One of the most important parts of a gas-fired heating system is a properly constructed chimney. It is no coincidence that gas service workers have strict but reasonable requirements for the chimneys of gas boilers. Not only the efficient operation of a gas boiler, but also the safety of the residents of the house depends on a properly installed system. When gas appliances operate, there is no visible smoke, as there is from appliances running on solid fuel, but this does not mean that there is no possibility of carbon monoxide accumulation. It is dangerous because it can negatively affect a person’s health without him noticing.

Requirements for chimneys of gas boilers

Owners of private houses must know how the smoke exhaust system is designed in the house where they live in order to operate it correctly. And those who are just planning to install a gas heating device should be aware in advance of what types of chimneys there are and how they are installed in order to decide which one to choose.

Requirements for chimneys of gas boilers

Heating with main gas is the most convenient and cheapest (the cost of connection is included in brackets); If the homeowner has the opportunity to install gas into the house, he rarely doubts. But, speaking in the dry language of official interviews, “for the safe operation of gas equipment, the removal of gas combustion products must be ensured, which is why such great importance is given to the proper operation of smoke channels.” Not even the quality of life, but life itself depends on the quality of the chimney of a gas boiler, which is why compliance with the requirements for the smoke ducts of gas boilers is so strictly controlled both in Moscow and in the most remote village.

These requirements are specified in a number of documents, including SNiP 2.04.05, SNiP-91. SP 7.13130.2013 and clause 5.1.1.VDPO. The manufacturer's recommendations are also always taken into account. Here are the main provisions from these documents:

- The draft must be such as to completely remove exhaust gases;

- The chimney must be resistant to high temperatures;

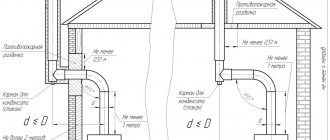

- According to SP 7.13130.2013 Heating, ventilation and air conditioning. Fire safety requirements, the height of the chimney cannot be less than five meters. It should protrude no less than 50 mm above the flat roof; no less than 500 mm - above the roof ridge or parapet (if located at a distance of up to 1.5 m from them); be not lower than the ridge of the roof or parapet (if located at a distance of 1.5-3 m from them) and not lower than a line drawn from the ridge down at an angle of 10° to the horizon (if it is located at a distance of more than 3 m from the ridge.

- If exhaust ventilation ducts are located near chimneys, they should be the same height as these pipes.

- The components of the chimney along its entire length must be sealed, and where it passes through the ceilings the pipe must be solid and without joints;

- The smoke exhaust system must include a condensate collector;

- The wall of the metal pipe is made of high quality alloy steel with an anti-corrosion coating.

During installation work, the following rules are taken into account:

- Each boiler must have a single chimney;

- The height and cross-sectional size of the chimney pipes must be correctly selected for free and complete smoke removal;

- The distance between chimney pipes and surfaces depends on the materials from which these surfaces are made; For non-combustible materials, a gap of 50 mm or more is established, for flammable materials - 25 cm or more.

Mr LeshiyFORUMHOUSE Member

For a gas boiler, 0.5 mm thickness is enough - the main thing is that the steel is grade 300, AISI 304, 316, 321.

- To clean smoke channels from soot, you need recesses of about 250 mm;

- There may be bends on the chimney pipes, but no more than three, their rounding is equal to the diameter of the pipe, there should be inspection hatches at the bends;

- It is recommended to install umbrellas and caps on chimneys.

Region190FORUMHOUSE participant, master inspector at VDPO

Collect condensate. The hatch for cleaning the chimney must be 25 cm lower than the tee (15-20 cm will be accepted, 10 cm will be clever). The acceleration section (straight pipe from the boiler) is at least 700 mm. Smoke turn - no more than three (a tee and two elbows, it is better to have two). The horizontal section is no more than 3 meters. Tee - 90 degrees (not all gas trusts will accept 45, they have their own recommendations and rules and they don’t care what is written in the boiler instructions). The distance of the monopipe from flammable materials is 25 cm, from non-flammable materials is 5 cm; thermal pipes - 5 cm. Do not touch the gas pipe under any circumstances; the chimney - gas duct is at least 5 cm from it!

