If gas is chosen for heating the house, care should be taken to remove combustion products. This means that you need to choose and install the chimney correctly for a gas boiler. Compliance with norms and rules in this matter absolutely cannot be neglected, since this can call into question not only the health, but also the life of the residents of the house.

Options for installing chimneys for a floor-standing gas boiler (with the smoke pipe exiting upward)

Types of chimneys for a gas boiler

The chimney is designed to remove exhaust gases into the atmosphere. The work is based on the principle of natural traction. Depending on the conditions of use, chimneys have many design features. The performance of a gas boiler depends on what material the chimney is made of.

A prerequisite for using a gas boiler is the installation of a ventilation system

Brick chimney. They are rarely used, since modern gas boilers have a high efficiency. The temperature of the gas emanating from the boiler is low (about 100 degrees), and when moving up the chimney it cools and condenses on the walls, since there is steam in the outgoing gases. Therefore, it is very difficult to warm up a brick chimney to the dew point transition temperature. What to do if you already have a chimney from an old stove in good condition? In order not to dismantle an existing chimney, you can use:

- lining, that is, insert stainless steel pipes inside, and fill the space between the chimney wall and the pipe with non-flammable heat insulator. Perlite, foam glass or expanded clay are suitable as a heat insulator. This procedure will insulate the chimney and significantly reduce the amount of condensate formed;

Sleeving

- line the channel. Lining is performed if the existing chimney is of non-standard size or has a crooked channel. This method is more expensive than installing steel pipes. A special elastic polymer liner is placed in the chimney duct. Then steam is pumped from below by a generator, a reaction occurs and the filler expands, taking on the shape of a channel.

Sandwich made of stainless steel pipes. Widespread technology. Perhaps one of the best designs for arranging the chimney of a gas boiler. Manufacturers offer ready-made modules from which chimneys of various sizes and configurations are assembled. Structurally, it is a pipe that is contained in a corrosion-resistant steel pipe that is resistant to acids. The distance between the pipes is filled, as a rule, with heat-resistant basalt wool.

Coaxial chimney. Has an attractive appearance. The design resembles a recuperator device, when combustion products are discharged into the atmosphere through an internal pipe, and heated air is supplied to the boiler furnace through an external pipe. Such a chimney device does not require additional installation of a ventilation system, since the air from the room is not used for combustion by the boiler, and accordingly this affects the comfort inside the room. A coaxial chimney increases the efficiency of the boiler.

Coaxial pipe components

Ceramic chimney made from ready-made modules. Their main trump card is fire resistance and durability. They do not collapse even at a combustion temperature of 1200 degrees C. The manufacturer guarantees their reliable operation for 30 years, confirmed by European certificates. Their only drawback is their unpresentable appearance.

Main elements of chimneys:

- pipes: chimney and extension;

- tees;

- knee;

- condensate outlet;

- draft regulators;

- ending elements.

Advice. Condensation also settles on the inner surface of asbestos-cement and galvanized steel pipes, which is why they are not used when installing a chimney.

How to reduce the temperature of flue gases in a chimney

The combustion of natural gas produces carbon dioxide, steam, sulfurous salt-forming oxides, etc. The optimal temperature of the flue gases at the chimney outlet should be 100–110 °C.

If the temperature of the flue gases is below the dew point, that is, the condensation temperature of the air, then the water vapor contained in the combustion products will settle on the walls of the chimney. If this happens constantly, the chimney can quickly collapse.

If the temperature of the flue gases is too low, condensation will form at the outlet of the chimney, and the outer part of the pipe will begin to freeze.

In addition, the presence of constant condensation in the smoke channel leads to a weakening of natural draft. Therefore, it is so important to monitor the temperature of the flue gases, which directly depends on the cross-section of the chimney.

From the above we can conclude that with correct calculation, the temperature of the flue gases will be in the region of optimal values. If the temperature is too high and needs to be reduced, this directly indicates that the cross-section of the chimney does not correspond to the power of the gas boiler. To reduce the temperature of the exhaust gases, it is recommended to reassemble the smoke exhaust system taking into account the standard values.

Video: condensation in the chimney

Installation of a chimney system

Chimneys of any design must necessarily comply with the requirements of regulatory documents SNiP and DBN.

