- Rules for placing a boiler room in a house

- Requirements for a boiler room attached to the house

- Boiler room area

- Dimensions of a boiler room in a private house

- Boiler placement

- Window in the boiler room

- Requirements for the boiler room door

- Wall requirements

- Ventilation in the boiler room

- Requirements for boiler houses using solid and liquid fuels

The room where heating equipment is installed in a private house is called a boiler room.

In accordance with current building regulations, very stringent requirements are imposed on this room, since powerful heaters operate on flammable fuel. In this article we will analyze the basic requirements for a boiler room in a private house and consider the rules for installing equipment in premises for various purposes.

Rules for placing a boiler room in a house

The main document regulating the rules for installing a boiler room in a house is SNiP 42-01-2002, in force since July 1, 2003. It contains all the basic requirements for the installation of a combustion chamber. And during construction it is necessary to focus on it.

Theoretically, the owner does not need to understand SNiPs, since according to current standards, the design of a boiler room in a house must be developed by a specialized enterprise. Design experts are well aware of all modern rules and can draw up design documentation in such a way that, in accordance with it, a boiler room that is functional and safe for residents is built in the building.

However, in practice, property owners would also benefit from knowledge of building regulations. Therefore, let us outline the basic requirements for a boiler room in a house for 2022:

- The minimum volume of the object must be 15 m3.

- The furnace room can be located on the first, ground floor, as well as in the basement.

- It is prohibited to build a furnace close to the bedrooms in the house.

- The shortest distance to the street exit should be no more than 12 m.

- Heating equipment can only be placed in rooms with a ceiling height of 220 cm or more.

- A door and window are required.

- A functional ventilation system is required.

How to hide communications?

The design of a kitchen with a gas boiler involves not only masking the heater itself, but also the pipe, hose and chimney. During repair work, under no circumstances should they be walled up in the walls. All parts of the gas boiler must be easily accessible and at hand. Communications just need to be decorated in the right colors. They are hidden in special boxes and profiles with doors that can be easily opened if desired. If the kitchen interior is done in high-tech style, then all communications can be left open and visible. It is enough just to tint some in the desired colors.

Pipes and gas meter inside the kitchen module

The pipes in this kitchen fit well into the loft interior, and the column is simply covered with a decorative panel

Dimensions of a boiler room in a private house

The suitable area of the boiler room in a building must be calculated individually, taking into account several important factors. One of them is the type of heating equipment. Let's talk about the two most common options.

Gas

Despite the permitted area of 5 m2, for a boiler room it is best to use a room of 8 m2 or more. If you place all the equipment necessary for the safe operation of the system along one wall, it will take up more than 3 meters in length and about 1.7 meters in width. If the equipment is moved slightly so as not to place it under one wall, it will occupy approximately 2.5 x 2.5 meters of space.

At the same time, the surrounding space itself must remain accessible even with open doors and windows. In addition, additional equipment can be placed here, for example, a washing machine or dryer.

Pellet

Pellets are bars of compressed sawdust measuring 0.8x3 cm. They are often used as the main fuel for boiler houses in situations where it is impossible to connect the facility to the gas supply system.

A pellet boiler room requires two rooms at once. The first will house a bunker for storing pellets, and the second will house the combustion chamber itself.

The size of the bunker in most cases is about 6 m2. It is recommended to allocate a room of about 7-8 m2 for the boiler room itself.

Simple rules of camouflage

Hiding equipment is not difficult if you follow certain recommendations.

- If you leave the equipment uncovered between two modules located on either side and identical in design, the column can look organic. However, do not forget about fire safety rules, especially if the cabinets are made of natural wood or flammable materials.

- If the location is between two modules, then it can be hidden behind a simple, elegant curtain. This trick will be indispensable for country-style interiors.

Gas boiler in a country style kitchen

Compact model of a gas boiler in the kitchen interior

An example of camouflaging a boiler against a white wall

Boiler placement

Today the heating boiler can be placed inside the building itself in existing rooms. Let's look at the most popular options.

