Are you faced with a situation where your old gas heating equipment has worn out or is no longer efficient enough? It seems that solving this problem is simple - just pay money and in a couple of days the new boiler will take over the functions of heating the house, right? But in reality, everything is different, since replacing a gas boiler in a private house is a labor-intensive procedure and requires proper registration. And it will take more than one day, because you will have to visit the gas service several times.

What do you need to know and how to properly arrange a boiler replacement? We will examine all these questions in detail in our article. Let's talk about the rules and regulations governing the connection of gas equipment, and the responsibility of the homeowner in case of their violation. Let's look at the step-by-step procedure for replacing a boiler. We will supplement the presented material with visual photos and thematic videos.

Documents for replacing gas equipment

All boilers operating on gaseous fuel have a certain service life.

So for wall-mounted models it is about 8 years, and for floor-standing units it reaches 15 years of service. Once the operating period is completed, the gas boiler must be replaced. The maintenance of this equipment, as well as its installation, is carried out exclusively by employees of government organizations, such as, for example, Gorgaz. AOGV and AGV boilers can only be changed with the consent of the relevant authorities.

The fact is that replacing a gas boiler in a private house or apartment is a responsible undertaking, since people’s lives depend on the correct execution of the work. For this reason, this should only be done by specialists. It is unacceptable to do the replacement yourself, but you can dismantle it yourself.

The property owner must first complete the relevant documents. To be legitimized, they must be submitted to government agencies. Documents must be prepared before replacing the heating boiler so that problems do not arise in the future due to illegal work. You can do this yourself or order a service from a special specialized organization.

The following documents will be required:

- certificate that meets safe operation standards;

- DVK inspection report;

- technical data sheet and instructions for the boiler;

- warranty service agreement for a period of 1 year;

- project with changes made to it.

When all of the above documents have been prepared, you can go to the city gas department to obtain permission. If the question arises as to whether a project is needed when replacing a gas boiler, then the answer is yes. It must be approved and only after that work can begin.

While waiting for permission, so as not to waste time, you can start selecting a unit model that meets the requirements, which will ensure efficient and uninterrupted heat supply.

Boiler and heating system testing

The initial start-up of the boiler is carried out by a gas specialist.

For start-up and testing, you must contact the office of the gas supplier. The service representative connects the boiler to the gas system and performs its initial start-up. Before start-up, a visual check of communications is carried out for malfunctions, leaks and other defects.

If the system is in working order, the boiler meets the declared characteristics, the owner is issued a permit to operate. Gas service employees also draw up an installation work report. The customer sends it to Gorgaz.

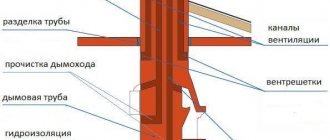

In addition to the work report, a written notification of their completion is sent to Gorgaz. The owner of the house must provide the document 5 days after installation of the device. Attached to the notification papers are certificates of inspection and connection of the ventilation system, chimney, and a contract for servicing the system.

Main stages of installation approval

The installation of gas boilers must be carried out by specialized organizations. If the user decides to change the boiler to a similar model that was previously specified in the technical specifications for gas supply, he will not have problems with preparing permits. If this is a more powerful unit, it needs to obtain new documents to put the boiler equipment into operation.

This process usually takes from two weeks to three months, but often many users cannot cope with the bureaucratic delay, rightly calling it “the three circles of hell.” Recently, the practice has become widespread when a specialized organization for replacing a boiler is also entrusted with the work of issuing permits, which makes life easier for the customer and does not lead to a significant increase in the cost of the project.

The basic norms and rules that guide the replacement of a boiler unit in domestic conditions are enshrined in SNiP documents on gas supply, heating, hot water supply and safe operation of boilers NoNo 42-01-2002, 31-02-2001, 2.04.08-87, 41- 01-2003, 21-01-97, 2.04.01-85.

Main stages of installation approval:

- Obtaining technical specifications from the city gas service.

- Development of an installation project: a diagram of the installation and laying of a gas pipeline connecting to gas networks with a diagram of the placement of internal gas networks at the user's site and determination of costs, how much it will cost to replace the unit.

- Coordination of the project with local authorities, the architectural department, Gorgaz and organizations that own utility networks: water, sewerage and electrical networks.

Package of documents for gas inspection:

- Project;

- technical passport of the gas boiler unit;

- factory instructions for its operation and electrical connection diagrams;

- certificates of compliance with state standards provided by the equipment manufacturer when purchasing the boiler.

Note! In case of refusal, the organization must provide a clear reason and a list of requirements for changing the design. An unauthorized gas boiler reconstruction project is prohibited at the legislative level, as it can pose a threat to the lives of a large number of people.

Documentation of the change of thermal installation

The paperwork, dictated by the possible scale of damage in the event of unauthorized replacement of equipment without complying with regulatory rules, provides for the collection and provision of the following documents:

- Imported equipment will require a certificate confirming compliance with domestic safety standards. For double-circuit models, it is additionally necessary to have a sanitary and hygienic certificate, which concerns hot water for domestic needs. As a rule, retail chains provide this package along with a warranty card.

- An inspection report with a positive conclusion about the suitability of smoke and ventilation ducts.

- A report on the results of connecting the boiler to engineering systems, as well as a report on hidden work when laying a coaxial chimney through the wall.

- Warranty service agreement concluded for at least 1 year with a service organization.

- The cornerstone of the documentation is the project with the changes made. A necessary condition for a new boiler to be considered legal.

Please note: the owner collects documents independently or delegates this process to a specialized installation organization, which is reflected in the overall price.

Stages of registration of boiler replacement

The procedure for replacing a boiler that differs from the old one in technical characteristics and volume of gas consumption per hour consists of several stages, which can only be performed after obtaining special permission from the gas service.

And this point cannot be ignored, especially if the difference in the power of the boilers is significant (the exact figure must be clarified with your city gas company). In addition, in most cases, documentary evidence will be required.

Replacement sequence:

- Submitting an application for the provision of technical conditions;

- Familiarization with technical conditions;

- Design;

- Project approval (coordination);

- Dismantling the old boiler;

- Installation of a new boiler;

- Testing the boiler and heating system;

- Submitting an application to connect the boiler.

It should be remembered that the specified procedure for replacing boilers is established by law and a number of by-laws. Therefore, if the owner of the building decides to somehow “simplify” the procedure, change it, or carry out work in circumvention of the law, then, at best, the responsible authority will not give permission for a replacement or will cancel it.

The procedure for replacing boilers has become simpler - domestic legislation is regularly updated, simplifying the requirements for replacing a gas boiler in a private home

In the worst case, for unauthorized connection and use of gas, if such actions do not entail serious consequences and do not contain criminal offenses, administrative liability will arise and you will have to pay a fine, the amount of which is 10-15 thousand rubles for individuals. This is stated in the Code of Administrative Offenses of the Russian Federation, Article 7.19. Clause 1 as amended by No. 307-FZ dated November 3, 2015.

You also need to know that the gas service has the right, and unilaterally, to terminate contracts for the supply of “blue” fuel and stop its supply. But this development option is extremely rare and only after a written reasoned notification.

We recommend: What to do if water drips from a heating boiler, how to stop the leak yourself in gas, solid fuel and other models with different heat exchangers

Next, we will consider the step-by-step process of registering the replacement of gas heating equipment.