Fire requirements

According to SNIP, the chimney and ventilation ducts must be checked and cleaned:

- Before the start of the heating season - chimneys in which boilers and heating devices operate seasonally.

- At least once a quarter - combined and brick chimneys.

- At least once a year - asbestos-cement chimneys and channels, pottery, made of heat-resistant concrete .

The initial inspection of gas boiler chimneys should cover the following points:

- correct use of materials is carried out in accordance with the requirements of DBN V.2.5–20;

- presence of clogged channels;

- checking partitions that serve as protection for combustible structures;

- How separated are the ventilation and smoke ducts;

- how serviceable and correctly positioned the head is;

- checking the presence of normal draft, this parameter depends on the correctness of the construction, in particular, the height and cross-section of the pipe have an influence (see How to improve draft).

The ventilation and chimneys are checked again for blockages, their separation and density, and the draft is checked:

- Inspections for the first time and after repairs of ventilation and chimneys are carried out by specialists. organization with the participation of the operating organization. The results obtained are included in the act.

- If the ventilation ducts and chimneys of gas boilers are recognized as unusable and not subject to operation, the inspector is obliged to warn the owner in writing about the dangers of using gas appliances.

- Chimney SNIP in private houses allows owners to clean ventilation ducts and chimneys if they have a document confirming that they have undergone training.

- Before starting repairs of ventilation passages and chimneys of gas boilers, the operating organization, which is the owner of the apartment building, is obliged to warn residents about the start of work. After completion of the repair, all chimneys and ventilation ducts should be checked.

Requirements for premises when placing gas appliances in them

The chimney must meet established standards!

- SNiP 31-01-2003 - on multi-apartment residential buildings;

- SNiP 41-01-2003 - everything about air conditioning, ventilation and heating is stated;

- SNiP 42-01-2002 - instructions on gas distribution systems;

- SP 31-106-2002 - will talk about the creation of a project and the construction of single-family houses used for living;

- SP 42-101-2003 - on the construction and design of gas distribution systems from pipes of various inlets.

What the letter of the law says:

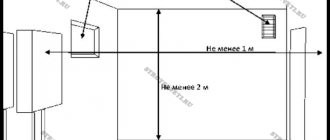

- The room in which the gas water heater will be placed and the chimney of the gas boiler will be provided for the removal of combustible products must meet certain requirements; not only the area, but also the height of the ceilings is regulated. So, the ceiling height should be at least 2 meters. The volume of space is not less than 7.5 m³ for installing one device, and not less than 13.5 m³ for two units.

- The room must also be equipped with a ventilation duct. A grate or passage between the floor and the door should be provided at the bottom of the door or wall, where the open cross-section should be at least 0.02 m² .

- Attention: It is unacceptable to exhaust smoke into the ventilation duct. It is prohibited to install ventilation grilles on smoke ducts.

- In rooms with a standard hood, it is necessary to compensate for the removed air by penetrating it from outside the room, as well as by replacing it from the remaining areas of this apartment.

- Attention: When installing airtight windows in a room, the speaker may turn off due to inconsistent air supply. This is due to the automation of the column itself.

- In the bathroom and utility rooms, doors should open outward.

- The installation of sockets and switches in the bathroom is strictly prohibited.

The principle of operation of the chimney

As with any heating system, a chimney for a gas boiler is needed to release combustion products into the atmosphere and supply fresh air for complete combustion of the fuel. How it works: in accordance with the law of physics, according to which light warm air tends upward, cold air settles below. Draft in the chimney appears due to the temperature difference: hot gases in the pipe and cold air outside.

