Here you will learn:

- What functions does automation perform for gas boilers?

- Automation design

- Varieties

- Which automation is better - mechanical or electronic?

- Checking the serviceability and replacing the automation

- How much does boiler automation cost?

- Review of popular manufacturers

Automation used for gas boilers are special devices that provide control over the operation of heating equipment after it has been started. The main purpose of automatic control devices is to ensure the safe operation of heating units and maintain optimal temperature conditions in the room.

Based on functionality, automation is divided into two main types:

- volatile devices;

- non-volatile control devices.

The first type is energy-dependent automation, used in autonomous heating systems, has a simpler design and operates on the residual principle. The temperature sensor signal about temperature changes is sent to the solenoid valve, which closes or opens, cutting off the gas supply to the gas boiler. Almost all heating boilers are equipped with this type of control equipment.

An example of a non-volatile unit for an automatic safety system for a gas boiler

The second type of automation - non-volatile devices operate on the basis of the physical properties of the substance located inside the closed circuit of the device. When heated, the substance expands, creating increased pressure inside the device. Under the influence of high pressure, the gas valve is activated, shutting off the gas supply to the combustion chamber. The boiler is turned on in the reverse order. As the temperature decreases, the volume of the substance decreases, as a result of which the pressure in the device decreases. The valve returns to its normal position, allowing gas access to the burner. Such automation devices are used to equip non-volatile gas boilers. Models of automation system units may differ only in the standard set of functions.

Volatile products

A volatile module is a small electronic device that responds to the supply of a fuel resource. It turns on and off when the main gas valve is activated or closed. It has a complex design and a large number of elements and microcircuits.

Allows owners to solve the following tasks:

- activation or termination of gas supply;

- starting the heating system in automatic mode;

- adjusting the power level of the base burner (due to the presence of a thermostat);

- turning off a running boiler both in emergency situations and within a user-specified mode;

- displaying current indicators on the display (the general level of air temperature in the room, the point to which the working coolant has been heated, etc.).

More sophisticated modules have additional functionality and offer users unlimited and most convenient conditions for monitoring the operation and control of the unit. Electronic panels provide full protection of heating equipment from malfunction of the three-way valve and prevent the boiler from freezing.

If the temperature in the room drops sharply, the “smart” system itself starts the heating equipment and turns it off when the home is filled with comfortable warm air.

The self-diagnosis option available for individual modules prevents operational failures and facilitates the timely identification of faulty parts and assemblies in the system. It makes it possible to notice a breakdown as early as possible and replace some small element even before it creates a real problem for the equipment.

Minor breakdowns of the heating system eventually turn into global complications and entail costs associated with the repair and dismantling (full or partial) of the equipment. Self-diagnosis helps to identify a malfunction and makes it possible to eliminate it in a timely manner.

Electronic automation, responsible for the safe operation of the equipment, ensures uninterrupted operation of the boiler, prevents the system from overheating and shuts off the gas supply in the event of a drop in draft or extinguishment of the flame in the burner.

The range of energy-dependent automation on the market today is pleasingly diverse. Useful and necessary mini-units are produced by world-famous brands and small companies that are just trying to earn their place in the sun.

Volatile automation is presented in the form of a control panel, where the user can set convenient operating parameters for the equipment. The cost of a “smart” element is high, but the costs are justified, because with the help of a control unit you can reduce resource consumption without any damage to your own comfort

Among the models offered there are both very simple products and more advanced units with a programming option.

On them, the user can select the most suitable individual settings for himself and program the system to operate in day/night mode or, based on the weather forecast, set a certain level of heating of the house or apartment for a period of 1 to 7 days.

Non-volatile units

Non-volatile automation is simpler and more practical. Control and adjustment are carried out manually using mechanical rotary toggle switches and are not difficult even for those who are far from technology. The device operates completely autonomously and does not need to be connected to a central electrical system.

To heat a residential building and supply hot water to the taps, it is enough to turn the control knob in the direction of increase by 2-3 divisions. If you need to take a bath or shower, the toggle switch must be set to the maximum setting

The product is marked with a digital scale with a list of values from minimum to maximum. To activate, the user selects the desired mark and in this way sets the appropriate operating temperature directly to the boiler.

After these manipulations, the thermostat is connected and takes control of the specified heating mode. The boiler actively works until the room warms up to the desired temperature. Then the thermostat turns off the gas supply to the system and is activated again only when the room gets colder.

The operating principle is based on the specific design of the device. The gas boiler thermocouple built into the heat exchanger is equipped with a special rod. It is made from a special iron-nickel alloy called invar.