Kitchen

In buildings with an area of less than 350 m2, for which a 50 kW boiler is sufficient for heating, there is no need to organize a separate boiler room. The necessary equipment can be placed in the kitchen, the main thing is that the area of the room is at least 7 m2 with a total volume of at least 21 m3.

There will be no difficulties in coordinating the installation of a boiler in a combined kitchen with a dining room. But in this case, the dimensions of the room should be larger: volume - 36 m3, area - 12 m2.

Additional requirements for the room include the presence of a window, as well as a natural ventilation duct with access to the roof of the house.

In addition to the boiler, the heating system may have other equipment:

- faucets;

- pumps;

- boiler;

- collector;

- expansion tank.

To place it in the room, you can use a special cabinet measuring 1x1.5 meters. The main thing is that all elements of the system are available for scheduled maintenance and repair.

Pantry

The requirements for the pantry when installing heating equipment are similar to other internal non-residential premises. That is, if the room meets the permitted criteria in its area and volume, you can place a gas boiler here without any problems.

However, it will not be possible to install a boiler in all non-residential premises. The law prohibits the installation of such heating equipment in bathrooms and toilets.

Corridor

It is unlikely that it will be possible to place a boiler in the corridor, as well as in the hallway, veranda and other similar rooms. Such premises almost always cannot meet current building codes and regulations. Either the volume/area is insufficient, or the living rooms are too close, or there is no window, etc.

Flue gas removal

Channels and pipes designed to remove gas combustion products must ensure normal combustion in the boiler furnace. Due to this:

- the cross-section of the smoke exhaust duct should not be less than the dimensions of the boiler connecting pipe;

- it is allowed to reduce the cross-sectional area of the chimney if the design of the heating unit provides for the forced removal of combustion products and air supply;

- channels can be located inside capital walls and partitions of appropriate thickness or be attached to them;

- the material for the manufacture of chimneys must be fireproof and not subject to active corrosion;

- the design of the chimney must include a special hatch for cleaning the channel from soot and a device for draining the resulting condensate;

- the height of the chimney is higher than the ridge of the roof or a line at an angle of 15° when moving away from it.

All butt connections of elements are made airtight and exclude not only the release of combustion products into the premises, but also the possibility of air leaks and a decrease in draft.

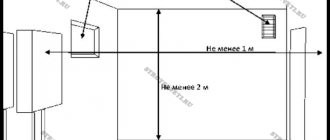

Window in the boiler room

The requirements for a gas boiler room in private houses stipulate the mandatory presence of a window. Not every window can meet the standards. It must comply with GOST R 56288-2014.

A window in the boiler room is needed to protect living quarters and their users from additional danger in the event of emergencies and explosions.

The requirements for the window directly depend on the area of the combustion chamber. For a room of less than 9 square meters, the glass area should be 80 cm2 or more.

Features of energy supply

The power supply of a gas boiler unit must be of two types: a separate power line from the subscriber panel and an emergency power supply, from batteries or a backup line. In addition, the boiler room power supply circuit must fulfill the following conditions:

- Mandatory installation of a boiler grounding system.

- Connecting the unit through a voltage stabilizer or uninterruptible power supply.

- The socket for the heating device must be located nearby in order to connect directly.

- The use of carriers is not permitted.

Requirements for the boiler room door

All attached furnace rooms must have a door leading to the street. If the heating equipment is located in the interior, it is not necessary to make an exit from them to the outside.

However, this requirement applies only to gas boiler rooms in a private home. If the furnace operates on a different fuel, for example, pellets, regardless of its location, there must be an exit from the room.

In internal gas boiler rooms, the door may not lead outside, but to other rooms of the house, for example, to a corridor or to a staircase. The main thing is that the distance from it to the exit from the house is no more than 12 meters.

Main requirements:

- must open outwards;

- width is 0.2 m larger than the size of the heating equipment;

- must comply with fire safety type 3 with EI15 (standard for steel doors with non-combustible basalt fiber filling).