Stage #1 - submitting an application for provision of technical specifications

Replacing any gas boiler begins with a trip to Gorgaz (raygaz). Where you will need to write an application requesting the provision of technical conditions and the issuance of permission to carry out design, if necessary.

The specified document should also indicate the planned volumes of gas consumption. If this is not done, the application will not be accepted. The necessary numbers are always in the passports of heating boilers.

If you encounter any difficulties, you can seek help from specialists. The city gas department can also perform the necessary calculations, but for this you will have to submit a separate application, and before applying to obtain technical conditions.

The documents regulating the procedure for replacing boilers do not prohibit owners from dismantling old and installing new equipment. But there is no need to rush to save on the service, since the contractor should have skills in handling electrical, gas networks, heating systems, and also be able to handle the boiler itself

Since only building owners have the right to replace boilers, you should have a passport with you to confirm your identity. As well as a document indicating that the applicant is the owner of the property. In some cases, you will have to confirm the right to own a land plot. For example, if a new boiler will be placed in a boiler room that has not yet been built. In this case, you will need to provide a situational plan of the allotment.

The technical conditions, together with the permission necessary to carry out the design (if necessary), will not be provided to the applicant immediately, but after the relevant calculations have been completed by Gorgaz specialists. Which will take some time.

The gas workers will indicate the exact date of issue of the document when accepting the application. Moreover, the realities are such that the deadlines do not depend on any legal norms, but solely on the workload of specialists. Although gas workers are given no more than 10 days to complete the necessary documents.

You should be aware that when performing replacement, certain technical work (connecting boilers to gas supply, testing work) can only be performed by licensed specialists

If the applicant does not have information about which gas organization to contact, then the application can be submitted to local authorities. The responsible persons are obliged to transfer the received document to the required city gas (ray gas). They are given 5 days for these actions.

The law also allows you to submit an application in the form of an electronic document.

Stage #2 - familiarization with technical conditions

The specified document (Technical Conditions) is a set of rules and regulations that must be followed when designing and connecting equipment. It also sets out the procedure for replacing a used gas boiler in any private home.

Technical conditions are determined and compiled on the basis of the current version of the rules for connecting to gas distribution networks of the Russian Federation PP dated December 30, 2013 No. 1314 .

Stage #3 - drawing up project documentation

This item is optional in most cases. This is indicated by the State Russian Federation dated December 29, 2004 No. 190-FZ , which states that design when replacing boilers can be omitted.

But there are exceptions, so the specified documentation will have to be completed if:

- more than one family lives in a private house;

- a private house has more than 3 floors.

In addition, the owner of the building has the right to carry out the design on his own initiative.

The task of the owner of a house in which gas equipment is being replaced is to obtain the necessary permits. Why should you contact your local gas company?

If the owner of the building belongs to one of the listed categories, then in accordance with the requirements it is necessary to draw up and then submit to the city gas a number of schemes.

These include a diagram for installing equipment (boiler, chimneys, etc.), diagrams for laying a gas pipeline, a diagram for laying a gas pipeline to the building, and a communications diagram.

In addition, you will need to attach the following documents to the listed documents (if the unit is not purchased from Gorgaz):

- certificate of conformity for the boiler, and, if available, also for the burner;

- passport or instructions for the boiler, and, if available, then for the burner;

- act of checking the so-called ground loop.

You will also need a contract for servicing gas equipment with a licensed organization. And for a period of no less than 1 year.

Stage #4 - approval (coordination) of the project

Once ready, all project documentation is submitted to Gorgaz for verification. Which can be carried out from 7 days to 4 months. That is, it all depends on the workload of the specialists responsible for the procedure.

If all the documentation provided to the gas workers meets the requirements, then everything will end with the issuance of a certified written document to the applicant, which allows them to proceed directly to replacing the boiler. From this moment on, the procedure for registering the replacement of a used gas boiler can be considered complete.

Another important task for the building owner is preparing the premises for installing the boiler. Which must comply with the technical conditions of the city gas

If specialists identify inconsistencies, the required permit will be refused. The positive point is that gas workers cannot simply prohibit changing equipment. That is, they are obliged to provide a document, a written one, with a list of shortcomings and options for eliminating them.

Stage #5 - dismantling the old boiler

You should know that the owner of the building can dismantle the old boiler himself. But this opportunity should be used only if there is a need to save on the cost of the service.

Dismantling should be carried out only after disconnecting the boiler from the gas pipeline or water supply. In addition, the old unit should be disconnected from the heating system. Why is water first drained, both from the gas equipment itself and from pipes, radiators, and other elements of the system?

Stage #6 - installation of a new boiler

There is an opinion that installation can only be carried out by specialists from city gas companies or other organizations that have received a special license. But in fact, it is not prohibited to independently install gas equipment and other related procedures. But the connection of the installed boiler is carried out only by a specialist who has the appropriate license.

We recommend: Fiber cement panels: what they are, pros and cons, characteristics, manufacturers, reviews, installation

Nevertheless, the opportunity to install the boiler yourself should be used only in cases where you have the appropriate knowledge and skills.

It should be remembered that violation of the rules when replacing any gas boiler can lead to Gorgaz stopping supplying gas

Since most owners are prudent and use the services of specialists, their role comes down to choosing the room where the new gas boiler will be installed.

But this procedure also applies to those responsible, since there are many requirements for it:

- To install the boiler, a room must be allocated with an area of at least 4 m² with supply and exhaust ventilation;

- ceiling height - from 2.5 m;

- There must be windows, in addition, of the appropriate area - 0.3 m² for every 10 m³ of volume;

- There must be an entrance door with a width of 80 cm.

As a result, when replacing a gas boiler in a private house, in most cases, it cannot be installed in corridors, bathrooms, toilets - this is not prohibited, but the listed premises extremely rarely comply with the above rules.

And the most convenient place for installation is usually the kitchen, but this applies to cases with wall-mounted units. If you plan to use floor-standing units with impressive dimensions, you usually have to allocate a separate room (boiler room) for installation.

The specified requirements and standards are set out in the current version of SNiP II-35-76 .

Stage #7 - testing the boiler and heating system

The first start-up of any installed boiler must be carried out by the specialists who installed it. For this purpose, an external and internal inspection is initially carried out in order to identify malfunctions, defects, coolant leaks and other problems. And only after that you can check the performance.

When replacing a heating connection, you should remember that the most important thing in this procedure is not any material benefit or speeding up the process, but compliance with safety measures

If the characteristics of the boiler meet the requirements, then the specialists who performed the installation must indicate this in the appropriate report. Which is supplied, and without fail, to Gorgaz.

At this point, the replacement of the boiler, the power of which differs from the same characteristics of the old unit, is considered complete. If deficiencies are identified during testing, the start of operation will be delayed until they are eliminated.

Based on the test results, the contractor is obliged to provide the customer with a corresponding report .

Stage #8 - notification of boiler replacement

After the replacement of the heating boiler has been completed, the owner of the building should once again contact Gorgaz for written notification of the work performed. This procedure must be completed within 5 days from the date of installation of the equipment.

An important point when replacing gas boilers is their correct placement. Since safety of operation depends on this

The notification should be accompanied by certificates of connection and inspection of ventilation and chimney, as well as an equipment maintenance agreement for a period of one year or more.

Why is the replacement carried out?

During operation of the boiler, its power and efficiency level gradually decrease. The equipment is becoming outdated and no longer meets modern standards.