If the chimney is installed correctly, it is not only safe, it improves the quality of the boiler’s operation and increases its efficiency, making the microclimate in the house more comfortable.

The chimney for a gas boiler is a complex structure, which includes:

- Smoke exhaust pipe;

- An adapter that connects the pipe and the boiler pipe;

- Branch pipe for passing the chimney through the wall, ceiling, roof;

- Fastening elements;

- Condensate collector;

- A tee with a fitting is necessary for draining condensate;

- Bends.

This is the basic configuration, there may be different variations.

Advantages and disadvantages of coaxial chimneys

Such systems for supplying air and removing combustion products have now gained wide popularity.

This is easily explained by the many advantages of such a scheme: First of all, the advantage is that the air necessary for the combustion of “blue fuel” is taken not from the room, but from the street. This circumstance greatly simplifies the organization of general ventilation - no calculations are required for additional inflow, there is no need to resort to frequent ventilation or organize other ways of air supply from the street

This is especially important for those cases when the boiler is installed in the “living area” of a house or apartment, for example, in the kitchen. In frosty weather there will be no unnecessary influx of cold into the premises. In principle, combustion products cannot enter the room - they are immediately discharged from the closed chamber to the street. The air taken from the street receives very noticeable heating from the internal pipe, through which waste products flow in a counter flow

And this is important for uniform and complete combustion of gas, for maximum boiler efficiency. In addition, complete combustion of gas ensures minimal emissions of substances that can cause air pollution. On the contrary, combustion products are effectively cooled, which significantly increases the fire safety of the system. The likelihood of ignition of soot particles, which can accumulate in the pipe over time, is sharply reduced. And at the outlet the gases no longer have a dangerous temperature. The outer surface of the coaxial pipe does not heat up to too high temperatures. And this is a big “plus” in the sense that the requirements for organizing safe passage through walls (floors, roofs) are significantly reduced. No other type of chimney, including sandwich pipes, allows such “liberty”.

Even through a wooden wall, you can lay a coaxial chimney without cutting out a huge window for a fireproof penetration.

- Installation of a coaxial combustion product exhaust system will not involve large-scale construction and installation work, as usually happens when installing “classic” vertical chimneys.

- The installation itself is quite simple and intuitive. Any kit is always accompanied by detailed instructions. So in many cases it is quite possible to carry out the installation work yourself.

- There is a wide range of coaxial chimney kits on sale, and therefore it is possible to select the desired system for a boiler of a certain model. As a rule, it is purchased immediately along with the heating equipment. And for any system, the assortment includes the necessary additional parts - tees, 90 or 45 degree bends, condensate collectors, inspection chambers, cuffs, clamps, fasteners, etc. That is, there are no problems with acquisition.

The main disadvantage of coaxial chimneys is the abundant formation of condensation, which is inevitable at the border of distinctly hot and cold gas flows. And as a result, ice freezes at the tip in severe frosts. And this, in turn, is fraught with failure not only of the combustion product removal system itself, but even of the heating unit.

In severe frosts, despite the very hot exhaust, ice build-up may form on the pipe of the coaxial chimney. This phenomenon must be combated so as not to “ruin” the entire system.

This drawback is often attributed to the fact that coaxial chimneys were originally developed for European countries with much more benign climatic conditions than in Russia. In an effort to increase the efficiency of boilers, designers tried to reduce to a minimum the possible diameter of the internal pipe for gas removal, which led to a shift in the dew point inside the air duct and heavy freezing of the condensate that fell.

Additional insulation of the outer section of the outer pipe of a coaxial chimney is a simple and effective means of combating icing.

The second, but very conditional, disadvantage is the high cost of high-quality coaxial chimneys. But there is something to argue with here. Firstly, the price still doesn’t look scary compared to the overall costs of the heating system. And secondly, if you add considerable savings on construction and installation work, then it becomes ridiculous to talk about cost in general. And this is without taking into account the other advantages of the coaxial system.