The physical characteristics of this advanced material give it the ability to almost instantly capture minimal temperature fluctuations.

If the room becomes too hot or too cold, the size of the rod changes. The connecting valve reacts to this and promptly shuts off or activates the flow of gas to the burner.

The presence of a non-volatile automatic control system allows users to set the most suitable temperature regime in their house or apartment and use fuel economically without overpaying on utility bills

Additionally, non-volatile automation has sensitive draft and flame sensors. If the pressure in the pipe suddenly decreases or the draft level in the chimney drops for some reason, the supply of the resource is immediately stopped and gas leakage can be avoided.

Non-volatile automation costs quite reasonable money and, unlike electronic analogues, does not require the purchase and installation of a stabilizer that controls voltage and equalizes unexpected surges in the central power grid

Correct operation of the flame sensor is ensured by a special plate. During normal and correct operation of the system, it is in a slightly curved state.

In this way, the part holds the shutoff valve in the “Open” mode. When the flame becomes smaller, the plate is leveled and the valve closes under its pressure.

Automation design

All internal equipment of automation for gas boilers, which is used when installing a heating system, can be divided into categories, there are only two of them:

- the first category is those devices that ensure the safe and proper operation of all boiler equipment;

- the second category is those devices that can significantly increase the comfort when using the boiler.

Safety automation for gas boilers consists of the following elements:

- the module that provides flame control. It consists of a thermocouple and a gas valve that works like an electromagnetic valve and shuts off the fuel supply;

- there is also a device that protects the system from overheating and maintains the required temperature; this task is performed by the thermostat. It independently, if necessary, turns on or off the boiler at those moments when the temperature approaches the specified peak levels;

- the sensor that controls traction. This device works based on vibrations depending on how the position of the bimetallic plate changes. It, in turn, is connected to a gas valve, which stops the gas supply to the burner;

- there is also a safety valve, which can be responsible for discharging excess coolant (for example, air or water) in the circuit. Some manufacturers immediately provide an element that helps dump excess.

The devices included in the security system are divided into the following types:

- mechanical;

- and operating from a power source.

They operate either under the influence of a drive and a controller that controls them, or are coordinated electronically.

Automation provides the user with more comfortable functionality, which is additional:

- automatic ignition of the burner;

- flame intensity modulation;

- self-diagnostic functions.

But such functionality is not limited to the internal design of the models.

Some design features of the models include additions such as sending data and processing it by an electronic system on equipment equipped with controllers and microprocessors. Then the following situation occurs: based on the received data, the controller itself begins to adjust the commands that activate the machine’s system drives.

Mechanical automation of a gas boiler also requires detailed consideration.

- The gas valve is completely closed and the heating installation is inoperative.

- In order to start a mechanical gas boiler, the washer is squeezed out, allowing the fuel to start and opening the valve.

- The valve opened under the influence of the washer and gas flowed to the igniter.

- Ignition is in progress.

- After this, gradual heating of the thermocouple begins.

- The electric shut-off magnet is supplied with a voltage that ensures its open position so that fuel access is not blocked.

- Mechanical rotation of the washer regulates the required power of the gas heating device, and the fuel in the required volume and with the required pressure is supplied to the burner itself. The fuel ignites and the boiler unit begins to operate.

- And after that, this process is controlled by a thermostat.

How the security system works

The installation of a security system in a gas boiler machine is a necessary attribute, since all internal processes take place under its control.

The following points are automatically adjusted:

- gas pressure is adjusted;

- if the values fall below those set by the manufacturer or user, then fuel access is blocked. This is achieved by the locking mechanism lowering the valve;

- if the operation of the module depends on energy sources, then pressure control is carried out through a relay that fluctuates depending on the pressure. They consist of a kind of membrane secured by a rod. And when the pressure stabilizes, the membranes take a position that helps open the contacts that provide power to the heating installation. But if the pressure returns to normal, the contacts close again and the installation works;

- ensuring a flame in the burner. If there is no flame, the thermocouple quickly cools down and the production of the required current stops. And the damper, operating on an electromagnetic principle, stops the supply of fuel to the burner itself;

- the presence of the necessary draft in the channel that provides smoke removal. When the thrust decreases, the bimetallic plate takes on a different shape due to heating. The rod that connected the sensor and the valve takes the system out of operating mode. The supply of fuel to the burner stops;

- the presence of a thermostat that monitors fluctuations in the temperature of the coolant itself circulating in the circuit. Almost all safety systems that meet modern requirements are equipped with relays and sensors that guarantee control of the presence of coolant inside the circuit.

But you need to understand that automation for gas boilers requires preventive inspections by specialists, because even the best automation can fail for many reasons. But if it is periodically inspected by a master, then the system should work flawlessly.

Varieties

All equipment of an automatic gas water heater that controls the heating system modes can generally be divided into two main components. Moreover, the first group includes safety devices that are capable of maintaining the operation of the AGV in a given temperature range and ensuring the reliability of the system.

The second group includes automatic safety devices designed to ensure the most comfortable operation of the units. For example, a built-in electric ignition or an electronic thermometer is used for this purpose.

The mandatory list of safety automation systems used for gas boilers includes a regulated group of elements.

- A unit that controls the pilot flame. It should include automatic elements for gas units that have the ability to independently stop the gas supply.

- A unit that controls heating parameters of the coolant, capable of stopping heating when the maximum permissible level is reached.

- A module that controls draft, capable of interrupting the gas supply to the operating burner in the event of violations of the exhaust outlet.

- A safety valve that allows the release of excess pressure in the coolant.

If all the specified elements are present that ensure adjustment of the equipment of the existing gas boiler, the existing heating system is recognized as suitable for safe use and is allowed to operate. An entry about this is made in the automatic safety log of the water heating boiler.

Principle of operation

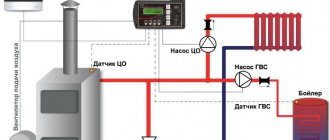

The operation of energy-dependent thermal process automation systems is based on the analysis of data from the microprocessor unit from primary sensors. All service mode settings that determine the normal operation of the boiler unit are displayed on the main panel, which is installed either on the boiler itself for household units or AOGV, or on a remote control panel for industrial and municipal devices.

Modern boilers are equipped with special programmers that configure multi-day operating modes of the equipment, taking into account the weather forecast; the average outside air temperature is used to test operating modes.

In addition to sensors, the automatic system can be equipped with a controller integrated with the boiler bus for transmitting encoded signals and communication modules that guarantee communication with the consumer of thermal energy via the Internet network remotely using phones. Therefore, with such a high level of service, it is very important that the gas boiler is in good working order, and the automation repairs are carried out by a service center.

Which automation is better - mechanical or electronic?

Devices that control the operation of heating equipment can be mechanical or electronic. In budget models of gas boilers, in most cases, a mechanical, manual control option is used. Despite the fact that the level of technical progress has reached unprecedented heights, mechanics remains a reliable and proven tool. Automated safety systems for gas boilers, operating in manual control mode, are an order of magnitude cheaper. The operating principle of most models of manually controlled boilers is simple and understandable for domestic use.

Regulator of coolant supply intensity to the radiator of a water heating system

The automation unit of the mechanical operating principle is easier to maintain and repair. Disassembling such a unit is quite within the capabilities of a specialist - a heating engineer who carries out a preventive inspection of the boiler equipment in your home.

Manual, mechanical control of a gas boiler is independent of the power supply - the home owner independently sets the temperature required for heating the living space, everything else depends on the laws of physics that form the basis of the mechanism’s operation.

For reference: the heat exchanger is equipped with a thermocouple - a mechanism based on a plate combined from two parts - steel and nickel. During the heating process, the plate lengthens, and when cooled, it decreases in length, acting on the valve, which opens or closes the gas supply to the working area. The draft regulator, which is equipped with gas boilers with an open combustion chamber, operates on the same principle. When the temperature rises to a critical level (more than 750C), the bimetallic plate bends, breaking the circuit. When the flame decreases, the plate returns to its natural position. Everything is simple and clear.

A different principle of operation is inherent in automation with electronic filling, which uses not the physical properties of materials and media, but a fundamentally different method of transmitting a signal to equipment.

Mechanical automation

Manual adjustment of household gas boilers is ensured by the entered settings of a given range of optimal temperature values. Ignition of the combustion chamber flame wick starts the thermostat, which is sensitive to changes in the coolant environment.

Gas boiler burner

The temperature regulator pumps the gas supply to the burner when the water cools in the heating system circuit, and shuts off the flow when it is sufficiently heated. A temperature sensor is installed in the gas pipeline. It is equipped with the following components:

- thermocouple;

- group of levers;

- spring pipe;

- core.

The core is a brass tube and an Invar rod, a sensitive element that responds to changes in the state of the coolant. By changing the length, it opens and closes the valve, adjusting the supply of energy to the combustion chamber of the device.

Electronic automatic control systems

The most common type of automation used in budget boiler models is an electronic thermostat.

The device is installed indoors and controls heating based on signals from an external temperature sensor located in the current zone of the room. When the temperature drops below the set limit, a signal is sent to the boiler to turn on. When optimal temperature parameters are reached, the sensors transmit a shutdown signal to the system. Room thermostats have a cable connection with gas boilers.

In this case, the presence of a thermostat ensures the optimal heating temperature of the gas boiler and economical consumption of blue fuel. Today, there are several types of thermostats on sale, differing in functionality, technical characteristics and installation method. Programmable devices ensure that the optimal temperature regime is maintained inside the living space for a given period of time.

Note: some models can automatically control the operation of a gas boiler during the day, while other models of equipment can control the operating unit during the week. Wireless automatic control devices are also produced that allow remote monitoring of the boiler operation. The range of modern remote control systems, depending on the chosen model, is 25-100 m.

Connecting the electric boiler to the panel

It is recommended to entrust the installation of the shield to a specialist. A metal shield and three-phase input are not enough to operate the heating device. The electrical appliance must be grounded. A separate ground wire must be connected to the electrical panel. Connection to the electric boiler is made through the panel.

Connection to the panel

Connection recommendations:

- ensure reliable grounding to prevent electric current from penetrating the housing;

- The high power consumer must be connected directly from the current input to the house. The circuit can only be interrupted by an automatic device that turns off the electric boiler in the event of a malfunction;

- the cable is selected in accordance with the rated load of the boiler;

- shut-off valves, which are usually used when connected to other types of boiler equipment, must turn off the unit from the common heating circuit. This will be needed when performing maintenance or repair of the electric boiler.

You can make an electric boiler yourself. Any man can do it. But you don’t need to connect the heating unit or make adjustments. It is better to entrust the work to a master. To avoid collisions due to improper installation of the device. Otherwise, the unit will not work efficiently and will break down.

Automation for electric boiler:

average rating

more than 0 ratings

Share link

Checking the serviceability and replacing the automation

The periodicity of checking the automation systems of boilers operating on gas fuel is stipulated in SNiP. Maintenance is carried out twice a year during a scheduled inspection, before and after the end of the heating season.

The following signs indicate the need for repair work:

- Increasing frequency of automatic malfunctions of gas-fired boilers. A problem is considered to be a situation in which the boiler turns off on its own every few weeks.

- Spontaneous extinguishing of fire.

- Ignition system failure.

The reasons for poor operation of automation can be very diverse, from errors made during installation to incorrect settings.

Maintenance and adjustment of the automatic gas heating boiler, in accordance with current rules, is carried out exclusively by qualified personnel who have the appropriate permit and license. Electronic control unit requires installation of special software (firmware).

During the next seasonal inspection, the microprocessor is diagnosed, which is required by the rules for servicing relay automation. Most controllers have a problem diagnostic function installed, a report of which is stored in the device memory. Error information is taken into account when configuring the module.

A complete replacement of the automation is extremely rarely required. In most cases, individual components are changed: thermocouple, valves, sensors, etc.

Description of non-volatile units

Such automation modules installed on gas boilers are much simpler in design, but poorer in capabilities. They are equipped with budget models of boilers with a power of up to 30 kW.

The operating principle of the control unit for such installations is mechanical; adjustment is carried out manually by turning the knob. The device will work reliably in the absence of electricity. On the handle or on the body around it there is a scale with some conditional power levels from 0 to, for example, 6 or 10. The user manual describes approximately what level of hot water consumption from the hot water supply system this or that value corresponds to

The mechanical thermostat opens the gas supply valve and keeps it open until the set temperature is reached. The automation of the gas unit is equipped with draft and flame sensors. When the draft in the chimney stops, the fuel supply is instantly shut off, eliminating leakage.

The flame in old-style boilers had to be lit manually. Modern models are equipped with a piezoelectric ignition device.

Italian automation for boilers produced by EuroSIT is popular among manufacturers. It is distinguished by well-thought-out design and high reliability. The presence of a EuroSIT valve is a strong argument in favor of purchasing a specific model.

In general, a non-volatile module is characterized by simplicity of design, high reliability, low price, limited functionality

How much does boiler automation cost?

The cost varies from several thousand rubles to half the cost of the boiler. The price is influenced by several factors:

- Manufacturer country.

- Automation type.

- Equipment.

