Boiler installation

It is unacceptable for the boiler body to be adjacent to any of the walls, so redo the fastenings of wall-mounted boilers, recess the boiler into a niche, etc.

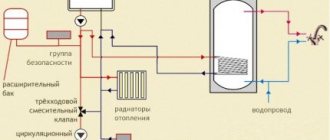

it is forbidden. After installing the boiler in place, its piping is done - connecting three systems: gas, hydraulic and electric. The gas connection should be done, as indicated, by a gas specialist, and last but not least, when everything else is already connected. You can do the electrical and hydraulic connections yourself. The main guiding document here is the instructions for the boiler. A typical boiler hydraulic circuit is shown in the figure. For any boiler, the following conditions must be strictly observed: water and hot gases in the boiler heat exchanger must flow countercurrently, otherwise it can simply explode with any automation.

Therefore, it is extremely important not to confuse, either through negligence or for the sake of ease of installation, cold and hot pipes. After hydropiping, carefully inspect the entire system again, then rest for an hour and inspect it again. If antifreeze has been poured into the heating system, drain it completely and rinse the system twice with clean water.

An admixture of antifreeze in the water entering the heat exchanger is also explosive. Do not neglect the “mud collectors” - coarse water filters. They should be located at the lowest points of the system. The accumulation of dirt between the thin fins of the heat exchanger also creates a dangerous situation, not to mention excessive gas consumption. At the beginning and end of the heating season, drain the sediment through the mud traps, check their condition and, if necessary, flush the system. If the boiler has a built-in expansion tank and a deaeration system, remove the old expansion tank and turn off the old air valve tightly, having first checked its condition: air leakage will also create a dangerous situation.

Installation of a gas boiler in combined kitchens

In modern construction, the arrangement of studio apartments or layouts in which the living room and kitchen are combined into one large space is actively practiced. Of course, such a solution has a lot of advantages - for example, it opens up a large portion of free space, which is perfect for implementing all kinds of design ideas.

The problem is that gas services regard such layouts as residential, so the installation of any gas equipment in them is prohibited. In studios this problem cannot be solved, but when combining a living room with a kitchen, options are possible.

Boiler room requirements

To use gas equipment with a power of 30 kW or more, you will need a separate room that complies with all current rules and instructions.

Most often, one of the rooms in the basement or basement is equipped as a boiler room. True, such an installation of a heating unit is permitted only for single-family residential buildings.

In a private household, the rules for installing a gas boiler allow the use of equipment of any power, since most often it is placed in a separate room attached to the house, which makes it possible to provide heat not only to living rooms, but also to utility rooms.

The important requirements that the boiler room must meet are the following:

- The minimum area for a gas boiler per unit is 4 m². At the same time, more than two devices cannot be placed in one room. This size of boiler room in a private house is required.

- The ceiling height must be at least 2.0–2.5 meters.

- To ensure natural light, it is necessary to have a window, the size of which is determined at the rate of 0.3 m² per 10 m³ of room volume for a gas boiler, but not less than 0.5 m². There is also a certain distance from the gas boiler to the window, from a safety point of view.

- The width of the doorway cannot be less than 80 centimeters.

- The minimum distance from the front door to the unit is 100 centimeters, but it is better if it is 130–150 centimeters.

- To create conditions for carrying out repair or preventive measures, a free space of at least 130 centimeters should be provided in front of the boiler.

- Correct installation of a gas boiler in a private home means that it is located in a horizontal position and stands stable. This allows you to minimize the level of possible noise due to vibration.

- The floor and walls must be made of non-combustible materials, in addition, the floor covering must be absolutely flat.

- Cold water must be supplied to the boiler room, and a sewer drain for the coolant must be installed in the floor.

- For electrical outlets, a ground loop must be made, since the ignition or pump is connected to the power supply.

- It is necessary to provide easy access to the chimney, or more precisely to the inspection window, in order to control the patency of the channels and clean them.

Useful tips

Even a well-calculated and constructed flue gas discharge channel can work effectively only with regular cleaning.

