The heating system of a private house based on an electric boiler is quite reliable, efficient and safe. However, for such heating to work without failure, it is necessary to correctly select, install and connect the equipment to the network. Let's look at what types of electric boilers there are, what are the pros and cons of this type of unit, what installation and safety rules need to be followed for them, what mandatory elements are required for piping and how to position them correctly, as well as what stages the installation of an electric heating boiler consists of.

A modern electric boiler is quite compact and does not require a special room for placement Source project-home.ru

General information about electric boilers

Thermal power units of this category are attractive due to their high efficiency and ease of operation, which is why they are especially popular among consumers. Manufacturers of electric boilers offer the following types of equipment:

- Heating element electric boilers. The operation of the heating device is ensured by a heating element in the heat exchanger. The device is distinguished by its ease of installation and connection, ease of use.

- Electrode devices. The coolant warms up as electricity passes through water and salts. The application of current causes the movement of water particles, their energy is converted into heat. Electrodes dissolve in the working environment over time, so periodic replacement of elements is required.

- Induction heating boilers. The heat exchanger is a dielectric tube with a ferromagnetic rod.

When the latter device operates, eddy currents arise and thermal energy is generated.

First start

After all installation work has been completed, water has been supplied to the system, air has been bled and all joints have been checked for leaks under pressure, the boiler can be started for the first time. The process of connecting to the power grid itself does not seem complicated. In the case of low-power ones, this is no more difficult than turning on the iron.

After supplying power to the unit, do not try to immediately start it at full power. First of all, make sure the circulation pump is working. Next, set it within 40-450C degrees and wait until the system warms up the water and turns off. This way you can make sure everything is working. Next, the temperature can be increased.

Remember that when heated, the pressure in the system may begin to increase, so it is not recommended to immediately apply a pressure of 1.5 Atm. It is better to wait for optimal heating and only then add water to the system. At this point, such a process as installing an electric boiler can be considered complete.

Advantages and disadvantages of using electric boilers

The competitive advantage of installing an electric boiler in a private home is considered to be a high level of operating comfort at a minimum cost. Also among the advantages of power equipment, the following points are noted:

- high level of efficiency, relatively compact size, ease of operation;

- wide power range. It is easy to choose a model of optimal performance for heating areas of various sizes;

- no permit is required to install the structure;

- safety of operation, ease of installation and maintenance;

- environmental friendliness of the equipment.

Electric boilers have a high level of efficiency.

In addition, models of electric heating boilers are presented in an affordable price segment.

The big disadvantage of using electric thermal power units is the significant level of electricity consumption. To mitigate the problem, you can install boiler equipment connected to a buffer tank. In addition to the high cost of consumed energy resources, the need for grounding and the risk of electric shock are also among the disadvantages of the devices.

Safety regulations

When carrying out installation work, it is necessary to comply with safety requirements. Violations can cause damage to the installation and a short circuit. Errors can cause ignition during the startup phase of the device.

Laying the power cable of the device requires disconnecting the voltage to prevent electric shock. Electrical equipment used to heat a room must be grounded.

When connecting, it is necessary to lay new wiring with a cross-section corresponding to the power consumption. The equipment must be mounted on a substrate made of non-combustible material.

Installation rules and features

To install an electric heating boiler with your own hands, you must carefully study the instructions that come with the product. Installation involves several stages:

- preparation of the installation site and installation of fasteners. The surface on which the thermal power unit is installed must be finished with a fire-resistant panel. To prevent distortions, the brackets are adjusted using a construction level;

- grounding For electrical safety purposes, the electric boiler installation diagram provides for connecting the power device to the grounding bus. Copper wire with a cross section of 4 mm is used. The conductor is connected to the neutral terminal at the bottom of the housing;

- install a circulation pump and an expansion tank if they are not provided for in the design of the heating boiler.

During commissioning, special attention is paid to such points as the tightness of the entire system and the removal of excess air. Next, the equipment is tested in various operating modes.