Domestic automation, fully equipped, including a burner device, igniter and multi-control unit, will cost approximately 5-6 thousand rubles. For this amount, you can purchase a set of APOK - 1, Iskra, Vakula, etc.

Italian microprocessor-based control automation will cost starting from 10 thousand rubles. and higher. The cost of a multiblock is approximately 1-2 thousand rubles. higher than that of the domestic analogue.

According to the method of exhaust gas emission

Based on how the smoke is released, the following types of boilers are distinguished:

- Chimneys.

- Turbocharged.

- Parapet.

The first type is boilers with an open combustion chamber. As the name suggests, they require the installation of a high-quality chimney.

Scheme of a turbocharged double-circuit gas boiler

Turbocharged boilers have a closed combustion chamber, and the gases are forced out by a built-in fan. Such devices need a coaxial pipe (essentially, these are two pipes one in one: smoke comes out through the inner pipe, and oxygen necessary for the combustion process enters through the outer pipe). Pipes are laid through external walls without installing a vertical channel.

Parapet. The boilers are similar to the previous version (also has a closed combustion chamber and a double pipe), but smoke is removed due to natural air circulation, and not by a fan. Therefore, parapet boilers do not require electricity.

Review of popular manufacturers

The duration of trouble-free operation of such household appliances, as well as the safety of property and people’s lives, will depend on the proper operation of the automation of safety systems for heating equipment. Considering this fact, the choice of automatic sensors should be approached extremely responsibly.

Purchasing products from popular manufacturers, despite higher prices, is more profitable, because such elements will last longer, and the reliability of equipment from well-known companies is much higher than cheap analogues made by handicraft methods. The most popular manufacturers of this type of equipment are:

- Eurosit. Automation for boilers produced under this brand has European quality and reliability. If necessary, you can purchase both individual elements of such systems and ready-made heating equipment protection systems.

- Orion. Domestic manufacturer of high-quality equipment for automatic systems of thermal equipment. At the same time, the company's products are in the budget price range. Orion security systems are installed, as a rule, in floor-standing gas boilers that were manufactured in Russia.

- Honeywell. An American company that has been producing high-end automatic systems for over 100 years. Various valves and relays sold under this brand will last at least 10 years if used properly.

Any type of automation produced by these companies can be used without any fear. Multi-level control in production and pre-sale preparation virtually eliminate the possibility of purchasing defective products.

Orion

The Orion automatic device is manufactured in Russia. The device includes a piezoelectric ignition and a draft sensor.

The Orion device looks simple and has a minimal set of functions. Its capabilities are not too great, but, thanks to its reasonable price and basic control method, the unit is in demand

The device turns off the gas in case of random extinguishing of the burner or lack of the required draft. When the room temperature drops, the thermostat activates the fuel supply and the boiler resumes operation.

The transition to the flame reduction mode when a certain (user-specified) temperature is reached occurs automatically and allows you to save fuel resources.

Honeywell

In addition to inexpensive budget models, Honeywell also produces other types of automatic equipment, for example, luxury chronothermostats of the premium ST series or programmed thermostats Honeywell YRLV430A1005/U.

The YRLV430A1005/U device, with the widest possible functionality, has a user-friendly interface and does not cause any difficulties for customers during use. The cost of the product is quite high, but still lower than that of competitors offering models with similar characteristics

These electronic panels allow you to set the heating equipment the most detailed and precise settings, up to changing the temperature several times a day depending on the time of day, weather conditions and personal wishes.

Honeywell 5474

The Honeywell 5474 device is manufactured by the German concern Honeywell, which has been specializing in the development and sale of various types of automation for more than a hundred years. Works correctly with domestic gas boilers with a power of up to 32 kW.

Honeywell 5474 is a non-volatile device for controlling the heating system. Equipped with micro-torch burners made of heat-resistant stainless steel. They ensure better gas combustion, reduce the emission of harmful substances into the atmosphere and prevent excess soot from depositing in the chimney

The Honeywell 5474 automatic system is equipped with a basic set of control functions that guarantee efficient operation of the boiler with absolute safety for users.

In automatic mode, the product maintains the specified coolant temperature (from 40 to 90 degrees), turns off the boiler in the event of a fuel supply cutoff, lack of draft at the required level in the chimney, reverse draft occurs, or burner extinguishment.