It is strictly unacceptable to use wood, plastic materials and polystyrene foam, any wallpaper and textile materials in the decoration of the boiler room. Emergency cooling valves that are independent of the electrical network can be of great benefit. If the coolant warms up to 95 degrees, part of it is redirected to the sewer, while the same amount of cold liquid is supplied inside. Without such devices, it is undesirable to operate high-power boilers. If it is decided to install a heat accumulator, then gravitational circulation must be ensured between it and the boiler. Even in a big city, not to mention remote areas, it is necessary to install uninterruptible power supply systems. They will help maintain the movement of the coolant even when the power supply is turned off. As soon as the supply is restored, the energy storage device will begin to charge. The required power of the backup device is 150% of the total peak consumption of all protected electronic components.

Tips for choosing a solid fuel boiler are in the next video.

Gas boiler in a private house - features

A gas boiler is the cheapest type of fuel, so many owners of apartments and country houses prefer this heating option. In addition, gas boilers have several advantages over other types of heating equipment.

- The gas boiler is safe to use. Modern models have a sensor that prevents the flame from going out. If this happens, the electronic system activates the spark and then the burner is re-ignited.

- A gas boiler has an excellent efficiency factor that exceeds even diesel ones. With minimal fuel consumption, they generate large amounts of heat.

- Gas boilers allow heating and providing hot water to large premises and industrial facilities.

Some clients ask us whether it is possible to install a gas boiler in an apartment? The answer is yes, it is possible. The main thing is to get permission, but this requires persistence and money. It is much easier and cheaper to install a gas boiler in a private home.

Stage one: boiler installation

Installing a gas appliance is usually not difficult. This is the simplest stage of installation of a heating system. Manufacturers have developed detailed installation instructions for each type of boiler.

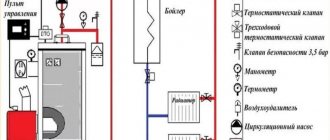

It is easier to install a floor-standing one, despite the fact that it is heavier in weight and larger in size. For wall mounting you need special brackets. They come included with the device. The diagram for connecting a wall-mounted boiler to the heating system is indicated in the instructions for the device

The most important thing is to choose the right location for installing the boiler, while also considering how the pipes will be connected to the boiler.

When choosing the location of the unit, not only ease of maintenance is taken into account. It is necessary to comply with the standards and requirements that apply to gas appliances. Their implementation guarantees the efficiency and safety of using the heating unit.

Two basic rules to follow:

- The room where the boiler will be installed must be provided with a window or window that can be easily opened if necessary.

- No devices or objects should be placed near the gas unit.

The connection diagram for a floor-standing boiler requires careful preparation of the base. The wall-mounted boiler is placed at a height of 80 cm from the floor, no closer than half a meter from the walls. These are standard operating safety requirements.

To know how to properly connect a double-circuit boiler, you need to become familiar with the conditions required for the installation of a chimney and ventilation system.

Turbo boilers greatly simplify the task because they do not require the installation of bulky chimneys and exhaust systems. This type of boiler is becoming increasingly popular today. The peculiarity of turbo boilers is the device for the forced removal of exhaust gases and the simultaneous influx of street air, like a “pipe in a pipe”. This is the safest system, as it allows you to install gas units in almost any room.

There is another type: floor-mounted parapet boilers. These are chimneyless, energy-independent units. They are used where it is impossible to build a large chimney. Parapet boilers have a closed combustion chamber, it is completely isolated from the room. In such boilers, the coolant circulates by gravity, without an electric pump. This is their main difference from turbocharged boilers with a coaxial chimney.

Reviews:

Object: Dacha - Mozhaisky district of SNT Khoroshilovo.

Task: Installation of heating from a solid fuel boiler.

Equipment: Solid fuel boiler, pump for the heating system, heating fluid, radiators, polypropylene pipes.

Customer review: “I contacted the VashKomfort company to install a heating system in my dacha. The guys did the job in two days. I liked everything, I'm very satisfied. I recommend. "

Antonina

Requirements for installing a boiler in the kitchen

The kitchen layout is carried out taking into account the requirements that apply to the installation of gas heating equipment. Current regulatory documents define:

- The presence of a door separating the kitchen and other rooms.

- Minimum requirements for window openings.

- The presence of supply and exhaust ventilation.

- Location of the socket, boiler pipes.

- Requirements for the smoke exhaust system.

Read also: Puff pastry buns with jam photo

The interior of a kitchen with a gas boiler on the wall or floor must strictly comply with current SNiP and sanitary standards. If gross violations are detected, a representative of the Gas Industry has the right to turn off the gas supply and impose penalties.

