Escaping from the bustle of the city, people try to buy or build a house away from civilization. But they are faced with the fact that often such remote places do not have a main gas pipeline and they have to look for ways that will ensure warmth and comfortable living in a country house. There are many options for heating a country house, but in this article we will answer the most important question that interests everyone without exception: what is the cheaper way to heat a house?

The following are the most popular types of fuel:

- The firewood is ordinary.

- Coal.

- Eurodrova.

- Electricity.

- Liquefied gas, in cylinders.

- Diesel fuel.

What kind of fuel will be appropriate in a particular building depends on the operating conditions of this building, the price of fuel and ease of use.

Conditions for choosing fuel:

- Fuel price.

- The price of the heating system and its installation.

- Heating system maintenance cost.

- Air temperature during the cold season in this region.

- Availability of communications.

- Possibility of fuel delivery.

- Purpose of the building: it is a place of permanent residence or a place of temporary residence for recreation or work.

- Presence of heat loss and degree of thermal insulation.

- Ease of operation of the heating and fuel system.

- Availability of a certain type of fuel in a given region.

To correctly select the most efficient type of fuel, it is necessary to carry out an appropriate calculation that will take into account the efficiency of a given heat source, heat loss, area and volume of the heated room.

All units of measurement must be reduced to a single denominator. It is most correct to use kilograms.

Heating costs with a heat pump with a two-tariff meter.

When metered with a two-tariff meter, the price of 1 kilowatt of electricity from 7-00 to 23-00 is 2 rubles. 72 kopecks, and from 23-00 to 7-00 - 92 kopecks. With a heat pump COP of 3, these figures will be 91 kopecks, respectively. and 30.6 kopecks. Thus, the cost of heating our house will be:

150*5*(13*0.91+11*0.306) = 12756 rubles. In reality, taking into account the fact that heat loss at home increases at night, this figure will be slightly lower.

With COP = 5, we obtain the following arithmetic: The cost of heat at the daytime tariff is 0.544 kopecks, at night - 18.4 kopecks. In total, heating costs during the heating season will be:

150*5(16*0.544+8*0.184) = 7632 rubles.

Modern economical technologies

This technology includes a heat pump.

With the help of earthly resources, it is capable of producing at least 4 times more energy than it consumes itself. If you need a boiler for your home with a power of 20 kW, then a heat pump with a power of only 5 kW will be suitable for heating. The heat pump runs on electricity. The pump also costs 3-4 times more than a first-class gas boiler with high efficiency. Solar collectors can be used for heating. There is no energy consumption required at all. When properly installed, solar collectors can heat heated floors and provide you with the necessary amount of hot water. But again, it all comes down to finances.

Our future lies in these technologies. The moment will come when both a heat pump and a solar collector will become available to everyone.

As a result, we get that using a warm floor + temperature control + a heat pump (or collector) we can get truly the most economical home heating.

If you are looking far ahead and are confident that you can afford such expenses, then you definitely will not regret having all this installed at home.

About choosing a heat source

It’s good if you are lucky and there is gas on the site. And if it is not there, then what to do? You can use liquefied propane gas, bury the gas tank, not forgetting to periodically service it and fill it on time.

You can use an electric boiler, if, of course, there is enough electricity power limit, you can use a solid fuel, wood, or pallet boiler, or you can use a boiler with a diesel burner or, which is now gaining popularity, a heat pump. The main thing is to know the costs of heating your home.

You can estimate how much the equipment and its installation cost quite accurately by calling specialized offices, but not everyone will ask how much they will then pay monthly for energy consumption. Even if he thinks about it, he is unlikely to find the answers.

So now we’ll figure out how much it costs to heat a house, or more precisely, how much does 1 kW of heat cost, depending on the choice of energy source?

Principles for choosing an energy carrier

Economical heating of a private home is based on the cost and availability of coolant. When choosing, you should focus not only on the current situation (for example, the opportunity to get coal or diesel fuel through an acquaintance at prices below the market average, or receive wood waste for free) but also to sensibly assess the prospects.

If the house is without gas, you need to choose at least two alternative energy sources - for the main and backup heat sources. This approach allows you to protect your home from serious problems associated not only with low temperatures in residential premises, but also with defrosting of the water heating system.

Before comparing the efficiency of energy carriers (excluding mains gas), it is necessary to highlight those types of fuel that are most accessible to the average consumer.

For example, the solar collector should be taken out of line, since it can only be seriously considered as an additional source of energy due to the fact that there are not enough sunny days a year on the main territory of Russia, and in addition, the equipment is not cheap.

Also, let’s leave aside the heat pump for now - it produces free energy, but to get it, you need to use electricity. Plus, the system is difficult to install and requires serious costs for professional calculations and construction.

Thus, the list of available coolants includes

- liquefied gas in cylinders (installation of a gas tank requires a one-time investment of serious funds);

- diesel fuel (diesel fuel);

- electricity;

- ordinary firewood;

- coal;

- pellets;

- eurowood.

Attention! If you have access to fuel such as cheap peat briquettes, etc., you can calculate their performance for comparison using the method given below.

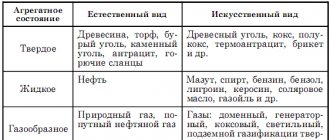

Solid fuels

Solid fuel used to be very popular. This is due to several reasons - the availability of most types of this energy carrier, low cost, poor level of gasification in populated areas, and the lack of free electrical power for electric heating complexes.

At the present stage, solid fuel is used less frequently. This is caused by a general rise in energy prices. Firewood of medium humidity costs 2–3 times more than gas, pellets – 3 times, black coal – more than 4 times. In addition, the construction of gas distribution systems is actively underway.

There are several main types of solid fuel:

- Firewood of various wood species with varying degrees of humidity;

- Coal of different types - black (long-flame, anthracite, etc.), brown;

- Pellets are granulated wood waste.

Boilers, stoves and fireplaces are used to operate on solid fuels. Most modifications of these devices require manual maintenance and operate in peak thermal mode. To equalize the thermal regime and increase the efficiency of heat use in water heating systems based on solid fuel units, it is recommended to use a heat accumulator.

A separate group among solid fuel boilers are long-burning boilers and pellet heat generators. They implement in their work the principle of high-quality combustion of all fuel components, primarily pyrolysis gas.

Pellets - granulated wood waste

Long-burning devices require fuel loading at a lower frequency; pellet boilers are equipped with automation and have a relatively independent operating mode. You can read about the design and operating algorithm of pellet boilers in a special publication.

The advantages of solid fuels are:

- No permit is required for installation of equipment;

- Low installation costs;

- Long service life;

- Availability of many types of fuel in most regions of the country;

- Possibility of organizing energy-independent heating.

Solid fuel thermal equipment also has disadvantages:

- Manual operation;

- Waste generation;

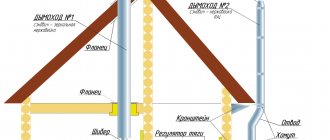

- Investments in the construction of a chimney;

- Low efficiency;

- Spasmodic thermal regime;

- Construction of a warehouse and creation of a fuel reserve;

- Large overall dimensions of brick stoves;

- The need for constant human presence and periodic cleaning of equipment.

A mandatory attribute when using solid fuel is a warehouse

Solid fuel boiler equipment is most often used in regions with close proximity to forests, coal mines, and large wood processing plants. It is also very popular in places of non-permanent residence - dachas, country houses.