Types of chimneys for boilers

There are different types of chimneys that are used in these cases:

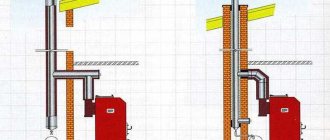

A brick chimney is made of fireclay bricks, which are placed either on clay mortar or glue. In most cases, it is made with a stainless or galvanized steel sleeve inside to protect the brick from the destructive effects of carbon dioxide.

Region190FORUMHOUSE participant, master inspector at VDPO

Over time, the brick will begin to crumble due to carbon dioxide, so the chimney must be lined. In the market you can be deceived with the steel grade; it is better to buy AISI 316 directly from the factory. This acid-resistant steel works reliably with any brand of boiler. Not a single inspection master will ask you about the steel grade or demand a certificate; we do not have the authority to do this, and it is impossible to visually distinguish 316 from 425.

The main disadvantage of such a chimney is that it is heavy, you will have to make an additional foundation, and it is bulky, and you will have to look for a stove maker who will lay it out. Previously, such chimneys were often made for gas boilers; now (if funds allow) homeowners prefer ceramics.

Ceramic chimney . This is a complex structure that includes a ceramic smoke exhaust duct, an air layer (or insulation) and an expanded clay concrete shell. Expanded clay concrete protects the fragile ceramic pipe and serves as insulation (and ceramics have high thermal conductivity).

Andrey50FORUMHOUSE member

Cool specialists with extensive experience in chimneys say that ceramics are the best, but unreasonably expensive.

It is much easier to install such a structure than a brick chimney; it is durable, fireproof (can heat up to 120 degrees), but it is also heavy and bulky, and also expensive.

Asbestos-cement chimney. For this type, it is important to have tight joints inside the channels and good insulation to prevent condensation from forming.

RegularUser .FORUMHOUSE

During my construction period, asbestos-cement pipe was the cheapest option. The main problem here is how to hermetically join the segments; I couldn’t get it to be hermetically sealed. Simply pouring concrete is not an option. It should be a sealed sleeve, clamp, insert, anything that provides a reliable and tight connection. Be sure to insulate your asbestos-cement pipes. Do not forget that the design of the chimney should not allow condensate to drain into the boiler and be sure to make a condensate collector at the bottom at the base of the pipe.

Single metal - chimney made of galvanized or stainless steel.

Sandwich chimney. Such a chimney is made of two metal pipes, one is inserted into the other, and insulation is laid between them. Smoke flows through the inner cylinder. This type is required for use as an external chimney and in unheated rooms.

Coaxial. In this chimney, one pipe is inserted into another without laying insulation. But this is a single rigid structure, united by jumpers along its entire length. Smoke exits through the inner pipe, and air enters the combustion chamber through the outer pipe; the room air does not participate in the operation of the gas boiler, the microclimate is maintained.

Mr LeshiyFORUMHOUSE Member

Sandwich is an insulated chimney made of two stainless steel cylinders, between which insulation is stuffed. Coaxial - the same two cylinders, but without insulation inside. Exhaust gases are removed through the inner cylinder to the outside, and air is supplied into the combustion chamber through the gap between the cylinders.

Boiler designs and methods of installing chimneys

There are two types of burners for gas boilers:

- Open. In them, oxygen for combustion is taken from the room in which the boiler is installed. That’s why this type of burner or catching is also called “atmospheric”. In such gas boilers, the removal of flue gases requires a pipe with an outlet to the atmosphere and good draft. Methods for venting a chimney from a gas boiler

- Closed combustion chambers (turbocharged boilers). They work in tandem with coaxial type chimneys - made of two pipes inserted into each other. Combustion products are removed through one pipe, and air enters through the other to maintain combustion. The coaxial pipe is usually routed through the wall to the street. That’s why they say that such gas boilers do not have a chimney. But, if desired, the chimney can also be taken out into an atmospheric chimney. In this case, normal draft is needed (when venting into a wall, this does not matter, since the movement of gases is ensured by a turbine).

