A steam boiler is one of the most popular and widely used types of heating units. The main structural part of the unit in question is the combustion chamber.

It burns the loaded fuel with intense release of thermal energy. The generated heat is used to heat water with further release of steam. Steam is used for various industrial and domestic needs, in particular for home heating. At the same time, you can easily handle making a simple boiler with your own hands.

DIY steam boiler

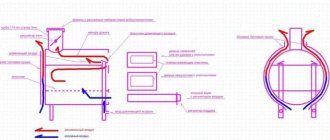

The design of the boiler in question is based on a kind of drum. Pre-prepared water is supplied to this piece of equipment through a system of pumps and pipes.

The lower compartment of the boiler contains down pipes. These elements have different diameters and do not heat up during boiler operation. Through a pipe system, liquid from the drum passes into the collectors. The latter are most often located at the bottom of the boiler.

Steam boiler

The collector is connected to the drum using a lifting pipeline. Due to the pipeline, heating surfaces are created at the place of combustion of the loaded fuel.

A pipeline system operating according to the mechanism of communicating vessels is connected to the steam generator. A mixture of liquid water and water vapor circulates in hot pipes. This mixture has a fairly low density, which allows it to easily flow into the separator compartment, where steam and water are separated. The liquid component is sent to the steam boiler drum.

The steam passes into the steam line, and then into special heaters, where the pressure and temperature of the steam increase to the required parameters. Finally, the steam is sent to the appropriate steam turbine.

Making a steam boiler

What is a steam boiler?

Steam home boiler

From the name itself it is clear that this is a device that generates juicy steam, which is subsequently used in the heating system of an apartment or house. In this case, the operation of the steam system is based on the fact that the steam has a pressure above atmospheric. In essence, this is a simple heating boiler that will work on any type of fuel. If you decide to install this type of heat generator in an apartment in the city, then the suitable fuel option is gas.

It must be said frankly that the design of a steam boiler is quite complex, so it is necessary to consider it briefly. The boiler itself consists of two parts, the upper of which is a drum saturated with water. The water supply system can be varied. For example, from a water meter unit or from any tank using a pump. From the drum downwards there are pipes through which the water will move. They are called descenders. Remember - these pipes do not heat up.

The lowering pipes are connected to the collectors, and lifting lines from the pipes go up from them. In other words, a system emerges that resembles connecting vessels. This is the working principle of a steam boiler. The riser pipes themselves form heating surfaces that pass through the area where fuel is burned. A steam-water mixture is formed in them, but this is not yet pure steam for a steam heating system. Zoning needs to be done.

This process takes place in, in other words, separators. The mixture enters there through pipes and is divided into water and steam. Water flows into the drum, and steam is supplied to the steam line connecting the separator and superheater. Here the steam is brought to the desired temperature and pressure. After this, it goes to a steam turbine, which drives it into the heating system.

How the system works

Do not confuse water and steam heating at home. They have many functional differences, despite their external similarities.

Both of these types have components:

- boiler;

- radiators;

- pipes.

Steam heating is considered effective; you can get by with a small number of batteries.

Steam is a coolant for steam heating of a private house. You can make such a system with your own hands, following the instructions for assembling and installing the components. For a water system, water plays the role of carrier. The boiler evaporates water rather than heating it. The coolant vapor moves through the pipes and becomes a source of comfortable temperature in the house. The steam cools inside, after which it condenses. In this case, 1 kg of steam is converted into 2000 kilojoules of heat. For comparison, water cooling at 50°C provides only 120 kJ.

The heat transfer of steam is several times higher, which explains the high efficiency of this type of heating. The condensate formed inside the radiator passes to the lower part and independently moves to the boiler. There are several types of heating systems. In this case, the specification is carried out according to the method of returning the coolant, which has been transformed into condensate.

- Closed. There are no contours in this case. Accordingly, condensate moves through pipes that lie at a certain angle. It goes straight into the boiler for further heating.

- Open. There is a storage tank here. Condensate enters it from the radiators, and the pump is involved in pumping it back into the boiler.

Steam boiler production technology

What is needed to make such a system?

- Stainless steel sheet metal 1 mm thick.

- Stainless steel pipes of various diameters - 100–120 mm, 10–30 mm.

- Valve for protection.

- Asbestos in the form of sheets.

The first step is to purchase the drawings of the steam boiler. This is not a problem today, because they are freely available on the World Wide Web. Task number 2 is to determine how much power the device needs. Everything depends on the steam heating system, the size of the private house, the number of heating devices in it, and so on. Other publications on this site can help you understand this issue. Third, it is necessary to select the shape of the unit. It can be round, rectangular or square.

High pressure steam boiler

For ease of manufacture, you can take a pipe 100–110 cm long. This will be the body of the unit. Please note that the wall thickness must be at least 2.5 mm. The fundamental point is the design of the combustion chamber and the supply of flame and smoke tubes to it.

It is best to make the firebox from stainless steel sheets, in which holes are drilled for the described tubes. Their ends are first rolled to create a tight fit to the surfaces. For better sealing and increased strength of the connection, the tubes should be welded using argon welding. If you do not have these abilities, you can attach them with regular electrodes.

Then you need to attach the pipe manifold by welding and install a safety valve. The unit is insulated using asbestos sheets. At this point we can consider the work done. Afterwards, the steam heating system and the boiler are connected.

Additional boiler elements

The design of a steam boiler is not limited to the basic elements that have already been described above. Sometimes a steam boiler can be equipped with additional devices to increase the efficiency or functionality of the system.

We are talking about the following elements:

- Superheater . This element allows you to heat steam to a temperature of over 100 degrees, which allows you to achieve greater efficiency by increasing the efficiency of the unit. When using a superheater, steam can reach a temperature of 500 degrees, and its heating is carried out already in the pipes, that is, after the stage of evaporation of water. The superheater can be either built-in or in the format of a separate device. There are convection and radiation devices (the second type has 2-3 times more power).

- Steam separator . This element of the steam boiler allows you to remove all excess moisture from the steam and dry it as much as possible. When using a separator, the efficiency of the entire boiler increases significantly.

- Steam accumulator . This device allows you to stabilize the system. The battery absorbs excess steam generated and returns it to the system if it becomes too low.

- Water purification device . This device allows you to reduce the saturation of water with oxygen and various chemicals. Timely water preparation makes it possible to reduce the impact of corrosion on the internal elements of the boiler and minimize the amount of deposits in the system.

What do steam units work on?

We have already said that there are no difficulties with choosing fuel for steam boilers. However, if we are talking about the effective and convenient operation of a steam heating system, then gas is a suitable option. There is less fuss with it, and you can make an automatic system. She herself will control all processes that are associated with temperature conditions, gas supply, fuel efficiency and fuel economy.

Steam boilers that run on wood or diesel fuel, and also electric analogues, operate on a similar principle, although there are quite serious differences in the design design. This is especially true for the combustion chamber and spray devices. The latter, for example, are completely absent in boilers running on wood or electricity. But in many cases, craftsmen who assemble boilers with their own hands try to fit them either to atmospheric burners or to diesel spray devices.

Consumers always have a substitution of choices. You can purchase a ready-made device, or you can create it yourself. But let's accept the true state of affairs. The circuit of a steam boiler is quite difficult, and it will not be possible to understand it without knowing the simple principles by which the device does not stop working. In addition, you will need to purchase special materials required by the standards and requirements to create this radiator. Here you will need reliable fireproof metal products. In addition, you will need to make very correct calculations.

It must be added that steam boilers operating in the heating system of an apartment or house, especially gas boilers, must be equipped with a safety unit. This is not just a stove or fireplace, and everything is connected with high-temperature steam, which is supplied to the system under pressure. Thanks to this, the automatic control system is an important and mandatory component.

Of course, it is impossible to say that every person can make a steam apparatus with his own hands. But everyone is simply obliged to know the working principle of the device, its design features, subtleties of operation and other points. This can be attributed to those who have decided to install this model in their home.

The operating principle of pyrolysis boilers and their features

By creating pyrolysis boilers with their own hands, people strive to save money in their wallet. If gas equipment is quite cheap, then solid fuel units are simply amazing in their price. A more or less decent model with a power of 10 kW will cost 50-60 thousand rubles - it would be cheaper to install gas if there was a gas main nearby. But if it is not there, then there are two options - purchase factory equipment or make it yourself.

It is possible to make a long-burning pyrolysis boiler with your own hands, but it is difficult. Let's first figure out why pyrolysis is needed in general. In conventional boilers and stoves, wood is burned in the traditional way - at high temperatures, with the release of combustion products into the atmosphere. The temperature in the combustion chamber is about +800-1100 degrees, and in the chimney - up to +150-200 degrees. Thus, a significant part of the heat simply flies out.

Direct combustion of wood is used in many heating units:

Solid fuel pyrolysis boilers can use several types of fuel, including waste from wood processing and agricultural processing.

- Solid fuel boilers;

- Stoves-fireplaces;

- Fireplaces with water circuits.

The main advantage of this technique is that it is simple - it is enough to create a combustion chamber and organize the removal of combustion products outside the equipment. The only regulator here is the blower door - by adjusting the clearance, we can adjust the intensity of combustion, thereby influencing the temperature.

In a pyrolysis boiler, assembled with your own hands or purchased in a store, the process of fuel combustion proceeds somewhat differently. Firewood here burns at a low temperature. We can say that this is not even combustion, but slow smoldering. In this case, the wood turns into a kind of coke, simultaneously releasing flammable pyrolysis gases. These gases are sent to the afterburning chamber, where they burn, releasing a large amount of heat.

If you think that this reaction will not give much effect, then you are deeply mistaken - if you look into the afterburner chamber, you will see a roaring flame of a bright yellow, almost white color. The combustion temperature is slightly above +1000 degrees, and more heat is released in this process than during standard wood combustion.

In order for a self-assembled pyrolysis boiler to show maximum efficiency, firewood with a low moisture content is needed. Wet wood will prevent the equipment from reaching full capacity.

The pyrolysis reaction is familiar to us from our school physics course. In the textbook (and maybe in the laboratory office), many of us saw an interesting reaction - wood was placed in a sealed glass flask with a tube, after which the flask was heated over a burner. After a few minutes, the wood began to darken, and pyrolysis products began to come out of the tube - these are flammable gases that could be set on fire and observe a yellow-orange flame.

A do-it-yourself pyrolysis boiler works in a similar way:

Pyrolysis boilers operate for about 4-6 hours on one load of fuel. So it’s worth taking care of a large and steadily replenished supply of firewood in advance.

- Firewood is lit in the firebox until a stable flame appears;

- After this, the access to oxygen is blocked, the flame goes out almost completely;

- The blower fan starts and a high-temperature flame appears in the afterburning chamber.

The design of a pyrolysis boiler is quite simple. The main elements here are: a combustion chamber in which firewood is stored, and an afterburning chamber in which pyrolysis products are burned. Heat is transferred to the heating system through a heat exchanger

In the pyrolysis boiler design, special attention is paid to it

The thing is that the heat exchangers in pyrolysis boilers, assembled with your own hands, are arranged differently from those in gas equipment. Combustion products with air pass here through many metal pipes washed with water. To increase efficiency, boiler water washes not only the heat exchanger itself, but also all other components - a kind of water jacket is created here, which removes excess heat from the hot elements of the boiler unit.

Making a homemade steam boiler

Many owners of comfortable apartments in the city dream of replacing them with a personal home. After all, modern housing outside the city limits is in no way inferior in terms of comfort to apartments in megacities. And many begin to make their dream come true by purchasing new country houses.

Naturally, a newly built house must have not only water supply and sewerage, but also a heating system. The cheapest and fastest option for good home heating is steam heating. This can be explained quite simply. First of all, due to the fact that it is not very difficult to assemble a steam boiler with your own hands.

This can be done by anyone who has a desire, even those who do not have certain knowledge. Secondly, this type of heat supply is good, it has been tested in operation. And, finally, a homemade steam boiler will cost the owner significantly less than purchasing very expensive foreign equipment. In addition, there are also certain advantages of this type of home heating, which will be discussed below.

Arguments for"

The steam method quickly heats the air in the house.

A wood burning system is a more economical option than gas or electricity.

It is not necessary to demolish the stove, since in addition to the expenditure of effort and time, major repairs may be required.

Due to the absence of mechanisms, any adjustment is carried out manually, which means that the equipment will not break down or malfunction.

This is an option for a dacha or country house, since the presence there is seasonal, and fuel can be stocked up in advance. The heating will not turn off due to bad weather, non-payment of electricity or gas.

Even if the furnace itself is located in a neighboring building, it is possible to install a steam system. The main thing is to take care of thermal insulation.

How to do this is clearly shown in the following video:

Demand for steam heating

This type of creating comfort and warmth in the house with the help of steam was and remains very common in our country. Steam heating for a private home is distinguished not only by its availability and commonality, but also by its efficiency. The main feature of this design is the use of superheated steam as a coolant. In this case, the heat source is either a steam apparatus purchased through a retail network or a homemade steam apparatus.

This device is used to produce superheated hot steam under pressure greater than atmospheric. It is formed using heat energy, which is released when fuel is burned in a specialized chamber.

To create this design yourself, no fundamental knowledge is required. But, still, have an idea about certain subtleties first of all.

In most cases, the steam heat supply of a residential home consists of the following devices and components:

- Steam unit

- Stoyakov

- Pipe-wires

- Heating devices

This set of components is typical for a personal heating system. The heat is generated in it by a steam boiler, assembled and installed with your own hands, which can operate on almost any fuel.

Such heating can be created single-circuit or double-circuit. With the first option, only heating of the premises will occur; the second method also involves the preparation of hot water.

The piping system consists of vertical and horizontal components. The wiring can be lower or upper - it depends on the properties of the structure.

Of course, before creating such a heating system in your own home, you need to carefully analyze all its pros and cons.

The important advantages are:

- Affordable installation process and small size

- Fast warm-up

- Possibility of heating large areas and volumes

- Economy

- High heat transfer without heat loss

- Inability to freeze the system

The disadvantages usually include:

- Inability to change the ambient temperature in the house

- Aggressive effect on pipes

As you can see, such heating has more advantages than disadvantages. And the installation of the system done on our own further complements the list of good qualities.

Why steam is better

If you wish, you can make such heating in your home, but these systems are not very popular today. Rather, only a few resort to it. At the same time, both advantages and disadvantages of such systems can be identified.

Steam heating can be single-pipe or double-pipe

The advantages can be considered:

- Heating efficiency. She's quite tall. That's why even a small number of radiators is enough to serve large rooms. Sometimes you can even do without them by installing only pipes.

- Reduced inertia. It promotes rapid heating of heating circuits. Accordingly, as soon as a few minutes pass after turning on the boiler, the rooms feel warm.

- Almost zero heat loss. For this reason, such a system is beneficial.

- Opportunity to use relatively rarely. There is a small amount of liquid in the pipes, so there is no need to defrost the system. As an alternative, it can be used in a country house where people visit from time to time.

You can install steam heating in a private house with your own hands according to the scheme if you have some experience. The main advantage here is efficiency. From the very beginning, the installation requires modest costs. In the process of using the system, insignificant amounts are spent.

Heating system overview:

But even with such an impressive range of advantages, there are significant disadvantages. They are associated with the use of water vapor as a coolant: its temperature can be quite high. Accordingly, all system components warm up to +100°C and even more.

You should not touch such a surface even briefly, so as not to get burned. Therefore, any pipes and radiators must be closed. The air in such a room actively moves. When steam heating is used, the air becomes dry and you have to use a humidifier.

