The gas boiler Ochag KGS is part of a wide range of products. The Russian manufacturer produces gas burners, control units and gas burners. The Ochag KGS boiler is the result of the implementation of innovative strategies combined with the technical experience accumulated by the largest specialized plant over many years. Just imagine, 63 types of boilers this company can offer!

Don’t be alarmed, our review today will only cover the standard and premium versions of boiler equipment from the Ulyanovsk plant:

How to turn off the Proterm boiler?

Complete shutdown of the heating system is carried out differently:

- On the main panel you will have to find the on/off button and hold it down for a while until the display goes out.

- In the off position, the external two-pole control lever must be moved.

- Gas access to the boiler is blocked.

Interesting materials:

When did silk appear? When did the term Orthodoxy appear? When do last minute tours appear? When do the first boletus mushrooms appear? When do the first mushrooms appear? When do magpie chicks hatch? When do birthmarks appear? When will the Kolosoviki go? When to buy pullets? When do buyers receive the keys to the apartment?

Gas boiler Hearth

The gas boiler Ochag KGS is part of a wide range of products. The Russian manufacturer produces gas burners, control units and gas burners. The Ochag KGS boiler is the result of the implementation of innovative strategies combined with the technical experience accumulated by the largest specialized plant over many years. Just imagine, 63 types of boilers this company can offer!

Don’t be alarmed, our review today will only cover the standard and premium versions of boiler equipment from the Ulyanovsk plant:

Boiler Hearth standard

Specifications

| OCHAG FLOOR FLOOR GAS BOILERS KSG-STANDARD SERIES | |||

| Name | Heating area | Dimensions/weight | Natural/liquefied gas consumption |

| Single-circuit heating only | |||

| KSG-7 S/E | 80 m2 | 244*470*710 / 46 kg. | 0.78 / 0.64 m³/hour |

| KSG-10 S/E | 100 m2 | 244*470*710 / 46 kg. | 1.11 / 0.88 m³/hour |

| KSG-12.5 S/E | 120 m2 | 300*470*710 / 49 kg. | 1.39 / 0.97 m³/hour |

| KSG-16 S/E | 160 m2 | 300*470*710 / 49 kg. | 1.78 / 1.1 m³/hour |

| KSG-20 S/E | 200 m2 | 376*470*710 / 60 kg. | 2.22 / 1.41 m³/hour |

| Double-circuit with DHW | |||

| KSGV-12.5 S/E | 120 m2 | 300*470*710 / 50 kg. | 1.39 / 0.97 m³/hour |

| KSGV-16 S/E | 160 m2 | 300*470*710 / 49 kg. | 1.78 / 1.1 m³/hour |

| KSGV-20 S/E | 200 m2 | 376*470*710 / 61 kg. | 2.22 / 1.41 m³/hour |

The gas boiler Ochag KSG is operated in automatic mode. Maintains the temperature of the coolant in the heating unit at the same level set by the consumer. Provides multi-level protection in case of emergency situations. In particular, the sensor system monitors the flame attenuation on the ignition burner and monitors the occurrence of a lack of draft situation - in each case, the gas supply is immediately blocked.

Boiler Hearth Advantages

- Laconic design;

- High efficiency up to 92%;

- Gas blocks of own design of the ServiceGas concern;

- Completely non-volatile. There is no need to connect to the electrical network;

- Possibility of conversion for further operation on liquefied gas;

- Stable operation of the device in case of low gas pressure;

- Heat-resistant stainless steel burner.

- The gas pressure and draft stabilizer is built into the Hearth boiler;

- Regular maintenance using easily removable turbulators in gas passage channels adds ease of operation;

- Easy installation with a choice of one of two gas connection options.

- Thermocouples serve as additional protection against operational breakdowns;

- Service maintenance due to the special mounting of the smoke collector does not interfere with convenient work with the flue part;

- Small pipe diameters = 1.5 inches contribute to reducing financial installation costs;

- Service life of at least 15 years;

- Warranty period from the manufacturer is 2 years.

The floor-standing gas boiler Hearth KSGV serves as a heat supply device for rooms with an area of up to 160 m2, taking into account that the ceiling height does not exceed 2.7 m. Higher ceilings will most likely require a more accurate calculation of heating equipment. The two-circuit model provides the consumer with heat in combination with hot water supply, as indicated by the “B” index.

Explanation of the abbreviation KSGV S -12.5 AT

The letter designations that the Ochag boiler has are intuitive and not difficult to decipher: “K” – boiler “C” – steel “G” – gas “B” – possibility of supplying hot water (a water heater coil is installed) “12.5” – boiler power in kilowatts “A” – a – possibility of operation as a solid fuel “E” – EUROSIT automation “C” – SABK-AT automation

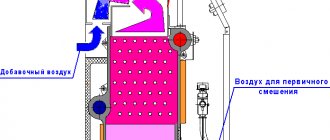

The device uses a gas pressure stabilizer designed to regulate the network pressure and ensure a uniform and stable flame on the main burners without changing thermal performance. A new heat-resistant stainless steel burner of atmospheric type is used. It is installed at the bottom of the heat exchanger, maintaining a uniform thermal zone in the combustion unit. The design has a uniform placement and prevents zonal overheating of the heat exchanger and its failure.