It is clear that the choice of chimney type primarily depends on the type of combustion chamber. In one case it should be a coaxial pipe, in the other - a regular one. But besides this, there are many more design nuances.

By condensation or smoke

We must not forget about the main feature of the chimney for a gas boiler: they have high efficiency and a fairly low temperature of the exhaust gases:

Condensation always and quickly forms in the chimneys of a gas boiler.

Therefore, the chimney installation must be done in such a way as to solve the condensation problem. Due to the low temperature of the exhaust gas, chimneys on modern gas boilers are made “through condensate” and not “through smoke”.

VadimProFORUMHOUSE Member

For smoke, this is when the pipe of the lower bend goes inside the pipe of the upper bend, and, accordingly, for condensate - vice versa.

Chimneys for modern gas boilers are collected strictly according to condensate.

This installation method allows condensate to flow calmly down inside the chimney without leaking out (this is dangerous and can cause a fire).

Operating principle of the device

The internal surfaces of the pipes in the coaxial channel do not come into contact with each other, thanks to reinforcing partitions located along the entire length.

Such devices operate in a system of gas units, radiators and convectors, which use oxygen from the street for combustion, and not from the utility room. The method of combined exhaust and ventilation cannot be used for units operating on solid fuels. Features of the functioning of a coaxial chimney:

- fresh air is supplied from the street through the outer shell to support combustion;

- the internal passage serves to remove smoke outside the room.

The main line of coaxial pipes is made up of separate standard modules; as a result, the chimney can be of different lengths or heights. Using straight sections of pipes, adapters, corners, tees, a pipeline of various configurations is made, which takes into account the architectural features of the structure.

How to choose the type of chimney

Choosing a gas boiler chimney for our user with the nickname gladiator was not easy, there was too much to consider, and the initial data did not allow us to arrive at the optimal result.

You can lay out a brick chimney and then insert a stainless steel sleeve into it, but according to calculations, a floor made of floor slabs simply will not withstand the load from a brick chimney;

You can install an expensive ceramic chimney system from a well-known one.

You can make a sandwich, but if it’s inside a building, but how can you secure the floors between floors and then not think about what the temperature is there; and how do you know when it’s time to remove the pipes from the wall and change the system? You can make an external chimney, but it would be a pity to spoil the appearance of a private house.

GladiatorFORUMHOUSE Member

Previously, a simple galvanized or brick chimney was made for a gas boiler, but now you don’t know what to choose from.

When choosing a chimney for a gas boiler, experts on our portal recommend taking into account:

- type of combustion chamber, boiler power;

- design features of the house;

- reasonable combination of price and quality.

The choice of boiler depends on the type of gas combustion chamber.

An open firebox is often found in floor-standing gas boilers. Such devices always need good draft, and here a brick and ceramic chimney is preferable; although a sandwich will work too. And we must take into account the design features of the building: a brick chimney is difficult to install and is hygroscopic; and the ceramic chimney is very heavy.

Closed combustion chamber . According to our experts, such devices need a coaxial chimney or sandwich.

The sandwich for a gas boiler looks like a universal model; everyone recommends it.

Alexey TeleginForumHouse user

For gas, a sandwich is ok, but it’s better to make it from acid-resistant 316 steel.

Teplov and SukhovFORUMHOUSE user

For a gas boiler in home use, a sandwich made of 316 steel will last a very, very long time. But change the boiler.

But it is better to choose a chimney for a boiler together with a specialist - this is a more responsible and mature approach. As our experts say, the approach to choosing a chimney system for a gas boiler must be comprehensive, “design/installation/operation” must be taken into account. And it is advisable that everything is done under the guidance of an invited professional.

TraksFORUMHOUSE User

The chimney will be assigned to you by gas workers and reflected in the design. But in addition to a specialist who will accept the completed work, a third-party professional is needed here.

