If gas is chosen for heating the house, care should be taken to remove combustion products. This means that you need to select and correctly install a chimney for a gas boiler. Compliance with the rules and regulations in this matter absolutely cannot be neglected, since this can call into question not only the health, but also the life of the residents of the house.

We are ready to share with you useful information about the rules for installing and connecting a chimney for a gas unit, and about the specifics of selecting the optimal design. The information is complemented by visual illustrations and video instructions.

Recommendations from the pros!

Accessories for a bath Do-it-yourself gazebo Concrete fence Do-it-yourself potbelly stove Do-it-yourself veranda Screw foundation Do-it-yourself country toilet Decorative brick Stone fence Pouring a foundation How to make a fence Wicket from corrugated sheets Do-it-yourself fireplace Brick fence Do-it-yourself flower beds Forged gates Do-it-yourself porch Pool for a bathhouse Chicken coop do it yourself DIY staircase Metal gates Installation of lining Installation of polycarbonate Pump for a summer house Arrangement of a garage Fences for flower beds Do-it-yourself blind area Steam room in a bathhouse Railings for stairs Do-it-yourself cellar Painting walls Press with your own hands Grilles on windows Rolling gates Do-it-yourself barn Alarm system for a summer residence Benches for a summer residence Fence posts Floor screed Solid fuel boilers DIY greenhouse Fence installation House insulation Attic insulation Foundation insulation

What to consider when installing a column

Let's consider the basic installation rules that must be observed when carrying out work:

- The room must have a minimum area of 7.5 m2.

- The minimum pressure readings should be 0.1 atm.

- Sufficient ventilation must be ensured.

- The equipment should be installed on a wall that has been protected with non-combustible materials.

- Placement directly above a gas stove is prohibited. A minimum distance of 10 cm must be maintained between such devices.

- A mandatory requirement for installing the device is the presence of a chimney. The diameter of the pipe should be from 120 mm.

- The ceilings in the room must be at least 2 meters high.

- There must be a gas meter in an apartment with a water heater.

Tools required for installation

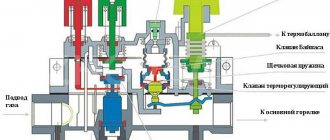

The device of a classic geyser

To install a gas water heater in an apartment, you need the following tools:

- Adjustable wrenches (two wrenches required).

- Two open-end wrenches (27 by 30 and 32 by 36).

- Sealant. Unipack is perfect.

- Tow or FUM tape.

To carry out installation work, you need to prepare the following materials:

Galvanized pipe, 1 meter long. Often such materials are supplied complete with heating equipment.

- Gas hose (its dimensions are specified in the documentation that comes with the kit).

- A filter designed for rough water purification. Keep in mind that the service life of such equipment directly depends on the quality of the water.

- A rosette ring required to lead out the entrance to the chimney.

- Dowels that will secure the equipment to the wall.

Installation work step by step

When the chimney and water supply are prepared for the installation of equipment, you can proceed directly to its installation. Replacing a gas water heater is carried out in several stages:

Mark the equipment attachment points. Here you should take into account the minimum length of the chimney, which is 50 cm for rooms with a ceiling height of 2 meters and 25 cm - where the ceiling height is 2.7 meters or higher.

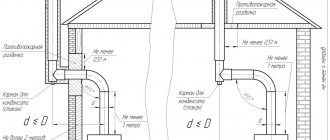

Diagram of the correct location of the speaker in the kitchen

- Holes are made in the wall according to the markings.

- Hooks are installed to hold the column.

- Now the device can be hung on the wall.

- We take PVC pipes and connecting rods, through which the pipeline is connected to the inlet and outlet of the column.

The video shows instructions for installing a geyser

Correct connection of the column to gas and water supply

- At the last stage of installation, gas is supplied to the device. To do this, take a flexible hose: one end is screwed to the gas supply valve, and the other to the gas inlet into the column. Next, you need to crimp the connections and treat them with a soap solution to check for leaks.

- We supply gas to the system. If there are no bubbles in the areas with the applied solution, then you can safely put the system into operation.

A correctly installed and ready-to-use geyser

Boiler room

Gas equipment is connected directly to the boiler room. Relative to the house, furnaces can be located:

- inside - built-in;

- nearby on a separate foundation - attached;

- at some distance - separate.

Depending on the location, the premises are subject to certain requirements aimed at ensuring safety during operation.

Built-in

According to SNiP, gas equipment with a power of up to 350 kW is allowed to be installed inside the house. Boilers up to 60 kW can be placed in any room. As a rule, this is a kitchen or domestic premises. More powerful heat generators are located on the first or ground floors, in the basement.

The ceiling in the room should not be lower than 2.5 meters. Ventilation is calculated to replace air three times within an hour, that is, the cross-section of the ventilation ducts should ensure the rate of natural circulation of an amount of air equal to triple the volume of the room.

The size of the window opening minus the sashes must meet the explosion safety requirements. In accordance with it, the area of easily removable structures, in this case glazing, is calculated from the condition of 0.03 m² per 1 cubic meter of room.

When the power of the heating unit is over 150 kW, the room is equipped with a separate exit. Regardless of the characteristics of the boiler, a passage along the front of at least 1 m is left.

Attached premises

An attached boiler room with heating units with a power of up to 350 kW is placed along the blank wall of the house. Set aside at least 1 meter from the nearest door or window opening. The furnace structure should not be rigidly adjacent to the foundation, walls and roof of a residential building.

The material for the walls of the boiler room is selected taking into account the minimum fire resistance limit - 0.75 hours. The structures should not burn or support combustion.

The height of the boiler room inside is at least 2.5 m. The equipment is placed so that it is convenient to service it. The size of the free area in front of the boiler is 1x1 meter.

The attached premises are equipped with a separate exit to the outside. The door should open to the street.

Natural light is a must. The glazing area is at least 0.03 m³ per 1 m³. The hood must support three hourly air exchanges.

The door leading to a residential building is made of fireproof materials. It must comply with the third type of fire safety.

Installing a gas boiler in the kitchen

When installing a gas stove, water heater and boiler with a power of up to 60 kW in the kitchen, the following requirements are imposed on the room:

When installing gas-using equipment, they are guided by the manufacturer’s passport. The walls must be made of fireproof materials, and the distance to the unit must be at least 20 mm.

It is allowed to install boilers near walls made of combustible materials, provided that the surface is protected with a 3 mm thick asbestos sheet and roofing steel or plaster. In this case, at least 30 mm should be removed from the enclosing structures. The insulation is extended beyond the dimensions of the equipment in height and width by 10 and 70 cm.

The floors under the boiler also protect against fire. Sheets of asbestos and metal are laid on them so that their boundaries exceed the dimensions of the body and protrude by 10 cm on all sides.

Pipe connections

Installation requires welding.

Quality control of welding work is regulated in SNiP 3.05. 03.85 5. Welding heating pipes

- Gas water heaters and other gas appliances must be connected to the chimney using pipes that are made using roofing steel.

- The length of connected pipes should not exceed 3 meters in new buildings and more than 6 meters in existing ones.

- The slope of the pipe in relation to the device must be at least 0.01.

- On smoke exhaust pipes, no more than 3 bends are allowed, the radius should not be less than the diameter of the pipe.

- The connection of the pipes must be tight; the entry of one pipe into the other must be at least half the diameter of the pipe.

- If the pipes are made of black iron, they require painting with fire-resistant varnish.

Is it possible to connect 2 boilers or more to one chimney?

You can connect no more than 2 boilers (heaters, stoves...) to one chimney, but only in existing houses. In others, each gas boiler must be equipped with its own chimney.

In existing houses, the cross-section of the chimney must correspond to the performance of the two boilers that are connected. Also, connections must be at different levels, and the distance between them is at least 0.75 meters. Or the connection can be made at one level, but from this place and above 0.75 m in the chimney a cut must be made to ensure the proper cross-section (which is rare in practice).

Or, no more than 2 boilers (water heaters, furnaces) can be connected, but they must work in turns, their simultaneous operation is not allowed, which must be provided with appropriate electrical (mechanical) protection, and the cross-section must correspond to the unit with high requirements.

Thus, it is possible to include the main and backup heat generators, or a boiler and a water heater, in one chimney, for example, if there is a blockage from their simultaneous operation.

More air supply requirements

But the operation of an atmospheric boiler must be ensured by a sufficient amount of air entering the room, unless the unit itself takes this air from the street through a separate pipe. Also, the air supply to the room and exhaust ventilation should ensure three times the air exchange within an hour. As for the inflow, it is allowed to enter from other rooms of the building, for which an inlet opening with an area of at least 200 cm2 is created in the door (structure) of the boiler room.

Or such a supply hole is made to allow air to come in from the street. But in order to prevent icing, which will inevitably occur, you can make an oblong box inside the room along the wall, descending from top to bottom, through which the supply air, entering the room, would be heated with heat, and the condensate would flow into a container and drain into the sewer...

Is it possible to install the boiler yourself?

Considering all the dangers that gas equipment poses in case of violation of installation technology, the answer to this question is obvious - it is impossible.

Before installing a gas boiler, you must obtain technical specifications. Otherwise, installation will be considered illegal and fraught with penalties. In addition, independent installation is very dangerous, especially if it is carried out in a high-rise building. There are many sad examples of this, and gas services are carefully monitoring this.

The user has the right to do whatever he wants with any of the other types of fuel, just not with natural gas.

You can install a wall-mounted gas boiler yourself, provided that the user has an understanding of this equipment and the nuances of installation, and strictly complies with the requirements regulated by SNiP. But the first start-up of the unit, insertion into the gas main and adjustment of the equipment must be carried out by specialized gas services.

Carrot caviar with mushrooms

A very tasty option is carrot caviar with mushrooms. To prepare the preparation, we will use honey mushrooms, which we will first boil in salted boiling water. You need to cook for about half an hour. A sign that honey mushrooms are ready is that the mushrooms will sink to the bottom.

- 1 kg of boiled honey mushrooms;

- 300 gr. carrots;

- 300 gr. onions;

- 4 cloves of garlic;

- 1.5 tablespoons of salt;

- 4 allspice peas;

- 0.5 teaspoon ground black pepper;

- 1 bay leaf;

- 0.5 tablespoon of vinegar essence (70%);

- 70 ml vegetable oil.

Preparation:

- Boil fresh mushrooms, and if we use frozen ones, put them in a colander and pour boiling water over them. Let the liquid drain. Then we pass the mushrooms through a meat grinder or grind them in a blender.

- Peel the onions and carrots, rinse and dry. Cut the onion into small cubes and grate the carrots. Fry the onion in a frying pan until it becomes translucent. Then add the carrots to the onion and continue frying for a quarter of an hour. Stir occasionally during cooking. They should be half cooked. Let the fried vegetables cool and grind them in a blender or using a meat grinder. Do not drain the oil remaining in the pan, but mix it with chopped vegetables.

- In a large saucepan, mix chopped mushrooms and vegetables, add salt, pepper, peppercorns and bay leaf. Add chopped garlic. Cook the caviar for 15 minutes from the moment it boils. Then pour in the vinegar, stir and turn off the heat.

Requirements for exhaust hoods by law

Ventilation rules are enshrined in SNiP. The basic requirement relates to the volume of air exchange - it must provide 3 times air circulation within an hour.

Ventilation of a boiler room in a private house is carried out only according to a preliminary design. Which presents executive diagrams of room ventilation, the type and quantity of necessary equipment, a list of materials and spare parts for installing a chimney.

Basic requirements for air exchange

When purchasing ventilation and smoke exhaust equipment for a gas boiler in a private house, specified in the design documentation, it is necessary to check them for compliance with the quality regulated by legal norms in the territory of the Russian Federation.

Basic legal requirements for installing ventilation systems for a gas boiler in a private home:

- Installation of a separate air duct in the ventilation structure.

- The tightness of ventilation ducts; all seams must be treated with heat-resistant sealants.

- Arrangement of a separate air channel in the ceiling of the combustion room.

- Installation of sleeves in wall structures to lead the gas duct from the room to the street.

- Connecting no more than 2 gas installations to one chimney.

- A distance of more than 300 mm must be maintained between the outer wall and the end point of the flue.

- The air supply can be organized both outside and inside the combustion chamber. However, the living room cannot be used as an adjacent room.

Internal section of the chimney

For pipes, SNiP for chimneys defines different cross-sectional sizes. This is due to the material of the pipe.

Brick and concrete pipes

- furnace power up to 3.5 kW – from 140*140 mm;

- for a furnace with a power from 3.5 to 5.2 kW - from 140*200 mm;

- if the furnace power is from 5.2 to 7 kW - from 140 * 270 mm.

Steel and ceramic chimneys

- if the oven power is up to 3.5 kW - from 16 cm (area approximately 200 cm2);

- for a stove with a power from 3.5 to 5.2 kW - from 19 cm (area approximately 280 cm2);

- oven power from 5.2 to 7 kW - from 22 cm (area approximately 378 cm2).

Errors in selection and arrangement

When building a house, errors in the selected heating system and gas equipment occur at different stages:

- the type of boiler was not taken into account during the design - after construction is completed, it may be necessary to rebuild the entire ventilation system;

- unsuccessful form - an abundance of turns reduces traction, in some cases provokes the movement of air from the pipe into the room;

- there is no possibility of cleaning, which can be hampered by sharp turns and the lack of technological holes;

- purchasing materials from different manufacturers - components for composite pipes may differ in geometric dimensions, which leads to air leaks or leaks of combustion products into the room;

- non-compliance with the height of the chimney on the roof, leading to reverse draft;

- incorrect choice of materials for the pipe;

- insufficient insulation.

Guiding documents allow independent construction of chimneys for gas boilers. The gas supply organization will not accept improperly installed chimneys for operation, and hidden defects can lead to accidents. It is necessary to study in detail the rules provided for by the governing documents; if you doubt your abilities, it is better to entrust construction to professionals.

Understanding Cravings: Factors Affecting Cravings

For normal operation of gas appliances, a constant supply of clean air is required, which is provided by natural supply and exhaust ventilation.

The removal of combustion products from gas appliances is provided through a chimney.

To remove gas combustion products into the atmosphere, there must be a certain draft - a force that forces air to penetrate the chimney, and the resulting combustion products to move along the chimney and dissipate into the atmosphere.

The draft depends on the temperature difference between the smoke and the air, the height of the chimney and a number of other factors.

To ensure better draft, the temperature of the exhaust gases must be high. The temperature of exhaust gases from water heaters is 180-200°C. Due to the cooling of the reinforced steel and the suction of air in the draft stabilizer, the temperature drops. When operating chimneys, condensation of vapors from flue gases must be prevented. Wetness of the channel reduces traction, leads to its destruction, and in the winter season it can lead to freezing and blockage of the channel. The temperature at which condensation begins is called the “dew point”. For natural gas combustion products = 60-65°C. The air intake in the draft stabilizer reduces the relative humidity of the exhaust gases, and the dew point also decreases to 40-50 degrees. To exclude condensation, the temperature of the flue gases at the exit from the pipe head is usually taken to be 65°C. The draft decreases with high ambient humidity.

Boiler rooms for solid and liquid fuel boilers

The following types of liquid and solid fuels are used to heat residential buildings:

- coal;

- fuel oil;

- gas oil, gasoline;

- diesel fuel;

- working off;

- kerosene;

- wood waste, pellets, firewood;

- oil shale;

- peat;

- petrol;

- vegetable or machine oils.

As a rule, floor-standing units are designed for the use of solid or liquid fuel. Loading requires fairly large chambers, and after combustion, waste is generated. Therefore, such boilers are less compact than gas boilers.

When building a boiler room in a private house with your own hands, you must comply with the same requirements as for gas boiler rooms, but with some additions:

- solid fuel and liquid boilers cannot be installed in residential premises due to strong odor or dust; for this purpose, an extension or a separate furnace room must be installed;

- To install a floor-standing boiler, a concrete foundation with a thickness of at least 50 mm is installed.

- there must be easy access for loading, cleaning the boiler, repairing and replacing parts;

- there must be at least 2 m from the place where the fuel is placed to the nearest wall;

- It is advisable to place the chimney closer to the ridge to create good draft;

- smoke exhaust is arranged through a chimney in the main wall or a pipe outside the house, and it should not coincide with the window openings;

- the chimney is made of a sandwich pipe with insulation and an internal heat-resistant layer of steel or brick;

- You cannot build an attic or living room above the boiler room;

- In the room where gas equipment is installed, flammable materials and chemicals that emit flammable vapors must not be stored.

To prevent dust from accumulating in the boiler room, which adversely affects the operation of the equipment, a supply opening is installed at a height of 30 cm from the floor, and an exhaust opening is located under the ceiling. Ventilation of the room should be natural.

You can quickly build a boiler room in a private house with your own hands if you use ready-made modular structures. During their production, all standards and requirements are taken into account.

A mini-boiler house can operate on any type of fuel and heat a residential building or cottage. The structure is installed on a monolithic or prefabricated foundation and connected to the heating system of the building. When using gas, the project must be agreed upon with the gas distribution organization.

Features of brick and concrete chimneys

A brick chimney must be vertical in all areas, and its walls, according to standards, must be at least 120 mm. thick.

For a concrete chimney, this figure is half as much - 60 mm.

Also, chimneys made of brick and concrete should have pockets up to 250 mm deep, with holes for cleaning.

|

Room requirements for installing a gas boiler:

- the room for installing a gas boiler must be at least 4 m2;

- the height of the ceilings in it is at least 2.5 m;

- the width of the external door is at least 80 cm;

- You need a window for natural light and an opening for the flow of outside air.

- the room in which the boiler is installed must have a separate exit to the street.

It is also necessary that the door to the room opens freely or is trimmed; an influx of oxygen is required for the combustion of the wick and burner.

When constructing chimneys, to ensure draft and prevent blowing out leading to the extinguishing of the flame, it is necessary to extend the upper cut of the chimney above the wind support zone. The height of the chimney above the roof of the house is set depending on the distance:

- at least 0.5 m above the ridge, if the pipe is located at a distance of up to 1.5 m from the ridge;

- not below the line, the level of the ridge, if the pipe is located at a distance from 1.5 m to 3 m;

- not lower than a straight line drawn from the ridge down at an angle of 10″ to the horizon, when placing pipes at a distance of more than 3 m from the ridge of the roof.

The chimney must have a cross-section in accordance with the passport for the installed equipment, but not less - for a boiler with an open combustion chamber and a power of up to 30 kW with a diameter of 130 mm, for a boiler with a 40 kW - 170 mm.

The chimney must have a minimum of elbows and bends, and its internal diameter cannot be less than the diameter of the boiler neck.

