Here you will learn:

- Rules for arranging a combustion room

- Equipment installation rules

- Coordination of gas boiler installation

- Preparing to install a floor-standing boiler

- Chimney installation

- Installation of boilers in individual houses

- Connection to the heating system

- Connection to the gas main

- Conducting a trial run

Installing a floor-standing gas boiler has a lot of mandatory regulatory requirements. You must first obtain approval and technical conditions for installation. Then equip the room where installation is planned. Then install the boiler itself, connect it to the heating system and gas mains.

Rules for arranging a combustion room

According to current SNiPs, a gas boiler is installed only in a specially equipped room called a furnace room.

This rule cannot be neglected, since a gas boiler belongs to the category of potentially dangerous equipment and should be handled with extreme care. Otherwise, penalties will inevitably follow and emergency situations may arise.

The optimal option for installing a floor-standing gas boiler is to organize a boiler room, isolated from residential premises, equipped with a supply and exhaust ventilation system

First you need to calculate the power of the gas boiler, then determine the location for installing the boiler. The instructions allow the placement of single-circuit heating devices with a power of no more than 60 kW in any room of the building. Most floor-standing gas units are single-circuit, because... Designed for servicing heating systems only.

Dual-circuit models of any power cannot be installed in the kitchen. These are miniature boiler rooms with a built-in safety group and their own expansion tank. A furnace room is set up for them. If the total power of the equipment does not exceed 150 kW, it can be installed on any floor.

More powerful installations or groups of devices can only be installed on the ground floor or in the basement. In any case, gas heating boilers are prohibited from being installed in living rooms, bathrooms and toilets.

The room intended for the furnace must have certain dimensions. Its minimum volume can be calculated by the formula: 0.2 m³ multiplied by 1 kW of device power, but not less than 15 m³.

If the walls of the combustion room are made of flammable materials, they are covered with special fire-resistant linings

In addition, there are a number of requirements for the premises:

- the minimum width of the doorway should be 80 cm;

- minimum ceiling height – 2.5 m;

- degree of fire resistance is not less than 0.75 hours;

- the presence of natural light, which is calculated as follows: 0.03 sq. m of window area for every 1 cubic meter of combustion volume;

- the presence of a gas analyzer connected to an automatic valve that will shut off the gas supply in the event of a leak;

- arrangement of effective ventilation;

- the door or wall leading to the next room must be equipped with a ventilation grille, the area of which is determined by the formula: for every kilowatt of power of the heating device there are 8 square meters. see designs;

- ensuring free access to the heating device and auxiliary equipment for repair and maintenance work.

These requirements are strictly required to be met in the case of arranging a combustion room for a boiler with an open combustion chamber. For units with a closed chamber, the area of the room is not important and the ventilation requirements are less stringent, since for their operation they do not use air from the room, but take it from the street.

A gas duct is installed in the combustion chamber. Its horizontal section within the premises should not exceed 3 m.

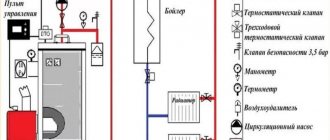

The installation process of a gas boiler largely depends on its design. The figure shows a general diagram of the design of such equipment (+)

In this case, the number of turns cannot be more than three. The vertical outlet of the chimney is raised above the level of a flat roof or a pitched ridge by at least a meter. The materials from which the structure is made must be resistant to aggressive thermal and chemical influences.

Multilayer materials, for example, asbestos-cement pipes, can only be used in areas more than 5 m from the exhaust pipe.

There should be no cavities or niches formed by horizontal surfaces in the combustion room. Combustion products can accumulate here, which is very dangerous for humans.

The space in front of the heating device must be free. The floor in front of it is covered with a metal sheet, the minimum size of which is 1x1 m. It is prohibited to use asbestos cement for these purposes, since it wears out quickly and is harmful to human health.

The predominant number of floor-standing gas units are designed to heat the coolant in heating systems with natural and artificial circulation types

Installation of a gas boiler in combined kitchens

In modern construction, the arrangement of studio apartments or layouts in which the living room and kitchen are combined into one large space is actively practiced. Of course, such a solution has a lot of advantages - for example, it opens up a large portion of free space, which is perfect for implementing all kinds of design ideas.

The problem is that gas services regard such layouts as residential, so the installation of any gas equipment in them is prohibited. In studios this problem cannot be solved, but when combining a living room with a kitchen, options are possible.

So, it is quite possible to call the room “kitchen-dining room” during the paperwork process. Thanks to this name, the combined room will not be considered residential, so you can safely install a gas boiler in it. Another option is the installation of a sliding partition between the rooms or a complete re-issuance of all certification papers.

Gas boiler location

A gas boiler in an apartment is usually placed in the kitchen, which is determined by the presence of all the necessary communications, and the distance from the gas pipe to the boiler is maintained without problems. As a rule, wall-mounted boilers are used for apartments, which are attached to the walls using special brackets that come with the equipment.

If the house has a staircase leading to the top floor, the owners have a desire to install a boiler under it. As a rule, the volume of space under the stairs is enough for a boiler, but there are problems with ventilation, so it has to be arranged separately using large-diameter pipes.

Deciding where to install a boiler in a private home depends on the format of the equipment and the requirements specified in the attached documentation. The passport for the boiler always indicates the required distances from the walls, ceiling and opposite wall, and you should definitely focus on these indicators.

Boiler room requirements

To use gas equipment with a power of 30 kW or more, you will need a separate room that complies with all current rules and instructions.

Most often, one of the rooms in the basement or basement is equipped as a boiler room. True, such an installation of a heating unit is permitted only for single-family residential buildings.

In a private household, the rules for installing a gas boiler allow the use of equipment of any power, since most often it is placed in a separate room attached to the house, which makes it possible to provide heat not only to living rooms, but also to utility rooms.

The important requirements that the boiler room must meet are the following:

- The minimum area for a gas boiler per unit is 4 m². At the same time, more than two devices cannot be placed in one room. This size of boiler room in a private house is required.

- The ceiling height must be at least 2.0–2.5 meters.

- To ensure natural light, it is necessary to have a window, the size of which is determined at the rate of 0.3 m² per 10 m³ of room volume for a gas boiler, but not less than 0.5 m². There is also a certain distance from the gas boiler to the window, from a safety point of view.

- The width of the doorway cannot be less than 80 centimeters.

- The minimum distance from the front door to the unit is 100 centimeters, but it is better if it is 130–150 centimeters.

- To create conditions for carrying out repair or preventive measures, a free space of at least 130 centimeters should be provided in front of the boiler.

- Correct installation of a gas boiler in a private home means that it is located in a horizontal position and stands stable. This allows you to minimize the level of possible noise due to vibration.

- The floor and walls must be made of non-combustible materials, in addition, the floor covering must be absolutely flat.

- Cold water must be supplied to the boiler room, and a sewer drain for the coolant must be installed in the floor.

- For electrical outlets, a ground loop must be made, since the ignition or pump is connected to the power supply.

- It is necessary to provide easy access to the chimney, or more precisely to the inspection window, in order to control the patency of the channels and clean them.

Equipment installation rules

Strictly follow all the rules and regulations of SNiP “Gas Distribution Systems” without deviating from them.

Any attempt to improvise or change classical technology may be noticed by inspectors.

And if this causes an accident or losses to other residents of the house, the owner faces administrative, and, in some cases, criminal penalties.

- If the boiler is wall-mounted, the floor under it must be perfectly level, since the pump pumping water can cause vibration and displacement of the boiler. If the vibration is strong, the gas pipes or water supply system may become disconnected from the boiler, leading to a gas leak or flood.

- If it is possible to make a stand for the boiler, this will secure the structure and increase the adhesion strength to the floor.

- If you install the boiler near a stove, boiler or other heating elements, then the total power of the thermal field between them will be higher than what the sensors show, since they measure this only inside the system itself. This rule is not specified in SNiP, but is often the cause of premature wear of the mechanism or failure.

Selection and equipment of premises for installation

In many ways, the choice of equipment and accessories depends on SNiP 42-01-2002 “Gas distribution systems”. This significantly narrows the range of choices, since a particular boiler may not be suitable for the selected room due to a discrepancy between the area and specific power.

IMPORTANT! SNiPs are regularly updated, and current laws amend them. It is necessary to check the legal framework immediately before installation.

Previously, for example, it was impossible to install a boiler in the basement of a house, but now it is possible if the house is single-family.

General requirements:

- The room should be well ventilated;

- The room should have window openings;

- The larger the boiler power, the larger the area.

Coordination of gas boiler installation

In order to install a gas boiler in a private house or apartment, it will not be enough to study the SNiP documents. First, you need to obtain technical conditions that will become the basis for organizing further work on connecting equipment to gas mains.

To do this, the home owner submits an application to the local gas supply service, which indicates the estimated gas consumption required for use in a particular building for heating and other needs. This parameter is calculated approximately on the basis of SNiP 31-02 standards, clause 9.1.3, which provides the average daily gas volume for a single-family house:

— gas stove (cooking) – 0.5 m³/day;

— hot water supply, that is, the use of a flow-through gas water heater (column) — 0.5 m³/day;

- heating using a household gas unit with a connected water circuit (for central Russia) - from 7 to 12 m³/day.

At the local organization that controls gas supply and installation of boiler equipment, the request is reviewed by specialists. A document with technical conditions or with a reasoned refusal is drawn up for the applicant. The review process can take from one week to a month, depending on the efficiency of the control service.

If the request is satisfied, then technical conditions are issued, which must be fully implemented when installing gas equipment. This document will simultaneously serve as a permit to carry out the relevant work.

You need to know for sure that installing gas equipment without obtaining technical specifications is illegal. In addition, unapproved independent installation of a boiler is very unsafe, especially in cases where such work will be carried out in a multi-story building. Unfortunately, there are plenty of sad examples of this.

Kinds

Floor-mounted double-circuit gas boilers are different. Let's take a closer look at the varieties of such units.

With a closed combustion chamber

Heating boilers with a closed combustion chamber (turbocharged) have the following distinctive characteristics:

- They have a forced air intake, powered by a fan (turbine). This component removes carbon dioxide and takes in fresh air. The turbine operates all the time, so such units operate quite noisily.

- These models have a built-in burner. It is a modulated device. Automation adjusts the burner power level to the specific heat requirements of the area, as well as the performance of the gas supply/heating system.

- These types of boilers operate in two main directions - “winter” and “summer”.

