Home » Classification of gas boilers » Operating principles » Rules and regulations for installing a gas boiler

When installing gas boilers, it is important to adhere to the standards that are prescribed in SNiP-II-35-76 “Boiler installations” and the set of rules for the design of autonomous heat supply systems SP-41-104-2000. Otherwise, if they are not followed, the inspection authorities will not give permission to operate gas equipment. Let's consider what standards exist for installing a gas boiler.

…

- 1 General requirements for installing a gas unit

- 2 Requirements for the room where the gas boiler is located 2.1 Room standards for a unit with an open combustion chamber

- 2.2 Room standards for a boiler with a closed firebox

General requirements for installing a gas unit

The first standard that needs to be taken into account when choosing a gas boiler is whether the power of the device matches the area of the heated room. Optimal performance is calculated using special formulas.

There are models of gas boilers with different characteristics: floor-mounted, wall-mounted, with open or closed combustion chambers.

To install units with an open firebox (atmospheric), a full-fledged chimney is required, so such models are mainly used for heating private houses. Boilers with an open chamber may only be installed in a separate, specially equipped room - a boiler room or furnace room.

A gas device with a closed firebox (turbocharged) only needs to connect a coaxial chimney to exhaust smoke. It consists of two pipes and simultaneously ensures the removal of smoke and the flow of air masses to the burner device. Such a unit can be installed in any non-residential premises, for example, a kitchen, hallway or bathroom. The main thing is that it meets all the requirements of SNiP. However, if your device with a closed combustion chamber has a power of more than 60 kW, then you will also have to look for a separate room for it - a boiler room.

…

Note! For an apartment in an apartment building, the installation of gas devices with a total capacity of up to 150 kW is allowed.

Advantages of Baxi boilers and equipment

The BAXI brand belongs to BDR Thermea, a large European manufacturer of household and industrial heat and power equipment.

The units are equipped with auxiliary devices of the same brand: a circulation pump for modifications with forced movement of the coolant, a blower fan in closed fireboxes and a safety group.

They ensure that the unit reaches factory operating parameters and have advantages in layout compared to devices that are assembled with components from different manufacturers.

The main advantages of BAXI boilers:

- high thermal efficiency, efficiency up to 92%;

- wide power range from 14 to 80 kW;

- environmental Safety;

- refers to energy efficient equipment;

- Wide range of settings for thermal conditions and automatic maintenance of specified operating parameters.

The latest modifications are available with a powerful self-diagnosis system, frost protection and antibacterial protection.

Integrated weather-dependent automation provides sanitary living conditions in the house, while guaranteeing low cost of generated thermal energy for heating and hot water needs.

Requirements for the room where the gas boiler is located

Depending on the power and type of combustion chamber, room standards for installing a gas boiler may differ.

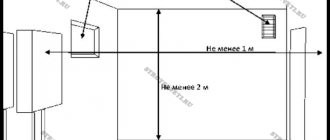

Room standards for a unit with an open combustion chamber

As already mentioned, a gas boiler with an open firebox must be located in a separate room, which is furnished and equipped in accordance with all standards. The boiler room must meet the following requirements:

- A room for installing the unit can be allocated on any floor of a private house, in the basement or attic. It is prohibited to install such a unit in a bathroom or toilet.

- If the power of the gas boiler does not exceed 30 kW, then the volume of the boiler room must be at least 7.5 m³. If the device’s performance is from 31 to 60 kW, then the required size is from 13.5 m³. With power from 61 to 200 kW – 15 m³.

- Ceiling height – 2-2.5 m.

- The width of the doors is not less than 0.8 m.

- The door to the boiler room should not be hermetically closed. It is necessary to leave a gap of 2.5 cm between the door leaf and the floor.

- An opening window with an area of at least 0.3×0.3 m², equipped with a window, should be provided. It provides sufficient illumination of the boiler room.

- Have a ventilation duct.

- Electrical switches located outside the boiler room.

Room standards for a boiler with a closed firebox

Technical standards for installing a gas boiler with a closed combustion chamber are not so strict. In this device, flue gases are removed from a closed firebox into a coaxial chimney, and a forced air flow is also provided through the same pipe. Therefore, gas boilers with a closed combustion chamber with a power of up to 60 kW are allowed to be installed in any non-residential premises that meet the following requirements:

- ceiling height more than 2 m;

- volume - at least 8 m²;

- well ventilated;

- The surface of the walls is made of fireproof materials.

It is even allowed to build turbocharged units into kitchen furniture.

…

Features and installation of parapet gas boilers

Read here - the stages of the first start-up of a gas boiler

Installation of a wall-mounted gas boiler with your own hands - stages of work

Comfort manual for technical personnel…

Page 15

- Image

- Text

Luna 3 Comfort technician manual

15

gas wall-mounted boilers

15.4 Overall dimensions of the air supply and exhaust system

combustion products through two separate pipes.