It is also necessary to have a natural ventilation channel in the upper part of the room.

If the gas boiler is volatile, then in accordance with the requirements it must have a separate circuit breaker. You can also install a differential circuit breaker (RCD), which protects a person from a short circuit to the body, and the boiler must be grounded.

When installing a boiler in a separate room without permanent presence of people, for example, a built-in or attached furnace room, according to current building codes, a gas analyzer must be installed in the room, which will warn of a leak and automatically shut off the gas supply using an emergency electric valve. An unconditional requirement is also the mandatory presence of a temperature shut-off valve at the gas pipeline inlet in the room for emergency shutdown of the gas supply in the event of a fire. All equipment is subject to annual maintenance by specialists.

Choosing a gas boiler.

The power of a gas boiler is calculated at the stage of building a house, since the diameter of the chimney and a number of parameters of various engineering systems depend on it.

Gas boilers can be steel or cast iron.

- A steel boiler is approximately two times lighter than a cast iron boiler of the same power and volume.

- The service life of a steel boiler is 10-15 years, cast iron up to 50 years.

- A cast iron boiler is afraid of sudden changes in temperature and therefore almost always fails if it is turned on without water, or without warming up in a very cold room after a long stop.

- A steel boiler will rust if it is left without water after shutdown.

Gas boilers are available in floor-mounted and wall-mounted versions.

The body of the wall-mounted boiler contains a gas burner, a heat exchanger, a circulation pump, an expansion tank, a pressure gauge, a thermometer and a boiler safety system. Wall-mounted boilers are always volatile, that is, they cannot work during a power outage. In connection with this, for stable and long-term operation, it is recommended to use a voltage stabilizer or surge protector. In this case, you need to remember 2 basic requirements. Read more…

Basic rules for installing a chimney

- The installation of a gas boiler should only be carried out when all the rules for installing a chimney are observed.

- It is necessary to ensure the correct selection of chimney parameters, on which the further operation of the gas boiler depends.

- It is important that all installation work is carried out by highly qualified workers, while observing all fire safety rules.

- All manufacturer's recommendations must be followed.

- It is necessary to choose the diameter of the chimney duct the same diameter as the device itself or perhaps a little larger.

- The air flow in the chimney duct should have a speed of 10-25 meters per second (NPB-98).

Rules for installing and connecting gas boiler equipment

Before you begin installing gas equipment of the type in question in a private home, you will need to prepare certain documents, and then carry out the required actions, which are the rules.

Rules for installing gas boilers:

- A contract with the supplier regarding the supply of natural combustible material will be required;

- Installation of gas equipment must be carried out by an installation organization that specializes in providing this type of service;

- Technical conditions, as well as the equipment installation project, must be agreed upon with the gas service representative at the location where the system is installed. Project documentation, as a rule, is developed by specialized institutes with the appropriate license for this type of activity;

- The heating system must be pressurized to P = 1.8 atm;

- An engineer from the regional or district gas service comes to the site, after which he checks the correct connection of natural gas in the furnace and kitchen. The engineer also checks compliance with the requirements put forward by equipment of this type;

- The valve opens only if the engineer has not identified any violations;

- There must be no air in the system;

- All connections are checked for leaks;

- A voltage stabilizer is installed, as well as an uninterruptible power supply;

- It is not allowed to add antifreeze to heating water, as this can damage the sealing gaskets and then lead to leaks in the home heating system.

The following are the features of installing a wall-mounted gas boiler.

Basic regulatory documents

Requirements for gas boiler houses are given in the following regulatory documents in force in 2022:

- SP 62.13330.2011 Gas distribution systems. (Updated edition of SNiP 42-01-2002) (mandatory for use according to post.985)

- SP 402.1325800.2018 Residential buildings. Rules for the design of gas consumption systems (acting on a voluntary basis under Order 687)

- SP 42-101-2003 General provisions for the design and construction of gas distribution systems made of metal and polyethylene pipes (of a recommendatory nature)

- Instructions for the placement of thermal units intended for heating and hot water supply of single-family or semi-detached residential buildings (MDS 41-2.2000) (is advisory in nature)

Let us highlight the most important requirements (point by point) that must be met when designing and building a gas boiler room in a house, as well as when designing the route for laying a gas pipeline:

According to SP62.13330.2011:

pp. 5.1.6* Gas pipeline entries into buildings should be provided directly into the room in which gas-using equipment is installed, or into an adjacent room connected by an open opening.

It is allowed to provide for gas pipelines entering apartment kitchens through loggias and balconies, provided that there are no detachable connections on the gas pipelines and access is provided for their inspection.

It is not allowed to enter gas pipelines into the premises of the basement and ground floors of buildings, except for the introduction of natural gas pipelines into single-family and semi-detached houses and industrial buildings, in which the introduction is determined by the production technology.

pp. 5.2.1 Gas pipelines should be laid at a depth of at least 0.8 m to the top of the gas pipeline, casing or ballasting device, except in specified cases. In those places where traffic and agricultural machinery are not expected, the depth of laying steel gas pipelines must be at least 0.6 m.

pp. 5.2.2 The vertical distance (clear) between the gas pipeline (case) and underground utility networks and structures at their intersections is recommended to be taken in accordance with Appendix B* SP62.13330.2011.

According to Appendix B*, when laying a gas pipeline underground (gas pressure up to 0.005 MPa) and the most common communications on the land plot of a private house:

- Vertically (at intersection) with water supply and sewerage - at least 0.2 m in clear space (between pipe walls)

- Horizontally (parallel) with water supply and sewerage - at least 1 m

- Horizontally (in parallel) with power cables up to 35 kV - at least 1 m (when installing a protective wall, it can be reduced to 0.5 m)

The main requirements for the chimney of a gas boiler

Diagram of a gas boiler.

- It is recommended to place the pipes in the internal wall of the building, which is permanent. If the chimney is located outside the building, insulation is required to prevent freezing. When making a channel inside an outer wall, the thickness of the brickwork should be at least 1.5 bricks, and in severe winter conditions - 2.5 bricks.

- The chimney of a gas boiler must be positioned vertically with a possible slight slope of no more than 30 °. Extensions and contractions are not allowed.

- The cross-sectional area of the duct must be larger than the cross-sectional area of the gas equipment to which it is connected.

- The gas boiler must be connected to the chimney through a special corrugation or using steel pipes with a heat-resistant enamel coating.

- The chimney pipe through which the gas boiler is connected to the chimney must have a vertical section at least 0.5 m long. The requirements do not allow more than three turns of the chimney pipes.

- The connection between the gas boiler pipe and the chimney must be sealed.

- All components must fit tightly together, be sealed and airtight. For this purpose, sealing agents that are resistant to high temperatures are used. The possibility of bending of pipes at their connections must be excluded.

- In rooms with a height of about 3 m, the length of the horizontal sections of pipes that make up the chimney should not exceed 3 m.

- The slope of the pipe towards the gas boiler is allowed at least 0.1 °

- There must be a container for collecting condensate with a window for cleaning. It is usually located below the point where the chimney pipe enters the channel.

- The permissible distance between surfaces made of heat-resistant materials and connecting pipes is 5 cm or more, and in the case of flammable surfaces - at least 25 cm.

- The chimney above the roof must rise no less than 50 cm if the pipe is located from the edge of the roof ridge at a distance of no more than 1.5 m. When the pipe is removed up to 3 m, it is aligned level with the roof ridge.

- If there is a flat roof, then the height of the chimney above its level should be at least 1 m.

Do-it-yourself brick chimney installation

The brick chimney design is an exclusively vertical channel with a square or rectangular cross-section. To lay a brick chimney, solid ceramic bricks are used, which are laid on mortar. The outer section of the channel is laid out with ordinary brick, corresponding in style to house construction, which can be seen in numerous photos of brick chimneys. If the house is lined with stone or plastered, you can decorate the chimney in the same way.

Brick chimneys for gas boilers: installation requirements

Before laying a brick chimney for a boiler, it is necessary to build a foundation, the height of which must be at least 0.3 m. The dimensions of the base around the perimeter must protrude beyond the contour of the channel itself by at least 0.15 m. If the chimney is located in part of the external wall, its foundation should be level with its base. Laying a brick chimney with your own hands (video instructions confirm this) begins at the stage of building the walls of the house.

When constructing a chimney, solid ceramic bricks are used, which are laid on the mortar

Requirements for brick chimneys:

- the smoke channel must be vertical, without ledges, narrowed or widened areas;

- the thickness of the brick pipe for the chimney is taken taking into account the exclusion of freezing;

- the minimum permissible cross-section of smoke exhaust channels is 14 x 14 cm, which corresponds to the size of half a brick, taking into account the seam;

- the size of a brick chimney, the height of which is less than 5 m, should be increased to a channel cross-section of 14 x 20 cm;

- the chimney is constructed in the walls between heated rooms, which will prevent it from cooling and reducing draft;

- tightness - the brick chimney is laid with ligation so that the vertical seam of the previous row overlaps with the brick of the next one;

- the inner surface of the channel must be smooth;

Helpful advice! To achieve a flat and smooth inner surface of the channel, use special templates when building a brick chimney with your own hands.

- the distance between adjacent smoke exhaust ducts should not be less than 5 average outer diameters of the pipe;

An example of a chimney in a brick channel and a diagram of laying a brick chimney pipe

- if ventilation ducts are located near the chimney, their height should be equal to the height of the chimneys.

To reduce construction costs, you should place as many channels as possible in a common chimney. In this case, adjacent chimney and ventilation ducts will heat each other, which will generally improve the functioning of the chimney.

Preparation of mortar for laying a brick chimney

The composition of the mortar for laying a brick chimney is selected taking into account which section of the pipe is being laid: external or internal. To construct the external channel, the same mortar is used as for laying load-bearing walls of house construction. It is prepared from cement, sand, water and can harden in air and water. The mixture is prepared in such a volume that it can be used within an hour, as it sets quickly.

To ensure that the mixture does not deteriorate under the influence of an aggressive environment, it is recommended to add special additives to it that increase its plasticity, strength and acid resistance. Thanks to these additives, you can improve the quality of the masonry itself, increase the speed of construction and the durability of the work performed.

The properties of the chimney mortar can be improved using various additives

The preparation of a solution for a brick chimney running inside a house is based on the use of fireclay and fireclay in its composition in a 1: 1 ratio. Such mixtures cope well with high temperatures, they are durable and do not emit harmful substances. To give the clay mixture strength, you can add table salt to its composition (about 120-150 g per bucket).

Helpful advice! The strength of the chimney mortar can be enhanced by adding Portland cement in a proportion of 1 kg per bucket.

When laying a brick chimney with your own hands, you can purchase ready-made mixtures that are heat-resistant and acid-resistant. Preparing the solution yourself can reduce the cost of building a chimney.

It is quite possible to build a brick chimney with your own hands - the video below will help you familiarize yourself in detail with the stages of constructing the structure, taking into account all the basic requirements.

The feasibility of using a brick chimney for a gas boiler

Taking into account the advantages and disadvantages of brick chimneys, it is possible to draw conclusions regarding their use in combination with gas boilers. Their advantages include:

- the likelihood of using an existing chimney duct, which reduces chimney costs;

- possibility of operation in conjunction with gas equipment with an open combustion chamber;

- reasonable cost of materials for construction and finishing of the structure.

The durability of brick channels is observed only when they are used for fireplaces or stoves. If they are used for gas boilers, due to the low temperature of the combustion products, condensation will form on the channel walls, and harsh operating conditions in an aggressive environment will lead to the gradual destruction of the brickwork and deterioration in performance.

In addition, the requirements for such chimneys are more stringent:

- impeccable masonry - if the skills are not enough, you will need to invite a qualified mason to do the work, which will cost a lot of money. Prices for work: rough brick masonry from 6,000 rubles per 1 m³, facing masonry - 2,500 rubles. for 1 m²;

Schemes for connecting a gas boiler to a brick chimney

- inability to perform a complex channel configuration (if you need to bypass, for example, a beam in a ceiling);

- the use of the old channel should be carried out using sleeves;

- the need for thermal insulation.

The disadvantages of such a system include a decrease in traction while the brick is warming up. Thus, the correct chimney for a gas boiler will be a brick channel together with a steel or ceramic liner. The photo of brick chimneys shows that liners are installed during the process of laying the channel. In this case, it is necessary to leave a gap between the liner pipe and the brick surface. This is necessary so that the pipe can move inside the channel.

Requirements for free-standing combustion chambers

Separate boiler houses are built for powerful heat generators, the operation of which requires an enhanced safety regime.

Requirements for furnaces built separately from a residential building:

The premises are equipped with concrete floors or covered with fireproof finishing. For equipment weighing over 200 kg, a reinforced base with a height of 15 cm is prepared.

d17f49b29c5c1639aceb856b52bd422c.jpe

Heated water enters the house through an insulated pipeline with low heat loss. A free-standing furnace does not take up the usable space of the house, is safe to use and does not disturb the architectural appearance of the building. Can be used for heating a group of buildings, for example, a house, a bathhouse and a greenhouse.

Requirements for doors

Two types of doors are used in furnace rooms:

- external without reinforcement for access to the street;

- internal fire protection for communication with residential premises.

External doors should be easy to break off their hinges in the event of an explosion. Then the energy will be directed outward and cause less destruction than with a rigidly and firmly fixed canvas. But in any case, you need to protect the premises from strangers who could enter and damage expensive equipment.

Interior doors are designed to contain flames in a fire for 15 minutes. Type 3 fabrics with a fire resistance limit of EI 15 comply with the standard. They retain their integrity and thermal insulation properties for a period of time sufficient for the evacuation of people from the house and the arrival of rescue services.

Boiler room ventilation

The requirements for a boiler room in a private house are very strict regarding ventilation. Combustion products formed when burning fuel are dangerous to humans. Inhalation of carbon monoxide leads to severe poisoning. High concentrations cause paralysis and even death.

Gas leaks in the network create a danger of explosion. Methane, propane and butane are heavier than air. They accumulate in the lower level of the room. That is why it is recommended to install gaps near the floor under the outer door or grated exhaust openings in the wall to remove hazardous substances. For every 10 kW of unit power, 0.01 m² of cross-sectional area of the supply channel is required.

Natural ventilation, recommended by the standard, includes supply and exhaust ducts to replace the air in the room. Their area is calculated based on the triple volume of the room and selected using special tables, diagrams or using online calculators.

For every 10 kW of power, 0.01 m² of cross-sectional area of the supply channel is required.

Combustion products are discharged through a chimney or a coaxial pipe built into the wall. In the first case, the cross-section of the channel must correspond to the diameter of the boiler pipe. The optimal shape is a circle or oval.

The chimney walls protect against condensation. Warm air, moving through the pipe, cools, which leads to the precipitation of water vapor in the form of dew. In winter, the moisture freezes and the channel narrows. This contributes to the deterioration of the removal of combustion products.

Protection against condensation is carried out by lining the chimney or installing a stainless steel pipe inside. Angles and turns must be smooth, and the joints of channel elements must be sealed.

In other cases, the ventilation duct may be lower. Separate smoke removal systems are installed for the two units.

Ventilation in the house

The house must use forced exhaust ventilation and forced supply ventilation. This is due to maintaining a normal draft level and preventing combustion products from entering the room.

It is also forbidden to combine a chimney with a ventilation duct and use the chimney as ventilation.

|

Types of boilers and smoke exhaust ducts

Gas boiler with coaxial chimney

The industry produces various models of gas heating boilers, but all types are built in two possible designs: with an open or closed chamber for gas combustion.

It is better to decide which boiler to purchase at the stage of designing a house. The chosen scheme determines how and where to build the boiler room, as well as how combustion products will be removed.

The project must be agreed upon with the gas supply organization - if construction technology is violated or unacceptable materials are used, gas equipment will not be put into operation, and alteration of the gas exhaust system may require significant financial costs.

Open chamber boilers

By design, devices with an open chamber are simpler than devices with a closed type.

Oxygen for fuel combustion is supplied from the surrounding space. This feature imposes additional requirements on the organization of room ventilation.

Equipment installation is carried out only in a separate room. To ensure operation, two channels are built to supply air and remove products from the burnt gas.

Among the advantages is the relative simplicity of the design without additional fans, and therefore without “extra” mechanical parts that are most susceptible to wear. The disadvantages should be considered lower efficiency and the need to build a vertical chimney at a level above the roof ridge.

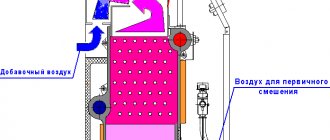

Features of equipment with a closed chamber

In a coaxial chimney, air is sucked in through one pipe and comes out through another - internal

Air is forced into gas boilers with a closed chamber. The chamber does not communicate with the room air, and the exhaust gases are removed by a supercharger.

Boilers with a closed chamber are economical, do not require the installation of vertical channels, and one coaxial pipe is used. Combustion products are removed through the internal insert, and external clean air enters through the cavity between the walls of the pipes.

To remove gases, there is no need to build vertical structures, which reduces the cost of the estimate. On the other hand, this type of boilers and pipes requires more frequent maintenance. Turbines periodically fail, which entails additional operating costs.

Installation options for chimneys

It is necessary to build a foundation under the internal chimney. If you also add a protective brick channel, this will minimize the amount of condensation. Sometimes chimneys are attached from the outside to the wall behind which the unit is located.

Internal design of the chimney

Before proceeding with the installation of the chimney, select a location for it. Then mark the places where it will pass through the ceiling and roof. Carefully check the accuracy of the markings and make openings. The next step is to connect the boiler pipe to the chimney, and then install the revision and tee.

A sheet of steel is fixed, the main bracket is installed, the pipe is extended, if necessary, “elbows” are used. In the area of contact with the ceiling, pipes are used. Take a sheet of galvanized steel with a hole such that a pipe can pass through it freely, and attach it to the ceiling. Clamps are used to strengthen joints. Every 2 m the chimney is secured with clamps, and every 4 m - with brackets.

The work is completed by checking the seams for leaks. To do this, take a soap solution and apply it to all joints. If everything is done efficiently, then when connecting the unit to the chimney, bubbles will not appear in these places.

External structure device

For an external chimney, a hole is made in a blank wall of such a diameter that a pipe with insulation can freely pass through it. Having installed the first element of the future chimney into the hole, secure it and wrap it with insulation. The next sections are added from the street side, controlling the verticality using a plumb line.

An external chimney is safer, but it needs to be well insulated. All elements of the purchased design are well matched, so assembly will not create problems

The pipe is fixed to the wall with brackets until it reaches the desired height. The process is completed by attaching the pipe to the boiler nozzle and sealing the joints. To ensure that the external chimney warms up quickly, it is insulated along its entire length with basalt wool.

Installation of a coaxial chimney

This type of chimney removes combustion products outside and at the same time supplies the boiler burner with oxygen-rich air. With this design, no additional ventilation is needed.

The chimney is made of round pipes - an outer steel pipe with a cross-section of 10 cm and a wall thickness of 0.1 - 0.2 cm and an inner aluminum pipe with a diameter of 6 cm. The pipes do not touch because there are jumpers between them.

Coaxial chimneys are installed for boilers with a closed combustion chamber, designed for wall and floor installation, as well as for water heaters and other gas units.

This gas outlet has several advantages:

- Structurally, the pipe is designed so that simultaneously with the heating of the incoming air, the exhaust gases are cooled;

- the chimney increases the efficiency of the equipment;

- It has compact dimensions, so it is used not only in private houses, but also in city apartments;

- safe - the exhaust gases do not come into contact with the room air and do not exit through the ventilation duct but directly into the atmosphere;

- easy to install.

Install a coaxial chimney both horizontally and vertically. Regardless of the installation method, the maximum length of the chimney should not be more than 4 m. There are models with solid parameters created specifically for long-distance chimney removal.

Directly for the installation of a coaxial chimney, manufacturers produce specially designed adapters used for vertical transitions through floors and roofs. To protect the system from precipitation and ensure tightness in the area where the pipe passes through the ceiling, there are special caps.

The figure shows tips and mandatory requirements for installing a coaxial type chimney. All of them relate to gas outlets for boilers whose power does not exceed 70 kW

If a coaxial chimney is used for a boiler installed on a wall, it should be positioned horizontally. In this case, it is necessary to ensure a 3-5% slope, otherwise condensation will enter the boiler.

The standards regulate not only the dimensions of the chimney itself for a gas boiler, but also the location of the hole in the wall. It should be at least 50 cm away from the window next to it and at least 25 cm if it is located above the window.

What else you should know about gas boiler chimneys

No more than two connection points for gas appliances are allowed to be connected to one chimney, which can be located either on the same or on different floors, but combustion products must be introduced into the duct at different levels and no closer than half a meter from each other. It is also possible to enter at the same level, but if there is a cut inside the channel to a height of 50 cm. In this case, the cross-section of the channel must be determined, providing for the simultaneous operation of all gas appliances that use this chimney.

The optimal shape for a chimney is a cylinder; in addition, oval and square shapes are allowed. But it should be remembered that square pipes have low traction. This is because the swirls that form in the corners trap smoke and cause soot to form. This may negatively affect the operation of heating devices.

Modern gas boilers have fairly high efficiency values, reaching 95%. Therefore, the temperature of the resulting gases is quite low, which contributes to the formation of condensate in large quantities. Its aggressive influence contributes to destruction. Therefore, it is recommended not just to line the pipes with brickwork, but to make a liner or lining of the channel.

- When making a liner, a single-wall pipe made of stainless, acid-resistant steel is placed in the brick shaft, which protects the brick from destruction.

- A flexible hose is installed to line the channel. This method is used for chimneys that have non-standard sizes or shapes.

The requirements allow for the installation of chimneys in the walls together with ventilation ducts. However, they should be separated by sealed partitions along the entire height. Partitions must be made of wall material and have a thickness of at least 1.2 cm.

Installation of chimneys for wall-mounted gas boilers

To remove combustion products from a wall-mounted boiler, it is allowed to install a wall-mounted (coaxial) chimney. It consists of two pipes inserted into one another, without a layer of insulation. This type of device ensures the removal of combustion products and at the same time the flow of fresh air. The distance from the ground to the pipe outlet must be at least 2 m.

There are modern models of gas heating boilers that have a sealed fuel combustion chamber. Their work is designed in such a way that the installation of traditional chimneys is not required.

How to remodel an old chimney?

If a gas boiler is included in a long-existing heating system instead of a conventional stove, the brick chimney does not have to be completely rebuilt. It can be upgraded by sleeving. There are two ways to do this.

Method number 1. Install a stainless steel pipe at the base of the existing chimney.

The pipe should be selected so that its height is equal to the height of the old chimney, and its diameter matches the boiler pipe. The gap between the walls of the existing chimney and the pipe is filled with heat-insulating material such as foam glass, expanded clay or perlite.

Method 2. Apply Furan-Flex technology. This option is more expensive than the first, but the diameter of the chimney remains unchanged. The material is frost-resistant, does not corrode, the diameter ranges from 6 to 100 cm.

FuranFlex technology allows you to modernize or repair a chimney with a slope of maximum 30⁰ quickly and efficiently

The technology itself consists of placing an elastic pipe inside the chimney under pressure. The pipe takes the shape of a chimney, then hardens and becomes a continuous, seamless shell that does not allow smoke or condensation to pass through.

What affects the efficiency of a chimney?

Perhaps the question is posed somewhat incorrectly from a professional’s point of view. Since the health and sometimes even the lives of people depend on the effective operation of the combustion product removal system, it is more advisable to consider the requirements for the chimney of a gas boiler.

A chimney of any design must be made in accordance with the requirements of SNiP 2.04.05-91, as well as DBN V.2.5-20-2001. Otherwise, the chimney will be installed incorrectly and the heating equipment will be connected to it. And this, in turn, calls into question the safety of operation of the entire heating system. These documents clearly regulate the design of boiler chimneys. These documents are subject to careful study, since violation of the standards set out in them will certainly lead to problems with the gas industry.

If we briefly outline the requirements for chimneys of gas boilers, then first of all you need to pay attention to the following points:

- Good traction is the key to efficient use of thermal energy from gas combustion.

- Correct design of the condensate collector - excess moisture should not accumulate on the walls of the chimney duct.

- It is prohibited to install deflectors, fungi, etc. on the chimney head. These elements reduce the efficiency of removing combustion products, and there is a risk of carbon monoxide entering the room.

- Requirements for chimneys of gas boilers require maximum attention to installation work. Particular emphasis should be placed on the tight fit of structural parts at the joints, that is, maximum tightness must be achieved. This will prevent hot gases from penetrating beyond the chimney.

- It is allowed to use common connecting flue pipes for several units.

From the outside it appears that the chimney is made of brick. In fact, it’s just a decoration, and it’s located inside the pipe

Why insulate a chimney pipe

If the chimney pipe for the boiler is cooled in the cold, then the temperature of the exhaust gases decreases - which means the draft decreases. This problem can be solved by insulating the pipe. How to insulate depends on the material from which the chimney is made:

- Brick structures are plastered, and if the attic is not insulated, then stone or basalt wool with foil on top is used;

- Ceramic chimneys are protected from the cold with mineral wool and ceramic blocks, metal ones are insulated with any non-combustible materials;

- The most difficult thing is with asbestos structures - they can explode if they overheat, so they must be insulated competently and carefully.

Types of chimneys depending on material

Brick pipe is used very rarely nowadays. To install such a pipe, the construction of a supporting foundation is required. Over time, the brick undergoes destruction from the inside and can allow a certain amount of gases to pass through.

For some interiors, a decorative brick chimney is used, but a stainless steel pipe is laid inside. The operation of a mixed chimney is actually quite effective.

Chimney made of steel pipe

- Single pipe is used for insertion into a brick structure, for repair work or for temporary testing installation.

- A double-wall pipe or sandwich is very often used for a chimney. Its principle is based on the operation of large and small pipes nested one inside the other. The gap between their walls is filled with insulation, which prevents condensation from forming on the walls of the chimney.

- The coaxial version of the chimney is used in those heating systems when combustion requires air supply and smoke outflow at the same time. Chimneys designed for double action have two pipes, as in the double-walled version, only the space between their walls is not filled with insulation, but serves to move fresh air. Smoke is removed along the inner diameter.

https://youtube.com/watch?v=iXYpDw4NjmA

Prefabricated elements for steel chimney of gas equipment

- Connecting adapter couplings for connecting the outlet of a gas boiler and a pipe.

- The main pipes, produced for ease of installation, are 1 m long.

- A tee for cleaning and checking pipe clogging, installed on a horizontal section.

- A tee for collecting condensate, mounted at the point where the chimney turns to a vertical position.

- Angles for turning pipes from a gas boiler.

- Compensator to soften the linear expansion of the chimney when temperature changes.

- A unit for designing a channel exit through the ceiling.

Conditions for the installation of smoke ducts for gas boilers in accordance with SNiP

A separate chimney should be provided for each gas device. As an exception, it is allowed to connect two boilers to this smoke removal system. But this can be done with an interval of 0.75 m from the previous insert.

Ensure mandatory sealing of pipes and their connections to prevent carbon monoxide leakage into the interior of the house.

Take all measures to remove condensate from the pipes. To prevent its formation, it is recommended to insulate the outer sections of the pipes.

The entire length of the internal cavity of the chimney must be free from cluttering objects, dirt and soot. All pollution leads to decreased cravings.

The size of the pipe cannot be smaller than the size of the outlet from the gas boiler; the same width or larger is allowed. A round pipe cross-section is considered ideal, sometimes rectangular or square is possible.

It is not recommended to place various umbrellas and canopies on the top of the chimney on the roof. All of these devices reduce draft and can lead to backdraft under certain weather conditions.

Where to start the installation?

- First you need to mark the installation location on the wall or on the floor, depending on the type of boiler.

- Check whether there are enough parts and other auxiliary elements. In general, we mentally install the boiler at its future place of operation.

- View installation instructions.

IMPORTANT! Alone, you can only install a small-sized or floor-standing boiler (and even then not always). In most cases, you will need the help of one or two people.

Premises requirements

- The size of the installation room depends on the power of the boiler. The minimum area is 4 square meters, and the ceiling height is 2-2.5 meters.

- The doorway is at least 80 centimeters wide.

- Windows are a must. The minimum requirement for a 4 square room is a small window measuring 0.15 square meters.

- For every kilowatt of device power there should be 8 cubic centimeters of ventilation.

- Gas pipes must be metal, no other material is allowed.

- The diameter of the chimney should depend on the power. The minimum diameter is 13 cm, and it should not taper towards the top and should protrude above the roof surface by at least half a meter.

- There should be gas sensors in the room, and a gas stop valve on the boiler itself.

- The boiler must be equipped with a fuel flow sensor.

- In an apartment building, you can install the boiler everywhere except the basement, and in a single-apartment building it is recommended to install it in the basement.

- The boiler power supply (for autonomous boilers) and the electricity supply system must have thermal insulation and electrical insulation screens.

How to install equipment correctly

Strictly follow all the rules and regulations of SNiP 42-01-2002 “Gas distribution systems”, without deviating from them.

Any attempt to improvise or change classical technology may be noticed by inspectors.

And if this causes an accident or losses to other residents of the house, the owner faces administrative, and, in some cases, criminal penalties.

- If the boiler is wall-mounted, the floor under it must be perfectly level, since the pump pumping water can cause vibration and displacement of the boiler. If the vibration is strong, the gas pipes or water supply system may become disconnected from the boiler, leading to a gas leak or flood.

- If it is possible to make a stand for the boiler, this will secure the structure and increase the adhesion strength to the floor.

- If you install the boiler near a stove, boiler or other heating elements, then the total power of the thermal field between them will be higher than what the sensors show, since they measure this only inside the system itself. This rule is not specified in SNiP, but is often the cause of premature wear of the mechanism or failure.

Documentation

Required documents:

- A summary of the fuel consumption of a specific device. This can be done both by the workers who install the boiler and by the owner-installer himself. The technical data sheet of the device must indicate data on the consumption of electricity, gas and water. Within 14 days, a gas service employee must issue preliminary consent to install the unit.

- Installation project, which indicates all installation points and steps, communication connection diagram and chimney outlet.

- Technical specification, which specifies data on installation and communication to the boiler.

- Certificate of the device, reviewed and certified by gas workers. Certificate of standardization of the boiler.

Once the project has been approved, installation can begin. Professionals typically keep an installation protocol that outlines basic steps to protect themselves in the event of equipment failure or an accident that results in damages.

The protocol is signed by the customer (boiler owner). If you are installing it yourself, the protocol should indicate the main steps specified in the instructions for the boiler. If an accident occurs during installation or the boiler does not function properly, the protocol will serve as legal protection.

ATTENTION! In the case when the installation is carried out by specialists, and the protocol is signed by the customer, it has legal force, and if the installation is performed by the customer himself, the protocol is a regular description of the actions.