Comparative analysis based on other criteria

In addition to the purely economic calculation of the cost of heating, there are other factors that influence the choice of energy source. For example, it is difficult for an elderly pensioner to chop and carry firewood to the boiler room. Some people don’t like the smell of diesel fuel or the dirt from coal, while others don’t have the opportunity to store a supply of pellets or briquettes. That is, choosing fuel for heating only from the point of view of economy is wrong. Additional criteria need to be taken into account:

- comfort during use;

- possibility of storage;

- frequency and cost of service.

Nuances of operation

It is most convenient to use electricity for heating, although it is difficult to classify it as an economical energy source. The electric boiler does not require supervision, the system is fully automated. The unit is easy to control remotely, and the boiler room is quiet, clean and free of unpleasant odors. An important point: the electrical heating installation does not require a chimney, which greatly simplifies and reduces the cost of installation.

Electric heaters and boilers are the cheapest heating devices; heat generators using other fuels are much more expensive

In addition to the high price, electric heating has another disadvantage. Not every private home has sufficient electrical power or a limit has been set that does not allow the use of energy for heating. And connecting units with a power of over 6 kW requires a 3-phase input with a voltage of 380 V.

It is almost as comfortable to operate boilers that burn natural and liquefied gas. But they require a chimney and good ventilation of the furnace room. Burning diesel and used oil is no longer so comfortable, since an odor inevitably appears and periodic replenishment of the fuel container is required. In this respect, a diesel heat generator is similar to a pellet heat generator, but the latter benefits from the absence of odors and dirt.

The champion in inconvenience is the wood and coal boiler, which requires constant attention and physical exercise. With the most economical method of heating with wood, the smell of combustion and dust mixed with dirt in the boiler room cannot be avoided (especially for coal). An exception is an automatic coal boiler, which operates on the principle of a pellet boiler, but it also requires periodic replenishment of the bunker.

Automatic boilers: pellet (pictured on the right) and coal (on the left)

About fuel storage

The nuances of warehousing and storage are easier to identify in the list:

- The electric and gas heating system of a private house operates from external sources; no storage is needed.

- For reliable operation of any solid fuel boilers, you need a supply of fuel; accordingly, it is necessary to organize its storage. You will have to make a firewood shed under a canopy or a warehouse in a barn.

- The supply of diesel fuel and waste also needs to be stored somewhere and, preferably, outside the residential building. It is necessary to purchase and install a container of sufficient volume.

- The most difficult thing is to organize storage with autonomous heating using liquefied gas as an alternative to natural gas. The cost of an underground gas tank and its installation will quickly make you forget about economical heating of your home.

Not everyone can afford to install a gas tank, and constantly carrying cylinders to refuel is hard work.

There is another, cheaper way to store liquefied gas - in cylinders. But “thanks to” frequent replacement and refilling of cylinders, comfort when operating a propane boiler is equal to exercises with firewood when loading a solid fuel heat generator.

Equipment service

Electric heating systems require virtually no maintenance (check and clean once every 2 years). If it were not for the draconian daily tariff, then with the help of electricity it would be possible to organize a “economical smart home” system. Gas boilers will have to be serviced more often; they require annual preventive cleaning of the heat exchanger and chimney. But here you can save money if you clean the unit yourself, as described in this article.

Due to the low quality of diesel fuel, diesel heat generators will need to be cleaned as they become dirty, which can happen several times a season. The same applies to waste oil boilers, and the cleaning process is very dirty. Faced with problems like this in the middle of winter, you'll think twice about whether you need energy-efficient heating while working.

It is advisable to clean the smoke pipes with the firebox of a boiler using wood and pellets once a week, and the ash pan daily. When working with wet wood from the combustion chamber, it is important to remove soot and tar more often before they become completely stuck.

Main fuels

Today, there are four types of fuel that have already been tested over the years, have been used for a long time and have proven themselves in one way or another.

- The first is natural gas. We have a lot of natural gas in our country. Therefore, it is quite cheap. If you don't consider the various nuances. But we'll talk about this a little later.

- The second method is liquefied gas. Or it is also called SPBT (technical propane-butane mixture). This gas is very often seen at gas stations. Cars are fueled with it. This gas can also be used for heating country houses and any premises.

- The third type of fuel is diesel fuel or diesel fuel.

- The fourth is electricity.

So, let's look at each of these types separately. What are the pros and cons, and its cost. Cost of investment and cost of operation per day, per month and per year.

Natural gas

Natural gas, by default, is the leader among other types of fuel according to almost all proposed criteria. In many regions, the cost of 1 kWh produced by gas exceeds the same price tag for firewood by only 10-20%. The efficiency of the most budget and simple gas boilers is at least 90%. For high-tech models, for example, for condensing models, this figure is much higher and close to ideal.

In terms of convenience, gas is also a leader. There is no need to store it, or carry it to the boiler; the “loading” is done automatically. In terms of environmental friendliness (relatively, at the place of combustion), gas is in second place after electricity. Why it is conditional will become clear below.

Natural gas has only one drawback (if it has an adequate price in your region, of course) - availability. As mentioned above, not every new built house has a central highway. Even if it is very close, bringing gas from it to the house is not just an expensive undertaking, but very expensive. In some regions, the cost of connection may exceed the estimate for the construction of a full-fledged wooden house with an attic.

This is the conclusion regarding gas. If it is available in your area, you can afford its connection, and the price per cubic meter does not deter you, then this is what you need.

How much does it cost to heat a house: prices for different areas

| Economy | Standard | Premium | |

| Wall material | Backing brick 250 + Facing brick 120 | Backing brick 250 + Facing brick 120 | Backing brick 250 + Facing brick 120 |

| Design thermal power | 10.5 kW | 10.5 kW | 10.5 kW |

| S heated floor | NOT PROVIDED | NOT PROVIDED | NOT PROVIDED |

| Radiators | Steel panel (Türkiye) | Steel panel (Austria) | Steel panel (Austria) |

| Pipeline, material | Polypropylene | Metal-plastic (KAN-therm, Poland) | Cross-linked polyethylene (TESE, Germany) |

| Pipeline, diagram | Two-pipe | Two-pipe | Collector |

| Boiler | Double-circuit non-condensing wall-mounted boiler, 24 kW (Fondital, Italy) | Double-circuit non-condensing wall-mounted boiler, 24 kW (Fondital, Italy) | Single-circuit non-condensing wall-mounted boiler, 24 kW (Fondital, Italy) |

| Boiler room equipment | A set of the minimum required set of materials | A set of the minimum required set of materials | A set of the minimum required set of materials |

| Automation | NOT PROVIDED | NOT PROVIDED | Thermostatic valves with thermal head on radiators + room regulator |

| Equipment for hot water supply | By means of a double-circuit boiler | By means of a double-circuit boiler | Indirect heating boiler with a volume of 150 liters (Huch EnTEC, Germany) |

| Cost, m2 | RUB 1,360/m2 | RUB 1,889/m2 | RUB 3,011/m2 |

Comparative characteristics of engines

Considering the features of engines, you can understand which fuel will be the best option for your equipment:

Diesel

Advantages of engines running on diesel fuel:

- Economy.

- Power.

- Durability.

Gasoline

Gasoline engines are popular due to:

- Low cost of maintenance.

- Frost resistance.

- Undemanding to fuel quality.