It is allowed to have several doors leading to the corridor/veranda/street. The main thing is that each of them meets the specified standards.

Fire safety

The combustion area must be kept clean, and there must be sufficient artificial lighting inside the room to provide good illumination for work and public areas. Storage of any flammable materials in such premises is prohibited. When pipes freeze, they can only be heated with steam or hot water. The use of open flame is prohibited.

Special requirements are imposed on the operation and maintenance of smoke ventilation systems; they must be checked and cleaned periodically:

- Every year in August – cleaning of smoke channels from soot contaminants and checking draft.

- Quarterly - cleaning of brick chimneys.

- The integrity of the ventilation ducts is inspected annually.

The entrance doors of the furnace room must open outwards. Windows - must have easily removable packages. At the entrance of the gas pipeline in the combustion chamber, a protective electromagnetic valve, a fire alarm and indoor gas sensors are installed.

Requirements for boiler houses using solid and liquid fuels

Such furnaces are subject to special requirements, which do not differ too much from the standards relating to gas equipment. Let's look at the main ones:

- mandatory presence of a door to the street, regardless of the location of the room;

- protection of surfaces from exposure to high temperatures and the risk of fire;

- installation of heating equipment at a distance of at least 10 cm from the walls;

- presence of a window;

- the width of the doorway from the room should be at least 80 cm;

- mandatory arrangement of a fuel storage warehouse, which must be covered, but not heated.

Render House specialists are engaged in the construction of houses with boiler rooms according to standard and individual projects. For more detailed advice, you can contact the phone number indicated in the header of the site.

Maintenance

Preventive measures for routine inspection of gas boilers include the following types of work :

- Checking the valves of the external and internal gas pipelines (disassembling, applying lubricant).

- Inspection of thermostats on floor-standing boilers.

- Washing or replacing filter elements.

- Inspection of nozzles , checking the tightness of the door, the operation of the igniter on floor-standing devices.

- draft control

- ice build-up in winter .

All components that have been subject to wear during operation must be replaced.

On a note! After completion of the repair and before starting the heating system, the gas service worker checks the tightness of all connections in the line. Usually a soap solution is used for this.

A competent preventive inspection will not only increase the service life of the equipment in use, but will also reduce gas consumption.

Repair and maintenance of gas equipment Source sanmaster62.ru

Chimney installation standards

The material for the chimney is selected depending on the fuel being burned and the type of boiler. For a gas boiler, the pipes must be cylindrical and made of metal, preferably stainless steel. Such chimneys are the safest, most durable and reliable.

The chimney is installed above the ridge of the house. A hatch for cleaning the chimney must be installed. In order to ensure convenient collection of soot during cleaning, collection and removal of condensate, an empty space under the chimney inlet is necessary.

Gas boiler chimney diagram

When installing a chimney, there should be no more than three elbows and turns. The pipe connecting the boiler and the chimney should be as short as possible, no more than 25 cm.

The vertical section at the boiler outlet must be equal to at least two diameters. Beyond this vertical section, the pipe of the connecting section must necessarily rise upward with a slope towards the boiler.

Smoke removal in this case is carried out due to natural draft through the chimney.

Following all the requirements and rules for installing gas boilers will ensure their efficient operation, durability and fire safety.

Required Documentation

To consider an application for technological connection of a residential building to the gas distribution network at the gas distribution organization (GRO), you need to collect the following documentation:

- documents confirming the applicant’s ownership of the house and land;

- a document confirming the compliance of the technical conditions of the house with the gas distribution network (TU);

- copy of passport;

- diagram of the land plot and adjacent territory;

- calculation of planned gas consumption;

- gasification project.

The application also indicates the location of the house that needs to be connected to the gas main, the applicant’s passport details and postal address, email address or telephone number for contact. The application can be submitted in electronic format on the GRO website, sent by mail or at the document acceptance center of the gas distribution organization. For the unreliability of documents attached by the applicant in electronic format, the legislation provides for administrative liability. The address of the GRO can be found in local authorities or found on the Internet, indicating the name of the subject of the Russian Federation.