15.5 Options for a smoke exhaust system using separate pipes with horizontal tips

Note!

It is necessary to ensure a horizontal inclination of the pipes to the outside of at least 1 cm for each meter of length. When installing the condensate collection kit, the drain pipe must be inclined towards the boiler.

Important: When arranging pipes of type C52, the tips for the air inlet and the outlet of combustion products should never be on opposite sides of the building

The total length of air supply pipes should not exceed 10 meters. If the chimney length is more than 6 m, the condensate collection kit (supplied additionally) must be installed in close proximity to the boiler.

Lmax = 10 m 240 Fi - 1.240 Fi Lmax = 8 m 280 Fi - 310 Fi - 1.310 Fi

(L1 + L2)max = 40m 240 Fi - 1.240 Fi (L1 + L2)max = 25m 280 Fi - 310 Fi - 1.310 Fi

Requirements for ventilation in the boiler room

In the boiler room or other room in which the gas boiler is located, it is necessary to provide forced and natural ventilation. Air replacement indicators are calculated based on the power of the unit.

Natural ventilation prevents the accumulation of carbon monoxide, which can be dangerous to the health and life of residents. Natural air flow is provided by windows, vents and doors.

Gas boilers with a closed combustion chamber do not require forced ventilation. It is provided by a coaxial chimney equipped with a fan, through which air is taken in from the street and smoke is removed.

In boiler rooms with an atmospheric unit, you will have to install supply and exhaust ventilation in the form of several fans that are connected to smoke detectors.

When the concentration of carbon dioxide increases, the sensors give a signal and the fans start working. Note! Good ventilation should ensure that the air in the room is replaced three times within 1 hour.

Standards for liquefied and natural gas

Various models of domestic heating boilers can operate on methane and a mixture of propane and butane. In both cases, the requirements for the minimum volume of the boiler room for a gas boiler, as well as other room parameters, are identical. However, there is one nuance in the issue of ventilation.

Methane is lighter than air and, when leaking, rises to the ceiling, while propane-butane is heavier and sinks to the floor or into the basement/cellar

If you plan to place equipment in a boiler room or kitchen using main methane fuel, then the natural ventilation openings in the room should be located under the ceiling. In this case, their distance from the ceiling should not exceed 20 cm.

If the gas appliance will be powered by a gas holder or cylinder, then the room must have ventilation vents at a height of 10–15 cm above the floor.

Natural ventilation should be arranged so that when the boiler goes out or there is another gas leak, the gas goes outside. The accumulation of methane or propane in a room is a direct path to an explosion and fire.

Fire safety standards

In order for a gas heating system to comply with fire safety standards, certain conditions must be met:

- Atmospheric devices can be located in the attic, basement or any other floor of the house. It is prohibited to place these units in the basement.

- Turbocharged gas boilers are allowed to be installed in any non-residential premises, as well as in the attic and basement.

- Doors to rooms containing gas appliances must open outward.

- The boiler room is finished with fireproof materials with a minimum fire resistance limit - no less than EI45.

- Turbocharged mounted gas boilers are fenced off from the adjoining wall with a shield made of non-flammable material. Floor-standing models are placed on a fire-resistant lining.

Flammable interior elements may be installed next to the boiler no closer than 30 cm.

Wall materials when mounting a gas-mounted boiler

The most common installation errors are related to insufficient fixation of the heat generator to the wall of the house. Existing standards indicate the need for rigid installation of boiler equipment. The boiler must be firmly fixed to the wall, strictly observing the vertical and horizontal levels.

The fastening requirements for installing a wall-mounted gas boiler largely depend on the material of the walls. Installation standards for wooden, plasterboard, reinforced concrete, brick, and hollow walls are specified separately.

How to hang a boiler on a wooden wall

According to SP 41-108-2004 “Apartment heat supply of residential buildings with gas-fuelled heat generators”, it is possible to hang a boiler on a wooden wall, provided that the following conditions are met:

- Material with a high degree of flammability, in the place where the boiler is installed, is treated with pyrine retardants.

- The wall is covered with plaster mixtures with a minimum thickness of 15 mm, or with roofing steel over asbestos sheets.

How to install a boiler on a plasterboard wall

A plasterboard wall is made by attaching sheets to a metal structure and implies the presence of voids. Firmly fixing the heat generator to drywall is problematic, but possible. At the stage of manufacturing the metal frame, a place is provided for installing the boiler. The mounting point is reinforced with a wooden beam and a metal profile.