The most common reasons for replacing equipment:

- The boiler performance is no longer satisfactory. If you made an extension or connected additional devices to the circuit (for example, a boiler), then the old unit may not be able to handle the load.

- Inappropriate functionality. Installing a double-circuit device instead of a single-circuit one allows you not only to heat the room, but also to use hot water supply (DHW).

- Questions of rationality. Standard boilers consume a lot of gas. But more modern condensing devices use not only gas, but also steam. This approach increases efficiency by 110%.

- Wear or breakdown of equipment.

Therefore, if your old “AOGV” is working “on its last breath”, if the cost of maintenance is equal to the purchase of a new device, then a replacement is simply necessary.

What designs does the market offer:

- With a closed combustion chamber . This is a safer variety because the burner is closed from external influences. Smoke removal occurs thanks to a fan. The connected coaxial chimney contains two tubes through which air enters and fumes are removed. Requires a network connection.

- With open camera . An open burner requires air to be drawn from the room to maintain the flame. Good ventilation and connection to the flue shaft are required.

Features of the gas boiler replacement process

In order to replace a gas boiler correctly, it is necessary to take into account a number of nuances and rules:

- The boiler should be installed in a room with an area of at least 4 square meters with a ceiling height of 2.5 meters. In addition, it must be ventilated, and the location of the device must be level and heat-resistant.

- The unit is positioned so that it has easy access.

- If a floor-standing boiler is being replaced with a wall-mounted unit, it is hung on brackets. They do it below the level.

- When installing a new floor-standing device, it is simply placed on a level place.

- The gas boiler is not installed in the bathroom, basement or balcony.

- The ideal place to replace a floor-standing gas boiler with a wall-mounted version is the kitchen, since it has much in common with the boiler room. In this room it is easiest to connect heating equipment to cold and hot water supply.

Restrictions on installing a gas unit

There are restrictions when installing a new gas boiler that must be taken into account when choosing a modification:

- The area of the room for installation must be more than 7 m2;

- the furnace room must have a door more than 0.8 m wide;

- lighting of the room should be ensured by installing windows in the ratio of 0.3 m2 of window per 10 m3 of room;

- ceiling height must be at least 2.5 m;

- natural ventilation in the furnace room should provide three air changes per hour;

- increasing the power of the unit will require changing the smoke exhaust system;

- there must be a cold water supply in the furnace room.

Is it possible to install it yourself?

In fact, the joint venture stipulates that installation work must be performed by a licensed and certified specialist. Few people know, but this standard applies exclusively to work on connecting to the gas main. You can connect the boiler yourself, provided you have a technical education.

When deciding to install a boiler yourself or involve specialists, several nuances are taken into account:

- When installing a condensing type boiler, you will need to connect the unit to the electrical network and connect the condensate removal system without disruption.

- Perform a number of approvals during installation. Additional approval of the chimney will be required when installing a gas heating boiler. The inspection is carried out by a representative of the gas industry “stove man”. During operation, such an audit will be carried out every year, before the heating season.

- There is no guarantee for self-installed gas equipment. Only when the connection is made by a representative of the company selling the boiler, a stamp is placed in the document indicating the start of service.

After installation, a representative of the gas industry must check the operation of the boiler and fill out commissioning documents.

Documentation for boiler installation

One of the rather unpleasant procedures when installing a heating boiler that runs on gas is the collection and execution of a voluminous package of documents. Many, faced with this process, soon rush to abandon this idea.

Before starting installation, you will have to spend a lot of time agreeing

Basic requirements and standards can be found in the document “Gas distribution systems”, included in SNiP 42-01-2002. In addition to this, it would be nice to study a document that is no longer working, but contains a large amount of information that will also be useful - this is “Gas Supply” SNiP 2.04.08-87. Additionally, you will have to familiarize yourself with the standards given in related documents that talk about boiler systems, ventilation systems, heating, sewerage, water supply, construction safety, sound insulation, fire safety, etc.

Is a new project needed when replacing a gas boiler?

The project specifies the model, type and power of the heating unit. In addition, each boiler has its own serial number, indicated in the technical passport and included in the project documentation. Therefore, when replacing, you will need to make a new project indicating new data.

You must go through the following registration steps again:

- Obtain technical specifications for replacing a gas boiler. At this stage, the gas distribution company can change the performance of the unit based on the actual living area of the house.

- Make a new project.

- Obtain approval by providing a gas distribution project, technical specifications, and the results of checking the chimney duct.

- Replace the old unit with a new one.

When replacing an old gas boiler with a new one, the following documents are needed:

- Passport.

- Documents of the owner of the residential premises.

- Technical passport for gas equipment.

- Technical conditions.

Standard prices for replacing already installed gas equipment are 1000-1500 rubles, depending on the region.

Installation restrictions

For safety reasons, appliances operating on gas fuel are prohibited from being installed in the following premises:

- in which there are no ventilation systems;

- in dormitories (rooms);

- in bathrooms;

- in the corridors and on the balcony;

- in basements;

- on the ground floor;

- on flammable wall surfaces.

One important clarification regarding installation on the ground floor and basement: installation is only permissible in a private single-apartment house, i.e. if the house is not divided into several owners.

Is it possible to replace a gas boiler with an electric one?

Replacement is quite possible, but for this you will have to obtain permission from another organization involved in electricity supply. Documents are needed only if the electric boiler has a power of more than 8 kW. Up to this performance limit, the unit belongs to ordinary household water heating devices of the boiler type, therefore, it is installed without permits or approvals.

We recommend: Foamed polyethylene (polyethylene foam)

For productive electric boilers, a separate power supply line will be required. You will need to make a project and obtain permission to increase the amount of electricity allocated. Separately, you need to write a statement about disconnecting the gas boiler from the main line.

Documents required for boiler certification

To start the boiler certification procedure, you will need to submit an application to the certification center, with which you must submit a set of documents containing the following content:

- details of the applicant or manufacturer;

- technical information on which the installation was carried out;

- description of the boiler indicating technical characteristics;

- equipment passport (for boilers operating under high pressure);

- operational manual;

- invoice (for an imported boiler);

- certificates or results of examinations carried out outside the scope of boiler certification according to technical regulations.

will provide assistance in obtaining certificates for various boilers for domestic and industrial use, as well as registering declarations of conformity of such equipment. Our experts will carry out all the necessary checks to establish the safety level of your boilers in a short time.

If you have any questions about the boiler certification procedure, you can contact our specialists for advice by writing to us at [email protected] or calling us or making an online application.

Service life of gas equipment

Heating equipment has its own service life, it is indicated by the manufacturer in the technical documentation, therefore, when choosing a boiler, it is necessary to pay attention to this important factor. The service life of a gas boiler in a private home depends on the material of the unit, the quality of tap water and proper operation.

Modern heat exchangers are the main part of the boiler; they are made of copper, with a service life of 5-10 years, stainless steel up to 20 years, or cast iron up to 30 years. Mid-range or mid-priced models typically last 10-15 years, are less efficient to operate, and do not have the latest control features. Boilers with high prices are made of high-quality materials, have electronic control and 100% process automation, which significantly increases their service life.

Wall and floor structures also have different operating periods. Wall-mounted boilers are less powerful, they operate more at maximum loads and therefore wear out faster. Boilers with natural and forced circulation also differ in the duration of trouble-free operation.

The former, due to the low velocity of the flue gases, are more often clogged with soot along the gas-air path, which reduces the speed of movement, heat removal and overheating of the heating surfaces. This leads to constant operation at maximum power and rapid wear.

