To avoid this, it is necessary to carefully consider the design of the heating system, special attention must be paid to such a nuance as the return temperature. Or include additional devices in the system, for example, a circulation pump or boiler, which will compensate for the loss of warm water

Radiator connection options

Now we can more than confidently say that when designing a heating system, the supply and return must be perfectly thought out and configured. If the design is incorrect, more than 50% of the heat can be lost.

There are three options for inserting a radiator into the heating system:

- Diagonal.

- Lateral.

- Bottom.

The diagonal system gives the highest efficiency coefficient, and is therefore more practical and efficient.

The diagram shows a diagonal inset

How to regulate the temperature in the heating system?

In order to regulate the temperature of the radiator and reduce the difference between the supply and return temperatures, you can use a heating system temperature controller.

When installing this device, do not forget about the jumper, which must be located in front of the heating device.

Types of open systems

Such water heating schemes are divided into types depending on the method of circulation and delivery of coolant to the radiators and its subsequent return back to the boiler. Heated water can move through pipelines in two ways:

- using natural circulation;

- artificial stimulation from the pump.

Due to the design features, there is practically no excess pressure in an open heating system. At the highest point it is equal to atmospheric pressure, and at the lowest it increases slightly due to the hydrostatic effect of the water column. The value of this pressure is small, which makes it possible to organize natural circulation of the coolant. The principle is based on the fact that coolant with different temperatures has different densities, and therefore mass. Example: 1 m3 of water at t = 40 °C weighs 992 kg; after the temperature rises to 60 °C, the mass of 1 m3 drops to 983 kg.

It would seem that the difference is insignificant. Nevertheless, it allows the cooled coolant at a low temperature to displace lighter hot water from the boiler. Natural (convective) circulation occurs in pipelines, and such systems are called gravity or gravitational, because movement in them occurs due to gravity. Therefore, the coolant flow rate in the mains and radiators is low, only 0.1–0.3 m/s. But such schemes are completely energy independent, provided that boilers for an open heating system that do not require electricity work together with them.

Note. In gravity systems, lines are made with increased slopes and pipe diameters.

In order to increase the speed of water flow through the pipes and reduce the heating time of the premises, a pump is built into the main line coming from the boiler. It forces the coolant to move at a speed of 0.3-0.7 m/s, which is why heat transfer occurs more intensely and all branches heat up more evenly. Thanks to the presence of a pump, the distance between the heat source and the batteries can be increased both in length and height.

Installing a pump unit allows you to create a slight excess pressure in the heating system, allowing the coolant to flow well into the radiators. This definitely increases the efficiency of the system as a whole, although it makes it dependent on the availability of electricity.

Note. To ensure that the heating of a private house does not stop when the electricity is cut off, it is customary to install the circulation pump on a parallel bypass line.

How to bleed air from a heating system - recommendations

With proper installation of the heating main, automatic air vents are installed on the pipeline and other distribution components, which do not require manual maintenance. Therefore, the implementation of the main method of how to bleed the heating system is associated with mechanical devices. This type of device includes Mayevsky taps built into radiators - with their help, the user will have to solve the problem of how to properly ventilate the heating system.

To carry out the battery deaeration procedure, the following operations are carried out:

- Prepare a container for draining the coolant; it can be a small jar or plastic bottle.

- Use a special key or a flat screwdriver to unscrew the screw on the head of the Mayevsky valve, placing a container under the outlet hole.

- The air is bled from the heating system, draining a certain amount of coolant. The presence of bubbles is determined by the sound of the liquid coming out (this is hissing) - when the noise decreases, tighten the screw back.

- The coolant collected from all batteries is poured back into the circuit.

Sometimes bleeding air from radiators in a heating system is difficult if they have a plug at the end instead of a valve. In this case, proceed as follows:

- Turns off the water supply to the radiator from the riser using a ball valve or other means.

- Remove the screw plug and replace it with a pre-purchased set with a Mayevsky tap of the same mounting size with a plug.

- Screw the device into the radiator using rubber or linen seals, fill the heat exchanger with water and bleed air through the Mayevsky tap.

Rice. 8 Mayevsky cranes - structural design

Coarse filter

As mentioned above, one of the reasons that there is no coolant circulation may be the accumulation of debris in the pipeline. To completely avoid this, again, we don’t save on pennies, but install a coarse filter in front of each device:

Using a filter, catching dirt is easier than correcting the consequences of clogged pipelines or boiler heat exchangers.

Conclusion! We place coarse filters in front of each heating system device (pump, boiler, etc.) and in front of each plumbing fixture. We do NOT save pennies to “buy” problems. There are arrows stamped on the filter housing indicating the direction of movement of the coolant or water in the water supply...

The filter needs to be cleaned regularly. And this is very simple to do: close the valves before and after the filter - unscrew the plug (1) on the filter - remove and rinse the mesh under the tap - put it in place and tighten the plug. All. Not like changing pipes

These are the simple “body movements” you need to perform in order to never complain that there is no circulation in the heating system. Good luck.

no circulation in the heating system

The return in the heating system is the coolant that has passed through all the heating radiators, lost its primary temperature and is now cold and supplied to the boiler for the next heating. The coolant can move in both a two-pipe and an improved single-pipe heating system.

A single-pipe system implies a sequence of connections of heating radiators. That is, the supply pipe is connected to the first radiator, from which the next pipe goes to the second radiator, and so on.

If a one-pipe heating system is improved, its design will be something like this: along the perimeter of the entire room there is one pipe into which the supply and return pipes of each radiator can be inserted. In this case, it is possible to install a control valve on each battery, with which you can very successfully regulate the air temperature in a given room.