Manufacturing technology. Instructions

After familiarizing yourself with the structure of the boiler, you can try to make a similar device at home

This process is not as difficult as it may seem, but it requires utmost care and attention. Otherwise the finished product may be unsafe

Stage 1. Preparing everything you need

To work you will need the following equipment:

- welding machine;

- electrodes;

- iron tee;

- electrode insulation (polyamide);

- neutral wire;

- coupling;

- ground terminals;

- steel pipe of appropriate dimensions;

- insulation for terminals.

Stage 2. Assembling the ion boiler

Assembling the boiler

First, let's clarify a few important aspects. So, the ion boiler needs grounding, as mentioned above, and the neutral cable must be supplied exclusively to the outer pipe. It is also worth remembering that the phase should only be supplied to the electrodes.

Assembling the boiler

With proper preparation, the assembly procedure should not cause any difficulties.

Assembling the boiler

Step 1. First, take a pre-prepared pipe (optimal dimensions - length 25 cm, diameter 8-10 cm). On one side, a set of electrodes is placed in the pipe, and on the other, a coupling is installed for connection to the heating main.

Ion boiler drawing

Step 2. An insulator is installed near the electrode, which, in addition to its direct function, will also serve for additional tightness of the boiler.

Step 3. High quality heat-resistant plastic is used to make the insulator. But not only tightness is important for the device, but also the possibility of threaded connection of the electrode with a tee. That is why it is recommended to entrust the manufacture of the insulator to an experienced specialist who will make the part in accordance with the required dimensions.

Parts for boiler assembly

Step 4. A large bolt is welded to the body. Next, the neutral cable and grounding terminals are attached to the bolt.

Step 5. After connecting to the heating system (this is done using a coupling), all that remains is to hide the finished boiler with a decorative coating. Such a coating is necessary not so much for aesthetic purposes, but for safety and protection from electric shock. This should not be neglected, since it is necessary to limit access to the heat generator as much as possible.

Stage 3. Installation work

Boiler connection diagram Boiler connection diagram

- air vents;

- pressure gauge;

- fuse.

In this case, the shut-off valves are installed after the expansion tank. The above diagram will help you get acquainted with the connection features in more detail.

Installation of an electrode boilerInstallation of an electrode boilerConnection diagramAssembling a heating systemAssembling a heating systemAssembling a heating systemPolyphosphate filterAdjusting an electrode boiler

Video - DIY ion boiler

Other important installation points.

- The boiler is installed exclusively vertically, which can only be explained by its operating features. Fasteners must be separate.

- Before installing the device, the entire heating system is thoroughly washed. To do this, take clean water diluted with an appropriate product (such as Rothenberger). If a contaminated coolant is used or the line has not been properly flushed, the performance of the ion boiler will decrease significantly.

- For grounding, you can only use a copper cable ø4 mm (or larger) with a resistance of no more than four ohms. The cable is connected to the zero terminal, which, accordingly, is located in the lower part of the unit body.

- Heating devices (batteries) are selected in accordance with the volume of the system. The best option is that a kilowatt of device power corresponds to 8 liters of total volume. If this figure is exceeded, the boiler will operate longer than required, resulting in increased energy costs.

- In addition, when arranging a heating system, preference should be given to bimetallic alloys or aluminum. The use of other alloys is unacceptable, since they contain many different impurities that affect the electrical conductivity of the working fluid.

- If an open system is installed, then the batteries used must in any case have a polymer coating on the inner surface, which will prevent air from entering and, as a result, prevent corrosion. Closed systems do not have this disadvantage.

- Cast iron products should be abandoned altogether, because the impurities they contain in large quantities will reduce the performance of the ion boiler. Also, such batteries are too large, which will increase energy consumption.

Installation procedure

The purchase of a solid fuel boiler equipped with everything necessary is available. But usually it needs to be installed. You can do this yourself. To complete this procedure, you must take the following steps:

- First install the fan. It can be placed where there is an ash pan door or one designed for air supply. Some models of solid fuel boilers already have space for installing a fan. If this is not the case, you will need to drill holes for the corresponding bolts yourself. In this case, the fan must be installed on a special heat-resistant gasket.

- Next, you need to directly connect the automation to the boiler. Typically, the installation location of the controller is provided in the upper part of the boiler body. It is important to make sure that the place where the electronic board is attached will not overheat. Otherwise, the increase in temperature may cause system malfunction.

- The necessary sensors are installed. Submersible ones can be used to control the coolant. Special sleeves are provided for them.

- All elements must be installed in accordance with the connection diagram. It is usually included in the documentation provided when purchasing the control system.

After the connection is completed, it is necessary to configure the equipment.

Operating principle of a solid fuel boiler Source househill.ru