Gas

Gas is used as an alternative to gasoline. To switch to this fuel, you will need to convert your car. This fuel does not always provide the power you get from fuel-efficient diesel or gasoline. Among the advantages are low cost and moderate consumption.

How to optimize heating costs?

You should know the following:

The greater the height of the room, the higher the heat loss. Plastic windows retain heat better than wooden ones. Corner apartments have more heat loss than apartments located in the middle of the house. Apartments on the top floor require more heat for heating. When installing radiators, you need to take into account that there should be 20% more batteries than necessary according to calculations, so that they provide full heat transfer in the event of breakthroughs, extreme frosts or other emergency circumstances

Please note that in terms of heat transfer, the following indicators are used in the standard calculation: cast iron radiators have 145 W, bimetallic – 185 W, aluminum – 190 W. In addition, in order to optimize heating costs, you need to properly seal the room, install double-glazed windows, eliminate all kinds of cracks and cracks, insulate the walls

The amount of heat loss is also influenced by different climatic conditions of the region

In addition, in order to optimize heating costs, you need to properly seal the room, install double-glazed windows, eliminate all kinds of cracks and cracks, and insulate the walls. The amount of heat loss is also influenced by different climatic conditions of the region.

The good thing about the heating cost calculator is that you don’t have to spend a long time calculating the cost of heating your home using complex and obscure formulas. You just need to measure correctly and indicate the requested data in the online program to get the most accurate result for your home.

Having made preliminary calculations and compared their results, the editors of santehnikportal.ru came to the conclusion that the most economical type of fuel is natural gas, and the most expensive fuel is electricity.

Use our online heating calculator and don’t be afraid of any frost!

- https://dekormyhome.ru/remont-i-oformlenie/kak-rasschitat-rashod-na-otoplenie.html

- https://diy.obi.ru/articles/schitaem-rashodi-na-otoplenie-v-zagorodnom-dome-511/

- https://domsdelat.ru/elektroprovodka/rashod-elektroenergii-na-otoplenie-doma-100m2.html

- https://eurosantehnik.ru/rasxody-na-otoplenie-doma.html

- https://santehnikportal.ru/calc/rashody-na-otoplenie.html

The main condition for economy

And it is probably necessary to start with that condition, without which all further presentation simply loses all meaning. That is, without which any heating system obviously cannot be classified to any degree of efficiency.

We are, of course, talking about maximally blocking the paths for heat leakage from the house. Or – about a well-thought-out, calculated and correctly executed thermal insulation system for a building.

In nature, everything strives for harmony and balance. And if a heated object suddenly appears against the general “cold background”, no matter what, then heat exchange processes are activated, trying to quickly level out the difference in temperature and bring it to one general level. This also applies to any home - without an insulation system, the temperature inside will tend to drop to the street temperature, and the only barrier to this will be the building envelope. Which, by the way, in most cases do not have the most outstanding resistance to this heat transfer. In a word, heat will actively go outside - for this there are several “traditional” directions. And the volume of heat leaks (heat loss) will depend on the location and features of the structure, its contact area with the external environment, the material of manufacture and the presence of thermal insulation qualities.

This is not all, but the main ways of heat loss in a residential building.

1 - Heat loss through the ceiling of the first floor, foundation, basement, basement. These leaks, by the way, are not so large against the general background - partly due to the fact that heat still tends to rise. So, this part of the house accounts for 10 to 15% of the total heat loss.

2 - The external walls of the building, due to their large area, become one of the main routes for heat leakage. They account for up to a third (up to 35%) of losses.

3 - Windows and doors are a special issue, since much depends on their type, quality of manufacture and installation, and operating mode (how often they are opened). But in total we can talk about losses of 15÷25%.

4 - A very problematic place is always the attic floor or roof (depending on the specifics of the building). They are natural barriers to the upward flow of heat, and with insufficient thermal insulation, losses here reach 20–25% of the total volume, and sometimes even more.

5 - Literally, the “highway” for heat release (up to 30÷40%!) can be the ventilation system (and without it, there’s no way) and chimneys (if there are any). Here, of course, the problem is solved not by thermal insulation, but somewhat differently - by air recovery, proper operation of furnace devices or structures, the presence of a valve system, etc. But forgetting about this is unacceptable!

Why does the author place such emphasis on all this? The reason is obvious - there is no point in talking about energy savings if heat leakage paths are ignored.

There are special methods for calculating heat losses, taking into account the specifics of the building and the climatic conditions of the region of residence. And the design of a heating system is precisely based on these calculations, which show how much heat this system must replace.

Moreover, modern electronic equipment allows one to personally recognize vulnerabilities in thermal insulation. It is enough to inspect the building from the outside in winter using a thermal imager - “holes” are immediately detected, through which the heat quickly escapes to the street.

Thermal imaging examination helps to find gaps in thermal insulation - it is clearly noticeable that heat literally radiates through such areas into the street.

Leaving it as it is is literally trying to “heat the street” with a obviously predictable result. And in this case, the choice of heating system does not matter much, since a priori it will be extremely uneconomical and unprofitable, regardless of the energy source used - even if the energy carrier is practically free.

That is, only then, after completely eliminating or, where this is not possible, minimizing heat losses, will it be justified to search for the most economical home heating system for your conditions. It is for such equal conditions that we will consider options.

By the way, in general terms, but with a fairly high degree of accuracy, the algorithm proposed on the pages of our portal allows us to calculate the predicted amount of heat losses for individual rooms and for the entire house (apartment) as a whole. Essentially, this gives the calculated thermal output of the heating system. And since this calculation, by its structure, takes into account the most unfavorable conditions (which, if they occur during the winter, do so infrequently and not for long), the resulting values of thermal power can be considered guaranteed to be sufficient to replenish heat losses.

If you want to more thoroughly evaluate your future heating system, we recommend that you follow the link and first calculate the required power of the system. It will be mentioned more than once below.

Is it possible to independently calculate the power of the heating system for your home?

Yes, this is possible - and with quite acceptable accuracy of the final result. Go to the publication on our portal dedicated to heating boilers - in the appendix there is a brief description of the algorithm and a convenient online calculator with the necessary explanations.

By the way, based on the power indicators obtained as a result of these calculations, the final heating devices are selected for specific rooms. For example, in the future you can select the desired radiator model, calculate the number of sections for dismountable batteries, the length of the “warm floor” circuits, etc. So it is best to save the compiled table with the values of thermal power for each of the heated rooms - the owners will need it more than once.

* * * * * * *

Now - directly to the topic of our publication. And the next question will be the cost-effectiveness of using various energy sources. To “bring it to a common denominator”, priority will be given to heating systems with liquid coolant, as the most popular and widespread. That is, when we talk about, say, solid fuel, we do not mean ordinary direct heating stoves, but boiler equipment that serves the entire house. It’s the same with electricity – not individual heating devices placed in rooms, but an entire heating system with a central heat generator powered by electricity.

Below will be presented a table of a kind of “rating” of efficiency - in the opinion of the author of these lines. Let no one be misled by the total scores - these are completely arbitrary evaluation criteria. That is, they do not actually show the level of efficiency - here, in addition to the cost of energy, they include issues of creating a heating system, delivery and storage of fuel, ease of use, safety and others. Buttons in each row of the table will immediately take the reader to a more detailed consideration of the advantages and disadvantages of a particular energy carrier.

Perhaps some issues seem controversial - I will be glad to receive comments in the comments to the article.

Choosing fuel for heating - which is cheaper?