Induction

The design of induction boilers consists of an induction coil and a metal core. The induction coil has two layers of windings. The first converts electrical energy into magnetic energy, under the influence of which the secondary winding heats the steel rod. Heat from the core is transferred to the coolant.

Advantages. High cost-effectiveness, efficiency and fire safety. Unlike heating element boilers, they do not form scale, and compared to electrode boilers, they are not so demanding on the coolant. In fact, any liquid medium from ordinary water to purified petroleum products can act as a coolant. The boiler design is extremely reliable, since there are no elements that are subject to mechanical wear. The regulated service life can exceed 25-30 years.

Flaws. High price. Significant weight even with compact dimensions. Only floor installation is allowed.

Electric heating boiler wiring

Electric boiler wiring includes the following elements:

- circulation pump - the device is designed to ensure the movement of coolant along the circuit to transfer thermal energy to heating devices;

- expansion tank - the design is designed to receive excess coolant when it overheats excessively;

- safety valve - the functionality is activated exclusively in emergency situations, for example, when the working medium boils when the pump stops or the tank overflows. The action of this piping element involves the discharge of excess coolant into the sewer system;

- automatic air vent - its task is to independently remove air from the circuit. The absence of a device may impede the circulation of the working fluid in the system;

- pressure gauge - designed to monitor the pressure level in the circuit; a device with a value of 4 bar is used.

Installation of an electric boiler

According to the regulations, the installation of an electric heating boiler is necessarily accompanied by the installation of a safety group.

Protective automation

Automation units from the first group, as its name suggests, are designed to protect the boiler and the room in which it is installed. These devices stop the gas supply in the event of an emergency.

Gas control

This is usually understood as “monitoring the presence of a flame” of the burner. When the burner goes out, the gas supply must be stopped. This is a basic protection function that is present in all boilers.

This automation module consists of two units: a gas supply valve and a thermocouple (Fig. 1).

Rice. 1 Thermocouple and solenoid valve

Thermocouple is a passive temperature sensor, i.e. does not require external power. It consists of two soldered conductors made of different metals (Fig. 2.). When the soldering point is heated, a thermo-emf is induced in the conductors; in other words, a small voltage arises, sufficient to open the gas supply electromagnetic valve.

Rice. 2 Operating principle of a thermocouple

That is why, when starting the boiler for the first time, you need to hold the ignition button for several seconds - the time during which the thermocouple will have time to heat up and sufficient voltage will arise on it to maintain the gas valve in the open position.

Do not be confused: in the description of the boiler, this automation unit is usually called “gas control”, however, it would be more correct to call this function “flame presence control”, because Other automation components, which we will consider later, can also turn off the gas supply in an emergency.

Boiler thermostat

Thermostat is a device necessary to maintain the set temperature of the coolant. It turns off the boiler when the set temperature is reached and turns on when the temperature drops below the set threshold. The thermostat handle has several modes, each mode corresponds to its own coolant temperature.

Rice. 3 Thermostat

If the boiler is electronically controlled, the temperature can be set using the user terminal and shown on the display.

The thermostat can be considered a device that regulates the operation of the boiler, but it also performs protective functions: protection against overheating and freezing. This is achieved by having the thermostat have upper and lower threshold values. When the coolant temperature reaches the upper emergency threshold, the boiler turns off to avoid overheating. When the lower emergency threshold is reached, the boiler turns on at maximum power to prevent the coolant from freezing.

It is worth keeping in mind that if “thermostat” is written in the list of technical characteristics of the boiler, this means the presence of a control thermostat. The overheating protection function is present in any boiler, even if it is not specifically indicated. But frost protection is present only in those boilers where this function is specified in the characteristics.

Traction control

The draft intensity must be sufficient to completely remove combustion products from the room in which the boiler is installed. If there is insufficient draft, combustion products accumulate inside the room, which is dangerous to human health. When the draft control sensor (Fig. 4) is triggered, a control signal is generated to stop the gas supply and turn off the boiler.