Not all finishing materials used indoors can withstand proximity to extremely hot radiators and pipes, so their choice is limited. The best option would be cement plaster, which is coated with heat-resistant paint. Everything else does not guarantee safety. In addition, steam passing through the pipe is a source of great noise.

The system is not well regulated. Heat transfer is uncontrollable, so the room easily overheats. The situation can be solved by installing an automatic system that will independently turn off steam boilers for a private home when they overheat and turn them on when the room cools down. Another time-consuming, but more realistic way is to install parallel branches that will work if necessary. The main disadvantage is the emergency hazard of the system.

If the pipe or radiator is seriously damaged, hot steam under pressure will escape. This is unsafe; such options are not used in apartment buildings. When planning to install steam heating, the owner of a private household can obtain permission for this, but only at his own responsibility.

We make an accurate calculation

The key structural element of the system is the heating apparatus. In order for all equipment to work with the greatest efficiency, it is necessary to make a good choice of steam boiler in terms of power. In this case, the area of the heated premises is taken into account.

There is the following relationship that must be adhered to when calculating a steam boiler:

- a power of 25 kW is enough to heat an area of up to 200 m2

- 25-30 kW corresponds to 300 m 2

- power 35-60 kW will heat up to 600 m 2

- 60-100 kW – up to 1200 m2.

Tags

Steam boilerhomemade steam boiler Boilers Steam boiler boilers for steam boiler automation. Steam boilerhomemade steam boilerassemble a steam boilerhomemade steam boilerThe popularity of steam heating with the help of steam was in the country. Steam heating, water steam. homemade steam apparatus. Steam heating Water heater Water heater coolant water steam.hot water.them water from Water treatment steam Water treatment for heating water prepared water.liquid water and

stepspipingfurnacematerialsinstallationcompartment

Design principle and production technology

The heating apparatus must include:

A steam boiler, the design of which is incredibly simple, is not very difficult to assemble with your own hands. The main component in this design is the drum.

The pipeline system is installed specifically to it, as well as safety devices and instrumentation, which make up the steam boiler automation circuit.

The design of the apparatus can be represented in detail by different elements. Liquid is supplied to the container located in its upper part by a pump. The lower pipes are directed to the bottom - they do not heat up. Through them, water from the tank is supplied to the collectors and then follows into the lifting wire of the pipes.

It forms heating surfaces located in the fuel combustion zone. The circulation system of such a device is based on the working principle of vessels that communicate with each other.

To create a working device with your own hands you will need:

- Pipes

- Sheet steel (stainless steel)

- Safety valve

- Asbestos

- Set of tools

- Welding machine

- Devices for measuring work

When starting work, you should first find and learn detailed drawings of such devices. Material must be prepared according to specific requirements. So stainless steel pipes should have a diameter of 100 to 120 mm, steel should be 1 mm thick, and the diameter of other pipes is 10 and 30 mm.

A piece of pipe, the length of which is at least 110 mm and the thickness of 2.5 mm, can be taken as the base of the boiler. They also make 12 smoke tubes (100 mm), and a fire tube, which is much larger in size.

Their length depends on the size of the device. The external and internal partitions of the boiler are made of stainless steel sheets. Holes are made in them for absolutely all existing tubes, which are fixed to the base using argon welding.

At another assembly step, the safety valve and manifold are welded to the body of the device. The thermal insulation of the unit is made from asbestos sheets.

A practical automation scheme for a steam boiler is designed to regulate its operation, remote control, thermal control, alarm and blocking.

Types of steam systems

Steam systems heat the room with steam, which is formed when water boils in the boiler. After formation, the steam goes into the pipes and then enters the batteries, which are installed throughout the entire area of the room. Typically the system consists of six components: boiler, exhaust valve, radiators, pipes, pump and firebox.

The systems are distinguished by high and low steam pressure. There are also vacuum steam boilers. The separation of boilers is influenced by the total length of pipes. Usually the distance from the boiler to the radiator, which is located at the farthest point, is calculated.

Types of pipework:

- Single-pipe. Steam and condensate flow through one pipe. The disadvantage of this type of wiring is constant extraneous sounds.

- Two-pipe. One pipe is designed for the passage of steam, the other for the resulting condensate. The pipes are closed in one cycle.

A two-pipe heating system is most suitable for heating a private house. Thanks to this type of wiring, simple temperature control can be achieved using a valve. In a single-pipe system, it is possible to regulate the temperature in this way only after reducing the power, and this entails underheating in the cold season.

Water treatment of steam boilers

Key disruptions to the good functioning of this type of heating equipment are caused by the formation of scale on the walls of the water supply system. To ensure trouble-free operation of the device, the water that enters the steam units must be purified in advance.

An important task facing the preparation of liquid for its subsequent use in the apparatus is to reduce its scale and corrosive activity. Destruction of heated surfaces and pipes occurs under the influence of carbon dioxide and oxygen entering the system with the liquid.

Water treatment for steam boilers can consist of both cleaning using chemicals and using an electromagnetic pulse. In the first option, substances are taken that prevent the appearance of scale and reduce the effect of rust on the internal surfaces. In the other, a field is formed that generates high-frequency vibrations that can prevent the appearance of scale.

Wood boiler installation

The simplest principle of wood boilers is to use the heat from the burned fuel to evaporate water.

