Autonomous heating is installed in a private house if the building is located at a significant distance from the centralized heating main and there is no possibility of connecting to it. In this case, a gas or solid fuel boiler is often installed. Therefore, a chimney for the boiler room must be installed to remove and disperse combustion products. Let's consider the basic requirements for it, the features of selecting the optimal option and calculating the required height.

Boilers with chimneys in the boiler room of a private house Source baxi.ru

Chimney requirements

A correctly calculated and installed chimney helps to comply with the maximum permissible concentration of harmful substances in the atmosphere. Without installing a chimney, it is impossible to divert fuel combustion products to the street so that they do not mix with the indoor air. The smoke exhaust system ensures safe and efficient operation of boilers by creating the necessary draft. Thanks to the chimney, people do not inhale toxic combustion products.

Only professionals know how to calculate a chimney, what technical nuances and rules for its construction must be observed. Therefore, when creating such a design, one almost never does without the help of specialists. After all, they will take into account all the requirements, which will guarantee the installation of a safe system that will operate effectively throughout the entire period of operation.

A properly constructed chimney will provide good draft. Its operation will not be negatively affected by:

- high temperatures during heating;

- settling condensate;

- aggressive substances, including soot, nitrogen oxides, sulfuric acid.

Effective smoke removal ensures comfortable and safe operation of boiler equipment Source userapi.com

When installing boiler rooms in private homes, cylindrical smoke exhaust ducts are often used. Pipes with smooth walls are installed, which reduces the likelihood of soot accumulation. Therefore, they need to be cleaned less often compared to brick chimneys, in which local turbulence contributes to blockages.

Important! Modern chimneys for domestic boiler houses consist of separate ready-made elements. To properly configure the system, it is better to use the help of specialists. These may be employees of the design and installation organization or equipment suppliers.

The chimney installation is carried out in accordance with building codes. Therefore, the following requirements are met:

- The cross-section of the smoke exhaust pipe cannot be less than the same size of the boiler pipe.

- According to the regulations, it is allowed to create a chimney with only 3 turns. In this case, the radius of curvature of each of them cannot exceed the diameter of the chimney.

According to regulations, it is allowed to create a chimney with only three turns Source sense-life.com

- When calculating the smoke exhaust duct, the height of the roof in relation to the height of the house and the rules for installing combustion product exhaust systems are taken into account.

- The manufacture of a metal chimney is made of alloy steel with a minimum thickness of 1 mm. In this case, only anti-corrosion metal is used.

- Be sure to create special pockets at the base of the smoke exhaust duct with a minimum depth of 250 mm. Soot accumulates in them. It is periodically removed during operation of boiler equipment.

Compliance with the basic requirements will ensure reliable operation of the chimney. By following the rules, there will be good traction in the channel.

Types of combustion chamber designs

Before we move on to calculating the diameter of the chimney for a gas boiler, let's look at their types. The design of the combustion chamber matters more. The chamber in which combustion occurs may or may not be sealed. If it is not sealed, then oxygen to support the combustion process comes from the room in which the boiler is located. The heater has a special air duct in the lower part, through which air is supplied naturally. For such systems, only horizontal chimneys can be installed. These are metal double-circuit and ceramic sandwich pipes. If the design provides for the use of one chimney by two heaters, then the minimum height between chimney inserts for gas boilers should be more than half a meter. Even if the heaters are on the same floor.

Sealed combustion chambers take air from the street. For this purpose, a special chimney has been developed, which is called coaxial. The dimensions of a coaxial chimney for a gas boiler are much smaller than a conventional one. It is a metal pipe within a pipe. The smoke goes out into the street along the internal circuit, and through the external circuit it enters the boiler. To maintain circulation, a fan is installed at the top of the heater. This chimney can be installed both vertically and horizontally.

The chimney standards for a gas boiler with a sealed combustion chamber provide for the installation of an individual outlet for carbon monoxide. It is impossible to connect two heaters to one coaxial system.