Figure 4. Traction control sensor

When installing a heating system, the draft is checked by a technician, but the draft may deteriorate during operation for many reasons (contamination of the exhaust pipe, etc.)

Therefore, draft sensors are an important component of the boiler safety system

Safety valve

Rice. 5 Safety valve

It is necessary to discharge excess coolant from the system when its pressure increases above the permissible limit. This situation is possible with a sharp increase in the temperature of the water (coolant) in the system. This can lead to damage to the boiler and other components of the heating system. Therefore, it is better to purchase a boiler with a built-in safety valve or install it separately.

Automatic air vent

When a heating system is put into operation, air inevitably gets into it, which can be quite difficult to get rid of. In addition, air can accumulate in the system during operation. It interferes with the normal operation of the heating system, creates noise and bubbling in the pipes. The air vent (Fig. 6) automatically releases all the air accumulated in the heating pipes. It cannot be called a mandatory node, but its presence in the system greatly simplifies the user’s life. Therefore, the best solution would be to choose a boiler with a built-in air vent.

Rice. 6 Air vent

Selecting a location and installation recommendations

The regulatory documents do not provide for restrictions on the installation location of an electric heating boiler. In this case, it is necessary to be guided by the rules for using electrical installations, which indicate restrictions on the placement of high-power power equipment.

Recommendations for installing an electric heating boiler in a private house:

- To limit access to power equipment for the safety of residents, it is worth installing the unit in an isolated space, for example, in a garage or other technical room. This is especially true for combined models of high-power underfloor heating systems.

- New models of boiler equipment with compact configurations can be placed in the kitchen or entrance area. The difficulty here is that you will have to connect a powerful power cable and a heating system main to the installation site of the electric boiler. This is accompanied by additional costs for communications; it is also necessary to organize decoration work to hide engineering structures.

- When installing an electric heating boiler on a wooden wall or other combustible surface, place a basalt panel or sheet of roofing steel under the adjacent part of the power equipment housing.

- The cable should be laid above the pipeline systems to prevent flooding in case of emergency situations.

- It is necessary to place the structure in a designated place so as to provide comfortable access to the power unit for ease of maintenance.

It is best to install an electric boiler in an isolated space.

You should also pay attention to ensure that the pipes do not load the connecting fittings of the electric boiler with their weight.

Number of circuits

Construction of a double-circuit boiler.

When installing a heating boiler, you can provide your home with an uninterrupted supply of hot water, but the equipment for this must be selected especially carefully. In this case, it is necessary to make a choice between devices with one or two circuits. Single-circuit appliances allow you to organize only a heating system, since they are not designed to heat water, which is supplied to the user through taps in the kitchen or bathroom. If there is a need for this, you need to choose double-circuit gas boilers. There is a separate classification here: gas boilers are produced as wall-mounted, floor-mounted, flow-through and with large storage tanks.

Which boiler should you choose? You must first decide what functions are required from the equipment. For example, single-circuit devices are capable of supplying coolant for heated floors.

Flow-type equipment is used when almost instantaneous heating of water is required, and they pump 10-15 liters through themselves in a minute, heating this volume to the set temperature.

Double-circuit heating boilers have additional tanks with a certain capacity. They contain a volume of already hot water, but when supplied it may not always be immediately hot, and this leads to liquid consumption. Therefore, the choice must be made based on how economical and effective the equipment is, and whether it fully meets all operating requirements.

Features of the location of boiler equipment piping

The regulations strictly oblige the installation of each piping unit in a certain area of the system:

- the safety group is installed behind the heating unit, since on this section of the circuit, when circulation stops, the point of highest pressure of the working medium is observed;

- the circulation pump is located in front of the boiler, at the point of the circuit with the minimum coolant temperature;

- the expansion tank is installed at a distance of twice the pump pressure if it is located before it, but if located after it, the distance should be equal to eight times the pump pressure.