Answers to any complex chimney questions can be obtained here: “Consultations on design standards and rules. If you have any questions about chimneys, just ask.”

Rules for installing a chimney for a geyser

The key to safe operation of a gas water heater is a proper exhaust system. For the column, chimneys are used, which discharge combustion products into the smoke exhaust channel or directly into the atmosphere. The following types of pipes are used to remove exhaust gases:

- corrugated pipe - easy to install, the flexibility of the material allows it to be stretched up to 2-3 m in length, and also extended by connecting several sections of corrugation;

- aluminum pipe - easy to install, resistant to condensation, requires additional thermal insulation;

- coaxial chimneys - the price of such systems can be reduced due to the possibility of leading the pipe through the wall. This reduces material consumption and installation costs. The main advantage of such a chimney is that air from the room is not involved in the operation of all equipment.

Recommendations for installing a geyser

Basic requirements for the installation of chimney pipes for geysers:

- operation of the devices is prohibited without a chimney securely fixed in it;

- the draft inside the chimney system must be constant;

- the pipe material must be non-flammable, resistant to corrosion, condensation and high temperatures;

- the outer section of the chimney must be vertical;

- the structure must be sealed to prevent carbon monoxide from entering the room;

- the exhaust pipe should be installed in an open place for quick troubleshooting if necessary;

- the chimney must be located at least 0.5 m above the roof level;

- It is strictly forbidden to use ventilation systems, the space between floors, or attics to remove combustion products.

Why insulate a chimney pipe

If the chimney pipe for the boiler is cooled in the cold, then the temperature of the exhaust gases decreases - which means the draft decreases. This problem can be solved by insulating the pipe. How to insulate depends on the material from which the chimney is made:

- Brick structures are plastered, and if the attic is not insulated, then stone or basalt wool with foil on top is used;

- Ceramic chimneys are protected from the cold with mineral wool and ceramic blocks, metal ones are insulated with any non-combustible materials;

- The most difficult thing is with asbestos structures - they can explode if they overheat, so they must be insulated competently and carefully.

Number of stoves per chimney

The main rule of SNiP for chimneys: each stove must have its own chimney. If the stoves are located on the same floor of the same house, their chimneys can be combined into a common channel. In this case, a cut of one meter in height is used inside the channel.

According to the requirements, on one floor one stove can heat no more than three rooms and it must have one chimney.

For a two-story house, you can use a two-tier oven. In this case, the stove must have two fireboxes, each firebox with its own chimney.

If you are using a two-tier oven, the house should not have wood floors between floors.

For two-story apartments, a different rule applies. The stove can be used with one firebox on the ground floor.

Gas and smoke: the most important

Here are the most important things to remember when installing a chimney for a gas boiler:

- It has its own characteristics, which are associated with the low temperature of the outgoing smoke, so it must be installed along condensate lines, and a condensate collector must be provided as part of the chimney structures.

- The type of chimney is chosen depending on the power of the boiler and the type of gas combustion chamber; most homeowners like ceramic chimneys, but they are heavy and expensive; Our experts consider sandwiches to be a universal solution, but the quality of the steel is critical here: it should be grade 300, AISI 304, 316, 321.

- Many experts give the following advice: in a private house under construction it is better to provide a ceramic chimney, in an existing one that is connected to a gas pipeline - a steel one;

- The chimney should not come into contact with the gas pipe; a distance of at least 5 cm must be maintained;

- When installing the chimney of a gas boiler in a private house, you must observe all the distances stipulated by regulatory documents (the installation pipe must be no less than 25 cm from flammable materials, and the distance of the thermal pipe from surfaces is 5 cm).

It is recommended for all homeowners to study the regulatory documentation for chimneys, but especially for those who decide to make a chimney with their own hands. Information from our forum on quality criteria for stainless steel chimneys and a thread about a brick chimney system for a gas boiler will help here. Read our article on how to choose a boiler for heating your home. Watch our video on how to properly maintain your chimney to extend its life.