Selection of the optimal chimney

The optimal chimney option is usually selected at the house design stage during the development of the heating system. It is often also necessary to select a chimney after the construction of a building is completed. In any case, the construction parameters are taken into account. Be sure to take into account, for example, the height of a one-story house with a roof in the form of an attic or non-residential attic space.

When calculating a chimney, the height of the house is always taken into account Source myhome.ru

Chimneys for boiler rooms of private houses are made from the following materials:

- stainless steel;

- bricks;

- ceramics.

Each of the materials can withstand high temperatures and is resistant to aggressive environments and moisture. In addition, boilers in private homes can also be connected to concrete and even glass ducts to remove smoke. However, the latter option is still very rarely used. Although it is absolutely corrosion resistant. Asbestos-cement pipes are often installed. After all, this is a fireproof and environmentally friendly option.

When choosing a chimney, the personal preferences of the homeowner and the architectural style of the building are taken into account. In this case, you always have to first calculate the height of the roof ridge in order to determine the appropriate size of the chimney. In addition, they focus on the type and characteristics of boiler equipment. The following must be taken into account:

- pipe pressure;

- smoke temperature;

- presence of condensation;

- resistance of the chimney material to spontaneous combustion of soot;

- amount of combustion products;

- the height of the ridge of a gable roof or the standard distance from a flat roof.

Standard minimum chimney height Source genrealtor.ru

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

Previously, brick was widely used for the construction of chimneys. Now this is also a popular material. Moreover, many manufacturers offer brick and mortar. In addition, there are a large number of companies where you can order professional chimney laying. By choosing this option, the homeowner will receive a guarantee of quality. He does not have to worry about the integrity of the masonry, foundation and safety of the house.

A brick chimney is installed when installing a solid fuel boiler. If the masonry is done well, the channel can easily withstand high temperatures. It will not even suffer significant damage if the soot ignites. However, brick chimneys are not installed if the boiler runs on gas or liquid fuel. After all, the combustion temperature of such fuel is lower, and this contributes to the formation of condensation, which negatively affects the integrity of the masonry.

On a note! When installing a gas boiler instead of solid fuel equipment, a brick chimney can be upgraded to a new type of fuel. To do this, a steel pipe is inserted into the existing channel. The homeowner can carry out the adaptation at minimal cost.

Options for installing a chimney from a gas boiler Source in4o.ru

Ceramic and sandwich chimneys are also available today due to the presence of a large number of manufacturers on the market. When choosing smoke exhaust ducts from such materials, attention is paid to their quality and methods of fastening structures. At the same time, installation should be trusted only to professionals.

When installing gas, liquid, pyrolysis and pellet boilers, a ceramic chimney has recently been increasingly installed. This option is characterized by high strength, corrosion resistance and durability. It is no worse than a steel pipe.

A ceramic chimney is a multilayer structure. Inside it is a ceramic pipe. It is insulated with mineral wool. On top, the thermal insulation material is protected by a casing made of stainless steel or even foam concrete. Ceramic chimneys are more expensive and durable compared to other similar structures. Installation is carried out according to the manufacturer's instructions. Some ceramic chimneys require a reinforced base.

Construction of a ceramic chimney Source tildacdn.com

Important! Sandwich pipes for removing combustion products cost an order of magnitude less compared to ceramic chimneys.

How to calculate the required section? Square or round?

When designing a gas duct, it is important to immediately determine which cross-section is more preferable for the user. The most common pipe shapes are square and circle. Square ones are, as a rule, brick flues, which today are increasingly becoming a thing of the past and are almost never used. The fact is that square (as well as rectangular) pipe shapes provoke the formation of smoke turbulence in the corner areas, which contributes to the formation of soot and condensation on the walls, and also prevents the freest movement of smoke along the channel.

Today, the most optimal shape of a flue is round or oval: this is the cross-section that the most common modular “sandwich” stainless steel chimneys have and are in demand on the world market. The round shape of the internal contour and smooth steel walls prevent condensation and soot from settling - it is very difficult to “attach” to the smooth surface of the pipe.

In addition, due to the shape, it is possible to use the entire area of the internal circuit to exhaust flue gases, which makes it possible to produce steel flue ducts in fairly compact dimensions. The described and many other operational advantages of steel chimneys have led to the fact that they are used to line (restore) existing brick smoke removal shafts of square or rectangular shape.

Calculation of the required chimney height

When choosing a chimney, its height is taken into account. To determine this parameter, a simplified calculation scheme is often used. However, before calculating the height of the chimney, you need to accurately determine the power of the boiler installation. Therefore, a boiler selection is always carried out first.

The combustion process in a furnace largely depends on draft. It also affects the efficiency of smoke removal. In this case, draft will be present in the pipe only with a constant supply of air to the boiler unit. Its entry into the equipment is carried out forcibly using a special pump or naturally.

Careful calculations must be made before purchasing materials.

Below we describe how to calculate a chimney for a gas boiler. Formulas for calculating the cross-section and power of the heater are presented. In addition, you will be able to superficially familiarize yourself with the types of materials used for the construction of chimneys and their designs, as well as the requirements for the exhaust system.

First, let's look at the materials of pipes for the chimney of a gas boiler. Brick ones have not been used for these purposes for a long time. This is due to the fact that the smoke released during combustion has a relatively low temperature, about 150 degrees. Based on this, its speed in the system will also be low. The smoke has time to cool down to the dew point temperature and condensation forms along the internal diameter of the chimney of the gas boiler. Moisture has an extremely destructive effect on brick. If it is possible to use a brick structure for the above-mentioned type of equipment, then only with a liner inside. Prefabricated structures are the most widely used. These are metal double-circuit pipes and three-layer ceramic ones. Therefore, you should choose one of them as a pipe for the chimney of a gas boiler.

Video description

What traction is is described in detail in the video:

Calculation of chimney height for gravity drafting

Natural normal draft is created when there is a balance between its force and the resistance that arises when smoke moves both through the chimney and through the gas-water boiler channels. Therefore, gravity is formed at a relatively low chimney height. After all, only in this case will a slight gas resistance be created.

Important! When determining the height of a pipe, specialists use SNiP 41-01-2003.

Calculation of the gas duct yourself or by professionals?

The desire of users to save on the services of design engineers is absolutely understandable and logical. With the only clarification that the chimney is a very bad area for saving, since these products are a source of fire hazard, and the slightest miscalculation in the calculations can lead to breakdown of the heat-generating equipment and the need for additional expenses - this is a minimum. In unfortunate cases, independent design and installation of a smoke duct can lead to a fire, loss of property, health and life. That's why:

Attention! The calculation of all required parameters of the smoke removal system, design, length, length and height of the flue is strongly recommended to be carried out with the involvement of competent specialists!

The services of professionals are quite affordable and guarantee the maximum level of fire safety. Moreover, professionally performed calculations will help organize the operation of the heating and smoke removal system in the complex at a high level: the thermal technical characteristics of the heat-generating device and the chimney connected to it will guarantee the user a comfortable and economical operating mode for many years. After all, professionals will not only calculate the chimney according to basic parameters and standards, but will also take into account the individual nuances and features of your home, equipment and heating tasks.

Briefly about the main thing

Before calculating the height of the chimney, determine the material from which it will be made. They create a smoke exhaust system from bricks and sandwich chimneys; ceramic pipes with lightweight casings. In this case, the smoke channel is equipped subject to specific requirements:

- maximum 3 turns;

- diameter is not less than the boiler pipe;

- only alloy steel and at least 1 mm thick;

- presence of pockets for soot.