For stable operation of the device, it must always contain fuel and oxygen as an oxidizer. Wood-fired steam unit design:

- The combustion device is located at the front of the boiler. It is equipped with a grate and is large in size.

- A cluster of pipes that perform the function of a convector connect both jackets of the device.

- The front plate is located on the front, as is the fuel loading door.

- A ventilation device is mounted on the door, designed specifically for a stable supply of oxygen to the oven.

On modern models of steam devices, the following are additionally installed:

- pressure gauge;

- column-water meter;

- safety valves that prevent leakage;

- control panel for measuring instruments, which send signals about any malfunctions and deviations in the operation of the device.

These devices are reliable, environmentally friendly and safe.

What to take into account when designing

The high price of other types of equipment is the main reason for attempts to build this device on our own. As we understand, this is not difficult to accomplish.

However, you need to understand that making such a unit with your own hands requires a preliminary correct calculation. Also, to do this you need the availability of refractory alloys, tools and equipment.

Steam units, especially those running on natural gas, must fully comply with safety standards. For this purpose, they are equipped with automated control systems.

Preparatory stage

Do-it-yourself wood-burning boiler drawings help you do this job. A simple device can be assembled with your own hands, without using complex installation equipment. The essence of the technology is to transform wood combustion into a smoldering process.

The diagram of a wood-burning boiler shows that there is an air gap between the inner and outer casing. A flow of cold air comes from below. It is heated by the walls of the inner casing, then rises up through the hole in the outer casing. The heated air heats the room.

Before making a homemade boiler, you need to prepare tools and materials, including:

- Sheets of metal 4–5 millimeters thick, or a 200-liter barrel, or a body from a used stove.

- Thick-walled pipe products.

- Metal fittings and corners.

- Fasteners.

- Welding equipment.

- Electrodes.

- Chisel and hammer.

- Bulgarian.

- Drill.

DIY steam boiler

A steam boiler is one of the most popular and widely used types of heating units. The main structural part of the unit in question is the combustion chamber. It burns the loaded fuel with intense release of thermal energy. The resulting heat is used to heat the water with the future release of steam. Steam is used for various industrial and domestic needs, especially home heating. At the same time, you can easily manage the manufacture of the simplest boiler with your own hands.

DIY steam boiler

Contents of step-by-step instructions:

Steam generator

Steam generators are types of steam boilers equipped with additional elements. In particular, the design of such a device may include several intermediate superheaters, which can greatly increase the power of the equipment.

Steam generators are most often used in nuclear power plants. The use of steam allows the energy generated by the decay of atoms to be converted into electricity.

Steam in nuclear reactors can work as follows:

- Water surrounds the outside of the reactor vessel, receiving its thermal energy. Steam is generated in its own circuit located outside the reactor. A steam generator in a similar design performs the function of a heat exchanger.

- The second scheme involves placing pipes for heating water in the reactor itself. As a result, it turns out that the reactor turns into a kind of combustion chamber, and the generated steam is sent directly to the electric generator. This design is called a boiling reactor and does not require the installation of a steam generator.

Conclusion

Steam boilers are quite powerful and efficient devices that are indispensable in a number of situations. Domestic steam boilers make it possible to warm up a house or perform some kind of work, and industrial units make it possible to generate electrical energy in huge quantities. In any case, to effectively solve the problems, the purpose and design of the boiler must correspond to each other.

A device for producing high temperature water steam is a steam boiler. In this case, the pressure of the water inside the boiler in a gaseous state significantly exceeds atmospheric pressure. Heating of water occurs as a result of the release of thermal energy due to the combustion of any fuel. Despite the fact that currently steam boilers have different designs and can be used for both industrial and domestic purposes, they have the same operating principle.

The latest two-pass boiler with reversible combustion chamber

Design Features

The design of the boiler in question is based on a kind of drum. Pre-prepared water is supplied to such a piece of equipment using a system of pumps and pipes. The compartment at the bottom of the boiler contains downcomers. Such elements have different diameters and do not heat up during boiler operation. Through a pipe system, liquid from the drum passes into the collectors. The latter are very often located at the bottom of the boiler.

The collector is connected to the drum using a lifting pipeline. Due to the pipeline, heating surfaces are created at the place of combustion of the loaded fuel.

A system of pipes and wires is connected to the steam generator, operating according to the mechanism of communicating vessels. A mixture of liquid water and superheated steam moves in hot pipes. This mixture has a fairly low density, which allows it to easily flow into the separator compartment, where zoning of steam and water occurs. The liquid component is sent to the steam boiler drum.

The steam passes into the steam line, and then into specialized heaters, where the pressure and also the temperature of the steam increase to the required values. Once completed, the steam is directed to the required steam turbine.

Making a steam boiler

Work technology

If the house does not initially have a stove, then you first need to partially open the floors to place the foundation, lay the foundation, and cover it with roofing material.

The first row is laid on waterproofing. The following are placed in order, controlling the vertical with a level or plumb line. Fire-resistant wire is inserted at the door installation sites, tying the door contour.

The firebox is laid out according to the previously described technology.

The chimney is made of two layers. A metal pipe is installed as a base, and the outside is tied with thermal insulation. All that remains is to lay bricks around it, leaving space for the damper.

For safety, each connected radiator is equipped with shut-off valves and air release valves.