How to attach to a reinforced concrete wall

Reinforced concrete is the optimal wall material for installing a gas heating boiler. Precast concrete structures are durable and belong to the group of NG (non-combustible) materials. To install the boiler, no additional conditions are required.

How to hang on a brick wall

The standards separately stipulate the conditions for installing the boiler on a brick wall. Brick is a non-combustible material, therefore, the heat generator can be installed directly on the wall. But sometimes, when putting a boiler installed in this way into operation, certain difficulties arise.

To satisfy all the wishes of gas workers, installation is carried out as follows. The walls are plastered. While plastering the surfaces, a plate is installed for mounting the boiler. After plastering, a seat (two bolts) remains protruding from the wall, onto which the boiler is installed.

Fastening the boiler to a wall made of foam concrete, gas silicate, aerated concrete

To hang a wall-mounted gas boiler on a wall made of blocks of foamed porous material, several methods are used:

- Mounting fasteners are installed during block laying. The installation of the boiler is carried out strictly after the mortar masonry mixture has completely hardened.

- Special “screws” for foam concrete are used. In their structure, they resemble similar plasterboard plugs. They have a deep thread with a large pitch and are hollow inside. After screwing into foam concrete, gas silicate or aerated concrete, any anchor can be screwed into the screws.

- Using studs - in this case, two studs are installed at the required distance from each other. On each side of the wall, a strip is installed, secured with bolts.

- Use of chemical, liquid anchors. Another option that provides the most durable fixation, but requires certain financial investments.

Energy supply rules

The energy supply of a gas boiler includes the following conditions:

- Mandatory grounding of the unit - this eliminates the possibility that a spark of static electricity will cause a fire.

- It is recommended to connect volatile devices to a voltage stabilizer and an uninterruptible power supply. Otherwise, if the power goes out, the owners will be left not only without light, but also without heating.

- The socket for the gas boiler must be located close to it so that it is possible to connect the device directly. Carrying bags are not permitted.

Equipment Maintenance

The operation of gas equipment must be carried out strictly in accordance with the instructions. You should always remember that any violations and gas leaks can lead to tragic consequences. Worn out and damaged equipment must not be used.

Boiler maintenance must be provided at least 2 times a year . Before the onset of cold weather, it is carried out without fail and in full. The tightness of all connections, the condition of the chimney and ventilation system are checked. The filters and burner are thoroughly cleaned. If necessary, worn parts and sealing gaskets are replaced.

We recommend reading: Which gas is best for heating a private home?

Gas boilers are increasingly used to provide heating and hot water supply to private homes. They are easy to use, and safety is guaranteed if installed and used correctly. Installation of equipment must be ensured in full compliance with established standards. It is important to remember that uncoordinated connection of such boilers is a serious offense and is fraught with administrative punishment.

Requirements for the chimney device

The rules for installing a gas boiler in a private house are supplemented by the rules for installing a chimney if the unit has an open combustion chamber. The following requirements apply to the chimney installation:

- The pipe cannot have more than 3 turns.

- The section connecting the boiler pipe and the chimney has a length of no more than 25 cm.

- The diameter of the pipe must correspond to the power of the unit.

- The edge of the chimney is placed at least 50 cm above the ridge of the roof.

- The hole for the pipe to pass through the ceiling is made larger than the diameter of the chimney. Fire-resistant material is placed between it and the ceiling material.

- To ensure the collection of condensate and soot during cleaning, a condensate collector should be provided at the bottom of the pipe.

When installing a gas boiler with your own hands, it is important to comply with all the requirements for the placement of a specific model of the unit. Otherwise, the gas supply company will not give permission to operate incorrectly installed equipment.

Installation of a floor-standing boiler

Installation of a floor-standing gas boiler is carried out in the following order:

- Forming a reliable foundation. For powerful boilers, a monolithic concrete foundation is required, and for low-power equipment, a metal sheet is required.

- Install the boiler after checking the level of the base using a level.

- Connecting the boiler to the chimney and checking the presence of the necessary draft.

- Connecting heating system pipes. Installation of the water purification and hardness filter, as well as shut-off elements in accordance with the instructions. Ball valves are usually installed.

- Supply and connection of water supply in the presence of a second circuit.

- Connection to the gas pipeline.

- Electrical network connection.

When installing equipment, it should be remembered that insertion into the gas main can only be carried out by a specialist with a special permit.

Do-it-yourself electric boiler installation

Unlike a gas or liquid boiler, an electric boiler is fireproof, does not require gas removal and can be installed entirely with your own hands. Electric options are made wall-mounted, since there are no bulky parts in their design. Heating wiring, circulation pump and expansion tank - everything is done in the same way as for a gas boiler. The difference will be that after hanging the boiler on the wall and connecting the heating pipes to it, you need to provide a high-quality power cable and an automatic shutdown. Almost all household electric boilers are designed for a voltage of 220 V, but if we are talking about powerful units, then it is more profitable to power them from a three-phase network of 380 V, which will require coordination.