The built-in draft stabilizer balances the pressure at the entrance to the ejector of the main burners and at the exit from the slot grooves. This ensures constant discharge and stable combustion of the gas-air mixture in the firebox without additional regulation.

Boiler Ochag Premium

Consider the Premium series AOGV and AKGV. This line has a power from 10 to 35 kW, and serves as a heating device for a residential building up to 300 square meters. The devices are characterized by high performance and reliability. The manufacturer provides for the equipment to operate on natural or liquefied gas. In case of planned connection to a liquefied gas cylinder, it will be necessary to purchase an additional set of nozzles with subsequent adjustment of the equipment.

Specifications

| OCHAG FLOOR FLOOR GAS BOILERS AOGV PREMIUM SERIES | |||

| Name | Heating area | Dimensions/weight | Natural/liquefied gas consumption |

| Heating unit Gas water heating, one circuit and works only for heating. | |||

| AOGV – 8 C/E | 80 m2 | 350*450*760 / 38 kg. | 0.81 / 0.63 m³/hour |

| AOGV – 8 11.6 C / E | 100 m2 | 350 450 850 / 57 kg. | 1.18 / 0.91 m³/hour |

| AOGV – 17.4 C/E | 160 m2 | 350 450 850 / 61 kg. | 1.76 / 1.36 m³/hour |

| AOGV-23.2 S/EM | 210 m2 | 430 565 850 / 66 kg. | 2.35 / 1.82 m³/hour |

| AOGV-29 S/EM | 260 m2 | 430 565 850 / 82 kg. | 2.95 / 2.28 m³/hour |

| AOGV-35 S/EM | 320 m2 | 430 565 850 / 96 kg. | 3.6 / 2.79 m³/hour |

| AOGV-45 S / EN | 400 m2 | 500 650 930 / 102 kg. | 4.6 / 3.54 m³/hour |

| Combined Gas Water Heating Unit, two circuits, one for heating the room, the other for heating hot water. | |||

| AKGV – 11.6 C/E | 100 m2 | 350x450x850 / 57 kg. | 1.18 / 0.91 m³/hour |

| AKGV – 17.4 C/E | 160 m2 | 350 450 850 / 62 kg. | 1.76 / 1.36 m³/hour |

| AKGV – 23.2 C/EM | 210 m2 | 430 565 850 / 68 kg. | 2.35 / 1.82 m³/hour |

| AKGV – 23.2 C/EM | 210 m2 | 430 565 850 / 68 kg. | 2.35 / 1.82 m³/hour |

| AKGV – 29 C/EM | 260 m2 | 430 565 850 / 86 kg. | 2.95 / 2.28 m³/hour |

| AKGV – 35 C | 320 m2 | 500 640 930 / 96 kg. | 3.6 / 2.77 m³/hour |

Boiler Hearth device:

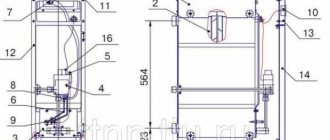

Structurally, the Hearth boiler is designed in such a way that it can be integrated into any heating system. The front door can be adjusted according to need and opens either on the left or right side. Two return lines, on the side and behind, make it possible to supply coolant from a convenient installation side.

The Hearth boiler consists of:

- Boiler body

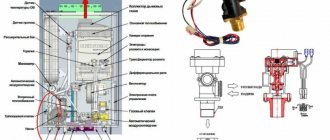

- Automatic control

- Heat exchanger

- Second circuit (if the boiler is double-circuit)

- Safety system

In the lower part of the body, there is a combustion chamber, closed on the sides and rear by sections of the water jacket. A heat exchanger is located above the combustion chamber. High efficiency of heat transfer and heat exchange between flue gases and coolant is achieved due to the developed convective part of the heat exchanger, consisting of “flame” pipes.

At the top of the heat exchanger there is a smoke collector with a built-in draft stabilizer. In the front part of the smoke collector there is a draft sensor, in the upper part of the smoke collector there is a boiler outlet pipe. When installing a boiler into a chimney, it is necessary to coordinate the diameter of the outlet pipe with the cross-section of the chimney. The technical parameters of the chimney must correspond to the technical parameters specified in the operating manual.

In the middle part of the smoke collector, there is a partition plate to ensure stable operation of the device regardless of weather conditions. The heat exchanger, complete with a smoke collector, ensures efficient operation of the boiler without consumer intervention and without requiring manual adjustments. The stabilizer draft contributes to stable operation of the boiler during unstable draft.

A gas burner device manufactured in Russia by the Service Gas company is installed in the combustion chamber of the apparatus. It consists of a front panel, burner pipes, safety sensors (flame sensor and draft sensor), and the SABC AT control unit.

An easily removable distribution grid is mounted below the burner pipes. Designed to supply secondary air for combustion. It is very important when installing the Hearth boiler in a room to ensure free access of air through the lower part of the boiler through the distribution grid to the burner pipes.

The boiler must be installed with clearance at the height of the legs relative to the floor. The Hearth boiler is connected to the gas main on both the left and right sides. This can be done by the design of the SABC AT block. A temperature sensor is installed on the front panel, which indicates the room temperature.

How to light a boiler?

In order to ignite the Hearth boiler, you need to turn the control knob clockwise until the point is opposite the pointer. Then press and hold the start button. Press the piezo ignition button until you hear a characteristic click. At this time, the igniter lights. We continue to hold the start button pressed while the thermocouple heats up. The gas block operates automatically on the igniter. Next, turn the knob counterclockwise to the required temperature.

The Hearth boiler achieves high efficiency due to efficient combustion of fuel and high heat transfer from flue gases through “flame” pipes to the coolant and a developed firebox. The manufacturer guarantees a service life of at least 15 years. Factory warranty for the product is 24 months.

Watch a video on how to light a gas boiler with Eurosit630 automation

Designations

Heating devices are designated by a letter abbreviation. Each letter contains certain information:

- K - boiler;

- G — the package includes gas burner equipment;

- T - can be used as solid fuel;

- C - steel;

- M - you can install heating elements and an expanded combustion chamber;

- B - there is a water heater.

By understanding what the letters mean, users will be able to decipher basic information about the product.

Types of models

All versions of gas boilers Hearth can be divided into 4 groups:

- AKGV;

- KSGV;

- AOGV;

- KSG.

Devices manufactured under these names can operate in open and closed heating systems. Coolant circulation - forced or natural. Next to the marking there is a number that indicates the power of the device - 7-35 kW. The marking also indicates the type of automation:

- T or AT - SABC AT;

- C — SABC S RD;

- E or EM - Eurosit.

Almost all models are made in accordance with minimalist trends. There is a pressure gauge in front, and other automatic elements are placed in the housing.

A characteristic feature of the products manufactured by ServiceGaz is their white color. The radiator is made of steel, and the burners are made of heat-resistant stainless steel. The device includes condensate collection.

Kinds

The Ochag company produces different structural types of boilers:

- Floor-standing. They do not require any special installation as they can be placed directly on the floor. This expands installation options compared to wall-mounted models.

- Wall-mounted. They require hanging installation on strong, preferably load-bearing walls. Temporary or plasterboard partitions are not suitable for this. The specifics of the installation require reducing the weight and reducing the size of the boiler, which affects power and performance.

- Parapet. They can be used both as part of a heating circuit and as an independent heat source.

By functionality:

- Single-circuit. Designed only to supply the heating circuit with hot coolant.

- Dual-circuit. Capable of simultaneous heating of coolant and preparation of hot water (DHW) for domestic needs.

By type of combustion chamber:

- Atmospheric (open). Smoke removal occurs through a common house chimney using a stove-type draft, and combustion air is taken directly from the room.

- Turbocharged (closed). Smoke removal and air supply are carried out by a special turbocharging fan. Possible only on energy-dependent models, but independent ones can also be modified using an external turbo nozzle.

There are many design options for Ochag boilers; the user can choose the most suitable option for his or her purposes.

Ignition sequence

Algorithm of actions for igniting the boiler.

Heating systems of the Hearth are equipped with automation that regulates its operation and facilitates ignition. To start the unit with SABK-AT automation, perform the following procedure:

- Open the gas supply valve.

- Place the handle in the “Ignition” position.

- The “Start” button is turned on and held for 10 seconds.

- Press the piezo ignition button several times; if it is missing, ignite the gas with a match.

- The “Start” button is held for 20-25 seconds until the thermocouple warms up. In this case, a magnetic plug holds the gas valve in the open position.

- The knob of the block is turned to position 5 and stable combustion of the gas burner is achieved.

- The required temperature is set on the gas block.

The ignition algorithm for other brands may differ in the position of the block handle, which is indicated in the instructions for the automatic system.

Advantages

Among the positive qualities of gas boilers are the following:

- High performance is achieved thanks to a special design. It is made of a steel heat exchanger. Efficiency reaches 90%.

- Precision temperature control.

- Compactness of the device.

- Multi-level inspection of each boiler. The company guarantees 100% quality.

- Unique device design. Thanks to its appearance, the device fits perfectly into any interior.

- Any heating device produced by Ochag is not affected by an external energy source.

- Ease of use.

- Cost-effectiveness is achieved due to the presence of a stabilizing device, which is responsible for equalizing the pressure. Accordingly, there is a reasonable gas consumption of approximately 30%.

- The set is equipped with reliable Italian eurosit automatic equipment.

- Highly environmentally friendly.

- The device is adapted to domestic gas supply conditions.

- High technical equipment.

Information about

The products have been manufactured since 1993 in the city of Ulyanovsk. The owner of the company is the trademark “Ochag”. There are more than six dozen models on the market. Domestic consumers are actively buying various modifications that have a loyal pricing policy.

The hot water gas boiler Ochag meets the European standard ISO 9001-2011.

Note! To provide consumers with maximum comfort when working with the device, specialists from the Ulyanovsk plant introduced an automatic mode.