Note! Forced removal of flue gases does not have these disadvantages and is therefore more effective.

Boiler room requirements

Gas equipment belongs to the category of explosion and fire hazards. Therefore, special requirements are imposed on the room in which it will be installed.

First of all, it must have natural light. In this case, for each cubic meter of room there should be at least 0.03 square meters. m of window opening without frame, that is, only glazing. The window must be equipped with a window.

The wall on which the gas boiler is installed must be finished with non-combustible materials

Another prerequisite is the presence of supply ventilation, which can ensure a change in the air volume of the room within 3 times in one hour. In this way, gas pollution in the room can be minimized.

In addition, the volume of the room in which it will be installed depends on the power of the selected boiler. Equipment with a power of 30 kW and below can be placed in 7.5 cubic meters. m boiler room.

For heating devices whose power varies from 30 to 60 kW, you will need a combustion chamber with a volume of 13.5 cubic meters. m and above. If the heating device is to be placed in an apartment, it is usually installed in the kitchen.

This is possible if all the requirements of SNiPs are met. An important nuance: in this case, the total thermal power from all heating devices in the kitchen should not exceed 150 kW.

According to the standards for installing wall-mounted gas boilers, to improve air exchange in the kitchen door, it is necessary to make a hole with an area of at least 0.02 square meters and cover it with a grill.

Experts recommend for installation in an apartment building only equipment with a closed firebox, equipped with a coaxial chimney. In kitchens with a volume of 7.5 cubic meters. m or less, it is prohibited to install more than one heating device.

Requirements for the installation of gas heating equipment are regulated by SP-41-104-2000 and SNiP 42-01-2002. Compliance with installation standards guarantees safe operation

In private houses, it is recommended to allocate a room for gas boilers, separated from the living rooms by fire-resistant, durable partitions.

It is optimal that the materials used to decorate the room have a fire resistance time limit of at least 45 minutes. It is desirable that the layout of the premises prevents the rapid spread of flames to living rooms.

The gas boiler can only be secured to a solid base. Partitions made of plywood or plasterboard are not suitable for these purposes. The wall on which the heating device will be placed must be finished with fire-resistant materials.

If this is not the case, a non-combustible substrate is installed under the boiler. The minimum distance from the device to supporting structures is 0.5 m to the ceiling or walls and 0.8 m to the floor.

The photo shows one of the options for connecting a wall-mounted gas boiler

How much does it cost to replace a boiler?

We will take the cost of the boiler itself out of brackets, since the price range is very high. Let's estimate the remaining costs. After selecting and purchasing a boiler, it needs to be delivered and installed, dismantling the old one.

Delivery

to the region (for example, Moscow) -

2-5 thousand rubles.

Dismantling

an old floor-standing boiler - the amount can range from

3-5 thousand to 15-20 thousand rubles

, depending on the amount of work. For example, if a cast iron boiler is installed in the basement: they lowered it there during the construction stage, but did not think about how to get it out. The task is not insurmountable, but very expensive.

Installation

a new boiler - the procedure includes re-cutting the pipelines, reconnecting to the chimney and, as a rule, several other minor changes in the design of the heating system, which could not have been foreseen at the stage of inspecting the site and drawing up a preliminary estimate. For example, a new boiler may not be the same size as the old one and the “stand” (concrete pedestal for the boiler) will require alteration. As for the chimney: floor-standing boilers (except gas boilers) do not allow the use of flexible corrugated hoses, and changes in the size and geometry of rigid chimneys may entail additional construction work, drilling and gating of walls.

Cost of installing boiler equipment

Installation

| Solid fuel boiler (15% of the boiler cost) no less | PC | from 10 000 ₽ |

| Floor-standing gas/diesel boiler (15% of the cost of the boiler) no less | PC | from 10 000 ₽ |

| Pellet boiler (10% of the cost of the boiler) no less | PC | from 15,000 ₽ |

| Wall-mounted single-circuit boiler up to 30 kW | PC | from 9 000 ₽ |

| Wall-mounted 2-circuit boiler up to 30 kW | PC | from 10 000 ₽ |

| Pump (D, up to DN 32) | PC | from 3 150 ₽ |

| Pump group (pump, shut-off valve assembly) | PC | from 2 500 ₽ |

| Expansion tank for heating system (up to 100 l.) | PC | from 2 500 ₽ |

| 3-way valve (D, up to 1 1/4″) | PC | from 2500 ₽ |

| 3-way valve mixer servo drive (D, up to 1 1/4″) | PC | from 3 150 ₽ |

| Chimney (D, up to 250 mm.) | m/linear | from 2,500 ₽ |

| Boiler (water heater, up to 200 l.) | PC | from 8 500 ₽ |

| Boiler (water heater, up to 500 l.) | PC | from 10,000 ₽ |

| Boiler safety groups | PC | from 2 250 ₽ |

| Water Heater Safety Groups | PC | from 2 250 ₽ |

| Boiler manifold | PC | from 5,500 ₽ |

| Hydraulic separator | PC | from 2,500 ₽ |

| Heated floor temperature control groups (thermostatic valve, thermostat with clamp-on sensor, bypass valve, starter) | PC | 3 750 ₽ |

| Fuel tank connection | PC | 5 000 ₽ |

| Fuel filter installation | PC | 2 000 ₽ |

| Air vent, thermometer, pressure gauge per unit | PC | 650 ₽ |

| Ball valve, mud filter, check valve | PC | 500 ₽ |

| Check the cost by phone: | 84957446774 |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Commissioning works

| Commissioning of a wall-mounted gas boiler | PC | from 10 000 ₽ |

| Commissioning of boiler house up to 60 kW (protherm, ferroli, baxi, dakon) | PC | from 14,000 ₽ |

| Commissioning of boiler house up to 60 kW (Vaillant, Viessmann, Buderus) | PC | from 18,000 ₽ |

| Commissioning of boiler house from 70 to 120 kW (protherm, ferroli, baxi, dakon) | PC | from 20,000 ₽ |

| Commissioning of a boiler house from 70 to 170 kW (Vaillant, Viessmann, Buderus) | PC | from 25,000 ₽ |

| Commissioning of a cascade boiler house (2 boilers or more) | PC | from 30,000 ₽ |

| Commissioning of electric boiler up to 6 kW | PC | from 7 000 ₽ |

| Commissioning of electric boilers from 8 to 30 kW | PC | from 8 500 ₽ |

| Commissioning of a pellet boiler up to 50 kW | PC | from 14 000 ₽ |

| Commissioning of pellet boiler from 60 kW to 100 kW | PC | from 18,000 ₽ |

| Commissioning of a boiler room with a pellet boiler up to 60 kW | PC | from 20,000 ₽ |

| Check the cost by phone: 8 495 744 67 74 | _____________ | |

| The exact cost is calculated after receiving the technical | _tasks_ |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Fines for changing independently without approval

Replacing a gas boiler in a private house without permission and without drawing up a project is prohibited by law - Art. 7.19 Code of Administrative Offenses of the Russian Federation “Unauthorized connection and use of electrical, thermal energy, oil or gas.” The fine ranges from 10 to 15 thousand rubles; in the event of an emergency, criminal liability is possible.

The replacement may be discovered during the next scheduled inspection: at a minimum, the boiler passport will not have a stamp indicating that specialists have carried out commissioning work. Then the gas distribution company terminates the contract, disconnects the house from the gas main, and imposes penalties.