- Closed-type equipment can be installed not only in private houses, but also in apartments in multi-apartment buildings. They are closed with a box and built into a furniture ensemble.

With open camera

Such units have a fairly simple design. In them, the burner is located directly under the heat exchanger. As fuel burns, fresh air is drawn from the room.

Equipment with an open burner is otherwise called atmospheric and has the following features:

- In it, air is taken in as gas is burned. The work uses air masses that come directly from the boiler room, which places greater demands on the location of the apparatus.

- These types of boilers are characterized by high efficiency (about 92%). Currently, there are quite strict standards that limit the possibility of installation and location of these units. For example, you should know that under no circumstances should you cover an atmospheric device with decorative stone or panels, and its installation is only allowed in a room with an area of at least 9 square meters. m.

- Such units have two burners - the main and pilot. Thus, the pilot burner operates continuously. The combustion intensity of the main element is regulated by turning the burner on/off.

Condensation

Such boilers are the most economical among the huge range of heating equipment powered by gas. Such units are characterized by a very high efficiency rate - 108 and 109%. Such a device works by using the heat emanating from gases.

Burnt gases leave such a device as follows:

- During fuel combustion, the dew temperature is constantly maintained. Because of this, the heating of the coolant varies from 60 to 70 degrees. Maintaining the temperature at the dew point provokes the active formation of moisture, which is contained in the flue gas.

- The smoke, which contains a lot of moisture, is sent to a condenser, which is necessary to accumulate heat stored in the heated steam.

- Condensation leads to additional heat energy (approximately 15-16%).

- After heat transfer, the smoke is sent directly into the chimney.

Gas floor-standing boilers are also divided into energy-dependent and electricity-independent.

Volatile devices have a special piezo ignition that must be started manually. The mechanical automatic system is connected to a thermal couple, which is responsible for generating low potential voltage. In this case, the power regulator is based on the principle of thermal expansion of metals. Such operation of thermal equipment is completely energy-independent - it does not need to be connected to the network.

Devices that depend on electricity most often have a closed combustion chamber. In them, the burner is equipped with electric ignition, and startup occurs thanks to a special key. The automation in such models is based on a microprocessor, which gives a signal to turn the burner on or off, as well as fire modulation. In addition, an automatic system of volatile units is responsible for controlling the intensity of fan rotation.

Preparing to install a floor-standing boiler

Before connecting a floor-standing gas boiler, you need to prepare tools and materials. You will also need to study the unit installation instructions and operating manual.

Materials and tools you need to have on hand:

- cement and sand;

- shovel;

- container for preparing the solution;

- drill;

- hammer;

- bolts and nails;

- wooden edging;

- pipes for the flue.

You can begin installing a gas appliance only after preparing the place for its location. The floor heating unit must be installed on a concrete base. The screed can be replaced with a flat metal sheet. It is placed under the legs of the boiler so that it protrudes onto the edges of the unit by at least 30 centimeters. The floor-standing unit must be absolutely level.

In apartments located in multi-storey buildings or in individual developments, boilers with a closed combustion chamber are installed, and a coaxial chimney is led to the street through the wall of the room. The hole for the flue, depending on the boiler model, is located either on its rear wall or on the top panel. As a rule, it is located at the back and thus the chimney can be easily brought out through the wall.

Features of different strapping schemes

The coolant moves through the pipeline due to the slope of the system or is forcibly pumped by a circulation pump. Depending on this, the boiler piping scheme is selected.

Method 1: strapping in gravity systems

Piping a boiler in a gravity heating system is simple and can be installed by anyone who knows how to use tools. The coolant moves in accordance with physical laws.

This does not require any equipment. The operation of the system does not depend on electricity, so a sudden shutdown will not affect the quality of heating.

Piping the boiler will cost minimal money, because... you don’t have to buy additional devices or pay a team of craftsmen for installation. The operation of such a system is also cheap, and breakdowns can be corrected independently.

You can install the boiler piping in a gravity heating system with your own hands, but it is not always possible to do it flawlessly. If errors are made when calculating the diameter and the heating does not work well, the situation can be corrected by installing a pump

The only negative: this scheme can only be used for a small house. In addition, you will have to carefully calculate the diameter of the pipes and double-check the data repeatedly, otherwise normal heating of the house cannot be guaranteed. A large diameter pipeline spoils the interior and is difficult to disguise.

Method 2: connecting the boiler with a circulation pump

Systems with pumping equipment are easier to manage than gravity systems. When installing forced heating, the boiler piping is more complicated and expensive, but the result is a comfortable temperature in all rooms.

This heating is energy-dependent, so it is advisable to play it safe and install it in such a way that if there is a power outage, you can switch the system to the gravitational coolant circulation mode.

It is impossible to organize forced circulation if the house is not connected to the power grid, but this does not happen often. For a large building this is the best heating scheme, although piping the boiler requires considerable effort

The boiler piping scheme is complicated by additional devices that will require regular maintenance during operation. Without experience, it is difficult to do it yourself, so you will have to hire craftsmen and pay for their work.

Hydrolevellers are connected to the heating of houses where many people live. Devices are needed where several circuits are provided and powerful boilers (more than 50 kW) are installed.

To minimize the number of additional devices, you can implement a circuit with primary-secondary rings with circulation pumps in each of them. If the boiler power is less than 50 kW, then collectors should be included in the circuit, otherwise the batteries will heat up unevenly.

Combined systems are economical and efficient. The heated floor works using heated water coming from the radiator circuit. This allows you to expend energy resources wisely and live with maximum comfort.

The best boiler piping for heating a small house is the simplest. There is no need to install unnecessary devices, because the simpler the design, the more reliable. However, for a spacious building with several heating circuits, it is worth choosing a scheme with forced movement of coolant and a comb collector.

Chimney installation

Before installing a floor-standing gas boiler, a smoke removal system should be installed. The unit is placed on the finished base, after which the location of the chimney is marked. However, these calculations can be carried out without installing a boiler. It is important to note that the diameter of the smoke exhaust pipe must correspond to the power of the floor-standing gas unit:

- for models with an open combustion chamber, a separate smoke exhaust of appropriate power is used;

- for devices with a power of less than 31 kW, a pipe with a cross-section of more than 14 cm is suitable;

- for units more powerful than 39 kW, choose a system with a diameter of 16 cm;

- heating devices with a closed combustion chamber are equipped with coaxial type chimneys.

Note! The manufacturer specifies the requirements for the smoke exhaust system in the technical documentation supplied with the gas boiler.

According to SNiP requirements, a chimney cannot be built next to a window. The minimum distance from it to the pipe must be 600 mm, otherwise combustion products will flow directly into the window.

The chimney outlet above the roof surface is made in height from 50 cm and above.

Solid fuel boiler piping

Any owner of a TT boiler knows that during the active combustion phase a lot of heat is released. Over time, experience comes - when and how exactly to close the damper, for what period of time, etc. But if you get a little distracted, the water in the system will overheat and may even boil. To prevent this phenomenon, the boiler piping without automation must contain several devices that prevent the system from boiling. Only in this case can wiring around the house be done with polymer pipes. Otherwise, sooner or later, the overheated coolant will soften the material, the pipes will burst with all the ensuing consequences. Therefore, piping a solid fuel boiler, in addition to the traditional elements - a safety group, an expansion tank and a circulation pump - contains a significant number of additional devices and usually requires quite a lot of money.

Installation of boilers in individual houses

The method of placing a heating boiler in a residential building depends on its design and can be floor- or wall-mounted. It should be noted that floor-standing models in most cases exceed the thermal power of wall-mounted heat sources.

In addition, a freer coolant circulation pattern in such devices allows them to be installed for operation in autonomous heating systems with natural circulation.

Installation of floor-standing boilers in a separate combustion chamber

If it is necessary to install a heat source with a power of more than 32 kW, gas boilers with floor installation are chosen, since the thermal performance of serial mounted models does not exceed the specified value. The developed standard furnace schemes for private houses provide for the presence of:

- expansion tank;

- domestic hot water heater;

- capacitive or speed separator;

- distribution comb;

- at least two circulation pumps.

In addition, it is necessary to install emergency discharge lines and safety valves that are activated when the pressure in the pipelines increases.

Boiler installation work begins with the preparation of brick or concrete foundations not only for it, but also for all tanks, which, after filling with water, will become quite heavy. After this, distribution combs and pumping blocks with shut-off valves should be assembled and secured to the wall according to the design diagram.

Recommendations for selection

Before you buy a floor-standing gas boiler, you need to determine the requirements for the heating system, as well as familiarize yourself with the main characteristics.

What to choose - with one circuit or two

The floor-standing unit can be equipped with one or two operating circuits. The first option heats only the coolant, that is, it functions as a heater. Such a device includes one heat exchanger, which means it has a compact size and simple design. However, it is worth considering that the dimensions also depend on the power of the device.

To turn a single-circuit boiler into a water heater, you will have to acquire additional equipment. For example, you can purchase an indirect heating boiler. But usually such devices are chosen for heating buildings that do not need hot water supply, and all their power is spent only on space heating.

Models with two circuits perform two functions simultaneously: they heat the coolant and water for domestic needs. Two heat exchangers are installed in such devices at once, which complicates their structure.

However, there are options with one heat exchanger, it is called bithermic. The element is divided into two segments - water moves through one for heating, and coolant fluid moves through the second. Units equipped with such a part are compact, but not so reliable and easy to use.

If in a large private house you need to solve not only the heating problem, but also the availability of hot water supply, it is preferable to opt for a device with two separate heat exchangers. Less scale accumulates in them and there is no need to turn off the heating segment to activate the hot water supply. A double-circuit boiler can only be used in small buildings, this is due to the limited power of such models and safety requirements.

Ordinary or condensation

Classic devices are convection devices, that is, their flue gases are discharged outside along with water vapor. But they provide a lot of heat that can be reused. Condensing-type units accumulate gas released during fuel combustion and then direct it to heating circuits. Due to this, the efficiency of the boiler and the entire system as a whole increases significantly.

In this way, you can significantly reduce the cost of blue fuel and increase the efficiency up to 100%. But such models are characterized by a complex design and high cost, while convection heaters are cheaper and simpler in design.

Power

Power is the main factor that determines the efficiency of a boiler for heating a particular room. You can find out the required indicator yourself, remembering that 10 m2 of house requires 1 kW of power. However, it is worth remembering that this is an approximate figure

When making calculations, it is important to take into account the height of the ceilings, the number of windows and doors, heat loss and thermal insulation of the building. You can always turn to a specialist for help, he will definitely take into account all the details

Control system

Floor-standing devices with automatic control are considered the most convenient and safe. They are able to work autonomously and do not require constant monitoring by the owner. The disadvantage of such devices is their high price.

In stores you can see simple budget installations with a mechanical system. But you need to monitor them, turn them on and off yourself, and also adjust the comfortable temperature.

Connection to the heating system

At the bottom of the boiler there are tubes for connecting hot and cold water supplies. Return and hot water supply to radiators should be connected, carefully observing all requirements and rules. When piping, sealants are used to insulate the system and prevent water leaks when starting the system.

When connecting the heating system, a filter is used in the water supply pipe to help prevent contaminants from entering the boiler. Be sure to take care of the shut-off valves. This will help make repairs and dismantling of equipment easier.

Electric and diesel heat generators

Connecting a diesel fuel boiler to the radiator system is identical to piping gas-using installations. Reason: a diesel unit operates on a similar principle - an electronically controlled burner heats the heat exchanger with a flame, maintaining the set coolant temperature.

Clarification. The recommendation does not apply to heaters equipped with a homemade burner device that burns diesel and waste oil, for example, a Babington flare burner. An individual approach is needed here.

Electric boilers, in which the water is heated by heating elements, an induction core, or through the electrolysis of salts, are also connected directly to the heating. Automation located in an electrical cabinet connected to the network according to the electrical diagram provided is responsible for maintaining temperature and safety. Other connection options are shown in a separate publication on the installation of electric heating boilers.

Wall-mounted mini-boiler rooms equipped with tubular heaters are intended only for closed heating systems. To work with gravity wiring, you will need an electrode or induction unit, which is tied according to the standard scheme:

If you look at it, there is no need for a bypass here - the boiler will not work without electricity either

Connection to the gas main

You need to know that according to the standards for installing gas floor-standing boilers, only a qualified specialist can perform this operation. You can do the work yourself, but an invited professional will still check the assembly and do the first start-up.

Connection work is carried out extremely carefully and accurately. They start by connecting the gas pipe to the corresponding element of the heating boiler.

Only tow can be used as a sealant. No other material will provide the required tightness of the connection. It is necessary to install a shut-off valve, which is additionally equipped with a filter.

At the same time, gas workers strongly recommend installing a high-quality system here. An insufficiently efficient filter can cause boiler failure.

For connection, it is recommended to use copper pipes, the diameter of which can vary from 1.5 to 3.2 cm, or special corrugated hoses. In any case, special attention should be paid to the quality of sealing of connections. Because gas tends to leak from loose connections and accumulate in the room, which can create an explosive situation.

There must be a flexible connection behind the filter, which can only be done using a corrugated hose. Rubber parts are strictly prohibited because over time they develop cracks, creating channels for gas leakage.

The corrugated parts are secured to the boiler pipe using a union nut. A mandatory element of such a connection is a paronite gasket.

After installing and connecting the gas heating unit, it is necessary to check the quality of connections and components. The simplest way to control is to apply a soap solution to the connection. If it bubbles, there is a leak.

Popular brands

The market for floor heating units can be divided into premium, medium, economy and super-economy classes. Of course, boilers of the first type are the highest quality devices that can operate for decades, are made from the most durable materials and do not fail even in critical situations. They are generally very reliable. Their average efficiency is about 98%. Premium boilers are produced by such market titans as De Dietrich, ACV, Wolf. The best boilers are produced by German companies Vaillant, Viessmann, Buderus.

Selecting a heating boiler

Products De Dietrich

Boiler WOLF CGG-1K

Middle-class units are usually produced under European brands. They work in milder conditions and last about 15 years. However, not all types of boilers are able to withstand fluctuations, for example, in electrical networks. Manufacturer brands: Ariston, Beretta, Baxi, Electrolux, Kiturami, Protherm.

Floor-standing gas boiler Beretta Fabula 43E CAI 90

Electrolux floor-standing double-circuit boiler with atmospheric burner, cast iron heat exchanger with built-in 100 liter boiler, FSB 15 Mi/HW series

Economy class boilers have low prices and are slightly inferior in quality and reliability to middle class units. These are the brands Mayak, Alphatherm, Mora, Olympia Boiler.

Gas floor-standing boiler AlphaTherm Beta AT 20

Super-economy class are the most affordable boilers in terms of cost. They are usually produced by Ukrainian, Chinese and Russian companies. Their warranty period rarely exceeds two years, and externally the units look quite simple. Brands: ATON, Dani, Termotechnik, Vektor Lux, ATEM, Borinskoe, Vulcan, Danko, Zvezda-Strela, Kirovsky, Termolux, Mimax.

Floor-standing gas boiler Aton Atmo 16ЕВМ (double-circuit)

Vaillant turboTEC pro VUW INT 202/5-3 H

Conducting a trial run

At this point, the main work on connecting the gas boiler has been completed. The exception is appliances with a closed firebox. They require a connection to the electrical network. It is better to do this through a stabilizer.

After which the system can be filled with coolant. This is done as slowly as possible to displace most of the air present in it. The liquid is pumped until a pressure of 2 atm is reached.

All connections are carefully checked for possible leaks. After a gas service representative inspects the connection and allows gas to flow, you should also carefully inspect all connections on this pipeline. They need to be coated with soapy water and make sure there are no bubbles. Now you can carry out the first start-up of the equipment.

A service agreement should be concluded with the representative of the gas company that installed the equipment, according to which the organization undertakes to conduct regular inspections to study the technical condition and repair the unit as necessary.

Features of installation of PPR pipelines

When piping a boiler, polypropylene pipes and fittings are connected mainly by cold or hot welding; when connecting to metal pipelines, threaded connections are used. Screwing on is much more convenient, but because of them, assembling the system will cost significantly more.

True, if you want to connect a polypropylene pipeline to a metal counterpart, you cannot do without threaded fittings.

An extensive line of fittings is produced to form linear and nodal connections of polypropylene pipes

“Hot” welding is done with a special apparatus (soldering iron, “iron”). The pipes are heated using a suitable nozzle to a melting temperature of 260 degrees, and then the parts with softened edges are pressed against each other. The result is a reliable and monolithic connection.

Before welding, the foil of reinforced pipes must be cleaned. Otherwise, it will interfere with the connection of polymer products, making the seam fragile. With fiberglass, these unnecessary steps will not be required. It melts easily along with the plastic.

PPR soldering technology is extremely simple, all work can be done with your own hands (+)

Cold welding involves the use of a specialized adhesive composition. In recent years, this method has rarely been used, because the result is not reliable enough.

Design with cabinet

If the boiler was purchased after the kitchen set had already been installed, and it is not possible to hide it, it is possible to hide it behind a self-made door. In order to make a cabinet, you will need wooden slats and chipboards. The tools you may need are: a tape measure, various bolts, a cutter, awnings and a ready-made door that will look like a kitchen set.

Before you start creating a cabinet, you will need to very accurately calculate the design parameters

Please note that the minimum distance from the boiler to each wall will be 3 cm. Accordingly, when calculating the width and height, you will need to add 6 cm to the dimensions of the boiler

Having received the required indicators, you can select the door of the desired size.

Now you can get to work.

To begin with, we make the side walls of the future cabinet from chipboard. The easiest way to do this is with an electric jigsaw.

Pay attention to the depth, it should be 3 cm greater than the depth of the gas boiler. At the bottom of one of the walls we make holes that will help connect communications to the boiler. You will need to make another hole at the top; it will be needed for the chimney. We make special holes on the right and left sides that will be required for the awnings. Maintaining perpendicularity, the entire structure must be assembled and fastened with bolts

There should not be a back wall; instead, several planks are attached. We attach the cabinet door to the prepared canopies. The finished structure can be placed on the boiler and hung on the wall.

You can close the boiler not only using chipboard, but also using drywall. This method is similar to the previous one, only here the basis will be drywall, which will be hung on the boiler.

To carry out this work you will need:

- metal profiles;

- GKL slabs;

- facade headset;

- hinges for installing the door;

- self-tapping screws;

- screwdriver or screwdriver.

Now that you have all the necessary materials at hand, you can begin the design process.

The operating technology is simple:

- in a parallel position from the walls of the boiler, retreating about 4 cm, we construct a profile frame;

- We fasten all metal elements using self-tapping screws and place them on the wall;

- We cut out sheets of the required size from plasterboard and mount them on the already assembled frame;

- in one of the installed walls we create several recesses to place hinges in them; they, in turn, must be screwed to the profile.

After this you can place the boiler. The last thing you need to do is hang the door.

Documents for the boiler

Let's say you have equipped the furnace room in compliance with all requirements. Are we buying a boiler? It is too early. First of all, check if the previous gas papers have been lost, and bring them out into the light of day:

- Gas supply contract if the boiler is a heating boiler. Subconsumers can only install hot water boilers.

- All documents for the gas meter. Any boiler cannot be installed without a meter. If it doesn’t exist yet, there’s nothing you can do, you need to install it and arrange it, but that’s a different topic.

Now you can buy a boiler. But, having bought it, it’s too early to install:

- The BTI needs to make changes to the registration certificate of the house. For privatized apartments - through the organization operating the house. In the new plan, a closet under the boiler should be shown, and clearly marked: “Furnace room” or “Boiler room”.

- Submit an application to the gas service for the project and specifications. The required documents also include a technical passport for the boiler, so it must already be purchased.

- Install the boiler (see next section), except for the gas system. This can be done while the gas workers are preparing the project, if the premises are approved.

- Call a specialist to make a gas connection.

- Submit an application to gas workers for commissioning.

- Wait for the gas service engineer to arrive, he will check everything, draw up a conclusion on suitability and give permission to open the gas shut-off valve to the boiler.

Recycling

In a parallel position to the main radiator heating circuit or a small circuit in the area from the boiler to the hydraulic switch, a low-temperature circuit is installed. It contains a bypass and a three-way thermostatic valve. Thanks to the pump, water constantly circulates inside the underfloor heating pipes.

To select new portions of hot coolant from the supply pipe when the temperature inside the return pipe drops, a three-way mixer is used. It can be replaced with a simple thermostatic valve equipped with a remote capillary-type temperature sensor or an electric thermocouple. The sensor is installed in a niche on the return line of the heated floor. The valve is activated when the coolant temperature drops.

Manifold wiring diagram of the heating system

If there are a large number of heating radiators located on different floors, or when connecting a “warm floor,” the best wiring diagram is a collector one. At least two collectors are installed in the boiler circuit: on the water supply - distributing, and on the “return” - collecting. The manifold is a piece of pipe into which taps with valves are inserted to allow regulation of individual groups.

Manifold group Example of connecting a heating circuit and a “warm floor” system using a manifold group

Collector wiring is also called radial, since the pipes can radiate in different directions throughout the house. This scheme is one of the most common in modern houses and is considered practical.

Primary-secondary rings

For boilers with a power of 50 kW or more or a group of boilers that are intended for heating and hot water supply to large houses, a primary-secondary ring scheme is used. The primary ring consists of boilers - heat generators, secondary rings - heat consumers. Moreover, consumers can be installed on the forward branch and be high-temperature, or on the reverse branch and be called low-temperature.

To ensure that there are no hydraulic distortions in the system and to separate the circuits, a hydraulic separator (arrow) is installed between the primary and secondary circulation rings. It also protects the boiler heat exchanger from hydraulic shocks.

If the house is large, then after the separator a collector (comb) is installed. For the system to work, you need to calculate the diameter of the arrow. The diameter is selected based on the maximum productivity (flow) of water and flow speed (not higher than 0.2 m/s) or as a derivative of the boiler power, taking into account the temperature gradient (recommended value Δt - 10 ° C).

Formulas for calculations:

- G—maximum flow rate, m3/h;

- w is the speed of water through the cross section of the arrow, m/s.

- P—boiler power, kW;

- w—water velocity through the cross section of the arrow, m/s;

- Δt—temperature gradient, °C.

Single-circuit boilers with DHW supply

To provide hot water supply, along with a safety group, a pump and an expansion tank, the piping of a single-circuit gas boiler must include an indirect heating boiler. A connection diagram for an indirect heating boiler with recirculation is possible. In this case, water is heated thanks to the coolant from the heating circuit. This leads to the appearance of two circulation circuits - a large one (through the heating system) and a small one (through the boiler). Each of them has shut-off valves, which allows you to turn them on separately. To break the supply bottling, a piping scheme is used for a single-circuit boiler with a boiler, immediately behind which a bypass with a tap is installed.

Systems with two boilers

If it is necessary to organize heating of the coolant in a closed circuit from two heat generators, use the parallel connection principle. Let us explain the algorithm for the joint operation of two boilers - electric and solid fuel (the piping is shown in the figure):

- The main heat source is a TT boiler, connected in the standard way through a three-way valve. To prevent flows from looping in the other direction, a check valve is installed on each branch.

- When a stack of firewood burns out, the air in the house begins to cool. The temperature drop is detected by the room thermostat and starts the electric boiler with a pump.

- A decrease in the temperature in the supply line of the TT boiler to 50-55 °C causes the overhead thermostat to turn off the circulation pump of the solid fuel circuit.

- After the next loading of firewood, the supply pipe heats up, the temperature sensor starts the pump and heating priority returns to the solid fuel unit. The room thermostat no longer turns on the electric boiler because the air temperature does not drop.

It is also necessary to install a safety group at the output of the electric boiler; it is not shown in the figure.

An important point. The above-described piping option can be used for any pair of boilers. When installing a wall heater, a second pump is not installed.

Two heat generators, for example, gas and electric, are easily connected through a heat accumulator. The turning on and stopping of both boilers can be organized in various ways - by the temperature of the water in the tank, by time using a timer. Check valves are not needed here.

If it is necessary to connect 2-3 units of thermal power equipment with several heating circuits, it is better to assemble a diagram of primary / secondary rings. The principle is as follows: all heat sources and consumers with their pumps are connected to a common ring made of a pipe of increased diameter Ø26...40 mm (depending on the number of branches). Circulation inside the ring is provided by a separate pump.

The order of equipment installation matters: the water heater receives the hottest coolant, followed by the batteries, and finally the TP (along the water flow)

In a system with natural coolant movement, two boilers are also combined in parallel. Here it is important to withstand slopes of pipes Ø40...50 mm, and also to avoid sharp turns, using bends at an angle of 45° or bends with a large bend radius.

The water diverges along two parallel branches with boilers. But the unit that is currently turned on will make it move by gravity; the pump starts at the request of the owner

Advice. A series connection of 2 units has a right to life, but it is better not to use such a connection. Water heated in the first boiler will pass through the cold heat exchanger of the second and will certainly lose some of the heat.

Watch this video on YouTube

Emergency circuits

In forced circulation systems, the pumps are dependent on a power supply that may be interrupted. To prevent boiler overheating, which can damage the equipment or even lead to depressurization, boilers are equipped with emergency systems.

First option. An uninterruptible power supply or generator that will power the circulation pumps. In terms of efficiency, this method is one of the most optimal.

Second option. A small reserve ring is being installed, operating on the gravitational principle. When the circulation pump is turned off, a natural circulation circuit is switched on in the system, ensuring the release of heat from the coolant. The additional circuit cannot provide full heating.

Third option. During construction, two full-fledged circuits are laid, one operates on the gravitational principle, the second using pumps. Systems must have the ability to exchange heat and mass during an emergency period.

Fourth way. If the water supply is centralized, then when the pumps are turned off, cold water is supplied to the heating circuits through a special pipe with a shut-off valve (a jumper between the water supply and heating systems).