Mayevsky tap on the radiator

At the beginning of the heating system, a cooling reducer and pressure reducing valve are installed, and a condensate tank is mounted at a slight slope. The liquid from it will be directed to the heat exchanger. A circulation pump is installed in front of the furnace.

Types of steam boilers

There are several variations of steam boilers. They are divided accordingly with the following characteristics:

- a method of moving a mixture of steam and water. Accordingly, with this parameter, the equipment is divided into boilers with forced and real movement;

- method of condensate return: open and closed devices;

- the nature of the movement of the coolant: gas-pipe and water-pipe units.

Gas-pipe and water-pipe heating equipment have different designs and performance. The category of gas-pipe equipment includes boilers in which gas movement is carried out in flame and smoke tubes. As they move, the gases heat the water in the system. The tubes rest on edges on the sides of the combustion chamber.

In water-tube equipment, water flows through tubes. In this case, gases wash the pipes from the outside.

The boilers in question can use solid fuel, as well as fuel oil and gas.

An example of organizing steam heat supply

Manufacturing instructions

When starting the production process, you need to start by preparing all the essentials:

- Pipes with the following diameters - 30 cm, 5-6 cm, 10 cm (the wall thickness of each is at least 3 mm)

- Steel sheet with a thickness of more than 4 mm

- Bulgarian

- Welding machine

- Hand tools

It is recommended to place the boiler on a level, hard surface. If such an installation will be installed at home in a boiler room, you should think about arranging the foundation, a few words about which will be said later.

Let's start making the boiler:

- Take a pipe suitable for its characteristics and cut off a piece from 70 to 100 cm. A short length will not allow you to load a sufficient amount of firewood, a large length will make loading extremely inconvenient

- Now you need to build a distributor. In order for it to move freely, its diameter is made 15-25 mm smaller than the main pipe

In the center of the circle you need to drill a hole with a diameter of 15 mm - air will flow through it into the combustion chamber. To ensure that the disk does not fit tightly to the panels and there is space for air circulation, it is necessary to weld an impeller to its inner side - several plates up to 5 cm high

A pipe with a diameter of 5-6 cm is welded in the center of the regulator, while its height is made 10-15 cm larger than the boiler. As mentioned earlier, it is recommended to make a damper at the top, which will allow you to adjust the draft at any time, thereby controlling the smoldering process. A door is cut out at the bottom with a grinder, through which ash will be removed

Also, the bottom is securely welded at the bottom of the boiler. At the top it is necessary to run a horizontal chimney pipe with a diameter of 8-10 cm and a length of no more than 40 cm (this is what is passed inside the heat exchanger)

The finishing touch of the design is the boiler lid, in which a hole is cut for the air intake pipe. It should lock the camera as tightly as possible

A good alternative to firewood is heating briquettes - see our review

Chimney and reflector

The walls of the boiler will constantly heat up and radiate thermal energy. If the installation is installed to heat a small room, reflectors should be placed around it - they will distribute the flow, increasing the heat flow inside.

If the oven will be located in a room where people are constantly present, you should think about their safety. One solution to the problem is to cover the structure with brickwork.

The chimney can be made from a 20 mm pipe. The horizontal straight section should be 5-10 cm larger than the diameter of the combustion chamber. It is necessary to take it outside with a minimum number of bends - 2 x 45 degrees.

A few other features:

- It is recommended to make the chimney collapsible so that it can be easily cleaned of soot 2-3 times a season

- The chimney sections must be connected in the direction opposite to the gas movement

- All structures and objects that are easily flammable must be kept at a safe distance

We are building the foundation

It can be assumed that a long-burning wood-burning stove will constantly heat up to high temperatures. A simple leveled floor is not the best solution for it - a foundation should be built.

The base can be made of burnt brick or rubble. They do not heat up when exposed to elevated temperatures. All those who want to make a more solid foundation can pour a solid monolithic slab.

The boiler can also be installed on legs, which can be easily welded from channel wood. They hide from view behind brickwork.

Using the boiler

Unlike a classic stove, air must enter a long-burning wood-burning boiler in a certain quantity. To achieve this, the filling must be done in full, trying not to leave any free cavities. It is recommended to add sawdust, pellets, peat or combustible waste to the logs.

Fuel must be added according to the following instructions:

- Remove the cap and remove the regulator from the tank

- Pack the fuel tightly

- Spray flammable liquid on top

- Install the regulator, cover with the lid and open the damper

- Throw a splinter into the air pipe and when it starts to smolder, close the damper

Let's sum it up

A simple long-burning wood-burning boiler is ready. You can install such a structure in any unheated room: from a small garage to a workshop. If everything was done correctly, there will be no doubt about the efficiency and high efficiency.

How does a stereotypical steam heating boiler keep working?

Heat is generated in the combustion chamber. Subsequently it arrives at the heating surfaces. There are 2 types of heating surfaces: convective and radiation.

Working principle of steam boiler

The composition of convective surfaces includes the following elements:

- air heaters;

- economizers;

- heat exchange devices.

The listed additional equipment is necessary to increase the efficiency of the boiler, rationalize fuel consumption and reduce the level of heat loss.

The main thing is that the water used to operate the boiler is exceptionally clean - impurities are not allowed. Due to this, before being fed into the boiler, the liquid is first cleaned of gases and various types of impurities, ultimately becoming nutritious.