- the chimney must be perpendicular to the foundation. A small tolerance from the perpendicular to the side is possible up to 1 m per 300;

Chimney installation

- inclined sections in cross-sectional area cannot be smaller than vertical sections;

- The surface of the chimney channels from the inside must be smooth-walled. The composition of the materials from which they are made must ensure their tightness and fire resistance;

- the channel cross-section is always calculated based on the boiler power;

- At the bottom of the vertical chimney, a tee with a plug must be installed to drain condensation;

- an inspection must be installed on the horizontal part of the pipe.

Recommendations from the pros!

Accessories for a bath Do-it-yourself gazebo Concrete fence Do-it-yourself potbelly stove Do-it-yourself veranda Screw foundation Do-it-yourself country toilet Decorative brick Stone fence Pouring a foundation How to make a fence Wicket from corrugated sheets Do-it-yourself fireplace Brick fence Do-it-yourself flower beds Forged gates Do-it-yourself porch Pool for a bathhouse Chicken coop do it yourself DIY staircase Metal gates Installation of lining Installation of polycarbonate Pump for a summer house Arrangement of a garage Fences for flower beds Do-it-yourself blind area Steam room in a bathhouse Railings for stairs Do-it-yourself cellar Painting walls Press with your own hands Grilles on windows Rolling gates Do-it-yourself barn Alarm system for a summer residence Benches for a summer residence Fence posts Floor screed Solid fuel boilers DIY greenhouse Fence installation House insulation Attic insulation Foundation insulation

Height of chimneys according to standards

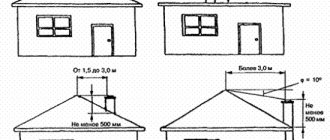

Correct placement of the chimney on the roof outside the wind pressure zone at the correct height relative to the roof ridge guarantees good draft and uninterrupted operation of the unit.

Standards for placing chimney pipes

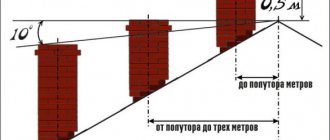

Standards for placing the chimney in height:

- The chimney must be located at least 50 cm above the roof ridge, provided that the chimney itself is located at a distance of one and a half meters from the ridge.

- If the pipe is located at a distance of one and a half to three meters from the roof ridge, then the top of the pipe should be level with the roof ridge or higher.

- Above a flat roof, the chimney must rise at least 1 m.

- Additional strengthening of the gas outlet will be required if it is more than 1.8 m higher than the roof.

Advice. The ideal shape of a gas outlet for a heating gas boiler is an oval. In square pipes, carbon monoxide creates turbulence in the corners of the flue structure, as the gases tend upward in a spiral, which leads to a deterioration in draft.

Forbidden:

- Make channels from loose, porous, slag concrete and other materials;

- Lay smoke exhaust pipes from stoves/appliances through living rooms;

- Install a damper when connecting devices with draft stabilizers to the chimney itself;

- Install the smoke duct outlet through the external walls:

— in entrances, covered passages, arches;

- closed balconies, bay windows, loggias;

- in monument buildings, without permission from the special department that protects them;

— through the walls of buildings facing streets/squares that have urban, historical and architectural value;

- in buildings in which the installation of gas appliances is prohibited in accordance with DBN No. V.2.2-9, SNiP No. 2.08.01, SNiP No. 2.04.05.

Openings of smoke ducts on the outer wall of buildings when combustion products exit from the heating device through the outer wall without vertical. channel should be placed in accordance with the gas installation instructions. manufacturer's equipment, but at a distance not less than those indicated in the following table:

Chimney pipes must be checked at least twice during the heating season and must be performed by highly qualified workers. They should also conduct an inspection of the chimneys themselves.

A chimney for a gas boiler according to SNiP will always work efficiently and, most importantly, taking into account all legal standards!

Share on social media networks

0

Tweet

Installation of a chimney according to the rules

Based on where the gas boiler will be located relative to the house, the chimney installation is carried out in two ways:

Indoors. Installing such a system is quite troublesome, and it is also necessary to strictly comply with fire safety requirements, because such a chimney has an increased risk of ignition or carbon monoxide leaking into the room. If all the rooms through which the chimney pipes pass are heated, then only the pipe located on the roof will need insulation. Please note that such a chimney is difficult to repair.