Subscribe to our Telegram channelExclusive posts every week

Do-it-yourself brick chimney installation

The brick chimney design is an exclusively vertical channel with a square or rectangular cross-section. To lay a brick chimney, solid ceramic bricks are used, which are laid on mortar. The outer section of the channel is laid out with ordinary brick, corresponding in style to house construction, which can be seen in numerous photos of brick chimneys. If the house is lined with stone or plastered, you can decorate the chimney in the same way.

Brick chimneys for gas boilers: installation requirements

Before laying a brick chimney for a boiler, it is necessary to build a foundation, the height of which must be at least 0.3 m. The dimensions of the base around the perimeter must protrude beyond the contour of the channel itself by at least 0.15 m. If the chimney is located in part of the external wall, its foundation should be level with its base. Laying a brick chimney with your own hands (video instructions confirm this) begins at the stage of building the walls of the house.

When constructing a chimney, solid ceramic bricks are used, which are laid on the mortar

Requirements for brick chimneys:

- the smoke channel must be vertical, without ledges, narrowed or widened areas;

- the thickness of the brick pipe for the chimney is taken taking into account the exclusion of freezing;

- the minimum permissible cross-section of smoke exhaust channels is 14 x 14 cm, which corresponds to the size of half a brick, taking into account the seam;

- the size of a brick chimney, the height of which is less than 5 m, should be increased to a channel cross-section of 14 x 20 cm;

- the chimney is constructed in the walls between heated rooms, which will prevent it from cooling and reducing draft;

- tightness - the brick chimney is laid with ligation so that the vertical seam of the previous row overlaps with the brick of the next one;

- the inner surface of the channel must be smooth;

Helpful advice! To achieve a flat and smooth inner surface of the channel, use special templates when building a brick chimney with your own hands.

- the distance between adjacent smoke exhaust ducts should not be less than 5 average outer diameters of the pipe;

An example of a chimney in a brick channel and a diagram of laying a brick chimney pipe

- if ventilation ducts are located near the chimney, their height should be equal to the height of the chimneys.

To reduce construction costs, you should place as many channels as possible in a common chimney. In this case, adjacent chimney and ventilation ducts will heat each other, which will generally improve the functioning of the chimney.

Preparation of mortar for laying a brick chimney

The composition of the mortar for laying a brick chimney is selected taking into account which section of the pipe is being laid: external or internal. To construct the external channel, the same mortar is used as for laying load-bearing walls of house construction. It is prepared from cement, sand, water and can harden in air and water. The mixture is prepared in such a volume that it can be used within an hour, as it sets quickly.

To ensure that the mixture does not deteriorate under the influence of an aggressive environment, it is recommended to add special additives to it that increase its plasticity, strength and acid resistance. Thanks to these additives, you can improve the quality of the masonry itself, increase the speed of construction and the durability of the work performed.

The properties of the chimney mortar can be improved using various additives

The preparation of a solution for a brick chimney running inside a house is based on the use of fireclay and fireclay in its composition in a 1: 1 ratio. Such mixtures cope well with high temperatures, they are durable and do not emit harmful substances. To give the clay mixture strength, you can add table salt to its composition (about 120-150 g per bucket).

Helpful advice! The strength of the chimney mortar can be enhanced by adding Portland cement in a proportion of 1 kg per bucket.

When laying a brick chimney with your own hands, you can purchase ready-made mixtures that are heat-resistant and acid-resistant. Preparing the solution yourself can reduce the cost of building a chimney.

It is quite possible to build a brick chimney with your own hands - the video below will help you familiarize yourself in detail with the stages of constructing the structure, taking into account all the basic requirements.