Do I need a door to the kitchen when installing a gas boiler?

The requirements for installing gas heating boilers in the kitchen stipulate that the room must be fenced off from the corridor and living rooms with a door leaf. It is strictly forbidden to replace the door with an arch.

Doors in a kitchen with a gas boiler installed should not have a lower threshold for unhindered air circulation. As an alternative, it is allowed to insert a convection channel into the canvas, covered with a decorative panel.

Do you need a window in the kitchen if there is a gas boiler?

The rules for placing a gas heating boiler in the kitchen, in particular SP 54.13330, stipulate the need for a window opening with an installed window. Strictly speaking, metal-plastic double-glazed windows with an opening window (without a window) are a violation of the norms

But usually representatives of the gas service do not pay attention to this

The window, like the convection holes in the door to the kitchen, is necessary to ensure continuous circulation of air flow

If you want to integrate a gas boiler into kitchen furniture, it is important to carefully choose the location so that it matches the direction of the circulating air. Convection holes are also made in the furniture facade

What should the ceiling be like in the kitchen?

According to this rule, it is not recommended to install a suspended ceiling in the kitchen if you plan to install gas-fired boiler equipment. The use of plastic panels is prohibited. It is recommended to use gypsum and cement-sand plasters with subsequent painting of the surface.

Where should the boiler socket be installed?

The distance from the gas heating equipment to the outlet is specified in the operating instructions. This requirement is controlled by Gaznadzor authorities. The electrical socket for the boiler should be installed no closer than 1 m.

Another requirement is the correct location of the refrigerator in the kitchen, relative to gas heating appliances. The minimum distance must be at least 30 cm. The gap is necessary for servicing the boiler.

How to remove a chimney from a kitchen for a gas boiler

In order to correctly position a gas boiler on the wall in combination with a kitchen unit, you will need to take into account the passage of the chimney. Boiler equipment is installed as close as possible to the place where the chimney goes out onto the street. This way, you can avoid the need to drill holes in the cabinets for the passage of the chimney.

The coaxial chimney is discharged through the wall. Atmospheric models are connected exclusively to a specially designed exhaust duct.

The requirements and standards stipulating the installation and placement of gas boiler equipment in the kitchen require strict compliance. To avoid mistakes, you should consult a gas service inspector.

Assembly and operation diagram

We haven't talked about this, but another feature of heating boilers is that there is a lot of metal in their construction. Consequently, such boilers will weigh a lot. It is for this reason that the assembly procedure should be carried out only where the boiler will be located in the future.

First, we make a foundation for the future boiler, using special heat-resistant bricks. When the solution dries, we install the bottom of the ash bin on the foundation. Next, along the perimeter of the bottom, we alternately place the inner walls of the heating boiler and weld them.

We have a ready-made building. We weld special guides inside it, to which heat exchangers and grate bars will later be attached. Stiffening ribs made from a metal rectangular profile are welded onto the outer part of the bunker. The ribs must be installed vertically.

Actually, that’s almost all, our boiler manufacturing procedure has smoothly approached its final stage. All that remains is to mount and install the top plate and the remaining outer walls.

Pre-prepared sand should be poured between these walls, which will perform two functions in the structure at once:

- Protect the walls of the combustion chamber so that they do not overheat and quickly burn out.

- Serve as an additional heat accumulator.

Important! A few words about the sand that will be filled up. To do this, you need to use well-washed sand, which does not contain dirt or organic elements.

Even before starting work, it should be heated in a flame - this is how you can burn out all the organic matter present from it. If you do not carry out a similar procedure in advance, then during operation of the boiler a characteristic unpleasant odor will form.

The top plate is installed. All manufactured stainless steel containers are installed on top of the stove and connected to the corresponding circuits of the system. That's all for sure now. All that remains is to replace the doors of both bunkers and try to start the solid fuel heating boiler with your own hands.

Not much about efficiency

As a small conclusion

So, we tried to figure out how to make and install a solid fuel boiler without resorting to the services of professionals. We have offered you some instructions and recommendations regarding manufacturing technology, as well as materials needed for work. If you strictly follow all our instructions for making your own heating device, then in the end you will get the most economical boiler, which will also be very inexpensive. Such a boiler, operating on solid fuel, is capable of providing comfortable living conditions, in which differences in night and day temperatures will be practically unnoticeable.