Stages of gasification at home

The Contractor reviews the application within three days from the date of receipt. If the applicant has not fulfilled all the requirements, he is notified that he must provide all missing information and documents within 20 days. Consideration of the application is suspended at this time.

Ownership documents

If you are not the sole owner of the land plot, then consent to gasification of all adult owners is required. Your rights and the rights of other owners can be represented by third parties under a power of attorney executed in a notary's office.

If your house is connected to the gas distribution network from a neighboring plot, the consent of the owner of the plot is required. However, power assignment is possible only if the neighboring building has been connected to the same gas distribution network for at least 5 years and there are no technical contraindications to connecting a new consumer.

A land plot diagram (situation plan) can be obtained free of charge from the local administration, as well as from the BTI and from cadastral engineers, however, you will have to pay for their services. The calculation of the planned gas consumption is compiled by the contractor’s employees (GRO). If it does not exceed 5 cubic meters. m. per hour, no document is required.

Types of gas heating equipment

Modern industry produces a fairly wide variety of types of equipment for equipping a gas boiler room or for installation in any other non-residential premises, which allows users of such devices to optimally select them in full accordance with their requirements and financial capabilities. So, depending on a number of parameters, boilers can be:

- single-circuit or double-circuit type;

- with a closed or open combustion chamber;

- equipped with various ignition systems;

- with a boiler for heating external or internal water;

- installed on the floor or mounted on the wall of the room.

In addition, of course, heating appliances for the kitchen differ in their power.

In a large kitchen you can also place a floor-standing gas boiler if you need to heat large areas

Differences between single- and double-circuit gas boilers

Single-circuit and double-circuit boilers for the kitchen differ not only in the number of circuits in their design, but also in functionality. Thus, single-circuit type equipment can only be used for heating, and a double-circuit gas boiler can also be used to heat water for domestic and household needs. Meanwhile, if you equip a single-circuit boiler with an external boiler, then it can also be used to heat water for hot water supply in the kitchen.

A boiler with one heat exchanger will be used only for heating, and equipment with two circuits will additionally solve the problem of hot water supply

A wall-mounted double-circuit boiler is a mini-boiler room slightly larger than a regular gas water heater.

Gas boilers with closed and open combustion chambers

Air enters boilers with an open combustion chamber directly from the kitchen, and exhaust gases naturally evaporate through the chimney. Installing a boiler of this type in the kitchen is not the best option, since when it operates in the kitchen, the amount of air decreases, which is especially critical if the room is small. Boilers with a closed combustion chamber operate on a slightly different principle, into which air is supplied from the street through a special coaxial-type chimney and gases formed during the combustion process are discharged through it. The installation location for a boiler with a closed combustion chamber can even be small kitchens (6–8 m2), where it is possible to install them inside kitchen cabinets.

Construction of boilers with different types of combustion chambers

This is what a coaxial chimney looks like from the street side

Differences in gas boilers by type of ignition

Heating appliances, depending on the model, can be equipped with automatic and manual ignition systems. In devices of the first type, the burner automatically turns on at the moment when gas begins to flow into it, and when using a type with manual ignition, accordingly, you will have to carry out this process yourself, using matches or a lighter.

Gas boiler automation can be non-volatile (mechanical) or volatile (electronic). In budget models, the first type is more often used

Gas boilers with external and built-in boilers

Naturally, it is much more convenient when, together with a gas boiler, a boiler is used in which water is heated to satisfy domestic and economic needs. Such boilers for the kitchen, as mentioned above, can be external or built into the boiler itself. Devices with built-in boilers are compact in size; such options are easier to install, but the volume of the tank that is built into them is quite small. The volume of the tank for boilers with an external boiler can be almost anything, but such devices, which should be taken into account when choosing them, take up more space, and in order to install them, it will be necessary to install additional communications.

Construction of a gas boiler with a built-in boiler

Placing an external boiler will require more space in the kitchen