However, in most cases, gas workers do not pay attention to the changes made or turn a blind eye even to serious violations; it is often possible to reach an agreement with the workers. Many owners of private houses, especially in rural areas, actively use loyalty, but what works today can be interrupted tomorrow, and it is impossible to legitimize an already installed gas boiler. Therefore, despite the huge bureaucracy, we recommend that you initially arrange a replacement in accordance with all the rules, especially since the process can be entrusted to specialists for relatively little money.

Cost of specialist work

Prices for a full replacement, paperwork and commissioning work depend on the type and model of the boiler, region and company providing the services. In Moscow and the Moscow region it is about 8-22 thousand rubles, for St. Petersburg – 6-15 thousand rubles, for the regions – 4.5-12 thousand rubles. About half of the cost is for dismantling the old and installing a new boiler unit, almost half is for commissioning.

Please note that the required paperwork process is not always included in replacement services.

Gas boilersInstructionsBoilers

Safety requirements when remodeling a kitchen with moving a gas stove

- A gas hob or a separate stove should be placed at an interval of 50 cm from windows or doors. Moving the stove to the window is unacceptable. The prescribed distance cannot be reduced without permission. If a draft occurs, it can lead to the ignition of flammable objects or, on the contrary, it will extinguish the flame with the gas on.

- The stove should be located strictly near the gas distribution and ventilation compartment, with free access to the shutoff valve.

- If you are replacing a gas model with an electric stove, the wiring must be powerful.

- You cannot place a gas stove in the corner near the refrigerator - just like in any other place next to refrigeration equipment.

Interesting: How much interest should a debtor with a second disability group be charged on a loan?

It is unacceptable to cut the stopcock from the pipe; this is an integral element of the gas system. You cannot even replace flexible hoses yourself, much less organize the movement or extension of pipes. This is only done by a gas service employee.

Transferring a geyser

2.1. Hello, if the technical specifications have not changed, then of course it is not legal, changes in the project are made during redevelopment and reconstruction, which is not the case in your case. Housing Code of the Russian Federation Article 25. Types of reconstruction and redevelopment of residential premises 1. Redevelopment of residential premises is the installation, replacement or transfer of utility networks, sanitary, electrical or other equipment that requires changes to the technical passport of the residential premises. 2. Redevelopment of a residential premises is a change in its configuration, requiring changes to the technical passport of the residential premises. Let them go to court.

6.1. Good afternoon You can legitimize in two ways - collect the documents provided for in Art. 26 of the Housing Code of the Russian Federation (that is, pretend that the redevelopment has not yet taken place), or file a lawsuit to preserve the residential premises in a rebuilt form.

Rostechnadzor explains: Categorization and accounting of equipment operating under excess pressure

Question:

The main activity of our enterprise is the generation of thermal energy and its delivery to consumers. The enterprise's facilities are supervised by the Federal Service for Environmental, Technological and Nuclear Supervision. One of the activities of our enterprise is the operation of hazardous production facilities of category 4 steam and hot water pipelines, external steam pipelines, heating networks with hot water temperatures above 115°C. Previously, when determining the category and groups of pipelines to be operated, we were guided in our work by PB 10-573-03; in connection with the approval of the new “Industrial Safety Rules for hazardous production facilities that use equipment operating under excess pressure”, questions arose during the work regarding the operation of pipelines steam and hot water.

Please clarify what regulatory documents, in addition to the “Industrial Safety Rules for hazardous production facilities where equipment operating under excess pressure is used,” must be used to guide the work at the stage of determining the category of pipelines and registering them with the supervisory authorities?

FNP ORPD does not establish requirements for the design and manufacture of pipelines, in contrast to the Rules for the design and safe operation of steam and hot water pipelines (PB 10-573-03), which were in force before the FNP ORPD came into force, due to the fact that from 01.02.2014 Mandatory requirements for the design and manufacture of this equipment are established by the technical regulations of the Customs Union “On the safety of equipment operating under excess pressure” (TR CU 032/2013), adopted by decision of the Council of the Eurasian Economic Commission dated July 2, 2013 No. 41.

In accordance with Appendix No. 1 to TR CU 032/2013, depending on the technical characteristics and properties of the working environment, equipment is divided into four hazard categories (1, 2, 3, 4) , and category 4 includes equipment with a higher degree of danger, in contrast, in PB 10-573-03 pipelines were categorized in ascending degree of danger in the reverse order of digital counting (4, 3, 2, 1); accordingly, pipelines with the most dangerous parameters were classified into category I.

Due to the presence in PB 10-573-03 and TR TS 032/2013 of differences in the numbering of categories of pipelines, as well as in the criteria for their assignment to a specific category (pressure, temperature in PB 10-573-03 and pressure, diameter, product of pressure on diameter and creep temperature in TR TS 032/2013), in order to eliminate errors when simultaneously applying FNP ORPD and TR TS 032/2013 in FNP ORPD in the text of paragraphs defining the scope of application of the requirements of FNP ORPD and cases in which equipment is not subject to accounting in Rostekhnadzor, in relation to pipelines, numerical values of parameters (pressure, temperature and diameter) are indicated, according to which they are divided into those that fall within and those that do not fall within the scope of application of the requirements of the FNP ORPD, as well as those that are subject to and those that are not subject to accounting.

For example, according to subparagraph d) of paragraph 3 of the FNP ORPD, their requirements do not apply to facilities that use steam and hot water pipelines with an outer diameter of less than 76 mm, in which the working environment parameters do not exceed a temperature of 450°C and a pressure of 8 MPa, which corresponds to that specified in subparagraph e) of paragraph 1.1.2 PB 10-573-03 for pipelines of II, III, IV categories, and according to subparagraph j) of paragraph 215 of the FNP ORPD, steam and hot water pipelines with a nominal bore 70 are not subject to registration in the territorial body of Rostechnadzor mm or less, in which the temperature of the working medium does not exceed 450°C with a pressure of the working medium more than 8.0 MPa, and also in which the temperature of the working medium exceeds 450°C without limiting the pressure of the working medium, which corresponds to pipelines of category I according to table 1 of paragraph 1.1.3 PB 10-573-03, registration of which with a diameter of 70 mm or less was not required previously, taking into account clause 5.1.3 PB 10-573-03.

In contrast to the requirements of PB 10-573-03, which were in force before the entry into force of the FNP ORPD, for the mandatory registration of pipelines with the territorial body of Rostechnadzor before putting them into operation, Section IV of the FNP ORPD establishes requirements for the procedure for commissioning equipment operating under excess pressure, including the need, in accordance with paragraphs 214 and 215 of the FNP ORPD, for the operating organization to send information to the territorial body of Rostechnadzor after putting the equipment into operation for its accounting in the amount established by paragraph 216 of the FNP ORPD.

Question:

According to paragraphs. “m” clause 215 of the Federal norms and rules in the field of industrial safety “Industrial safety rules for hazardous production facilities that use equipment operating under excess pressure”, steam and hot water pipelines whose working environment parameters are not subject to registration by Rostekhnadzor authorities do not exceed a temperature of 250°C and a pressure of 1.6 MPa (with the exception of such pipelines with a nominal bore of more than 100 mm, located within the buildings of thermal power plants, boiler rooms and production premises of enterprises, as well as with the exception of pipelines of heating networks as part of hazardous production facilities of III hazard class , having the danger sign specified in subparagraphs “a” and “b” of paragraph 2 of these FNP.