Where is it possible to install a gas boiler?

Installing a gas boiler in a house must meet certain requirements. Moreover, they are mandatory, regardless of whether it works for hot water supply or not.

1. The boiler should be installed in a separate room with an area of at least 4 m2, and the ceilings must be at least 2.5 meters. The rules also indicate the volumetric size of the room - at least 4 m3.

2. In a room with a boiler, an opening window or window is required. The door must be no less than 80 cm wide.

3. Interior decoration made of flammable materials is prohibited. Suspended ceiling technology is prohibited.

4. It is necessary to organize a constant flow of fresh air into the room. The inflow opening must be constantly open, and its cross-section must be from 8 cm2 for every 1 kW of the declared power of the heating equipment.

Please pay attention! In order to install a gas boiler in a house with a power of 30 kW, you need 8 m3 of free space. Further increase in power - for 31-60 kW 13.5 8 m3 should be provided, for 61-200 kW 15 m3 of free volume is required

In addition, for the operation of heating equipment of any type, the following standards must also be ensured:

- The exhaust pipe must be routed into a separate flue. Connection to ventilation ducts is prohibited.

- The horizontal flue should be no more than 3 meters long indoors. It is allowed to organize no more than three corners and turns.

- The flue exits the house vertically. The height is 1 meter greater than the highest point of the pediment.

- The chimney must be made of bases highly resistant to chemical and thermal influences. The use of a layered base (asbestos-cement pipes) is permitted only at a distance of 5 meters from the edge of the outlet pipe.

When connecting a gas boiler in the kitchen, the following requirements are also added:

- The hanging height of the boiler must be organized according to the following scheme - the lowest pipe should not be lower than the top of the spout at the sink. However, in any case, the height from the floor should not be less than 80 cm.

- There must be free space under the hung boiler.

- The floor under gas equipment must be covered with a metal sheet (size 1000 x 1000 mm). The requirements of gas workers and the fire service do not allow asbestos-cement coatings, because it wears off over time. On the other hand, the requirements of the SES do not allow the presence in the house of elements that contain asbestos.

- Premises with gas equipment should not have any cavities in which explosive mixtures or combustion products can accumulate.

As you can see, the rules strictly regulate the installation process. However, there is a justification for this, because... gas is a dangerous thing. That is why you can forget about installing a gas boiler if:

- You are the owner of an apartment in a multi-storey building (Khrushchev), which does not have a main gas duct.

- The kitchen has equipped false ceilings or heavily made wooden furniture.

- In the absence of privatization for the apartment. Only installation of a water heating device is possible. The thing is that redevelopment will be required, which only the owners are allowed to carry out.

In other cases, the installation of water heating boilers in apartments is permitted. Wall heating is allowed, but with floor heating there will be big problems.

A private house will be simpler in this regard. In such a case, there are no clear requirements for installing a boiler room in the house itself. You can build an extension that does not raise unnecessary questions.

In private housing, the best option would be to install a wall-mounted boiler. It will not require the installation of cunning protective structures.

Heating system calculation

Like all thermal calculations, this one is quite complex when done thoroughly. But we will present a very simple technique that allows you to determine the necessary parameters with fairly high accuracy.

Video

Calculation of heating of a private house

The initial data for the calculation are the following parameters:

- Area of heated premises. You should only use data on rooms in which heating is installed, that is, one or two walls of the house in contact with the street.

- Climate power. This parameter takes into account the location of the private house. So, for the southern regions it is 0.8-0.95, for the central regions - 1.3-1.6, and for the northern regions - 1.6-2.2.

The calculation for a room with an area of 130 square meters is as follows:

N = 130 x 1.2 / 10 = 15.6 (kW)

The calculation necessarily includes calculating the number of radiator sections. The following data is used for this:

- Area – only the rooms in which the batteries are installed are taken into account.

- The number 100 is determined from the SNiP requirement for the power of one section per square meter of area.

- The area is 30 square meters.

- The power of one battery section is 180 W.

N = 30 x 100 / 180 = 16.7 = 17 (pcs)

Calculation of the heating system using this method is quite reliable and suitable for practical use.