The purified liquid is sent to the economizer. A specialized pump helps her do this. In the economizer, a liquid heat carrier is heated under the influence of gases. Then the liquid passes into the upper compartment of the drum compartment. Here the boiler water is mixed with the nutrient liquid.

Some water volume passes from the upper compartment of the drum compartment to its lower compartment. The movement of water is carried out through boiling tubes.

At the top of the steam boiler, the gases have a lower temperature, which gradually becomes higher as they approach the lower compartment of the unit.

The water is heated and everything, together with a mixture of steam and water, is sent to the upper chamber of the drum.

The second part of the liquid from the upper drum compartment goes for redistribution. The water in the boiler is heated. The resulting steam bubbles go to the upper compartment of the drum compartment.

In the upper chamber of the drum, due to the separator, almost complete zoning of the mixture of liquid and steam occurs. As a result, juicy steam is formed, which helps to further increase the beneficial effect of the boiler. It is this juicy steam that is used by the end consumer.

In order to increase the efficiency of boilers, their operation is organized in such a way that in the upper chamber of the drum compartment the level of “low” and “high” water fluctuates. Between the mentioned liquid levels there is a reserve water reserve, which is designed to maintain the operation of the heating unit in the event of a stoppage of liquid flow into the system.

The possible “highest” liquid level in the drum compartment is determined based on the fact that water does not enter the superheater.

The maximum possible “low” level of liquid in the drum must be calculated in such a way as to prevent overheating of the upper compartment of the drum, as well as the boiler bundle. The main thing is that water enters the lowering tubes in a stable volume.

To further increase efficiency, the design is equipped with an air heater.

The liquid in the system can circulate forcibly and naturally. Natural movement is based on the difference in density between the liquid and the vapor being created. The mixture of water and steam in the rising tubes has a lower density than the similar composition in the descending tubes. However, the pressure reading and temperature reading remain similar throughout the tube. Eventually the steam, which is a gas by nature, rushes upward.

Forced circulation is provided by specialized pumping equipment.

Scheme for transferring a steam boiler to water heating mode

Tips and tricks

It is recommended to periodically clean the chimney to remove soot accumulation. To ensure that condensate flows smoothly along the return line, the stove should be assembled as low as possible, preferably in the basement.

The installation of valves cannot be ignored in order to prevent an emergency.

Cover all flammable materials on walls, floors, and ceilings with a safe coating to prevent fire.

At the stage of drawing up diagrams and calculating the amount of materials, seek advice from professionals. Hire an experienced welder to ensure all seams are solid and strong.

You should not leave the damper open: the house will cool down.

An example of a hand-made heat exchanger is discussed in the following video:

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...

Assembling a conventional steam heating boiler

If you wish, a simple boiler can be assembled with your own hands. A home-made device will have a somewhat simplified design when compared with factory-assembled equipment, but this will in no way affect its efficiency and efficiency.

Boiler assembly kit

Before you begin, prepare the following items:

- pipes of various diameters;

- stainless steel sheets;

- sheet asbestos;

- safety valve;

- hacksaw;

- ruler;

- roulette;

- chisel;

- hammer;

- welding machine;

- file.

Is it worth designing a gas boiler yourself?

A home-made gas boiler will not be allowed into operation, even if its assembly is perfect and no worse than the factory one; this is required from regulatory authorities by regulations on the rules for the safe operation of gas equipment.

Therefore, when choosing the type of fuel for a homemade boiler, gas and heating oil should be abandoned immediately. Solid fuel boilers using coal, firewood, pallets and electric boilers are considered the safest heating units; it is quite possible to make them yourself.

A homemade heating boiler will cost the owner much less than a factory one, but it will work less economically and with lower efficiency. In order to increase these indicators, it will be necessary to increase the heating surface of the boiler, for which a heat exchanger is installed in addition to the water jacket.

Also, the efficiency of heat transfer in the boiler is affected by the coolant circulation rate. With natural circulation, an expansion tank and large diameter pipes are installed. However, better hydraulic conditions can be achieved using forced circulation by installing a circulation pump in the heating circuit on the return line in front of the boiler.

Assembly of the unit

The work of making a boiler yourself is done in a couple of simple steps. Do each step of the instructions gradually, while looking at the drawings and diagrams.

Step one. Set good dimensions for the upcoming steam boiler. The size of the equipment determines its performance. Please clarify this point individually, taking into account the specifics of your own situation.

At the same step, prepare all the necessary drawings. If you wish, you can choose to have them compiled by a specialist or use ready-made drawings from open sources.

Second step. Prepare related materials. Previously, a list of required components was provided. First of all, purchase pipes with a diameter of 32 mm and 12 mm. Stainless steel sheets must have a thickness of about 2-3 mm.

3rd step. Prepare the boiler body. A good option is to weld the body without outside help from sheet metal. Choose the dimensions of the case personally, according to your own needs.

Fourth step. Make the base of the boiler. It used to be said that the design of steam boilers is based on a system of interconnecting pipes. First of all, prepare a piece of pipe about 11 cm long with a wall thickness of approximately 3 mm.

Cut a pipe 11 cm in diameter into 12 components - they will perform the functions of flame tubes. Cut the larger pipe into flame tubes.

Choose the length of the pipes according to your diagrams.

Fifth step. Make the required number of bulkheads and walls of the steam boiler. To do this, use stainless steel sheet type.