The big advantage of this option is the minimal number of pipes in it. And the minus is the temperature difference between the first radiator from the boiler and the last. This problem can be eliminated with the help of a circulation pump, which will move all the water through the heating system much faster, and thus the coolant will not have time to reduce the temperature.

The two-pipe option represents the wiring of two pipes. One pipe is the supply of hot coolant, the second pipe is the return pipe in the heating system, through which already cooled water from the radiators enters the boiler. This system allows you to connect all radiators almost in parallel, which allows for flexible configuration of each radiator individually without affecting the operation of the others.

Basic malfunctions of heating systems and their elimination

Air jams

Air pockets occur in radiators and pipes and interfere with the normal circulation of water in the heating system. They appear for various reasons:

- violation of the technology for filling the system with water after the summer period;

- non-compliance with water deaeration regime;

- performing repairs with disassembling pipelines;

- failure to observe slopes when installing the heating system;

- air leakage through leaky joints.

To remove air from the system, use a Mayevsky valve installed on the radiator. You should open it, wait until the air comes out, the hissing stops, and the water begins to pour out calmly without bubbles. After this, the valve is closed. Don't forget to provide a container or towel to drain the water.

Old cast iron batteries do not have Mayevsky taps. The air is released without completely unscrewing the plugs at the ends of the radiators. It is better to entrust this operation to plumbers - if you unscrew the plug completely, you can flood the apartment.

The heating system is a complex structure consisting of several elements combined into one circuit and put into operation through a chain reaction.

But it happens that the system fails and the water in the batteries becomes cold. The reason for this may be problems with the return line.

Options for solving the return problem

Depending on what is the root cause of the problem, appropriate methods are selected to eliminate it. For example, if the return flow does not work well due to insufficient pressure or water speed, it is recommended to purchase a special pump.

His job will be to push water into the system with a certain force to avoid stagnation and ensure continuous movement of liquid through the batteries.

- If the pipes are clogged, you can use special water mixtures, biological products, or use pneumatic hydraulic shock.

- In the case of biological products, they involve the use of special microbes that are launched into the system and help break down the scale, sediment and other deposits that have stagnated there.

- They are good to use for older systems. The cleaning process will only take a few days. Regarding the use of pneumatic-hydraulic hammer, it helps break through scale and slag deposits without damaging the pipe walls.

Heating systems with forced circulation

A standard forced circulation heating system operates using the same connection methods. The difference is that due to the large extent of this system or the lack of natural conditions to create an inclination of the pipes, it is necessary to include a pump in the system. The circulation pump is mounted to the main pipe - this helps to increase the service life of the heating system. Using a pump helps not only increase heating efficiency, but also reduce the number of lines. A forced circulation system has the ability to heat not just several rooms, but even a house with several floors.

Heating systems with forced circulation

In order to produce high-quality operation of this type of system, a continuous power supply is required. Installation of a circulation pump in the heating system is required in order to create forced circulation of water in a closed loop. In this type of system, the pump is the central component among the equipment. It should be noted that the circulation pump may not have significant performance: its power is only needed to direct the liquid into the supply pipe. The same pressure pushes the water in the opposite direction, since the system is closed.

The circulation pump is necessary to ensure uninterrupted operation of the heating system, therefore it must fully comply with the system into which it is installed. Due to its functionality, this type of pump can be widely used in a wide variety of pipelines.

Principles for calculating a membrane expansion tank

Often the reason why there is a loss of pressure in the heating system is the wrong choice of a double-circuit heating boiler. That is, the calculation takes into account the area of the premises in which heating will be carried out. This parameter affects the choice of area of heating radiators - and they use a relatively small amount of coolant. However, sometimes after the calculation, radiators are replaced with pipes, which use a significantly larger amount of water (and this fact is not taken into account). Accordingly, it is precisely this error in the calculation that leads to an insufficient level of pressure in the system.

For the normal functioning of a double-circuit system with 120 liters 6-8 liters is sufficient . However, this amount is calculated for a system that uses radiators. When using pipes instead of radiators, there is more water in the system. Accordingly, it expands more strongly, thereby filling the expansion tank completely. This situation leads to an emergency release of excess liquid using a special valve. This causes the system to shut down. The water gradually cools down and its volume decreases. And it turns out that there is not enough fluid in the system to maintain the pressure at a normal level.

Expansion tank operation

Tip: It should be taken into account that if there is a lack of water, the boiler will not turn on - and this may cause the system to defrost.

In order to avoid such an unpleasant situation (hardly anyone will be happy about the breakdown of the heating system in the cold season), it is necessary to carefully calculate the volume of the required expansion tank. In closed systems supplemented by a circulation pump, the most rational is to use a membrane expansion tank, which functions as an element such as a heating pressure regulator.

Of course, it is quite difficult to calculate the exact amount of water in the pipes of the heating system. However, an approximate figure can be obtained by multiplying the boiler power by 15 . That is, if a boiler with a capacity of 17 kW , then the approximate volume of coolant in the system will be 255 liters . This indicator is useful for calculating the appropriate volume of the expansion tank.

The volume of the expansion tank can be found using the formula (V*E)/D. In this case, V is an indicator of the volume of coolant in the system, E is the expansion coefficient of the coolant, and D is the efficiency level of the tank.

You should definitely pay attention to the technical documentation of the boiler. In particular, a 17 kW has a built-in expansion tank with a volume of 6.5 liters . Thus, for the correct functioning of the system and to prevent such cases as pressure drop in the heating system, it is necessary to supplement it with an auxiliary tank with a volume of 10 l . Such a pressure regulator in the heating system can normalize it.

Pressure gauge values for different tank conditions

For more information about the pressure in the expansion tank, watch the video: