Calculation of thermal energy production of a boiler house

To satisfy the various needs of consumers, there must be enough heat, which is provided by the boiler room.

Calculation of the thermal energy production of a boiler house shows how much fuel it will require and how much heat will be produced, which will then be used to ensure the operation of various engineering systems at the facilities. The results of such calculations must be economically justified. To understand how many fuel resources a boiler room needs to produce a given amount of energy, take into account:

- type of fuel;

- thermal power per hour (Gcal/hour);

- boiler efficiency;

- performance maps (according to performance testing), SNiP tables.

- heat load on DHW in one hour;

- daily system operation in hours;

- heating season time;

- own temperatures of unheated water in winter/summer.

If there are no ready-made regime maps, the efficiency of the boiler unit is calculated according to its condition, technical parameters, features and duration of operation. Calculations of fuel volumes are made in accordance with the instructions of the Ministry of Energy of the Russian Federation, which substantiates the standards for fuel supply to obtain the required amount of heat.

Fuel demand can be determined as follows:

Votp = Qotp * votp * 10-3

otp is the average fuel consumption rate, and Qotp is the volume of heat in Gcal that goes to the heating network.

Calculation of liquefied gas consumption

Many boilers can run on liquefied gas. How profitable is this? What will be the consumption of liquefied gas for heating? All this can also be calculated. The technique is the same: you need to know either the heat loss or the power of the boiler. Next, we convert the required quantity into liters (units of measurement of liquefied gas), and, if desired, we count the number of required cylinders.

Let's look at the calculation using an example. Let the boiler power be 18 kW, respectively, the average heat demand is 9 kW/hour. When burning 1 kg of liquefied gas, we obtain 12.5 kW of heat . This means that to get 9 kW, you will need 0.72 kg (9 kW / 12.5 kW = 0.72 kg).

Next we consider:

- per day: 0.72 kg * 24 hours = 17.28 kg;

- per month 17.28 kg * 30 days = 518.4 kg.

Let's add a correction for the boiler efficiency. We need to look at each specific case, but let’s take 90%, that is, add another 10%, it turns out that the monthly consumption will be 570.24 kg.

Liquefied gas is one of the heating options

To calculate the number of cylinders, divide this figure by 21.2 kg (this is the average kg of gas in a 50 liter cylinder).

Mass of liquefied gas in various cylinders

In total, this boiler will require 27 liquefied gas cylinders. Calculate the cost yourself - prices vary in the regions. But don't forget about transportation costs. By the way, they can be reduced by making a gas holder - a sealed container for storing liquefied gas, which can be refilled once a month or less often - depending on the storage volume and demand.

Again, remember that this is just an approximate figure. In cold months, gas consumption for heating will be higher, in warm months it will be much less.

PS If it is more convenient for you to calculate the consumption in liters:

- 1 liter of liquefied gas weighs approximately 0.55 kg and, when burned, produces approximately 6500 kW of heat;

- There are about 42 liters of gas in a 50 liter cylinder.

Calculation of the volumes of thermal energy received

The amount of heat (Gcal) that is received from the boiler house during the year can be determined as the sum of indicators - energy received for different needs:

Qtotal year = Qyear1 + Qyear2 + Qyear3

This is the energy that needs to be generated in 12 reporting months for heating systems of objects (Qyear1), for ventilation systems (Qyear2) and for hot water supply (Qyear3).

Calculation of heat supply to a boiler room for domestic hot water is carried out taking into account the following parameters:

- heat load on DHW in one hour;

- daily system operation in hours;

- heating season time;

- own temperatures of unheated water in winter/summer.

The average monthly volume of heat (Gcal) supplied to the heating and ventilation system is calculated on the basis of the usual thermal load on such systems (Qо,вmax). A correction is made for the internal temperature, which is determined by the purpose of the object, and the average temperature of the month outside (according to SNiP 2.04.07-86). The formula also includes indicators of how many hours per day (Tsut) and how many days per month (nmonth) the boiler room operates.

Qav/month = Qo,vmax* (tin - tout av/month) / tin - tout) * Tout * nmonth

To determine what the thermal power of the boiler room is, the calculation is done in the following order:

- determination according to the energy generation plan;

- calculation of how much heat will be used to meet the technical and other needs of the boiler room itself.

At the same time, they take into account the shutdown of the boiler house in the summer months (various preventive maintenance, current or major repairs and preparation for the new heating season). Such activities are implemented according to pre-prepared special schedules, which are determined for different climatic areas.

Calculation of the thermal energy production of a boiler house in accordance with the standards in given periods is an event that ensures the necessary economic indicators and useful heat supply for all consumers. For such calculations, there are regulations and numerous formulas that professional designers use.

You can calculate the cost of a heating project using the calculator below:

Online design cost calculation

Calculation method for natural gas

The approximate gas consumption for heating is calculated based on half the power of the installed boiler. The thing is that when determining the power of a gas boiler, the lowest temperature is set. This is understandable - even when it is very cold outside, the house should be warm.

You can calculate gas consumption for heating yourself

But calculating gas consumption for heating using this maximum figure is completely incorrect - after all, the temperature is generally much higher, which means much less fuel is burned. That’s why it is generally accepted that the average fuel consumption for heating is about 50% of the heat loss or boiler power.

We calculate gas consumption by heat loss

If you don’t have a boiler yet, and you estimate the cost of heating in different ways, you can calculate it from the total heat loss of the building. They are most likely known to you. The technique here is this: they take 50% of the total heat loss, add 10% to provide hot water supply and 10% to remove heat during ventilation. As a result, we obtain the average consumption in kilowatts per hour.

Next, you can find out the fuel consumption per day (multiply by 24 hours), per month (by 30 days), and, if desired, for the entire heating season (multiply by the number of months during which the heating operates). All these figures can be converted into cubic meters (knowing the specific heat of combustion of gas), and then multiply the cubic meters by the price of gas and, thus, find out the heating costs.

| Crowd name | Unit | Specific heat of combustion in kcal | Specific heat of combustion in kW | Specific heat of combustion in MJ |

| Natural gas | 1 m 3 | 8000 kcal | 9.2 kW | 33.5 MJ |

| Liquefied gas | 1 kg | 10800 kcal | 12.5 kW | 45.2 MJ |

| Coal (W=10%) | 1 kg | 6450 kcal | 7.5 kW | 27 MJ |

| Wood pellets | 1 kg | 4100 kcal | 4.7 kW | 17.17 MJ |

| Dried wood (W=20%) | 1 kg | 3400 kcal | 3.9 kW | 14.24 MJ |

Example of heat loss calculation

Let the heat loss of the house be 16 kW/hour. Let's start counting:

- average heat demand per hour - 8 kW/h + 1.6 kW/h + 1.6 kW/h = 11.2 kW/h;

- per day - 11.2 kW * 24 hours = 268.8 kW;

- per month - 268.8 kW * 30 days = 8064 kW.

The actual gas consumption for heating also depends on the type of burner - modulating ones are the most economical

Convert to cubic meters. If we use natural gas, we divide the gas consumption for heating per hour: 11.2 kW/h / 9.3 kW = 1.2 m3/h. In calculations, the figure 9.3 kW is the specific heat capacity of natural gas combustion (available in the table).

By the way, you can also calculate the required amount of fuel of any type - you just need to take the heat capacity for the required fuel.

Since the boiler has not 100% efficiency, but 88-92%, you will have to make further adjustments for this - add about 10% of the obtained figure. In total, we get gas consumption for heating per hour - 1.32 cubic meters per hour. Next you can calculate:

- consumption per day: 1.32 m3 * 24 hours = 28.8 m3/day

- monthly demand: 28.8 m3/day * 30 days = 864 m3/month.

The average consumption for the heating season depends on its duration - multiply by the number of months while the heating season lasts.

This calculation is approximate. In some months, gas consumption will be much less, in the coldest month - more, but on average the figure will be about the same.

Boiler power calculation

The calculations will be a little simpler if you have the calculated boiler power - all the necessary reserves (for hot water supply and ventilation) have already been taken into account. Therefore, we simply take 50% of the calculated capacity and then calculate the consumption per day, month, per season.

For example, the design power of the boiler is 24 kW. To calculate gas consumption for heating, we take half: 12 k/W. This will be the average heat demand per hour. To determine fuel consumption per hour, we divide by the calorific value, we get 12 kW/hour / 9.3 k/W = 1.3 m3. Then everything is calculated as in the example above:

- per day: 12 kW/h * 24 hours = 288 kW in terms of the amount of gas - 1.3 m3 * 24 = 31.2 m3

- per month: 288 kW * 30 days = 8640 m3, consumption in cubic meters 31.2 m3 * 30 = 936 m3.

You can calculate gas consumption for heating a house using the design capacity of the boiler

Next, add 10% for the imperfection of the boiler, we find that for this case the consumption will be slightly more than 1000 cubic meters per month (1029.3 cubic meters). As you can see, in this case everything is even simpler - fewer numbers, but the principle is the same.

By quadrature

Even more approximate calculations can be obtained based on the square footage of the house. There are two ways:

- You can calculate according to SNiP standards - on average, heating one square meter in Central Russia requires 80 W/m2. This figure can be used if your house is built according to all requirements and has good insulation.

- You can estimate based on average statistical data: with good insulation of the house, 2.5-3 cubic meters/m2 is required;

- with average insulation, gas consumption is 4-5 cubic meters/m2.

The better the house is insulated, the lower the gas consumption for heating will be.

Each owner can assess the degree of insulation of his home; accordingly, one can estimate what gas consumption will be in this case. For example, for a house of 100 sq. m. with average insulation, 400-500 cubic meters of gas will be required for heating, for a house of 150 square meters it will take 600-750 cubic meters per month, for heating a house with an area of 200 m2 - 800-100 cubic meters of blue fuel. All this is very approximate, but the figures are derived based on many factual data.

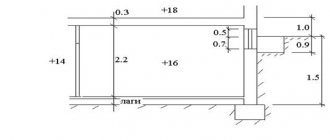

Example of a cottage heating project

Back

Forward