Coaxial pipe installation options

If you decide to install a chimney for a heating gas boiler yourself, then you first need to apply marks for drilling holes for the flue pipe in the ceiling and roof. Then double-check everything again, as they say: “measure seven times, cut once.” Cut out the opening. Now, let’s actually assemble the chimney:

- connect the heating boiler pipe to the adapter;

- Now you need to connect the tee and revision. After this, a sheet of steel is attached and the main holder is secured;

- we extend the gas outlet pipe from the bottom up, if necessary, use elbows;

- a special pipe is used in the place where the chimney crosses the floor of the house;

- Next, you need to throw a galvanized sheet over the chimney with a hole made in it, which is larger than the diameter of the chimney, and secure this sheet at the top and bottom of the ceiling;

- all places where gas outlet structures are joined must be additionally reinforced with clamps;

- We put a cap on the very top of the chimney - it will protect the chimney from bad weather.

Internal and external placement of the chimney

Outside. Due to the uniformity of the constituent elements of the chimney, it is easy to install and therefore easy to repair. Such a chimney requires thermal insulation along its entire length. If you are installing a chimney on the outside of the house, then the procedure is as follows:

- We mark the places for drilling openings and double-check. Then we thread the system passage through the drilled opening, one end of which is hermetically connected to the boiler pipe. The area that penetrates the wall is thermally insulated;

- we attach the revision and tee, then connect the plug;

- We install the flue elements from the bottom up. Don’t forget to attach the holders to the surface of the house;

- We reinforce all joints with clamps;

- Now you need to attach thermal insulation along the entire length of the chimney; this does not need to be done if you used a sandwich pipe.

Chimney installation methods

When installing a chimney, remember:

- all structural elements must be assembled correctly, gaps are unacceptable, and deflection of elements is also unacceptable;

- in places where the chimney crosses the structure of the house, it is necessary to install passage elements;

- The boiler and chimney are connected by applying heat-resistant sealant to the joints.

Advice. Thermal insulation of the chimney is performed with mineral wool, which is wrapped on top with foil or a sheet of galvanized steel. But there are ready-made products made from mineral materials on sale; you only need to measure the diameter and length of the pipe.

Boiler rooms for solid and liquid fuel boilers

The following types of liquid and solid fuels are used to heat residential buildings:

- coal;

- fuel oil;

- gas oil, gasoline;

- diesel fuel;

- working off;

- kerosene;

- wood waste, pellets, firewood;

- oil shale;

- peat;

- petrol;

- vegetable or machine oils.

As a rule, floor-standing units are designed for the use of solid or liquid fuel. Loading requires fairly large chambers, and after combustion, waste is generated. Therefore, such boilers are less compact than gas boilers.

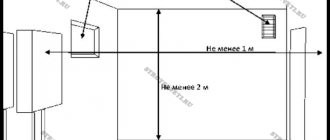

When building a boiler room in a private house with your own hands, you must comply with the same requirements as for gas boiler rooms, but with some additions:

- solid fuel and liquid boilers cannot be installed in residential premises due to strong odor or dust; for this purpose, an extension or a separate furnace room must be installed;

- To install a floor-standing boiler, a concrete foundation with a thickness of at least 50 mm is installed.

- there must be easy access for loading, cleaning the boiler, repairing and replacing parts;

- there must be at least 2 m from the place where the fuel is placed to the nearest wall;

- It is advisable to place the chimney closer to the ridge to create good draft;

- smoke exhaust is arranged through a chimney in the main wall or a pipe outside the house, and it should not coincide with the window openings;

- the chimney is made of a sandwich pipe with insulation and an internal heat-resistant layer of steel or brick;

- You cannot build an attic or living room above the boiler room;

- In the room where gas equipment is installed, flammable materials and chemicals that emit flammable vapors must not be stored.

To prevent dust from accumulating in the boiler room, which adversely affects the operation of the equipment, a supply opening is installed at a height of 30 cm from the floor, and an exhaust opening is located under the ceiling. Ventilation of the room should be natural.

You can quickly build a boiler room in a private house with your own hands if you use ready-made modular structures. During their production, all standards and requirements are taken into account.

A mini-boiler house can operate on any type of fuel and heat a residential building or cottage. The structure is installed on a monolithic or prefabricated foundation and connected to the heating system of the building. When using gas, the project must be agreed upon with the gas distribution organization.