Please clarify which HIFs of hazard class III are meant in this subclause: HIFs for which hazard class III is assigned precisely according to the criterion specified in clause 5 of Appendix 2 to the Federal Law of July 21, 1997 N 116-FZ “On industrial safety of hazardous production facilities” or hazardous production facilities, for which hazard class III is assigned according to any hazard criterion.

Rostechnadzor's response: The Department of State Construction Supervision of the Federal Service for Environmental, Technological and Nuclear Supervision, having considered your appeal received via public information systems, reports.

The text of subparagraph m), paragraph 215 of the Federal norms and rules of industrial safety “Industrial safety rules for hazardous production facilities that use equipment operating under pressure” refers to all hazardous production facilities of hazard class III that have a hazard sign, which is assigned based on the results identification of a hazardous production facility.

Question:

Is a hot water boiler with a capacity of 885 liters (0.885 m3) with a maximum operating pressure of 0.5 MPa and a temperature in the boiler circuit of 110 degrees Celsius, planned for inclusion in the hazardous production facility - the gas consumption network, subject to registration with the Rostekhnadzor authorities?

Answer: According to paragraph 3 of the federal norms and regulations in the field of industrial safety “Industrial safety rules for hazardous production facilities that use equipment operating under excess pressure”, approved by Decree of the Government of the Russian Federation dated March 25, 2014 No. 116 (hereinafter referred to as FNP ORPD), FNP ORPD are aimed at ensuring industrial safety, preventing accidents, incidents, and industrial injuries at facilities when using equipment operating under excess pressure of more than 0.07 megapascal (MPa), including water at a temperature of more than 115 degrees Celsius.

If, in accordance with the passport characteristics, the temperature in the boiler circuit of the boiler is 115 degrees Celsius or lower, then the FNP ORPD does not apply to such boilers, and therefore they are not subject to registration with Rostechnadzor authorities.

Site sections related to this news:

Sequence of events and news on this topic

(moving through news related to each other)

Obtaining approval for gas pipeline replacement

Whether a transfer is possible or not can only be decided by authorized bodies, that is, the gas service of your city (district). Only a qualified specialist has the right to carry out any dismantling and installation work. Of course, pipes cannot be moved without approval.

The permit is issued in the following sequence:

- Find out the contact details of the gas service at the place of registration, contact specialists, explain the situation, and consult.

- You draw up an application (using a standard form) that will “launch” the approval process.

- Based on your application, a gas service representative will arrive at your home. The time will be confirmed in advance.

- The specialist performs an inspection, listens to wishes, and answers questions. Often at this stage it is necessary to change plans, since the desired transfer does not meet safety requirements (a preliminary study of the gas pipeline installation standards will eliminate this unpleasant moment).

- Approval of the final transfer scheme, drawing up an estimate. All documents are prepared by the organization providing the services. No work will be carried out without the consent of the property owner.

- If the transfer conditions are met, pay for the service using a receipt and agree on the start time of the work.

The approval procedure usually takes several days; it can drag on for a long period for only one reason: if the property owners and representatives of the gas service have not found a compromise solution.

Any factors that violate the installation standards for gas stoves (boilers, meters, water heaters) may cause refusal to move pipes.

Conditions for placing a wall-mounted boiler

Another common type of equipment is wall-mounted gas boilers. Their installation is ensured in the following sequence:

- The equipment is mounted on a load-bearing, high-strength wall or partition that meets fire resistance requirements.

- The boiler body should be 45-55 mm from the wall surface and 50-60 cm from the adjacent wall. There should be a distance of at least 75 cm to the ceiling. The boiler is mounted strictly parallel to the floor surface.

- Installation of a water filter and shut-off elements. Connection to the heating system.

- Installation of a chimney, if provided for in the instructions.

- Connection to the gas pipeline.

- Electrical network connection.

Gasification of a private house: connection stages, requirements, documentation

The process of gasification at home is a technically complex and costly undertaking. It is the material issue that is often the main obstacle to providing a building with the most economical method of heat supply. However, the costs of laying a gas pipeline can be recouped in the coming years, provided that the connection is made in compliance with the requirements and the approval of all documents.

Without a full-fledged heating system, ensuring comfortable living in winter is quite problematic. For heating, you can use various types of heating equipment - electric, solid fuel, powered by solar energy. However, gas boilers have been considered the most effective and reliable solution in organizing heat supply for many years.

How to gasify a private house for heating and hot water preparation:

Connection to central gas supply

It is considered the most common option.

If there is a gas main on the street where the house is located, you can contact the gas utility at your place of residence and gasify the building using its services.

Central gas supply is safer compared to an autonomous system (gas holder) and requires homeowners to periodically adjust the parameters of the gas boiler.

Gas tank installation

Gasification of a country house using gas tanks is resorted to in cases where it is impossible to connect to a centralized main line. Gas holder systems are designed to store relatively small volumes of natural fuel - on average from 2,500 to 20,000 m3, but can provide buildings with the necessary gas reserves year-round.

Application of gas generator or biogas equipment

Gas generators and biogas plants are a rare phenomenon in Russian realities. They are highly efficient and, with proper planning, supply the home with sufficient amounts of fuel. However, some consumers are put off by the need to allocate large areas for their installation and take care of constant supplies of wood, manure and other materials for gas production.

If you decide to gasify your home by connecting to a gas main, first you should find out in whose jurisdiction the gas pipeline running nearby is located. As a rule, it is managed by the local Gorgaz, which should be contacted to obtain permits and the necessary documentation.

//www.youtube.com/watch?v=LCppiTGPJ88

The first document required for laying a gas pipeline is technical specifications. Specifications are a permit to connect to the main line, according to which the gas distribution organization (GDO) guarantees an uninterrupted supply of natural fuel and maintenance of its pressure at the proper level.

What documents need to be submitted to the State Registration Office to draw up technical conditions for gasification of a house:

- a request for the issuance of technical specifications indicating the planned launch date of the gas pipeline and the expected gas consumption;

- copies of certificates of ownership of the plot and building;

- copy of ID;

- calculations of maximum fuel consumption (when used over 5 m3 per hour);

- plan of the site and adjacent territory;

- consent of the owner (if the documents are submitted by the tenant);

- power of attorney (when submitting documentation by a representative).

The development of specifications is carried out by GRO specialists. The finished document must specify: hourly fuel consumption, timing of pipeline connection and period of validity of technical conditions.

After issuing the specifications, you need to draw up an agreement with a design bureau - GRO or a third-party company that will prepare a project for gasification of the house. To prepare the agreement, you will need a topographic plan of the site, technical passports for the building and installed equipment. If necessary, the designer can visit the site to take measurements and clarify details.

After receiving the finished project, you will need to coordinate it with the technical department of Gorgaz, as well as enter into an agreement with the State Distribution Organization for technical supervision, which requires a chimney inspection report. Another necessary document is an agreement for the connection of natural fuel, which is drawn up with the gas distribution organization at the request of the owner.

Drafting

A gasification project for a country house is a mandatory item when carrying out installation work, allowing you to correctly plan the wiring, calculate and select the necessary equipment. Visually, it looks like an explanatory note of several sheets, which reflects:

- floor plan of the building indicating the locations of pipes and devices;

- energy efficiency parameters of the facility;

- gas equipment specification;

- installation estimate;

- justification for choosing one or another installation method;

- precautions and protection measures.