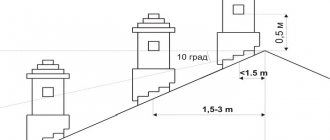

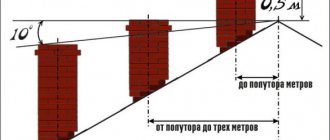

Typically, the height of the pipe is calculated using a simplified scheme, taking into account the distance from the smoke exhaust duct to the roof ridge. The chimney can be located above, below or level with it.

Design rules for boilers with natural removal of combustion products

- The chimney pipe must be located above the roof ridge , at least 0.5 meters higher than it, provided that its axis is close to the ridge or parapet (less than 1 m and no more than 1.5 m).

- If the pipe is located further from the ridge (from 1.5 m to 3 m), then its height should be level with the ridge.

- If the chimney is located at a distance of more than 3 m , its height must not exceed the boundary of the line laid down from the ridge at an angle of 10° to the horizontal.

- If you have a flat roof , the height of your chimney should also have a minimum limit of 0.5 m, and in the case of a combined roof - 2 m.

- The system for ejecting combustion products must be fixed to the wall at intervals of no more than 2.5 meters, in areas with a slope - every 1.5 meters.

- The clamp must be used on any connecting section of an insulated chimney.

- The chimney elbow must have a slope angle of at least 15° and no more than 90° (no more than three rotary elbows are allowed in the system). The vertical section following the turn must be clearly secured with fastenings. It is prohibited to load inclined sections of the pipe or its bends.

- It is mandatory to equip the chimney with a condensate drain , which must be accessible for maintenance.

- The chimney must be insulated from flammable materials using brickwork or asbestos board . The distance from the connecting pipe to flammable surfaces must be at least 25 cm, and if a protective layer is applied - from 10 to 5 cm.

- Stable traction can be ensured if the pipe is erected above the wind support zone.

- Smoke exhaust systems built inside the building do not need to be additionally insulated , but it is necessary to take care of the tightness and ventilation system. Toxic smoke can easily seep even through the brickwork of the protective casing.

- Areas located outside the structure are insulated . In the absence of thermal insulation, the gases quickly cool, the draft decreases, and the boiler power drops. Condensation forms on the walls.

We assemble an air dehumidifier with our own hands: diagram and principle of operation.

If the air in your child's room is too dry, you should consider buying a humidifier.

What is more profitable: making it yourself or ordering it?

At first glance, the design is quite simple, so it seems that you can buy material, arm yourself with tools, and save money. In this article we will not tell you how to properly make a chimney for a solid fuel boiler with your own hands, for the following reasons:

- To connect it you need to hire professionals. Because it is necessary to accurately think through the project, ensure the quality of the joints, and take into account all safety standards. Only specialists who have practical experience can guarantee all this.

- Only a product from a well-known and proven manufacturer in the market provides a guarantee of compliance with all fire safety requirements and the raw materials used.

Remember that shortcomings can result in improper operation of the heating system, fire, or backdraft. In an effort to reduce costs, do not put your life and the health of your loved ones at risk.

Delivery and installation of large diameter gas ducts

After completion of the last stage of production of industrial aspiration gas ducts, the finished elements are sent to the installation site using road or rail transport.

If necessary, our specialists are ready to perform the full range of work on the installation of flue ducts for an industrial aspiration system.

The workers of our installation teams have the appropriate certification to perform work on the installation of industrial aspiration gas ducts not only “on the ground” and indoors, but also at height.

Fire safety technology

Installation rules are determined by SNiP 2 04 05-91U, NAPB A 01 001-2004, DBN B 2.5-20-200. According to them, the room under the heating unit must have an individual hose for removing combustion products, a separate ventilation system, and a sufficient level of natural and artificial lighting. The firebox must be located at a certain distance from walls and passages. It is important to make the floors fireproof; it is better if the supply of coal or firewood does not exceed the volume designed for one shift.

Only masters can take into account all these and many other points. Therefore, it is better to entrust the connection of a solid fuel boiler to the chimney and commissioning of the heating system to specialists. And in addition to this advice, we attach several more interesting thematic videos: