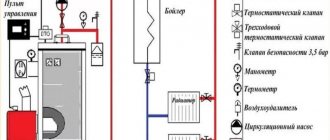

In my house, I have long installed an electric heating control system - a pyrolysis boiler that heats water in a barrel, which goes into the radiators. However, this winter there were frequent power outages, which was unpleasant. In this regard, I decided to independently manufacture an uninterruptible power supply for a heating boiler, and in the future for a circular pump. Therefore, next I will tell you about this device and how to make an uninterruptible power supply with your own hands.

Source domsgazom.ru

Why does a boiler need a UPS?

Typically heating systems use gas, solid or liquid fuel. However, for stable operation you need a current source that will work without interruption. If the power goes out, the furnace will turn off and the coolants will cool down. And if this happens frequently, due to constant temperature changes, cracks will begin to appear in the system, which will then only increase. All this leads to rapid wear and tear of the equipment.

Source ytimg.com

If you use electric heating in your home, then most likely you have encountered the problem that the light can turn off at the most necessary moment. To solve this problem, install an uninterruptible power supply - a device that serves as a power source even when the main power supply is turned off. You can buy it in a specialized store or make an uninterruptible power supply yourself.

As practice shows, a homemade device will cost you two times less than a purchased one, which is considered to be one of the main advantages of why it is worth making.

But keep in mind that without the appropriate skills, you can spend much more time and resources than professionals. Therefore, it is worth considering whether it would be advisable to independently manufacture such a device.

Possible problems in the operation of the uninterruptible power supply

During operation of the equipment, the following malfunctions may occur:

- contamination of the internal surface of the UPS, dust settling on it (especially during construction work indoors);

- Frequent overloads in the operation of an uninterruptible power supply can lead to the inverter failing;

- the end of the battery life (with long-term use of the device);

- The special lubricant on the cooling fans may dry out, which can also cause the device to fail.

What you need

One of the most important parts for making an uninterruptible power supply for a heating boiler with your own hands is the inverter.

Source cezar.ua

An inverter is a device that converts the direct voltage of the battery into an alternating voltage of 220 volts.

It is better to make the device itself from rechargeable batteries, since they are cheaper than any generators. For the normal functioning of the boiler, which depends on the electric current, it is worth installing CPS type inverters (the best type indices are 7500, 3500 and 5000 PRO).

In addition to the inverter, you will need batteries that will provide uninterrupted power for the pump or boiler, and a charger. Batteries for a homemade uninterruptible power supply are selected with maximum capacity, because the larger the capacity, the longer the device itself will last.

To give you an idea, with an equipment capacity of 45 ampere-hours, the device will operate for about 8 hours, and at 95 ampere-hours – up to 24 hours.

The charger must match the battery capacity.

Source akb-s.ru

It is important to calibrate after replacing the battery with a larger one.

In some UPSs, calibration is performed by pressing a button on the front/rear panel, on others it can only be done from the service menu when connected via RS232/USB to a PC, and in some it is not provided at all.

But it is believed that if calibration is not performed, the UPS will not completely consume the battery charge, and even with an increase in the battery capacity, it will work as little from them as with old batteries. Although in reality this is not the case. Without calibration, the UPS will not correctly display the remaining battery capacity as a percentage, but this will not affect in any way when the UPS decides that the batteries are completely discharged. This can only affect the equipment, the connection is connected to the interface connector of the UPS, and depending on the settings, after a certain level of the percentage remaining of the battery capacity, it turns off this equipment upon command. In my case, the APC Smart 3000 UPS was calibrated about a year ago, but despite the fact that the batteries were not changed, the graph of the percentage of battery capacity and voltage shows that the UPS is lying about the first. From it you can see that from 100 to 23% the UPS simply linearly reduces the percentage regardless of the voltage on the batteries, then at 23% the charge “freezes” for several hours, and then smoothly decreases to 11%. Unfortunately, I couldn’t wait until it was completely discharged; I had to apply external power, and at that moment something incomprehensible began. Judging by the graph, the voltage on the battery began to rise, the charge began, and the charge percentages, on the contrary, went down until they dropped to 1%, and only after that they began to rise smoothly, depending on the voltage on the battery. Perhaps, in order for the UPS not to lie, calibration needs to be done more often than once a year, but there is no great sense in this, because the UPS itself will turn off based on the voltage on the battery (if a battery life limit is not set), and not at all not by percentage.

Manufacturing instructions

If you have already purchased everything you need (inverter, batteries and charger), then to manufacture a UPS for a gas boiler you need to do the following:

- Connect the symbols “+” and “-”, which are marked on the inverter, with a powerful wire with the corresponding marks on the battery.

- Insert the boiler plug into the inverter and press the “On” button.

Your homemade uninterruptible power supply is ready, the device is working.

When assembling, also keep in mind that the wires for connection must be thick and copper, and their fastenings must be reliable. It will be necessary to check the connections periodically, as there is a possibility of metal oxidation, which will impair the operation of the system.

Necessity

If something extraordinary happens to the power line (breaks, accidents, etc.), the heating boiler stops working automatically. Such situations can not only damage the engine of a gas or solid fuel boiler, but also completely destroy the equipment.

The pump stops working, the coolant overheats, and the consequence could be a major accident in the heating system. The UPS will provide electricity not only to the pump, but also to the entire heating system. As a rule, an uninterruptible power supply is purchased to work with gas boilers, but boilers running on solid fuel can also fail as a result of interruptions in the electricity supply.

Nuances of filter assembly

To monitor the stability of the device, a harmonious system for voltage filters will help you. You can do it yourself by finding a proven scheme, or order it from professionals if you are not confident in your abilities. Such filters consist of various transformers, resistors and other additional devices.

If you have assembled the filter system correctly, then your system will stabilize any source of electrical current. It will not be difficult to assemble it, but to do this, follow the following diagram:

Source radiostorage.net

The main problem is in calculating the parameters. And the contour elements are easy to calculate and make, but they are assembled in different ways - one parallel, the other sequential. Regardless of the assembly method, tune to 50 Hz.

You will need to calculate the parameters of the inductors for the core, and in the core you need to make a gap between the turns.

Use the following formulas:

- Gap in millimeters: number of turns * max. current in amperes * 1.257E-3

- Number of turns: core cross-sectional area in square millimeters * max. current in amperes * inductance of the inductor in H * 1.257E6 - round the result up

- For a series circuit: the maximum current in amperes is 1.4 * {load power, W} / 220 V.

- For a parallel circuit: the maximum current in amperes is 1.4 * 220 V / 28 * {signal frequency, Hz - 50 Hz} * {inductance of the choke, H}.

Source habrastorage.org

Advantages and disadvantages

The advantages of using a UPS include the following:

- the equipment ensures continuous operation of the pump, regardless of possible problems with the power supply;

- volatile devices are protected from network problems, the entire system works efficiently;

- ease of installation;

- convenience and reliability in use;

- absence of noise during equipment operation.

Disadvantages of using uninterruptible power supply:

- high level of electricity consumption from batteries;

- often encountered low power of chargers built into the UPS.

Precautionary measures

If you decide to make an uninterruptible power supply for your heating boiler with your own hands, then first of all follow safety precautions and wear special clothing (at least gloves so as not to accidentally receive an electric shock from exposed wires).

Also carefully examine all the wires in order to identify even the slightest damage, because a short circuit is not uncommon, it is very dangerous and can cause a fire.

Several batteries (2-4) should be connected to the system at once, they should be fully charged, and they should be connected in parallel. Do not skimp on the device, as this can seriously affect the service life and even the quality of your equipment.

Use the device for those devices for which its power is designed - do not connect everything. Although, as a rule, there is enough power to connect and operate the computer normally, it is only important that the total power does not exceed the maximum permissible.

According to the advice of experts, the best choice would be models with phase-dependent equipment.

A little background

A year ago, when the UPS was installed, the gas boiler was as simple as possible, a minimum of electronics, manual ignition.

Actually, manual ignition was the only drawback of the boiler, because when the power was turned off, the boiler extinguished the torch for safety reasons, and was not able to light it back up. The UPS solved this problem, but there was another problem: with a strong gust of wind, the torch could simply blow out. This did not happen often, but it caused some inconvenience. And about six months ago, it was decided to replace the boiler with a slightly more “smart” one, with the ability to automatically ignite the burner, as well as with a turbine that creates the draft necessary for the boiler to operate, as a result of which there was no need to use a long exhaust pipe. There was one fundamental difference between the old and new boiler - phase dependence. For a new boiler, it was necessary to connect phase to L, zero to N, otherwise the boiler would ignite the burner and almost immediately extinguish it, giving the error “It is impossible to light the burner.” There was an assumption that during the transition to a battery, the UPS switches phase and zero, so the boiler stops working. An indicator screwdriver with a neon showed that there was a phase on both wires coming out of the UPS. The voltmeter showed that the voltage between phase and ground is 150V, and between zero and ground 90V, and between phase and zero, respectively, their sum. This situation clearly did not suit the cauldron.

Self service

After assembling a UPS for a circular pump with your own hands, its maintenance seems like a trifle. It will only be necessary to periodically change the batteries after some time and check the system for integrity.

I advise you to place the uninterruptible power supply in a basement or semi-basement cabinet, since it will take up less space there, and since moisture ingress is unacceptable, placing it in a small cabinet would be an excellent option.

I recommend the following video, in which the author explains how to choose a UPS for a boiler:

Device installation

It is quite possible to connect an uninterruptible power supply with your own hands. To do this you will need a socket and an indicator screwdriver. First, the phase of the UPS at the output is determined. To do this, you must first enable it in offline mode. After this, plug the device into the network and check again to see if the indicator has changed. If not, then everything is correct and you can connect the boiler.

As a result…

Making your own uninterruptible power supply for a gas boiler is not difficult if you have the appropriate skills. To make the device you will need an inverter, charger, batteries, wires and tools. After making a UPS for a circular pump, you will need a harmonious system for voltage filters, which will help you monitor the stability of the device. You can use the diagram posted above.

Question

Write in the comments whether you think it’s easier to make an uninterruptible power supply yourself or buy it?

Kinds

There are two types of uninterruptible heating pumps: linear and linear-interactive.

- Linear. These are the simplest devices of this type; they do not have a voltage stabilizer. If the equipment is disconnected from the power supply, it will automatically charge from the battery.

- Line-interactive, they are also called double conversion UPS. Such equipment is equipped with a system that stabilizes the voltage; it can be connected to a generator. Line-interactive systems monitor the battery charge level without intervention. If there is a power outage, the battery automatically starts up. When power is restored, the systems automatically resume normal operation. Line-interactive uninterruptible power supplies are more expensive.

Both types of devices are always connected to the power supply; in addition to charging the batteries, the equipment also monitors the battery charge level.