Among gas heating boilers, products from European manufacturers are considered leaders in quality and reliability.

However, their approach to the creation of heating equipment does not always fit well into the Russian technological framework.

The products of domestic companies often confidently outperform them in various positions, the main one of which is cost.

Siberia heating boilers are a striking example of such superiority, demonstrating a completely different approach to creating autonomous heating systems.

Let's consider one of the most popular models of boilers from this company.

Model of gas boilers Siberia 23

The Siberia trademark belongs to CJSC Rostovgazoapparat. The company offers floor-standing boilers with an atmospheric burner and a stainless steel heat exchanger.

The Siberia 23 model under consideration is a gas single-circuit unit designed only to power the heating circuit.

There is also a double-circuit option, Siberia 23 K (combined), capable of supplying hot water for household needs in addition to heating the coolant. The numbers “23” in the name mean the thermal power of the model is 23 kW.

Based on the power value, you can roughly determine how much area the boiler can heat by multiplying it by 10.

For example, Siberia 23 is designed to serve premises of 230 m2.

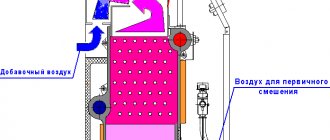

Smoke removal is carried out naturally, using a stove-type draft (atmospheric burner).

Coolant circulation is also based on the process of rising heated layers of liquid upward, which introduces special requirements into the configuration of the heating circuit.

Popular models

Let's look at the most interesting boiler models from the Rostov manufacturer. These included both floor-mounted and wall-mounted units. Each category of equipment is characterized by structural complexity; the differences lie in the technical characteristics.

Boiler Siberia 11

The floor-standing gas boiler Siberia 11 is one of the most popular models. This is the youngest model in the entire line of equipment with steel heat exchangers. The device can heat up to 125 sq. m, which depends on the amount of heat loss. The efficiency is up to 90%, the control system used is mechanical. The boiler does not require an electrical outlet; it operates autonomously. The gas burner of the device is made by the Polidoro brand. To operate in difficult conditions, a gas pressure stabilizer is provided on board.

Siberia 35

Before us is the most powerful floor-standing gas boiler Siberia with a heat exchanger made of high-quality carbon steel. The thermal power of the unit is 35 kW, the heated area is up to 400 sq. m. A mechanical control system, built on a capillary-type modulating thermostat, is responsible for maintaining the set temperature. Basalt fiber used in the space industry is used as insulation. The maximum heating temperature of the coolant is +90 degrees.

Siberia 17K

The Siberia 17K double-circuit boiler is designed for heating households up to 200 square meters. m. At the same time, it prepares hot water. Despite the dual-circuit design, the device does not require connection to the electrical network - it operates exclusively from the gas mains. The declared rated power is 17.4 kW, the heating temperature of the coolant is up to +90 degrees (with slight differences).

A similar model is Siberia 17 (without the K index) - it is built according to a single-circuit scheme. Please note that all boilers with steel heat exchangers can operate both from the gas main and from bottled gas.

Siberia KCHGO-25

Before us is the Siberia boiler, made on the basis of a cast iron heat exchanger.

Cast iron is resistant to corrosion, durable, and resistant to high temperatures. This alloy has two disadvantages - low resistance to temperature changes and fragility. But if you follow the operating rules, nothing bad will happen to it. The floor-standing gas boiler Siberia KCHGO-25 is built according to a single-circuit design with an open combustion chamber. Efficiency is up to 90% and higher, heating area is up to 270 sq. m. Natural gas consumption reaches 2.45 cubic meters. m/hour, operation on liquefied gas is not provided.

Siberia KCHGO-25E

This modification is based on a more advanced electronic control module. It can operate in cascades and control connected boilers. You can also connect a room thermostat to it for remote control and maintaining the set air temperature (not the coolant). Other advantages of the device:

- Minimum power consumption is only 4 W/hour.

- The thickness of the heat exchanger is 4 mm.

- Reliable protection against corrosion.

- High accuracy of temperature maintenance.

The boiler is powered by a gas main; there is no possibility of switching to a gas cylinder. Maximum consumption when operating at full power is 2.45 cubic meters. m/hour.

Siberia TopLine 24

This gas boiler belongs to the wall-mounted category. It is equipped with an atmospheric combustion chamber and a copper bithermal heat exchanger. The productivity of the DHW circuit is up to 12 l/min at ∆t=25°. If you need hotter water, the productivity will drop to 7 l/min. The maximum gas flow is up to 2.65 cubic meters.

m/hour, when powered by a gas cylinder – 1.9 kg/hour. The wall-mounted boiler Siberia TopLine 24 is designed to heat an area from 30 to 200 square meters. m. Features of the model:

- Built-in Grundfos circulation pump from a well-known brand.