In the latest generation electric boilers, all piping elements are often built into the structure.

Pipes

What kind of pipes can be used for installation of filling and connections to the boiler and heating devices?

Low operating temperatures and moderate operating pressure allow the use of all types of metal, high-temperature plastic and metal-plastic pipes. The only thing that needs to be mentioned separately is the use of polypropylene:

Pipes must be reinforced with aluminum foil. It will reduce the elongation of the pipeline when heating water in the circuit;

The use of polypropylene pipes without reinforcement for heating needs. The heated spills lengthened and went in waves.

On long straight sections of pipes, expansion joints are needed - U-shaped, ring or bellows. They will not allow the bottling or riser to bend when heating water in the pipes;

Ring and bellows expansion joints for polypropylene pipelines.

- Straight sections are fastened movably with sliding clamps;

- When pipes are laid hidden, gaps remain at the ends of the grooves. They will allow the pipe to lengthen without destroying the groove seal.

Connection diagram development

Depending on the design features and nuances of connecting electric boilers to the heating system, appropriate diagrams are used. Standard power device connection diagrams have been developed for various cases, for example:

- installation of a boiler unit that is not equipped with a pumping system and expansion tank;

- if a piping with a buffer tank is provided;

- if there is a connection to be made with an indirect heating boiler;

- An electric heat generator works in tandem with a TT boiler or gas fuel device.

The dual-circuit device must be connected to the heating and hot water mains.

Nuances of work

Electric heat generators have high efficiency, which means they are suitable for large areas. Electrode boilers are the most economical of all.

All electric boilers are equipped with a regulation system for temperature control and a stabilizer that protects against power surges - the devices are almost always sensitive to them. By the way, the main problem in calculating an electric boiler is most often the load on the network, which, as a rule, is higher than normal.

Connection with heating system

Wall-mounted models of electric boilers with a built-in safety group, which provide for operation in closed-type heating systems with forced circulation, are connected by connecting the supply and return pipelines to the corresponding pipes of the thermal power unit.

An electric boiler with a heating element, which is not equipped with an expansion tank and a pump, is connected according to the following diagram:

- the expansion tank is installed on the direct outlet section of the supply pipeline, after which a shut-off valve with a ball mechanism is inserted;

- the pump and sump can be installed both on the supply and return;

- the make-up pipeline is cut into the return line.

Using a similar scheme, the electrode/induction thermal power unit is connected to a closed-type heating system with a membrane expansion tank.

How to connect a gas boiler in a private house in order?

It is possible to install and connect the device correctly on your own, but this requires approval from gas services. In the course of the work, thoughtful activity and the need for paperwork will be required: agreeing on a number of issues and obtaining documents.

First, an agreement is drawn up with a natural gas supplier for its supply to private households. They are also involved in the project of gasification of the building and installation of the necessary equipment.

Before installation, all papers (certificate, product serial number) are verified. If everything is in order, proceed to installation.

The installation location is selected depending on the type of device.

The floor-standing gas boiler is installed on a flat surface made of non-combustible materials. For example, tiles or concrete screed are used. And sometimes they put a sheet of galvanized steel with a protrusion on the front side of up to 30 cm. Access to the structure should be unlimited from either side.

Important! It is necessary that the boiler is located away from electrical appliances and fire sources, and not close to the wall. The structure must have a uniform load on all supports

The structure must have a uniform load on all supports.

The wall-mounted gas boiler is secured using brackets (included in the kit). Installation height is about 1 meter above the floor. First, the planks are fastened, then the unit is mounted on them.

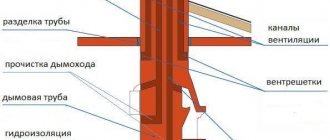

Then the connection to the chimney occurs. Before this, the presence of traction is checked. To prevent the leakage of toxic gases, the connections are carefully sealed.