How to decide on the type of fuel for a heating boiler? Let's just do the math.

Numerous advertising statements from sellers of heating equipment and multi-page disputes on the Internet about the unprecedented efficiency of using certain heating boilers using one type of fuel or another have led to the desire to pick up a pencil, open reference books, call fuel sellers and, finally, finally figure it out — how much does heating cost using different types of fuel?

The calculations were based on the calorific value - the specific heat of combustion of a kilogram of fuel. The calorific value of kilograms was converted into convenient, generally accepted trade units for different types of fuel, liters, cubic meters and the same kilograms.

The price per kilowatt of heat that can be released when burning a specific type of fuel turned out to speak for itself. But heating boilers using different types of fuel also have different efficiencies.

Solid fuel boilers have the lowest efficiency, gas boilers have the highest efficiency, and diesel fuel boilers are close to gas boilers. Therefore, the average parameters of different types of heating boilers were taken and the price per kilowatt of heat received was calculated, taking into account the efficiency. I suggest you look at the table in which the calculation results were summarized. They turned out to be quite expected for me, but obviously contradicting popular stereotypes and statements of cunning marketers:

| Type of fuel | Price in rubles | Calorific value | Price per kilowatt of heat | Boiler efficiency for a given fuel | Price kW of heat taking into account efficiency |

| Dry firewood, kg | 5 rub. | 3.6 kW per kilogram | RUB 1.39 | 70% | 1 ruble 98 kopecks |

| Quality coal, kg | 3 rub. | 7.5 kW per kilogram | 0.4 rub. | 70% | 57 kopecks |

| Natural gas, m3 | 4.2 rub. | 9.7 kW per cubic meter | 0.43 rub. | 92% | 47 kopecks |

| Liquefied gas, liter | 18 rub. | 6.4 kW per liter | 2.8 rub. | 92% | 3 rubles |

| Diesel fuel, liter | 27 rub. | 10.3 kW per liter | 2.6 rub. | 88% | 2 rubles 95 kopecks |

| Electricity, kW | 2.18 rub. | 1 kW | 2.18 rub. | 99% | 2 rubles 20 kopecks |

| Pellets, kg | 6.5 rub. | 5 kW per kilogram | 1.3 rub. | 70% | 1 ruble 86 kopecks |

So, our hit parade of cost per kilowatt:

The most expensive type of fuel turned out to be liquefied gas - 3 rubles per kilowatt.

Second place, with a very small gap from the leader, is taken by diesel fuel - 2.95 rubles per kilowatt.

Electricity closes the top three at 2.2 rubles.

Dry birch firewood comes in fourth place - 1.98 rubles.

Wood pellets (pellets) breathe in the back of firewood - 1.86 rubles.

High-quality graded coal unexpectedly surpasses natural gas in cost with a price of 57 kopecks.

And closing the list, occupying an honorable place as the leader in savings, is our asset - natural gas, with a price of 47 kopecks! Ta-daa!

Now that the cost of heating energy is known, let’s supplement it with the estimated cost of boiler equipment and, as an example, take the most popular power of 24 kilowatts:

For liquefied gas, boiler and gas tank: 350-550 thousand rubles.

For diesel fuel, boiler and fuel tank: 90-150 thousand rubles.

Electric boiler: 20-35 thousand rubles.

Solid fuel boiler: 30-50 thousand rubles.

Pellet boiler: 200 thousand rubles.

Natural gas boiler: 25-60 thousand rubles.

Conclusions:

Installing a boiler for liquefied gas with a gas holder is an absolutely meaningless economically, obviously unprofitable idea, in fact, a marketing deception of the consumer.

In addition to the cost and payback period of several centuries, colossal excavation work is also required, compliance with requirements at the installation site, removal of several Kamaz trucks of soil, delivery of several Kamaz trucks of sand for backfilling, ensuring normal evaporation of liquefied gas in winter at temperatures below -20, periodic pumping of gas condensate from the gas tank and so on, and so on...

If there is no natural gas, and you don’t want to bother with solid fuel, then it would be quite appropriate to install a diesel boiler, or an electric one, if the allocated power allows.

And it would definitely be appropriate to install an electric boiler in a small house with good thermal insulation.

You may also be interested in:

Wall-mounted gas combi boilers

Examples of installation of heating systems

What's cheaper to heat a house? comparison table

Choosing the optimal method of heating a country house comes down to comparing all types of fuel and technical characteristics of heating systems.

Fuel comparison table:

| Heat source | Boiler efficiency | Calorific value 1 kg per kWh | Requirement for a house 100m2 | Costs per season |

| Firewood | 70 | 4,5 | 25000 | 25000 |

| Eurodrova | 70 | 5,5 | 25000 | 34000 |

| Pellets | 70 | 5,2 | 25000 | 33750 |

| Coal | 90 | 7,7 | 25000 | 29250 |

| Diesel fuel | 75 | 11,9 | 25000 | 71500 |

| Liquefied gas | 75 | 13 | 25000 | 65500 |

| Electricity. One tariff | 99 | 25000 | 112500 | |

| Electricity including night tariff | 99 | 25000 | 89131 | |

| Electricity. Two tariffs | 99 | 25000 | 59300 |

* — main gas was not taken into account in this calculation, since it is beyond competition.

After carrying out all the calculations and comparing the positive and negative aspects of all types of heating, we find out what is cheaper to heat a house and it turned out to be ordinary firewood. It is advisable to install two types of boilers. The one that is more profitable and convenient during a certain period will be used.

Main fuels

Today, there are four types of fuel that have already been tested over the years, have been used for a long time and have proven themselves in one way or another.

- The first is natural gas

. We have a lot of natural gas in our country. Therefore, it is quite cheap. If you don't consider the various nuances. But we'll talk about this a little later. - The second method is liquefied gas. Or it is also called SPBT (technical propane-butane mixture). This gas is very often seen at gas stations. Cars are fueled with it. This gas can also be used for heating country houses and any premises.

- The third type of fuel is diesel fuel or diesel fuel.

- The fourth is electricity.

So, let's look at each of these types separately. What are the pros and cons, and its cost. Cost of investment and cost of operation per day, per month and per year.

https://youtube.com/watch?v=oCRBHHlPllQ

Pellets

Pellets are granules that, like briquettes, are pressed from wood waste. To use them you need a special boiler. Such equipment is equipped with a hopper for loading pellets, and automation, which is responsible for dosing their supply into the combustion chamber. In principle, in terms of ease of use, this fuel is better than firewood, briquettes and coal.

However, there are a number of nuances. Firstly, pellet boilers are relatively expensive. Secondly, the fuel itself is still expensive, even though it is made from waste. Thirdly, pellet boilers are bulky.

Conclusion. In terms of convenience, pellets, of course, are inferior to natural gas and electricity. In some respects, this type of heating is better than wood and coal. But there are a number of factors due to which this type of fuel is not very popular among the mass user.

Features of gas holder (liquefied) fuel

A gas holder (GasHolder) is a banal tank for storing gas (propane + butane). It is pumped there in liquefied form. Then gradually this “liquid” turns into a gaseous state, increasing the pressure in the container. And due to the high pressure, the gas is squeezed out of the tank into the pipes for supply to the house.

The use of propane and butane in gas holders is due to the presence of these gases in fairly large volumes and the simplicity of their liquefaction technology

In fact, butane and propane are by-products remaining after the separation of methane from “natural gas” raised from the depths. Their share in the mixture pumped out of the ground often reaches 30%.