- Burner from Polidoro.

- Possibility of connecting a room thermostat.

- Smooth ignition without popping or rattling.

- Support for the “Anti-freeze” operating mode.

Scope of application – heating of apartments and private houses.

Also on sale is a modification of Siberia TopLine 24C. It differs from its analogue in a closed combustion chamber. In addition, a turbocharged boiler is characterized by increased energy consumption - 130 kW versus 85 kW for an atmospheric sample.

Siberia KCHGO-50

The most powerful floor-standing gas boiler from the Siberia brand. It is capable of heating buildings up to 600 square meters. m. with a power of 50 kW. When reaching maximum power, gas consumption is 5.5 kW. The water in the cast iron heat exchanger is heated to a temperature of +90 degrees. The model is single-circuit and does not prepare hot water. The boiler is available in two versions - with a mechanical or electronic control system (the latter is marked with the index E).

Siberia 17

Another popular floor-standing gas boiler, built on the basis of a steel heat exchanger. It is distinguished by its compact design and simple mechanical controls. There is no second circuit on board, but a similar model with index K has one. The maximum heating area is 200 square meters. m, thermal power – 17.4 kW. If necessary, the boiler can be reconfigured to work with a gas cylinder.

What functions does it have?

The main function that the boiler performs is heating the coolant and supplying it to the heating circuit.

In addition, the boiler has the following capabilities:

- Determining the temperature of a liquid using a thermometer.

- Pressure control using a capillary action pressure gauge.

- Piezo ignition.

- Availability of mechanical sensors for controlling traction, gas pressure, flame.

The list of boiler functions is not as wide as that of imported models, but this does not prevent the device from performing its task efficiently.

IMPORTANT!

The list of functions of the Siberia 23 boiler is quite modest, but this does not indicate the primitiveness of its design, but indicates the absence of unnecessary components and parts that complicate the work.

Official website of boilers with catalog

The official website of the manufacturer is located at https://www.rndgaz.ru/. By turning to the Siberia section, you can find all the implemented modifications of boilers and a description of their main functions. Detailed operational characteristics are indicated in the passport documentation of the boiler units.

Digital copies of the instruction manual can be found in the “Info Center” section. The instructions for the required configuration provide characteristics, installation plan, connection procedure and the process of adjusting heat supply modes, maintenance features, and contain intelligible schematic representations.

Specifications

Let's consider the technical parameters of the unit:

| Options | Values |

| Boiler type | Gas convection |

| Installation type | Floor |

| Fuel type | Natural or liquefied gas |

| Functionality | Preparation of coolant for heating systems |

| Efficiency | 90 % |

| Serviced area (maximum) | 230 m2 |

| Boiler power | 23 kW |

| Power supply | Absent |

| Burner type | Atmospheric (open type) |

| Burner material | Stainless steel |

| Ignition type | Piezo |

| Chimney diameter | 125 mm |

| Weight | 65 kg |

| Dimensions | 850×380×560 mm |

| Guarantee period | 24 months |

| Service life with proper maintenance, maximum | 25 years |

Equipment installation

Equipment installation must be carried out by a specialist. To do this, you will additionally need to obtain permission to install:

- Registration of permission;

- The gap between the wall and the equipment must be at least 3 cm;

- For a floor-standing unit, you will need to prepare a foundation;

- To prevent gas leakage, all connections must be carefully insulated;

- The boiler should be started up for the first time by a specialist;

- must provide the equipment with a warranty upon first start-up

- If you connect an electric boiler , you will need to install the electrical network and water supply;

- When connecting heaters that are not volatile , additional equipment will need to be installed separately;

- If you connect it to the network using the “cascade” principle, you can increase the power several times. Thus, it is possible to connect all types of boilers;

- A piezoelectric element is used for ignition;

- Initially, the igniter lights , and then the main burner.

If condensation appears on the heat exchanger during the first start-up, this is not a problem. When the unit heats up, it will disappear.

Advantages and disadvantages

The advantages of the Siberia 23 model include:

- Reliability, stability of the operating mode, unpretentiousness.

- Economical, low gas consumption.

- Non-volatility, no need to connect to power grids or voltage stabilization.

- The price of boilers of this brand is almost half that of other similar devices.

- The boilers are created taking into account Russian technological operating conditions and are maximally adapted to them.

- Service support available.

The disadvantages of Siberia 23 gas boilers can be considered:

- Ignition of the burner is done manually, which requires some skill.

- Atmospheric thrust is unstable and is often subject to external influences that can change the thrust vector to the opposite.

- The coolant circulation mode is quite weak; it often has to be strengthened using an external circulation pump.

The disadvantages of boilers are due to design features, in particular, energy independence.