If your house does not have a voltage stabilizer at the time of installation of the electric boiler, then it is worth installing it, since surges in the network can disable the automation, and this is the most expensive part in the boiler.

Separate portable stabilizer for boiler

Prices for electricity voltage stabilizers

Electricity voltage stabilizers

These recommendations apply to boilers with tubular heating elements. But electricity can do everything, so there are original options when using it. We are talking about electrode boilers. The water is heated in them by passing current through metal plates, which quickly heat up. The fact is that such a scheme can be implemented in a device of very compact dimensions: no storage tanks or a block of heating elements are needed. If there are only two or three heated rooms in the house, you can even make a separate battery under each window and embed an electrode boiler into it. All additional work is to connect them to a common electronically controlled machine, but it is much easier to pull wires than pipes with coolant. The only requirement is timely cleaning, since even filtered water crystallizes the salts soluble in it on the electrodes. An option is to use distilled water.

Choosing a heating scheme for a heating boiler in a private house

The boiler itself is only an element of the heating system. Without pipes and radiators through which the coolant circulates, its work is useless. Therefore, heating wiring must be provided in advance, before purchasing a unit that produces heat. The task is made easier by the fact that the heating circuit for all types of boilers has more similarities than differences.

Gravity diagram

Most often, this scheme is used for connection with a solid fuel or liquid boiler. If we approach the issue strictly, taking into account the preservation of efficiency, then modern gas boilers do not require gravity circulation of the coolant. Many wall-mounted and floor-mounted models with electronic control already have a built-in circulation pump, which forcibly drives water or antifreeze through pipes and radiators. In conditions of frequent power outages, such a boiler will be inactive.

General view of the gravitational scheme

However, in many houses, gravity circuits continue to operate in conjunction with a simple gas non-volatile boiler with mechanical control. By using large diameter heating pipes, the system creates sufficient water pressure to start the gas burner. In old systems, pipes with a cross-section of 100 - 150 mm were used, which encircled the rooms around the perimeter. The heat transfer of such a design is low, but it itself is reliable and durable. When installing radiators, the diameter of the supply pipes must be at least 40 mm to reduce hydrodynamic resistance.

In gravity systems, an expansion tank is a mandatory element. If the water in the system reaches high temperatures, excess water enters the tank due to the increased volume. The tank insures the system against leaks and depressurization in the event of an abrupt increase in pressure. In open-type systems, the tank is always located at the top point.

The gravity circuit is single-pipe. This means that the coolant sequentially passes through all the radiators, and then returns through the “return”. To install batteries in such a system, bypasses are used - bypass pipes with shut-off valves, thanks to which it is possible to dismantle and replace batteries without stopping the boiler and draining the coolant. Also, a Mayevsky valve is installed on each radiator to bleed the air that accumulates inside the wiring.

Mayevsky crane

Forced circulation circuit

The only disadvantage of this type of heating wiring is the dependence on the presence of voltage in the household electrical network. In addition to the boiler, the second important component of such a scheme is the circulation pump, which cuts into the “return” before returning it to the boiler. Modern pumps are silent, efficient and consume electricity like an incandescent light bulb. But thanks to this device, it becomes possible to make a choice in favor of a two-pipe system. In this case, the piping pipe passes through all heated rooms of the house. From it, a separate stream of hot water is supplied to each battery, and from it the cooled coolant is drained into the “return”, which is the very second pipe in the circuit. This allows you to distribute heat evenly across all radiators and maintain the same temperature even in the rooms furthest from the boiler.

If there is a circulation pump, the expansion tank must be closed so that a certain pressure can be created in the system. In case of exceeding normal values, an emergency pressure relief valve is provided.

Visual representation of a two-pipe circuit

In both schemes, a make-up unit must be provided through which coolant is poured into the system. If water is used, then a pipe from the water supply network is cut in to fill the pipelines, installing a filtration system at the inlet. When using antifreeze, an inlet valve with shut-off valves is installed, and injection is carried out using a “baby” submersible pump or other pumping equipment.

Required documents

To obtain technical conditions, the following documents must be attached to the application:

- passport of the gas boiler, which comes with it in packaging from the manufacturer;

- installation and operating instructions;

- quality certificate;

- a certificate stating that the boiler complies with the standards and requirements put forward by the state in relation to gas equipment.

For private houses, Raigas often offer to issue a technical certificate for the premises where the boiler will be placed. This document records the purpose of the room. That is, it is now either a boiler room or a furnace room. Separate buildings fit the definition of the first. For the second, premises built into the house or attached to it.