Photo 3. Wall-mounted gas boiler, installed more than a meter higher from the floor, connected to the chimney.

25 cm is the maximum length of the pipe section that connects the boiler to the chimney.

The next step is connecting to the water supply. The first step is to install a filter for hard water purification, which prevents the heat exchanger from clogging. Taps and/or valves are installed on both sides of it.

To ensure optimal pressure in the system, tapping into the water supply is carried out either to the point where the pipe branches, or as close as possible to its entrance to the building. Typically, the water supply pipe is connected to the top of the unit, and the return pipe is connected to the bottom.

All communications must be equipped with a locking mechanism to enable emergency shutdown of the gas supply in case of danger.

Materials and tools

- Adjustable wrenches and dowels;

- building level for choosing the location for attaching the brackets, its length should not be less than 1 meter;

- a hammer drill with a set of drills of different diameters for making holes in the wall intended for fastening them;

- brackets - included in the kit, but it is better to have some in reserve;

- scissors, so that when cutting pipes, they do not damage their protective layer, which is responsible for the tightness;

- calibrator for pipe flaring;

- valves, taps - for fastening locking mechanisms;

- galvanized steel sheets and tools for cutting them.

Step-by-step connection of the heating circuit

There are several ways to connect the circuit to the boiler, depending on the model and auxiliary equipment.

When connecting a single-circuit gas appliance to a heating system, the easiest way is to use shut-off valves and use them to connect the circuit directly to the boiler.

The coolant circulates in a natural mode, and a conventional expansion tank is installed in the system.

When connecting double-circuit devices, the work becomes more complicated, since a double set of pipes is supplied to the boiler. The coolant flows directly through one, and hot water circulates through the second. The connection is also established using shut-off valves.

If the system is closed, then additional devices must be installed: a circulation pump, a membrane expansion tank and a safety group.

Connection to the heating system

Location of connections to the heating system (from the front side):

- on the left - supply of hot coolant to the circuit;

- on the right is the return line.

When connecting the boiler, you should carefully check the sealing and tightening of the components, but you should not be too zealous because of the risk of damaging the threads and facing the problem of replacing all connecting elements.

It is also necessary to install a coarse filter on the return line, which will extend the life of the device by stopping solid particles.

How to organize a connection to an open-type gravity heating network?

The connection of an electric boiler with a gravity heating system is carried out according to the following scheme:

- an open expansion tank is installed at the top point of the network, followed by a shut-off valve;

- pipelines in both directions are laid with a slope of 3 mm/linear meter;

- The circulation pump is placed on the bypass.

Since, to ensure stable gravity flow, a vertical height of 2 meters between the electric boiler and the tank is recommended, the expansion tank is placed in the attic.

Components

Correct connection of the electric boiler to the heating system ensures further trouble-free operation and efficiency. The electric boiler installation system consists of the following components:

- apparatus;

- temperature sensors;

- radiators;

- drain and shut-off valves;

- expansion tank;

- circulation pump and filter.

Electrical connection

When connecting an electric boiler with your own hands, follow a number of rules:

- Devices with a power of up to 3.5 kW are connected to the outlet;

- power devices with a power of up to 7 kW are connected to the distribution panel;

- Boiler equipment with a power of up to 12 kW is connected to a single-phase 220 V network; for units with a power of more than 12 kW, a three-phase 380 V network is used.

Materials required for installation:

- Power cable brand VVG with copper conductors. The number of cores depends on the number of phases - 3 or 5, the cross-section must correspond to the power of the boiler unit, this parameter is indicated in the product data sheet.

- A bunch of RCDs complete with a circuit breaker or a differential circuit breaker. The rating of the latter depends on the power of the heating boiler. The triggering voltage of the difavtomat is 30 mA.

- Ground loop. To lay a grounding loop near a private house, you can use a strip with a cross section of 40x5 mm + 3 steel rods d16 mm 2 m long with a sharp end.