However, most users treat the presence of these limitations with understanding, considering the guarantee of stable operation of the unit even during a power outage more important.

NOTE!

If necessary, the draft and circulation of the coolant can be enhanced by installing external devices - a turbo nozzle and a circulation pump. In this case, the system configuration should in any case be calculated so that the boiler can operate independently if the power supply suddenly turns off.

Owner reviews

With high quality, prices for Siberia boilers are very reasonable. Here are some owner reviews:

- I have Siberia 17 K for a house of 100 square meters. I took it on the manufacturer’s recommendation with a power reserve and I don’t regret it. Even in the coldest weather, the house is warm and the water flows a little more. But in general, it doesn’t heat the water well. If you like it to have pressure and be hot, it is better to install a boiler. It works quietly and consumes less gas than the Don that was installed before.

- A cauldron is like a cauldron, only the way everything we do is made. No one thought about how to get to the burner. And the instructions say that you need to clean the heat exchanger once a year. This is a whole torment and adventure.

Device - location of the main functional parts - A good boiler from the “Set it and forget it” series. I have Siberia 29. It lasts 6 years. The house is two-story, heated area is 200 square meters. Pump system. 4 radiator circuits are heated (only 2 are in operation all the time) and 4 heated floor circuits. The radiators are connected through a manifold, the heated floor through its own comb with a mixing unit. The boiler is equipped with an automatic Minisit 710, it can modulate the flame height. When there is a power outage, the boiler quickly turns off due to overheating of the coolant - about a minute after the pump stops.

- Like all boilers and columns with an atmospheric burner, this boiler works like a vacuum cleaner. It draws air from the premises, and dust, soot, etc. fly with it. All this settles on the burner. Therefore, this burner must be cleaned regularly. Then there will be no problems with ignition. So I clean it once a year. No problem.

- I replaced the old boiler with a Siberia 17 with hot water. There are no problems with heating, but with water - not so much. While it was cold and the burner was almost at maximum, the water was warm. As it got warmer and the regime changed, she became cold.

- On a brick house of 70 square meters there is Siberia 17. For the coldest month it came out to 1800 rubles (at prices of 16 years).

In general, this is normal equipment that works even in not very good conditions - at low gas pressure.

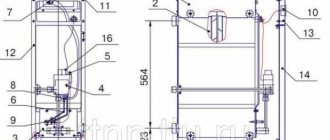

Device

The main design elements of the Siberia 23 boiler are a steel heat exchanger and an open type gas burner. They are combined to obtain maximum effect when working.

In addition, the elements of the unit include:

- A three-way valve in which a colder return flow is mixed into the heated coolant to obtain the desired temperature in the heating circuit.

- Gas equipment, including a magnetic valve, supply system and control unit.

- External chimney (not included in delivery and must be purchased separately).

The operation of the unit consists of the coolant entering the primary steel heat exchanger, heating it to the maximum temperature and passing into a three-way valve. Having reached the operating temperature, the coolant is removed from the boiler and re-entered the heating circuit.

Smoke removal occurs under the influence of natural draft, as does the movement of the coolant.

All work is based on mechanical effects and occurs without the use of electricity.

The most common problems and breakdowns

It is clear that there is no perfect equipment and it breaks down or does not work as it should. In most cases there are specific reasons for this. Based on the operating experience of Siberia boilers, we can identify several characteristic problems that owners often encounter:

- Low heating of water for domestic hot water supply by Siberia double-circuit floor-standing boilers. There's nothing you can do about it - it's not their strong point. If you look at the technical specifications, the maximum hot water flow is very small. And this is at normal gas pressure. If the pressure is low (which usually happens in cold weather), then the water will be slightly warm.

- The water at the boiler outlet does not heat up to the stated 90°C (if you turn the regulator even to the very last, 7th position). There are several possible reasons. The first is low gas pressure. When the pressure drops below 130 mm. water the column's power decreases proportionally. When you call the gas service (they are responsible for the nominal pressure), ask them to clean the inlet filter. If it is clogged, the pressure will be low. The second possible reason is a burner clogged with soot and dust. It needs to be cleaned once a year. If this is not done, the efficiency decreases and the Siberia boiler heats worse.

They differ in the heat exchanger material - steel and cast iron - The pilot burner does not ignite the working burner. Again, there may be several reasons. And the first is low gas pressure in the pipe. But this time it is below 50mm. water pillar At this pressure the boiler does not start. The second reason is a clogged gas valve. The third is a smoked burner. In all cases, we clean the valve and/or burner. Fourth, the thermocouple sensor is located too far away (you can see it visually, if it doesn’t reach the flame, that’s the reason). In this case, you need to loosen the thermocouple mounting nut and move the contacts a little closer. Fifth - weak traction.