Plus, they are formed during the processing of associated gas, which comes out of wells along with oil. They have to either be burned in flares at the field, or find ways to use them in the energy sector.

Gas tanks can be used to store various gases. But for autonomous gas supply to private homes, it is customary to use equipment designed for a propane-butane mixture. It is also called liquefied petroleum gas (LPG). Liquefying methane for injection into such household containers is too expensive and unprofitable.

A mixture of liquefied propane and butane (LPG) differs in:

- winter;

- summer

Butane is cheaper than propane. But it freezes faster at negative atmospheric temperatures, so it is added to the winter mixture in smaller proportions. In winter, LPG is more expensive not because of the desire of power engineers to earn more, but because of the technological need to increase the percentage of expensive propane in it.

However, it is not worth purchasing liquefied gas for future use in the summer. In winter, with severe frosts, the summer composition may “freeze”. It will not turn into ice, but it will change from a liquid to a gaseous state in smaller volumes.

The capacity of a gas tank is usually calculated so that there is enough hydrocarbon gas in it for six months of uninterrupted operation of all gas equipment installed in the cottage

Gas holders are vertical and horizontal, and are also divided into:

- underground;

- aboveground.

In Russian climatic conditions, it is recommended to install only the underground version. At low outside temperatures, liquefied propane-butane begins to evaporate less efficiently.

It is easier to dig a deep pit so that the bottom of the gas tank is below the freezing level of the soil in the area. It is more expensive to insulate and artificially maintain the temperature parameters required for evaporation in the container by installing special evaporators.

Some “experts” claim that vertical gas holders have lower thermal efficiency compared to their horizontal counterparts. The evaporation mirror inside them is much smaller. And indeed it is. The smaller the area of liquid on top means less of it evaporates.

However, in vertical LPG tanks the evaporation process occurs at a slightly higher rate, which fully compensates for the smaller size of the “mirror”. The end result is almost the same. It is not for nothing that in Scandinavia, where the climate is in many ways similar to Russia, they prefer to install gas tanks in a vertical design.

Features of heating systems with different energy sources

| Photo | Name | Rating | Energy cost | System creation costs | Price | |

| #1 | Gas heating | ⭐ 4.8 / 5 13 — votes | moderate | high | For a more detailed analysis | |

| #2 | Solid fuel | ⭐ 4.6 / 5 6 — votes | low | average | For a more detailed analysis | |

| #3 | Electric heating | ⭐ 4.45 / 5 13 — votes | high | average | For a more detailed analysis | |

| #4 | Liquid fuel | ⭐ 4.25 / 5 1 - voice | high | average | For a more detailed analysis | |

| #5 | Alternative sources | ⭐ 4.1 / 5 5 — votes | practically free | extremely high | For a more detailed analysis |

Which of the following systems would you choose?

Take the survey

Now let’s try to figure out what kind of energy carrier seems most economical to us. And in some places it will even be possible to evaluate the “accounting” of a particular source purely mathematically.

Heating with gas boiler

Network gas today has no real competitors in terms of efficiency, that is, in terms of the combination of the cost of a unit of measurement of the energy carrier and its energy potential. So all these “gas wars” with Western neighbors have a very serious economic background.

“Blue fuel” confidently remains in the highest position of efficiency in terms of organizing the heating system.

Indeed, the cost of a cubic meter of gas is low. And even heating a fairly spacious house should not create a catastrophic “hole” in the family’s budget.

In addition, modern gas boilers have very high efficiency, and condensation-type devices that extract heat even from the water vapor produced during gas combustion even allow us to talk about exceeding 100%! Gas equipment is relatively inexpensive, but it is equipped with timely electronics that automatically select the optimal mode of operation of the system and, by keeping the boiler always in “healthy” operating condition.

Modern gas boilers are very economical in themselves and extremely comfortable to use.

It would seem that this is the best option, and there is no need to “fool your head” anymore.

However, this whole “fairy tale” is only possible if the house is connected to the gas main or is located in close proximity to it. Or such a connection is planned and will inevitably take place during the construction phase. Then yes - there is no need to “fence the garden”, gas becomes the optimal solution.

True, the overall picture is somewhat “blackened” by the need to draw up and coordinate with the authorities a project for the installation of gas equipment (any kind!). And all this usually takes a lot of time, nerves, and requires material costs - both official and often “shadow”, so that the decision is not delayed by every trifle.

Drawing up and coordinating a home gasification project sometimes turns into a lengthy and rather expensive “difficulty”.

But if these “administrative obstacles” are passed successfully, and the installation of the system is carried out with the proper quality, you can enjoy the convenience of such heating at low subsequent costs.

By the way, you can calculate the estimated costs yourself. Of course, we are not talking about high accuracy here - this is just a forecast for an average winter. And as we know, this time of year is famous for its weather anomalies - both in the direction of warming (more and more often lately), and sometimes in the direction of severe frosts that are unusual for the area.

Calculator for calculating network gas consumption for heating

Go to calculations

How brief are the explanations:

- The required thermal power is exactly what was discussed above in the first section of the article. This should not be confused with the capacity of the existing boiler.

- It is necessary to indicate whether a conventional boiler is used or a condensing boiler.

- If two efficiency values are indicated in the technical documentation of the boiler, then the value for Hi, the lower calorific value, is taken for the calculator.

- In the vast majority of cases, the G20 network gas mixture is used. But it’s still better to clarify - there is also G25, but its energy potential is somewhat lower.

- Every interested reader probably knows local tariffs.

The calculator will show the average consumption per hour, per day, per week, per month, as well as for the entire heating period. At the same time, an approximate “cash equivalent” will be shown for monthly and total expenses.

* * * * *

So, network gas is a very convenient solution. However, sad as it may be, it is very premature to talk about universal gasification of residential buildings in Russia. That is, in many cases, it is also necessary to resolve the issues of connecting the highway to the place of residence - and this sometimes results in “astronomical” amounts for most homeowners.

But there are also settlements where there is no gas pipeline at all.

In such cases, some homeowners also opt for convenient and efficient gas heating equipment, but using liquefied gas from reserves created in advance.

Autonomous gasification of a country house - gas holders (underground tanks) or replaceable gas cylinders can be used.

The optimal solution seems to be the creation of a large underground storage facility - a gas tank, the capacity of which allows for autonomy, if not for the entire heating season, then for sure for a couple of months. Of course, the equipment of such a storage facility (including mandatory design surveys and excavation work) will cost a very substantial amount. And calling special equipment to replenish gas reserves is also not free. But many owners, having calculated the “accounting” and compared with other options for heating the house, go to such expenses, believing that in terms of the total cost of liquefied gas and the convenience of its use for heating, they still win. And switching modern gas boilers with all their amenities from network gas to liquefied gas does not take much time and does not require special expenses.

Is it possible to calculate the consumption of liquefied gas?

Yes, quite - if there are initial values for this. The calculation algorithm is implemented in a calculator for calculating liquefied gas consumption for heating needs - it is given a separate page on our portal.

Based on the results of these calculations, it will not be difficult to estimate quite accurately what expenses the owners expect during the heating season (not forgetting to add to them the costs of transportation).

So, let's summarize the gas:

pros

- The most affordable price for the resulting kilowatt of thermal energy, especially if we consider network gas.

- Large selection of modern heating equipment.

- High efficiency of boilers.

- Ease of use, sensitivity to settings.

- For many boilers, the construction of classical chimneys is not even required - coaxial ones passing through the wall in the immediate vicinity of the unit are sufficient.

Minuses

- Very complex preparatory activities for the design and permitting plan.

- Transport problems - for liquefied gas systems.

- Natural gas is dangerous at all stages of its use. Thus, it is capable of creating explosive mixtures in the event of a leak; it is toxic to humans in itself, not to mention the products of its combustion.

Gas boiler 12 kW

Heating with solid fuel

Russia is a country with a predominance of forested areas, and therefore in many regions the cost of solid fuel (firewood) is even more profitable than network gas. And some homeowners can boast of an almost free source.

Solid fuel may be the cheapest, and sometimes even free

But according to other evaluation criteria, not everything is so good, and therefore such heating systems cannot lay claim to leadership.

One of the main problems of solid fuel boilers is the need for frequent maintenance, loading and cleaning.

One of the key problems is the need for frequent, regular human intervention in the operation of the system. If only because the boiler needs to be loaded with firewood, and when it burns, the ash chamber needs to be cleaned.

To a certain extent, the severity of this issue is reduced in long-burning boilers that operate on the principle of afterburning pyrolysis gases. There is equipment that runs on pellets (mini-briquettes), equipped with an automatic fuel supply line. But this is only lengthening the intervals between loads, even up to 12 ÷ 15 hours or even up to several days. It will not be possible a priori to completely get rid of this need.

Another huge disadvantage is the cyclical operation of the system. That is, a pronounced alternation of the stages of loading, ignition, reaching full power, burning, cooling, cleaning the chambers - and so on.

To prevent such temperature jumps from affecting the performance of the entire system, a buffer tank is needed - a heat accumulator. It will accumulate heat during periods when it is produced in excess, and transfer it to the batteries during periods of temporary downtime of the boiler. The solution is good, but very expensive to implement.

The solid fuel boiler works in tandem with a heat accumulator

What volume of buffer tank is needed?

This depends on the design power of the heating system, the parameters of the solid fuel boiler, and the selected operating mode. Our calculator for calculating the volume of a heat accumulator will help you carry out the necessary calculations.

The next problem is that storing solid fuel reserves requires compliance with certain conditions and a lot of space. It doesn’t matter what it is – a well-equipped firewood shed on the street or a dry room (bunker) for coal, briquettes, bags of pellets, etc.

Storing even an “operational” supply of solid fuel, even for at least one season, will require a lot of free space and the creation of optimal conditions there.

There are other unpleasant aspects that make the use of boiler equipment, let’s say, uncomfortable, even against the backdrop of cheap or even completely free solid fuel.

Let's try to draw the line:

pros

- Fuel in many regions of the country is cheap and easily accessible.

- Very high heat transfer from solid fuel.

- Organizing a heating system does not require “going through the authorities.”

Minuses

- There may be difficulties with “logistics” and storage organization - the fuel takes up considerable volumes and is massive.

- A high-quality chimney is required, with protection against condensation accumulation. Chimneys gradually become overgrown with soot and require regular inspections and cleaning.

- Due to the very high combustion temperatures of fuel, there is an increased fire hazard, which imposes special requirements for the installation of the boiler and chimney.

- The system often turns out to be quite inert and difficult to manage operationally.

- Ash becomes an additional source of dirt in the house.

- You have to go outside to get a supply of firewood in any weather - be it a snowstorm, strong wind, rain or severe frost.

And yet this is an honorable second place. If it is impossible to use gas, most homeowners first turn to solid fuel.

Long burning boiler 20 kW

Heating with electric boiler

Many may rush to argue - they say, electricity should take the last line in terms of cost. But the article sets out the subjective opinion of the author, who is open to dialogue, and this is how he sees it for now.

With electricity it turns out easier and more comfortable than any other options. But - expensive to operate...

Of all other types, electric heating is the easiest to implement. It is enough that the power line of the required power is connected to the house - everything else can be done independently.

Electric boilers are usually very compact, operate silently - often there is no need for them to organize a separate boiler room.

This is understandable - no open flame, complete absence of the need for a chimney. In the illustration above, the boiler is generally hanging on a wooden wall - this is not surprising, since the unit never heats up to critically high temperatures, above 90-95℃. A huge plus in terms of fire safety at home!

Electric boilers are presented in a wide variety, including those based on the principle of converting electrical energy into heat. A huge advantage is that such devices can be very precisely adjusted and, as a rule, are equipped with modern electronics that allow you to automatically select and maintain the optimal operating mode of the system. This achieves the greatest possible energy savings.

What are electric heating boilers?

The reader will be able to get acquainted with the existing varieties of such boiler equipment, evaluate the advantages and disadvantages of each, and see the main characteristics of popular models if he follows the link to an article entirely devoted to electric heating boilers .

We can say that the only significant disadvantage of electric heating is the high cost of electricity. This circumstance is precisely what scares away many from the prospect of acquiring just such a system.

To a certain extent, this problem is simplified by installing the previously mentioned heat accumulator. Then, if a multi-tariff payment system operates in your region of residence, you can “load the tank with heat” during the period of the night tariff - and gradually use it up during the day. Most boiler control modules allow this type of programming.

And leave idle speculation about the increased danger of electric shock to the grandmothers. Electric boilers, with their built-in protection systems, when properly connected to the network, are no more dangerous in this regard than a coffee grinder or iron.

So, to summarize:

pros

- Maximum simplicity in creating the system.

- As a rule, electric boilers are inexpensive.

- The efficiency of any modern electric boilers is close to 100%.

- Maximum ease of use, sensitivity in control.

- Best performance in terms of safety.

Minuses

- The main disadvantage is the high cost of electricity.

- Complete dependence on the stability of the electrical grid. If interruptions are a common occurrence in your area of residence, there is no need to even think about this option.

It is clear that with a complete transition to electric heating, the quality of the building’s thermal insulation becomes especially important. “Heating the street” is too expensive.

Electric boiler 9 kW

Heating with liquid fuel

There is no point in writing much about this heating - for the reason that in the Russian sphere of private housing construction it has not gained much popularity. There is a combination of both high price and clearly insufficient operating comfort.

Usually we are not talking about special liquid fuel boilers, but about special burners mounted in the combustion chamber.

Agree that calling diesel or kerosene a cheap type of fuel just doesn’t work. Somewhat less, you may have to pay for fuel oil or waste - but they also have lower heat transfer rates.

But in general - fuel must be delivered in sufficient quantities and its storage must be organized - there is a certain analogy with the gas tank discussed above. The degree of fire safety of both the storage facility and the boiler room should be clear to everyone without explanation. Add to this the presence of an odor characteristic of petroleum products - and the situation is not in favor of such a system.

You can independently estimate the approximate costs of heating with liquid fuel - this does not take into account transport problems.

How much liquid fuel is needed to heat a house?

Surely a lot, but it’s better to have a more substantive idea. The calculator for calculating liquid fuel for heating needs will help you with this . There are also all the necessary explanations.

By the way, the principle of a multi-fuel boiler is often used. This means that the combustion chamber of a wood-burning boiler assumes the possibility of installing burners operating, for example, on network or liquefied gas or liquid fuel.

A diesel burner that can be installed on a solid fuel boiler.

Then, of course, the boiler unit acquires excellent versatility. Depending on the circumstances, you can switch from one type of fuel to another.

We will not separately consider the pros and cons of infrequently encountered and unpopular liquid fuel systems - everything is already clear from what has been stated.

Diesel burner for boiler

Alternative sources of thermal energy

The author deliberately put this category in last place. But not at all because it denies the possibilities and, without a doubt, the enormous future of such energy sources.

The use of solar energy and geothermal heat are promising areas. But they are still available to very few.

The goal is to “cool the heads” a little for those applicants who are ready to “put everything on the line” to achieve a not entirely clearly expressed goal.

Alternative sources most often include wind energy, solar energy, and geothermal heat. There are some other options - but they are less pronounced.

- We dismiss the wind right away - it is a priori impossible to create a wind turbine in a private household that would cover the electricity needs for heating a house.

- Solar collectors can provide heating of water or coolant. But this requires considerable areas to “receive” the sun’s rays, and the system itself becomes extremely dependent on the time of year, the time of day, and the current weather. That is, it is better to consider collectors only as one of the heat sources transferred to a common “piggy bank” (heat accumulator).

Video: Solar collector as an additional heat source in a heating system with a solid fuel boiler

- Finally, a heat pump, operating due to the difference in temperatures on the surface of the earth and in the depths of the soil (below the freezing level at depth, a temperature of 10÷12 ℃ is almost constantly maintained, thanks to geothermal “feeding”. Yes, this direction is very promising, but it must believe, is at the very beginning of its development. The equipment is still very expensive, and its installation requires very large-scale work to place tubular or probe heat exchangers at depth. That is, the costs ahead are colossal, associated with the purchase, installation, and commissioning works.

Laying a horizontal heat exchange circuit

And with all this, you should correctly understand that even starting the system does not mean that from now on you will be heated completely free of charge. Yes, the system must be becoming the most economical! But you will still have to pay for heating - the operation of a heat pump requires significant electricity consumption. In principle, you can count on payback. But it will probably be achieved during the lifetime of your children, or even grandchildren.

That is, one should not hope that by taking, say, a loan for such construction, it will be possible to easily and quickly pay off through savings. No, this becomes an investment in a rather distant future.

It is hoped that advances in technology will soon allow these sources to be treated as equals when evaluating all options. For now - it’s as it is...

It is only due to such uncertainty that alternative sources have so far been given the last place in our “rating”. But they will still play their part!

Heat pump

Which gas boiler is better to install in the house? Their types and characteristics

A gas boiler is a device for producing thermal energy through the oxidation process of natural gas. Boilers are designed to maintain heat in residential premises and to heat water.

Principle of operation

The principle of operation of a gas boiler comes down to the fact that a torch is ignited by a piezoelectric element, which ignites the main burner, which, in turn, heats the heat exchanger through which water moves.

To protect the consumer from possible accidents (since natural gas is flammable, poisonous, and explosive), the boilers are equipped with an automatic system that, if the torch goes out, turns off it and the gas supply to the main burner.

Constant maintenance of the coolant temperature is ensured thanks to a control valve and a thermocouple that measures the temperature.

Classification

Gas boilers are divided into industrial-type devices and for domestic needs. Production-type products are used to produce both high-pressure and low-pressure steam.

Gas boilers for domestic use are designed for heating and hot water heating (DHW). They are divided into:

- single-circuit;

- double-circuit;

- flow-through.

Single-circuit devices are used for heating. Double-circuit - for heating and hot water supply. Flow-through products are designed for heating water used for domestic needs.

By type of installation, boilers are divided into:

- floor;

- wall-mounted

Based on the type of combustion chamber, they are divided into boilers with:

- open camera;

- closed camera.

In an open combustion chamber, the oxidation process occurs with natural air movement (natural draft). In a closed combustion chamber, draft is provided by a built-in fan in the boiler itself.

Comparison of different types of boilers

The advantages and disadvantages of various types of boilers (in relation to each other) can be noted as follows:

- floor-standing devices are more powerful than their wall-mounted counterparts, but the latter are more compact in size;

- single-circuit products do not perform the function of providing hot water; moreover, they require additional installation of a pump that will pump coolant through the heating system;

- the process of providing hot water with dual-circuit devices is accompanied by large costs of water and gas, since a considerable amount of time will pass until the liquid of the required temperature reaches the consumer;

- with an open combustion chamber, the product is most convenient for installation, and also does not require an additional fan connection;

- flowing gas devices are not used for space heating.

Briquettes

For those who are not in the know, briquettes (aka Euro firewood) are bricks that are made from waste from the wood processing industry by pressing. There are a lot of myths and false opinions floating around this fuel. You can even find information that 1 ton of briquettes can replace an entire KAMAZ truck of ordinary firewood. However, such data is nothing more than advertising, which can only be verified in practice.

This doesn't mean that braces are bad fuel. Not at all. Firstly, due to its high density, Euro firewood is compact, which means it is easier to store than ordinary logs. Secondly, the so-called calorie content of braces is higher than that of the most energy-intensive wood (oak, apple tree). This means that you will have to throw them into the firebox less often. Thirdly, European firewood is dry by default, which makes it easier to use and also makes cleaning of chimney systems less frequent.

Unfortunately, today the price tag for pressed briquettes is still at an unreasonably high level. Yes, they are comfortable. Yes, compact. Yes, they burn for a long time. But do you want to pay extra money for this, which is not converted into heat, this is a big question.

The following conclusion can be drawn regarding briquettes. There is no economic benefit in terms of obtaining 1 kWh of heat for a specific amount of money when using European firewood. They are preferred only by those users who need solid fuel heating and are reluctant to bother with firewood. As practice shows, this type of fuel does not stay on the farm for long, since sooner or later the user returns to the good old ordinary firewood.

Inappropriate options

There are several types of electrical equipment designed for space heating, but not recommended for use as the main heat source:

- Heat fans. These devices have the simplest design and are a large hair dryer consisting of a heated coil and a fan that drives a flow of air through it. Their use will definitely not be cheap - the air cools down extremely quickly, and it will not be possible to maintain a comfortable temperature for a long time. Do not forget also about the load on the electrical network and the dangers - too dry air is harmful to house plants and people.

- Oil radiators are probably the most common device used by residents of apartment buildings when the central heating power is not enough. Surprisingly, this is also the least efficient heating method. And even if you manage to heat the room to a comfortable temperature, it won’t be cheap at all.

Why is this equipment so widespread if it is ineffective? The fact is that all of these are auxiliary devices designed to help out in emergency situations or when the main heating does not cope with its tasks. For a garage, for example, constant heating is not always needed. During repair work, it can be heated using a heat gun (fan heater) powered by electricity or gas. But in a house where it is necessary to constantly maintain the temperature at a certain level, infrared panels are much more effective.

Infrared heating system

This is a relatively new method of heating residential buildings. It is based on the use of infrared radiation. Scientists have found that infrared rays can have different lengths. Long-wave radiation, similar to what we receive from the Sun, is safe and even beneficial for humans. It is used in heating devices operating in the infrared range.

Infrared film heaters can be mounted on the ceiling. Then the radiation will fall down and reach the floor, which will begin to warm up

For heating premises, a special infrared film is used. A thin layer of carbon paste is applied to a non-woven base, which is activated under the influence of current and emits infrared waves. The resulting emitter is laminated on both sides with a film, which gives it strength and extends its service life.

The operating principle of infrared heating is as follows. The film is placed on the floor or on the ceiling. When the system is turned on, current is applied to the emitter and it produces infrared waves. They move and reach the first massive obstacle. This can be large furniture, household appliances, and most often the floor. Such objects are impenetrable to infrared rays; they are retained and accumulated in them.

Objects gradually heat up and release the resulting heat into the air, due to this the room warms up very quickly. In another article, we talked in more detail about installing infrared heating with our own hands.

It must be admitted that this type of heating is the most comfortable. Due to the fact that the floor is heated, the temperature distribution is as pleasant and beneficial for humans as possible. The lower part of the room is about 2-3 °C warmer than the upper part.

In addition, natural humidity and the amount of oxygen are completely preserved, and there are no convection currents that carry dust. There are no drafts either. Film heaters operate absolutely silently and are safe for humans.

If infrared heaters are placed under the floor covering, the radiation rises up, reaches the floor and heats its surface, and then the air in the room

Another advantage is fully automated system control. This allows it to operate in the most economical mode and at the same time provide the owner with complete comfort. Thanks to this, the film system has no heat losses and its efficiency is almost 100%.

The minimum service life of the equipment is 25 years, and the service life is twice as long. In this case, the system does not require maintenance.

The next advantage is compactness. The film is very thin and does not “eat up” the free space. No additional room is required for the heating unit; there are no batteries or air ducts. The film is very easy to install and connect. If necessary, dismantling and reuse is possible.

Among the disadvantages, it is worth noting that as the voltage drops, the amount of heat generated by the film decreases. In this case, the operating time of the heater increases, which leads to greater energy consumption. The film can be covered with a variety of finishing coatings, except putty, wallpaper and paint. The cost of equipment for installing infrared heating is quite high.

What do the costs depend on?

What determines heating costs?

Using the techniques and formulas of precise technical calculations, which will take into account absolutely the entire range of possible heat losses in the building, which are possible through the walls of the pipeline, building structures, through window and door openings, the number and size of which is determined by the architectural design of the structure, etc.

These characteristics are individual, and trying to bring them to a common denominator is only wasting your energy and time.

However, experts believe that if you make a preliminary calculation, which will be based on a typical suburban building, and on its basis, with approximate, but very close to the real values of the figures, it will be much easier for the owners of suburban areas to decide on the choice of the most optimal and priority heating system system.

So, for example, you can take a country cottage as a standard, which has a standard indoor ceiling height of 2.2 meters.

The total area of the cottage will be 200 square meters.

It is also necessary to take into account that for central Russia, it is not typical to use large panoramic windows, glass walls and a light-conducting roof for attics or attic greenhouses in suburban construction.

The owner of the described cottage, which will be equipped with a heating network, expects the following monetary costs:

- Purchase and installation of a boiler, heating and metering devices, laying of various pipelines, installation and purchase of shut-off, regulating and locking devices;

- Monthly payment for maintenance of heating utility networks;

- Periodic purchase of fuel, which is necessary to fully heat the building;

- The cost of laying the pipeline will directly depend on the total length of the entire heating circuit, the price of maintenance will depend on the type of generator used that generates thermal energy and the complexity of the utilities used.

The main expensive element of the upcoming expenses and the main component of the entire heating system will be the fuel boiler, which, by processing a certain type of fuel, will produce the necessary thermal energy.

We heat the house with electricity

There are two main types of electric heating systems on the market today:

- water heating;

- and using convectors.

The first type requires the presence of a coolant, which is heated and supplied through the heating system to the rooms that need to be heated.

As with any water system, a boiler is naturally needed here to heat the water in the pipes. This type of heating is very effective, since water has great thermal inertia.

With convector heating, a large number of radiators are installed to heat each room. They can be installed to operate autonomously, or they can be combined into a common system with unified control.

Installation of such a heating system is quite simple and does not require a lot of materials. It is enough to fix the convector on the wall and supply 220V power to it. Affordable prices and ease of installation are the main advantages of this type of heating.

Advantages of electric heating

According to many developers, heating with electricity is more profitable for owners of country houses, since this does not require connecting to the main gas pipeline, which, moreover, is not available everywhere.

Wood stove heating

If the house is built far from gas mains or you don’t want to pay for expensive coolant, you can install a wood heating system. This option is ideal from an environmental point of view and does not harm the health of residents. How does a wood heating stove work?

The operating principle of this design is simple and clear. You buy a stove, put wood in it, and light it. The wood burns and heats the stove equipment. The stove gives off heat and the air in the room warms up.

Despite the seemingly primitive design, this heating option has a number of advantages:

- the oven heats up quickly;

- there is no need to buy and install pipes, radiators, pumps;

- the design is reliable, designed for long-term use, and is difficult to damage;

- Firewood can be purchased inexpensively.

Modern heating stoves bear little resemblance to the well-known potbelly stoves. The design of the furnace is designed so that the installation gives off a lot of heat and can operate for a long time on one load.

The structure of a boiler for wood.

A boiler can be integrated into a wood heating system. When choosing a boiler, it is better to choose a pyrolysis type design. Heat will be generated as a result of combustion of pyrolysis gases. This type of boiler equipment can function without electricity.

Now about the disadvantages of this type of heating of buildings:

the furnace installation is quite large, you will have to think about where to install it; the equipment weighs a lot, so you won’t be able to install the stove yourself; near the house you will have to provide a covered room for firewood; it is important that the supply of wood is sufficient for the heating period; combustion products if the stove device is used incorrectly can be hazardous to health; when heating with wood, you will have to provide a chimney; the stove will heat the room unevenly.

Heating a country house with liquefied gas

If there is no gas main nearby, you can heat the house with liquefied gas (a mixture of propane and butane). It's not much more expensive. Gas has no expiration date. The main problem is the supply and storage of fuel. Cylinders are used to heat small houses; for cottages with a significant living area (for example, for two-story houses made of foam blocks), an underground storage tank (gas holder) is installed. The heating system is connected to it.

Heating cylinders have a volume of 30-50 liters. The gas container is installed outside, in a special cabinet near the wall of the house. The pipe connecting the cylinder to the boiler should not have threaded connections or sharp corners.

Rules for using gas cylinders:

- It is prohibited to gasify basements and basements

- It is necessary to provide free access to the tank from all sides

- Do not expose the gas container to heat or direct sunlight.

- It is not allowed to operate tanks with damaged housings or corrosion.

- The distance from the cylinder to the boiler must be at least 1 m

For a continuous supply of fuel, it is best to install several cylinders. They are connected through a special ramp that has a flexible connection, a gas pressure measurement sensor and a safety valve. If the cylinder heats up, the valve releases excess gas, thereby reducing the pressure inside the cylinder.

Gas boilers operating on natural and liquefied gas have no fundamental differences. The only thing is that when connecting a cylinder, due to the high calorific value of liquefied gas, it is necessary to install a nozzle of a smaller diameter.

Any houses for permanent residence, whether made of foam blocks or frame houses. need a heating system. The comfort of living depends on how well the heating system and other utilities are implemented.

Even if you do not plan to build a house for permanent residence, but only for seasonal residence, you still need a toilet, for example, a peat one. And for this, in turn, a cesspool is needed. Read about the process of constructing a peat toilet for your dacha in this article. about the construction of a cesspool - here.

Finally. Installation of gas heating is best left to specialists. Unprofessional installation of equipment is fraught with more than just breakdowns. The health and lives of users are put at risk. A properly installed system is convenient, safe, and economical, because the homeowner can independently regulate the temperature of radiators and hot water.