In conclusion, we suggest watching a video about the rules for calculating a single-pipe heating system for a private house.

rmnt.ru

Radiator connection of serial type

This option is possible if a condensing gas boiler is used, because The operation of classical equipment is difficult at return temperatures below +55 degrees. The fact is that a cooled heat exchanger collects condensate on its surface. Gas combustion products contain, along with water and carbon dioxide, aggressive acids. In this case, there is a real threat of destruction of steel or copper heat exchangers.

Condensing boilers have a different operating principle. A special stainless steel heat exchanger (economizer) is used to collect combustion products. As a result, additional heat transfer occurs and equipment efficiency increases. Because of this, the return pipe temperature level of +30-40 degrees is optimal. The heating system consists of two series-connected circuits - radiator and in-floor. The return pipe of the first is the supply pipe of the second.

Basic rules for using a gas unit

Gas heating appliances must be used in compliance with certain rules:

- The boiler room or other room should always be dry.

- Coolant filters should be cleaned of dirt in a timely manner to extend the life of the heat exchanger.

- It is strictly forbidden to make independent changes to the structural design of the boiler.

- The pipe of the smoke exhaust structure must be cleaned of combustion products deposited on its walls in a timely manner.

- In a private household or boiler room, it is advisable to install a gas analyzer to help identify problems in the functioning of gas equipment.

- You should not avoid timely maintenance of the heating unit, which experts recommend to carry out before the start of the heating season and after its completion. To do this, you need to invite a specialist who will comprehensively check the condition and operation of the chimney, ventilation system, filters, burner and boiler as a whole.

Proper installation and compliance with preventive measures can ensure long-term and trouble-free operation of gas equipment, and accordingly the entire heating system of the household.

Natural circulation

The gravity system is characterized by complete energy independence: its operation is ensured by atmospheric pressure. Instead of a bulky safety group in the piping of a single-circuit boiler, an expansion tank is sufficient. For bottling, it is advisable to install a vent in front of the boiler heat exchanger: this will make it possible to completely drain the water into the sewer or drainage well. Typically, such a need arises in the event of a long departure, or when the gas supply is cut off. As a result, the system is protected from defrosting.

The individual components of the system are located as follows:

- It is recommended to install the tank above all other elements.

- The bottling located immediately after the boiler is positioned in the vertical direction (a small angle is allowed). Thanks to the acceleration section, the water heated in the heat exchanger rises to the top filling point.

- It is important to maintain a constant slope when laying the bottling after the tank. As a result, the cooling water will return by gravity: in this case, air bubbles will be able to escape inside the expansion tank.

- The boiler must be lowered as low as possible. The best place to place the heater is in a pit, basement or basement. Due to the difference in height between the heat exchanger and heating devices, the proper level of hydraulic pressure is ensured, ensuring water circulation in the circuit.

Some features of arranging an inertial heating system:

- For the internal filling diameter, an indicator of 32 mm is selected. If plastic or metal-plastic pipes are used, then the outer diameter is 40 mm. Thanks to the large cross-section, compensation is achieved for the minimum hydraulic pressure due to which the coolant moves.

- The gravity system sometimes includes a pump: however, this does not mean that the circuit loses its energy independence. In this case, the pump is mounted not in the filling gap, but parallel to it. To connect individual taps, a ball-type check valve is used, which is characterized by very low hydraulic resistance. A ball valve is also installed. If the pump stops, the bypass is shut off, which preserves the functionality of the natural circulation circuit.

Rules for the installation of a chimney, conditions for its installation

For the safe operation of a gas-fired heating unit, not only good ventilation in the room is required, but also constant removal of fuel combustion products. Chimney pipes manufactured according to certain rules are intended for this purpose.

Attention! The rules for installing a chimney indicate the inadmissibility of connecting it to a ventilation duct. The reasons for this ban are obvious

First, ventilation is designed to ensure constant air circulation

The reasons for this ban are obvious. First, ventilation is designed to ensure constant air circulation.

Secondly, it cannot provide effective draft, thereby preventing the full use of the power of the boiler equipment.

There are also certain requirements for the chimney installation. They affect both its design and the material of its manufacture.

Regardless of the location of the chimney outlet (through the roof or through the wall), it is made from a round metal pipe. The use of pipes of a different cross-section is not permitted. Stainless or carbon sheet steel is used in the production of the chimney.

When installing a chimney, the following requirements must be observed:

- the diameter of the exhaust hole of the pipe is chosen larger than that of the boiler pipe;

- no more than three bends are allowed along the length of the chimney;

- a metal chimney pipe may be supplemented with an asbestos concrete pipe, but the permissible distance from it to the chimney pipe is at least 500 mm;

- the height of the chimney depends on the shape of the roof and the location of its installation, and is determined by established standards;

- It is prohibited to install a protective cap on the chimney.

The installation requirements for a classic chimney are relevant for floor-standing models equipped with an open combustion chamber. A separate room is most often used for their installation. Most of the problems associated with chimney installation disappear when purchasing a wall-mounted boiler model.

It uses a more modern method of removing combustion products - installing a coaxial chimney. It is mounted in an external wall and performs two tasks at the same time - it removes waste generated during gas combustion and supplies the air necessary for the operation of the burner.

Photo 3. Coaxial chimney for a gas boiler. The product consists of several parts and is located horizontally.