- After a summer of inactivity, it is difficult to start the boiler. During downtime, air collects in the gas supply pipe. Until it is “corroded”, it will not be possible to light the boiler. When igniting for the first time, open the window/vent and monitor your health. Take a break between launch trials. During this time, the burner will be ventilated and the Siberia floor-standing gas boiler will start up faster.

As you can see, there are a lot of problems, but most of them are related to the peculiarities of the work of public utilities in our country. Of course, there are reasons in the equipment. But this is a small part of the total number of cases of non-working equipment. In order for the Siberia floor-standing gas boiler to work without problems, it is worth fulfilling all installation requirements and carrying out regular maintenance.

For which rooms is it best suited?

Siberia 23 boilers are designed for heating residential or public premises with an area of about 230 m2.

This is the most common size for a private home, office, shopping pavilion, etc.

In general, boilers of this model can be used in any premises where there are no strong drafts, multidirectional air flows and constantly opening doors. This is important to ensure stable traction.

How to install correctly

The boiler must be installed in a well-ventilated room with a ceiling height of at least 2 m.

It is placed near a fireproof wall at a distance of at least 15 cm, and there must be a free space of at least 1 m in front of the unit to ensure normal maintenance conditions . If the floor is wooden, a sheet of asbestos is first laid, on top of which a sheet of metal is placed.

They must protrude beyond the boiler body on all sides by at least 10 cm.

Start-up and operating instructions

The boiler is started only after all communications are connected and the system is filled with water.

Needs to be attached:

- Heating circuit forward and return pipelines.

- Water make-up pipeline.

- Gas pipeline.

After this, check the tightness of the connections, paying special attention to the gas pipe. The system is filled by opening the feed tap. When water flows from the signal pipe, the process is completed.

The boiler is turned on by pressing the control knob all the way while simultaneously pressing the ignition button.

They must be held in this position for some time (up to 1 minute) until a flame appears on the pilot burner.

After this, the control knob is set to the desired value, which will cause a flame to appear on the main burner and start the boiler.

Operation of the unit does not require any special actions from the user and consists only of maintaining the cleanliness of the housing.

Once a year, you need to call a technician to clean the internal components, check traction and other important elements.

Also, a technician should be called immediately if problems or unusual behavior of the installation occurs during operation.

Connection and first start-up must be performed by technicians from the service center.

Download instructions

Download instructions for gas boilers Siberia 23.

The most reliable models

All Siberia gas boilers have a good trouble-free operation period of more than 10 years.

The most popular model lines:

- Single-circuit floor heating with power from 11 to 35 kW: Siberia 11, Siberia 17.

- Double-circuit gas boilers with simultaneous heat supply for heating and hot water supply: Siberia 17K, Siberia 23K.

- Models with increased power and cast iron heat exchanger: Siberia KCHGO-40, Siberia KCHGO-16.

Price range

The average price for a gas floor-standing boiler Siberia 23 is in the range of 26-28 thousand rubles. Please note that this is only the cost of the boiler itself in the basic configuration . The chimney and other additional devices (if needed) will have to be purchased separately.

IMPORTANT!

The guarantee agreement will also cost some money, but it should not be ignored. In the event of a breakdown or other problem, the ability to quickly have a qualified repair will be invaluable.

Cost-effectiveness of models

All Siberia gas boilers, reviews of which are widely presented on the Internet, use natural gas as a source of thermal energy. Some models - for example, the Siberia 17k boiler (reviews of which can be read on our website) can also use liquefied gas fuel for their operation.

To switch to another type of fuel, you will need to change the gas burner. This may be relevant if there are interruptions in the supply of main gas.

Gas consumption will depend on the power of the Siberia gas boiler, reviews of which are largely determined by its “gluttony.” On average, Siberia boilers consume about 1.2-3.7 m3/hour.

If we are talking about liquefied fuel, then the consumption is in the range of 1-1.2 m3/h.

The efficiency of Siberia floor-standing gas boilers, reviews of which are largely determined by this parameter, is quite high - 90%.

More on this topic on our website:

- Gas boilers Lemax - technical characteristics and user reviews The domestic manufacturer of gas boilers Lemax is considered one of the largest in the country. The company traces its history back to 1992. Initially the organization...

- Gas boilers Vaillant - technical specifications and reviews from owners The first models of Vaillant heating boilers appeared in Russia only 15 years ago, although this brand is already well known in the world…

- Baxi double-circuit wall-mounted gas boilers - owner reviews and technical characteristics The Baxi company was founded back in the 19th century, and today Baxi devices are recognized by many as one of the best in the industry...

- Gas boilers Proterm Bear 30 KLOM - technical characteristics and features Heating boilers “Bear” from the Slovak manufacturer Protherm are completely independent of electricity; the source of thermal energy is gas fuel. Proterm Bear 30 KLOM…