The feasibility of using a brick chimney for a gas boiler

Taking into account the advantages and disadvantages of brick chimneys, it is possible to draw conclusions regarding their use in combination with gas boilers. Their advantages include:

- the likelihood of using an existing chimney duct, which reduces chimney costs;

- possibility of operation in conjunction with gas equipment with an open combustion chamber;

- reasonable cost of materials for construction and finishing of the structure.

The durability of brick channels is observed only when they are used for fireplaces or stoves. If they are used for gas boilers, due to the low temperature of the combustion products, condensation will form on the channel walls, and harsh operating conditions in an aggressive environment will lead to the gradual destruction of the brickwork and deterioration in performance.

In addition, the requirements for such chimneys are more stringent:

- impeccable masonry - if the skills are not enough, you will need to invite a qualified mason to do the work, which will cost a lot of money. Prices for work: rough brick masonry from 6,000 rubles per 1 m³, facing masonry - 2,500 rubles. for 1 m²;

Schemes for connecting a gas boiler to a brick chimney

- inability to perform a complex channel configuration (if you need to bypass, for example, a beam in a ceiling);

- the use of the old channel should be carried out using sleeves;

- the need for thermal insulation.

The disadvantages of such a system include a decrease in traction while the brick is warming up. Thus, the correct chimney for a gas boiler will be a brick channel together with a steel or ceramic liner. The photo of brick chimneys shows that liners are installed during the process of laying the channel. In this case, it is necessary to leave a gap between the liner pipe and the brick surface. This is necessary so that the pipe can move inside the channel.

Selection of materials

Stainless steel chimneys are the best option. These structures have exceptional resistance to various types of corrosion, are lightweight and provide good traction. The service life of a steel chimney, as a rule, is no more than 20 years.

But galvanized steel copes much worse with removing combustion products, unlike stainless steel. Heated, moist fumes with high acidity very quickly destroy galvanizing. The service life of this chimney is about 5 years.

Ceramic chimneys are characterized by an exceptionally long service life; they last more than 50 years. The most convenient are European models with an external steel contour. However, this design also has some disadvantages.

First of all, this is a significant mass of the chimney, which must be correlated with the load-bearing capacity of the base and walls of the building. There are high requirements for the installation of ceramic chimneys. It is believed that for normal traction, ceramic pipes must be strictly vertical, and this configuration is not always convenient.

https://youtube.com/watch?v=8c3FmjPFSwg

A coaxial chimney is a modern and effective choice, but quite expensive. The design of this chimney consists of two pipes that are nested inside each other. Combustion products are removed through the inner pipe, and air is supplied through the outer pipe.

A traditional brick chimney is not the best solution. The bulky design, as a rule, is not characterized by high traction, is heavy, and has a short service life.

However, if there is already an old brick chimney at home, then it is quite suitable for use. A stainless steel liner is installed inside the structure, and the brickwork serves as a protective case. Naturally, the cross-section and shape of the liner must comply with the standards described above.

It is very rare, but you can still see chimneys made of asbestos-cement pipes, as they have been replaced by more modern materials. These structures are quite dangerous because they can rupture if overheated. Operating time is no more than 5 years.

Pipe slope

Horizontal chimneys can be installed either with a slope towards the ground or towards the boiler. In the first case, condensate under the influence of gravity will be discharged outside the low-rise building and go into the soil. Thus, chimneys are usually installed in the southern regions of the country.

In the northern regions of Russia it is impossible to install pipes in this way. During the winter season, draining condensate can form ice at the end of the chimney. At the same time, due to ice, air will stop flowing to the heating unit, which will sooner or later lead to its breakdown.

In the middle zone and in the north of the country, coaxial chimneys are still installed with a slope towards the boiler. In this case, it becomes necessary to use a condensate collector. Without it, moisture will begin to flow directly into the boiler, which, of course, will negatively affect its operation and service life.

In any case, wherever the pipe is directed - towards the ground or towards the boiler - its slope, according to the standards, must be at least 3°.