On the last pages of the project, special conditions for the work are prescribed and an assembly drawing is placed that defines the features of the placement and welding of pipelines. The cost of the project for gasification of a private house can be established in accordance with FAS Order No. 1151 (upon contacting the State Distribution Organization), or at market prices if the document is ordered from third-party organizations.

Construction and installation works

After preparing the documentation, it is necessary to draw up an agreement with the organization that will carry out the installation work. The selected company must have a license and permits to carry out such activities. The entire gas supply process can be divided into several stages:

- Laying an external gas pipeline.

The pipeline from the central highway to the site can be laid underground or above ground. When choosing an underground gasification method at home, pipes with a diameter of 15 cm are used, which are placed in pre-dug trenches. A gas control point is installed in the local area, designed to normalize the pressure of natural gas. - Boiler room installation.

Preparing the premises for equipment installation is carried out simultaneously with external work. As part of this work, the necessary equipment is purchased and installed, the boiler room is finished in accordance with the requirements of the fire department and the gas industry, and places are prepared for the entry of the gas pipeline. The boiler room must be equipped with a chimney and an artificial or natural ventilation system. Similar preparations are carried out in the kitchen where the gas stove will be located. - Connecting communications.

At the last stage of gasification of a country house, a pipe is inserted into the building and connected to the main riser. After the assembly is completed, control and measuring instruments are connected - a meter, various sensors, shut-off valves.

Before launching the gas supply system, it is checked by the UGC commission, which draws up a corresponding act.

To carry out the first gas launch, it is necessary to obtain permission from the State Distribution Organization to put the pipeline into operation. In addition, it will be necessary to conclude an agreement for the supply of natural fuel.

Please note that the gas supplier and gas distribution organization are not always the same company.

When the system is actually started, the functionality of all devices is checked and pressure indicators are established. The absence of gas leaks is also monitored. If no problems are identified, a connection certificate is signed, which confirms that the building is gasified.

Installation requirements

When gasifying a house, it is necessary to strictly comply with the requirements for laying a gas pipeline and performing other installation work:

- The depth of placement of pipes on the site should be 1.25–1.75 m from the ground surface.

- Where the pipeline enters the building, the pipes should be placed at a depth of 0.75–1.25 m.

- It is allowed to conduct the pipeline inside the building both through the wall and through the foundation.

- The distance from the gas pipeline to heat, water supply or sewer lines must be at least 0.2 m vertically. For telephone and electrical cables, this parameter is at least 0.5 m.

- When laying steel pipes in the ground, care must be taken to waterproof them, which will prevent the development of corrosion processes.

- As part of the gasification of a private home, it is prohibited to install risers and distribution networks in residential premises.

- Do not lay the gas pipeline through chimneys or ventilation ducts. Pipes should not cross the openings of doors and windows, and when they are placed in places where people pass, they should be at a height of at least 2 m.

- The gas pipeline is introduced into the building and routed through the premises only through steel pipes. It is unacceptable to use polyethylene pipes for above-ground gas pipelines. They are not used in regions with increased seismic activity or in places where air temperatures can drop below -45 °C.

Requirements of the Federal Law on gasification of a private home

The procedure for gasification of a country house is determined at the federal level, that is, gas services and local authorities do not have the right to establish their own or request additional documentation.

According to Federal Law 69, 1314 and a number of other regulations, when connecting to a centralized pipeline, the following requirements must be observed: Only capital construction projects, including residential or industrial buildings, the construction of which has not yet been completed, are allowed to connect to the gas distribution network. It is unacceptable to gasify non-permanent buildings - greenhouses, garages, summer kitchens and other structures without a foundation, as well as separate residential premises in apartment buildings. An application for gasification of a house can be made by the owner or tenants who have the written approval of the owner of the property. If there are several owners in the building, the consent of each of them is required.

The period for issuing technical specifications by the gas distribution company cannot exceed 14 days. The technical specifications are considered valid for no more than 70 days; after this period, the document will need to be reissued.

The gas connection period cannot exceed 9 months for applicants of the first category (with a maximum fuel consumption of up to 20,000 m3), unless they require permission to build a gas pipeline with a capacity of up to 0.6 MPa. If necessary, obtaining permission to connect is given no more than 12 months. For other categories of consumers, gasification of a private home is carried out within a period of no more than 1.5–2 years.

The main difficulty in organizing gas supply is compliance with legal regulations and a large number of approvals, which require a significant investment of time and effort.

Use the service to make the task of laying a gas pipeline easier.

We are participating in a program to provide natural fuel to the Moscow region and are working to create a simplified gas connection system accessible to every resident of the region.

Our specialists are ready to provide qualified services for connecting to distribution networks in strict accordance with the rules and requirements.

In addition, in our online store you can buy equipment for home gasification, including boilers, meters, geysers and stoves.

All products are sold at a competitive price and can be promptly delivered to your address in Moscow or throughout the region.

Source: //shop.mosoblgaz.ru/articles/gazifikatsia-doma/

Work order

Professional teams spend no more than an hour moving or installing a gas meter in an apartment. The first step is to turn off the gas supply in the house. This is done in agreement with local utility services, with a warning to other residents.

Further actions occur as follows:

- The device is removed using gas welding.

- Gas pipes are being transferred to comply with the new scheme.

- The device is installed in a new location.

At the end of the work, representatives of the gas service must check the tightness of the connections. To do this, gas is released through the riser, and soap foam is applied to the joints.

The absence of bubbles indicates that the connections are good. The appearance indicates a leak. In this case, the gas is shut off and the seams are welded again.

It is necessary to prepare the workspace for the gas workers’ visit: ensure the accessibility of gas equipment and pipes, pull back the curtains, remove kitchen utensils and foreign objects

Flange connections are retightened. Simultaneously with leakage monitoring, the functionality of the device is checked.

Installing a new device when moving

The work of moving the flow meter can be combined with replacing the device with a new one. This is beneficial when:

- the service life of the old meter is approaching its end;

- desire to install a modern device with remote data transfer;

- absence of documents confirming the positive outcome of the last verification.

When you hand over an old device for verification, you will have to spend time waiting for the service to be provided and money to pay for it.

If the equipment is found unusable, costs will increase: it will be necessary to purchase a new meter. Therefore, in some cases, when transferring, it is more profitable to plan the installation of a new device.

Acceptance, accompanying documents

By being present during the work, the owner can check the correctness of the installation and the compliance of the new arrangement of pipes and meter with the approved diagram. If everything is done correctly, the craftsmen must fill out a certificate of completed work.

It states:

- information about the gas distribution organization that issued the permit and sent its representatives;

- information about the employees who performed the work;

- technical data of the metering device, its serial number.

The second required document is the act of putting the device into operation. It must record the launch date and time and confirm the functionality of the device.

When submitting an application to transfer the meter, ask the gas company if the device can be sealed immediately after installation. Some organizations present this opportunity. In others, you must submit a separate application after completion of installation work

Both acts are drawn up in two copies. The owner of the premises must store his copies along with the technical data sheet of the product.

Installing a filling after transfer

After you have managed to move the gas meter in the kitchen, you need to seal it. To do this, you need to fill out an application and take it to the customer service department.

The following documents will be required at the time of application:

- Applicant's passport, certificate of ownership.

- Technical data sheet of the product or a copy thereof.

- Acts drawn up by gas company foremen during the transfer.

The period allotted for installation of the seal is 5 days. During this time, the company is obliged to agree on and determine the date of the specialist’s visit, perform the work, and prepare a service agreement.