In order to independently connect an electric boiler, you should remove the front panel of the case, connect the cores of the power cable of the corresponding colors to the terminal block contacts. When installing an electric heating boiler with your own hands, it is worth remembering that such voltage is a source of increased danger.

Required Tools

The quality and speed of work completion depend on proper preparation.

For installation you will need:

- A drill with different attachments for making holes for fasteners.

- Level for mounting equipment.

- Fastening elements capable of withstanding the load created on them by the mass of the electric boiler.

- Pipes for highways.

- Cable for laying the power line from the mains.

Additionally, you will need to purchase circuit breakers and RCDs.

What could be the “pitfalls”?

Well, as you understand, there is no ideal option for all conditions, and the problem that you may encounter when independently connecting electric heating at your dacha is frequent power outages in the area. Indeed, in many villages problems with electricity still arise, and in our case, if there is no light, then there is no heat.

Therefore, of course, first of all take this point into account if you want to make electric heating for your dacha yourself. In any case, you can get out of this situation without any problems by purchasing an additional gasoline or diesel generator (shown in the photo below), but this requires additional money, which not everyone can allocate!

That's all the information about this issue! We hope that now you know how to properly install electric heating and what nuances exist in relation to a country house!

Also read:

Content

No. 5. Oil radiators for summer cottages

You can consider an oil radiator as the only source of heat only when the dacha is small and you appear there infrequently ; in other cases, it is a backup and additional method of heating. The design of such devices is simple: the heating element transfers energy to the oil (coolant), which circulates inside the device body. The oil heats the body, which, in turn, heats the air in the room. You can heat a room to an acceptable temperature with such a heater without any problems. Among its advantages :

- the ability to transport from one room to another;

- high level of safety, the surface does not heat above 60 0 C;

- durability and reliability;

- noiselessness;

- low price;

- no unpleasant odors.

Such devices do not heat the room very quickly, but they also cool down slowly, maintaining a comfortable temperature for a long time. For faster heating of the room, some models have a built-in fan. Device power is from 1 to 2.5 kW. The power calculation is approximately the same as with a convector.

No. 6. Fan heaters for cottages

A fan heater is another way to backup heating a country house . It is not possible to constantly maintain the required temperature. However, fan heaters have earned great popularity because:

- are inexpensive;

- compact and mobile;

- allow you to quickly warm up the room;

- easy to operate.

Disadvantages include inefficiency, fire hazard, noise and unpleasant odor, since during operation dust and dirt particles get onto the hot coil. You cannot warm up a large area with such a device, but for this there are thermal curtains and heat guns , which work on the same principle as a fan heater.

The device is quite primitive: air masses are heated by contact with a heated heating element, and are moved due to the presence of a fan. The differences are only in the type of heating element (spiral is the cheapest, but dangerous, and ceramic is safe, but expensive), power (0.4-2.5 kW), type of control, and the type and shape of the fan.

No. 7. Infrared heaters

Infrared heaters are 20-35% more economical than conventional electric boilers , and experts are confident that such devices will soon become on par with traditional heating systems. So far they are losing to their competitors in terms of popularity, but the demand for them is growing at an immediate pace. The principle of operation is to convert electricity into infrared rays, which heat not the air, but objects, like the sun. Heated objects release heat to the environment, and the room temperature rises. Objects are heated only in the area where the heater rays are directed.

Infrared heaters are presented in two modifications:

- devices on legs;

- flat panels that are attached to walls or even ceilings.

It will not be possible to quickly heat a room in this way, but due to their efficiency, environmental friendliness and operating features, infrared heaters can be used as an independent source of heat in a country house , unless, of course, they live there permanently. Remember that such devices are often placed in the open areas of cafes, so for autumn and spring outdoor gatherings these heaters will be just right - you will get a warm and cozy relaxation area.

The power of such devices ranges from 0.25 to 3-4 kW. Infrared heaters are fireproof and durable, can last up to 25 years .