Gas boilers without traditional chimneys

Gas heating boilers without traditional chimneys are a solution for apartments. These are units with a closed combustion chamber; they have a special system built into them for removing carbon monoxide. These boilers do not need a chimney with natural draft, because a special turbine in forced mode removes exhaust gases from the firebox. The gas exhaust system for such gas boilers can be used from polyvinyl chloride with any number of turns, and it is not necessary to maintain a vertical position. This type of chimney is designed as a coaxial type, it is led out through a hole in the wall of the apartment, and is aesthetically attractive.

Standards for installing a chimney relative to the building facade

When choosing a chimney for a gas heating boiler, be guided by the parameters of your device and the requirements for the installation of chimneys. This will guarantee your safety, as well as the uninterrupted operation of your gas equipment.

Use of wood based on its heat capacity

When choosing a type of firewood, it is worth considering the ratio of cost and heat capacity of a particular wood. As practice shows, the best option can be considered birch firewood, which has the best balance of these indicators. If you purchase more expensive firewood, the costs will be less effective.

To heat a house with a solid fuel boiler, it is not recommended to use types of wood such as spruce, pine or fir. The fact is that in this case, the combustion temperature of the wood in the boiler will not be high enough, and a lot of soot will accumulate on the chimneys.

Firewood made from alder, aspen, linden and poplar also has low thermal efficiency due to its porous structure. In addition, sometimes during the burning process alder and some other types of firewood shoot out coals. In the case of an open furnace, such micro-explosions can lead to fires.

It is worth noting that no matter what the wood is, if it is damp, it burns worse than dry wood and does not burn completely, leaving a lot of ash.

Chimney for a gas boiler: photo

Requirements for free-standing combustion chambers

Separate boiler houses are built for powerful heat generators, the operation of which requires an enhanced safety regime.

Requirements for furnaces built separately from a residential building:

The premises are equipped with concrete floors or covered with fireproof finishing. For equipment weighing over 200 kg, a reinforced base with a height of 15 cm is prepared.

d17f49b29c5c1639aceb856b52bd422c.jpe

Heated water enters the house through an insulated pipeline with low heat loss. A free-standing furnace does not take up the usable space of the house, is safe to use and does not disturb the architectural appearance of the building. Can be used for heating a group of buildings, for example, a house, a bathhouse and a greenhouse.

Requirements for doors

Two types of doors are used in furnace rooms:

- external without reinforcement for access to the street;

- internal fire protection for communication with residential premises.

External doors should be easy to break off their hinges in the event of an explosion. Then the energy will be directed outward and cause less destruction than with a rigidly and firmly fixed canvas. But in any case, you need to protect the premises from strangers who could enter and damage expensive equipment.

Interior doors are designed to contain flames in a fire for 15 minutes. Type 3 fabrics with a fire resistance limit of EI 15 comply with the standard. They retain their integrity and thermal insulation properties for a period of time sufficient for the evacuation of people from the house and the arrival of rescue services.

Boiler room ventilation

The requirements for a boiler room in a private house are very strict regarding ventilation. Combustion products formed when burning fuel are dangerous to humans. Inhalation of carbon monoxide leads to severe poisoning. High concentrations cause paralysis and even death.

Gas leaks in the network create a danger of explosion. Methane, propane and butane are heavier than air. They accumulate in the lower level of the room. That is why it is recommended to install gaps near the floor under the outer door or grated exhaust openings in the wall to remove hazardous substances. For every 10 kW of unit power, 0.01 m² of cross-sectional area of the supply channel is required.

Natural ventilation, recommended by the standard, includes supply and exhaust ducts to replace the air in the room. Their area is calculated based on the triple volume of the room and selected using special tables, diagrams or using online calculators.

For every 10 kW of power, 0.01 m² of cross-sectional area of the supply channel is required.

Combustion products are discharged through a chimney or a coaxial pipe built into the wall. In the first case, the cross-section of the channel must correspond to the diameter of the boiler pipe. The optimal shape is a circle or oval.

The chimney walls protect against condensation. Warm air, moving through the pipe, cools, which leads to the precipitation of water vapor in the form of dew. In winter, the moisture freezes and the channel narrows. This contributes to the deterioration of the removal of combustion products.

Protection against condensation is carried out by lining the chimney or installing a stainless steel pipe inside. Angles and turns must be smooth, and the joints of channel elements must be sealed.

In other cases, the ventilation duct may be lower. Separate smoke removal systems are installed for the two units.