After transferring the meter and sealing it, it is necessary to record the readings. The data must be documented. This rule applies to both new and used devices.

Payments are calculated on the meter from the day following the date of sealing. Until this point, when calculating expenses, the consumer must be guided by regional and seasonal standards.

Installation of a floor-standing boiler

Installation of a floor-standing gas boiler is carried out in the following order:

- Forming a reliable foundation. For powerful boilers, a monolithic concrete foundation is required, and for low-power equipment, a metal sheet is required.

- Install the boiler after checking the level of the base using a level.

- Connecting the boiler to the chimney and checking the presence of the necessary draft.

- Connecting heating system pipes. Installation of the water purification and hardness filter, as well as shut-off elements in accordance with the instructions. Ball valves are usually installed.

- Supply and connection of water supply in the presence of a second circuit.

- Connection to the gas pipeline.

- Electrical network connection.

When installing equipment, it should be remembered that insertion into the gas main can only be carried out by a specialist with a special permit.

Who needs to join an SRO to install equipment?

In accordance with the amendments made to the Civil Code of the Russian Federation No. 372-FZ, registration of membership in an SRO for the installation of gas equipment is mandatory for a number of organizations.

To join a partnership you need:

- legal entities and individual entrepreneurs working under a contract directly with developers and technical customers;

- companies entering into contracts with obligations exceeding 3 million rubles;

- organizations participating in programs with government funding or procurement in the form of competitive bidding and offering a contract price of more than 3 million rubles.

Membership in a construction SRO is confirmed by an extract from the register.

The following are exempt from mandatory membership in associations:

- subcontractors and companies working under contracts up to 3 million rubles;

- municipal and state-owned enterprises, enterprises with a share of government agencies of 50% or more;

- organizations involved in autonomous gasification of individual housing construction projects - country houses, dachas, cottages.

Membership in an SRO for servicing gas equipment (technical diagnostics and routine repairs of boiler rooms, gas control systems, household stoves) is not required.

Starting gas into a private house

Gas supply is a gas-hazardous job that requires strict adherence to instructions and standards. The procedure is performed by a specially trained team, which, before starting the fuel, thoroughly checks the tightness and performance of the gas pipeline and gas equipment. It is important to follow safety precautions while working, as the slightest mistake can lead to a serious accident.

Connection procedure. Documentation and practical implementation

The supply of gas to a residential building is strictly regulated by state standards and regulations. Gas hazardous work requires constant monitoring. The necessary documentation is pre-prepared and technical standards are developed.

The launch of blue fuel is carried out by employees of the operating company upon special requests. When gas is supplied, the owner of the house must be present; if absent, his legal representative must be present.

When working with multi-apartment buildings, at least two workers are involved under the supervision of a foreman. When supplying gas to a private house, two people can handle it.

Read on the topic: How to save gas and Which heating is more profitable, gas or electric

Paperwork

Gas supply is carried out on the basis of the act of putting the facility into operation. The document must contain the signatures of representatives of the state commission. The work is carried out according to the work permit under the control of an engineer and technical worker.

Read more: Site gasification design

Also, an agreement is concluded between the customer (the owner of the residential building) and the facility with the gas distribution organization. The company first issues technical connection conditions. To draw up a gasification agreement for a building, technical conditions are not required. The documents specify the procedure for gas supply.

All subscribers over 12 years of age undergo training. After this, they are given a subscription book, and they sign a receipt that they undertake to follow technical safety requirements. Also, all subscribers sign in the journal. This confirms the fact that they listened to the instructions.

Before leaving for the work site to start the gas, the manager receives a work order certificate. He must also familiarize himself with the executive documentation. Then the foreman instructs workers and checks the presence of all necessary tools and protective equipment.

If you do not have a central gas supply, we recommend reading: What is a gas holder and its role in heating a private home and How to organize heating using a gas cylinder

Starting procedure

Blue fuel is supplied during the day. Citizens must be informed about the work at least 3 days in advance. The initial start-up of gas in a new building is carried out before the residents move in. If there is no access to at least one apartment in a multi-story building, work is prohibited.

The gas start-up procedure is determined as follows:

- Visual inspection of the gas pipeline for mechanical damage. Disconnecting devices not connected to the network are sealed, which is confirmed by the drawn up report.

- Monitoring the performance of locking and protective devices on pipes indoors.

- Inspection of gas inlets on internal pipes. They must be disconnected, closed and plugged with special metal plugs.

- Elimination of identified damage.

- Checking documentation confirming the serviceability of chimneys and ventilation.

- Carrying out control pressure testing and gas purging. The procedure lasts 5 minutes. An air pressure of 500 daPa is used. The gas is released through a window to the street using a hose. It is prohibited to release the gas-air mixture into the chimney or ventilation.

- Connecting internal pipes to gas inlets. During the procedure, it is important to ensure that the shutoff devices and risers are closed.

- Checking connections and disconnecting devices at the input for leaks.

- Gradual opening of disconnecting devices, starting from the most distant riser and ending with devices on the top floor.

According to the gas start-up rules, the end of the purge is determined by analyzing or burning the samples taken. oxygen in the gas-air mixture should not exceed 1%, and popping noises should not occur during fuel combustion.

After completing the work, the pressure on the gas equipment, the strength of all connections, and the functionality of the safety automation are checked. Ventilation and smoke ducts must be inspected for the presence of draft. You also need to light the burner to adjust the burning intensity of the blue fuel.

The successful completion of the gas supply is noted in the work order report, after which the document is handed over. To confirm the work done, you need to sign in the work order log.

Read on the topic: Why the gas is turned off and what gas is used in country houses

Commissioning of gas supply networks

Gas supply is carried out after checking the network for safety and performance. After which the object is ready for operation. All work is carried out in the presence of the customer or his official representative. There should be no pause between purging the system and starting the fuel. Commissioning of the gas supply network is carried out on the basis of the following documentation:

- For new buildings - an act of acceptance of the gas supply facility;

- Gas consumption network acceptance certificate;

- Document on putting the gas pipeline into use;

- Certificate of inspection of the serviceability of smoke ducts and ventilation;

- Agreement with a gas distribution organization on connection to the gas main;

- Document on network maintenance during operation;

- Gas supply agreement.

After the facility is put into operation, a special act is drawn up. It is signed by a representative of the operating company and the customer. The acts must be kept together with the writs of execution. Read on the topic: What is the fine for unauthorized connection to a gas pipeline and How to supply gas to a dacha

Source: //domsgazom.ru/podklyuchenie-gaza/pusk-gaza-v-chastnyj-dom

Unauthorized replacement and transfer of a column

As we have already found out, various types of punishments are provided only for independent work with gas. Next, we’ll look at what the consumer faces from unauthorized replacement or relocation of the dispenser.

What are the risks of replacing the column yourself?

We have found that the consumer has the right to carry out installation and dismantling of an unattached device independently or to involve third parties.

Clause 10 of Section II of the Decree of the Government of the Russian Federation dated May 14, 2019 N 410 establishes that the replacement of in-house or in-apartment equipment must be carried out by a specialized organization.

Independent manipulations with the replacement of gas equipment, in particular the water heater, will entail a number of consequences.

So, according to Art. 7.19 of the Code of Administrative Offences, a fine of ten to fifteen thousand rubles will be assessed, civil servants will be subject to sanctions in the amount of 30-90 thousand rubles, and penalties of 100 to 200 thousand rubles will be applied to business entities.