Sixth step. Prepare holes in the walls of the unit to locate the flame and flame tubes. Connect the mentioned parts in flared form to the boiler base. A welding machine will help you with this. At this step, you also need to focus on the inherent drawings and diagrams.

Seventh step. Attach the safety valve and steam manifold to the unit body. You will subsequently release the last steam through the valve.

Eighth step. Make thermal insulation of the boiler using asbestos sheet.

Steam generator connection diagram

Similarly, having understood the key provisions of the instructions, you will be able to assemble a simple steam generator with your own hands and include it in the heating system of your home. At each step of the work, you need to focus on your own drawings, because It is unrealistic to understand the order of assembling the unit using textual advice alone.

Ways to reduce gas consumption

To understand how to make a gas boiler more economical, you should analyze not only the characteristics and condition of the unit, but also consider the conditions of the heated area. In addition, to ensure that the gas device does not increase fuel consumption, it is necessary to timely clean its components from soot and burning, and heat exchangers from scale.

Gas boiler power

The first thing you need to pay attention to is whether the power of the installed unit matches the heated area. It’s bad if there is not enough productivity or there is a significant excess of it

If the power of the unit is not enough to heat a given room, it will constantly work at the limit of its capabilities, consuming a lot of fuel. This operating mode will shorten the service life of key boiler components. In addition, if there is insufficient power, the unit will not be able to provide high-quality heating of the home. The situation can be corrected using drastic methods - reducing the number of heated rooms or installing an additional gas appliance.

A situation where the power of the unit is more than 20% higher than optimal for a given room is also undesirable. Otherwise, the gas boiler will turn on and off too often - this is called “clocking”. It turns out that the unit heats the coolant too quickly to the set temperature, after which it immediately turns off. In this mode, some radiators will remain unheated, and equipment wear and gas consumption will be high. In this case, the unit should be switched to a lower operating mode.

Insulation of the house

The degree of insulation of a house or apartment is of significant importance in saving gas. If the building is not insulated, and the doors and windows are ventilated, a significant part of the heat will go outside. The material of the walls of the house also matters. For example, wood and block transmit heat faster than double brickwork.

Good insulation of the ceiling, floor and walls will save a lot of fuel. It is advisable to replace old frames with energy-efficient double-glazed windows, and wooden doors with a more airtight modern analogue. A well-insulated building will save up to 30% on gas.

Particular attention should be paid to insulating the attic and basement, since a lot of heat also escapes through them. Note! To increase the energy efficiency of your home, you can install reflective screens made of aluminum foil between the radiator and the wall; they will allow you to return some of the heat to the room

Note! To increase the energy efficiency of your home, you can install reflective screens made of aluminum foil between the radiator and the wall; they will allow you to return some of the heat to the room

Installation of modern automation

Thermostats that automatically maintain a given heat level help save fuel. There are a lot of different options on sale to suit every budget. These devices set the desired room temperature, and it is maintained using sensors. If the temperature in the room drops by at least a quarter of a degree, the sensor will signal the gas boiler to turn on. After reaching the desired temperature, the unit will turn off. This mode of operation will save up to 20% of fuel.

The disadvantage of a thermostat is that it allows you to maintain a given heating level in only one room. But new thermoregulation models have appeared that are equipped with outside temperature sensors. When it gets warmer outside, a signal is given to reduce the burner flame.

One of the most profitable heating options is the “warm floor” system. The coolant in it usually has a temperature of 30-45°C. To maintain coolant heating at this level, the system does not require a lot of fuel.

Conditions for safe operation of the boiler

The boiler must be not only practical, but also non-hazardous. The key to good and good functioning of a steam heating boiler is maintaining a given level of heating of metal elements.

In view of this, the coolant must constantly circulate from inside the heated tubes with simultaneous cooling of the heating surfaces. The main thing is that the coolant stably removes heat from the pipe material, which is heated under the influence of flue gases. If heat removal is insufficient, the metal will simply overheat, become less strong, and the efficiency and safety of the equipment will decrease. In the worst case, the pipes will simply burst.

Constantly monitor the operation of the boiler. Correct all damage immediately after finding it. Even a very small flaw can quickly lead to a significant decrease in the efficiency of the unit and a deterioration in the safety performance of the system. Water will come out of the drum, steam will make its way into the lowering tubes, the drum and tubes will heat up very much, and an accident will occur.

Also, you, as the owner, must ensure that all structural elements and equipment used are of exceptionally good quality.

Features of operation

The operation of steam boilers requires careful water treatment, regular cleaning of the furnace and control of the operation of the device.

- Preparation of water used in boiler operation. Each water contains mineral salts to a greater or lesser extent, which, as a result of heating, form scale on the surfaces of the boiler. As a result, not only does the heat transfer of the burning fuel to water deteriorate (the efficiency of the boiler sharply decreases), but depressurization of the pipes may also occur as a result of their burning out. Therefore, before supplying water to the boiler, it is cleaned of salts by adding special reagents, for example, sodium zeolite. It is also necessary to remove oxygen dissolved in water, since it contributes to pipe corrosion.

- Removal of ash on the outer walls of the firebox should be carried out periodically (as it accumulates).

- Currently, the operation of steam boilers is controlled by automatic systems built on semiconductor electronic circuits. At home, the operation of the boiler (starting, turning off and adjusting fuel consumption) is controlled manually.