A parapet gas boiler is a chimneyless, energy-independent unit, which in most cases is installed in country houses. It is the absence of the need to install a chimney that makes such equipment very popular among residential property owners, including city apartments.

First of all, parapet boilers differ from alternative heating equipment in that the combustion chamber is completely insulated, which completely eliminates the possibility of smoke entering the rooms. This plus will be appreciated by owners of small spaces, since air for more efficient combustion is not taken from the apartment. Where does it get into the system from?

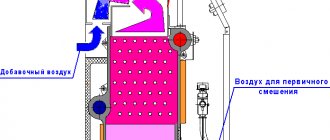

A parapet gas individual boiler still requires air intake and smoke removal. This means that you cannot do without a coaxial chimney mounted horizontally in the adjacent external wall. The design of the chimney is quite simple - two pipes inside each other. With the help of the outer tube, air is drawn into the combustion chamber, and the inner tube is intended to exhaust smoke. This design is simple and efficient, which makes it the optimal solution for installing heating equipment in living rooms.

The undoubted advantage of parapet models is the covering of the convection hole, due to which it is possible to heat the room where the device is installed without installing a traditional heating radiator. This makes the equipment even more compact and functional.

Parapet gas boilers have a rectangular shape, which greatly facilitates their installation in limited space. Depending on the characteristics of a particular location, it is possible to purchase equipment with one or another arrangement of automation and pipes.

There are two main types of parapet units - single- and dual-functional. The latter are equipped with a tubular water heater installed in the unit body, which is necessary for heating water for technical purposes. In most cases, the tubular heater is made of copper, which has decent thermal conductivity.

A gas parapet boiler can be installed in a variety of places under any conditions, since it does not need to be connected to a chimney. In a living room, it is most often installed in the window sill, where it fits perfectly despite its small dimensions.

Such units can operate on both natural and liquefied gas. This allows them to be installed even in those country houses that do not have a gas pipeline.

Pros and cons of Danko gas boilers

The Danko solid fuel boiler runs on wood, coke, and coal.

The advantages of these units include:

- use of advanced technologies and high-quality components;

- long service life of equipment;

- economical fuel consumption and quiet operation;

- relatively low cost of the product.

The advantage of boilers in this series is also their compactness and attractive appearance. Like most heating units powered by natural gas, Danko products have characteristic disadvantages.

- It is necessary to periodically service the unit, be sure to clean the chimney.

- During operation, the flame may go out due to external factors.

- Danko wall-mounted models have power limitations, while floor-mounted ones have an increased noise level.

The listed disadvantages do not have a serious impact on the overall assessment of the purchased equipment. Technical indicators are usually used as criteria for choosing the right model. Among them, the following factors stand out:

- average gas consumption for the allocated period of time;

- placement method;

- energy efficiency;

- functionality and warranty period.

Often, to the listed criteria, an assessment of equipment based on the heated area is added.

Advantages of the equipment

The best parapet gas boilers have a number of advantages that set them apart from other heating units. The natural, main advantage is the closed combustion chamber, which allows you to avoid installing a chimney and install the unit in any convenient place. But there are other advantages:

- Dimensions. Due to their size, many popular models can be installed in the kitchen from below the window sill. If the device is mounted near a wall, you need to make a hole to bring the coaxial chimney out.

- Convection system. In the room where the parapet boiler is installed, an additional convector will not be needed. The functional unit can replace the battery and oven.

- Versatility. The unit can be used for heating private houses and apartments in a multi-storey building. The model range includes devices with both two and one circuit.

- Huge assortment. For a room of any size you can find a first-class parapet-type gas boiler. The model range of all well-known manufacturers includes units with a power from 15 to 40 kW. The most advanced device is capable of heating an area of 200-250 sq.m.

- Reasonable price. The main problem of individual heating systems is the high price. A parapet gas boiler is a budget solution for an apartment or house.

Note: Power, quality of materials and technical characteristics affect the economy, efficiency and reliability of the equipment.

Specifications

Gas floor-standing boiler Danko from a Ukrainian manufacturer

The technical characteristics of Danko boilers include:

- type of combustion chamber - turbocharged or atmospheric;

- average fuel consumption does not exceed 1.9-2.7 m3/hour;

- Efficiency – 92%;

- heating area – from 70 to 300 meters;

- power supply 220 Volt 50 Hertz.

These same indicators include a set of additional functions available for each specific model.

Choosing a place to install a parapet-type boiler

Parapet-type boilers are installed only in non-residential and non-service premises, i.e. they cannot be installed in living rooms and offices, but they may well be located in kitchens, halls, corridors and other utility rooms.

Gas boilers of this type do not require constant monitoring. Parapet gas boilers are installed only on the outer wall of the building in such a way that there are no combustible structural elements near their installation site. If the wall includes combustible elements, then the distance from the pipe to such elements must be at least 20 cm, and these elements themselves must be protected with fire-resistant material on the side of the pipe and the gas boiler. On the facade itself there should be no combustible elements closer than 30 cm from the pipe. If such elements exist, they are either removed or protected with fireproof material.

The pipe should not go into the loggia, onto the balcony, under the canopy, and especially into the entrance or arch. You should immediately make sure that the pipe does not disturb passers-by if the boiler is installed at a low height relative to the ground, and does not throw combustion products out the window to neighbors.

Figure 3. Diagram of a parapet boiler.

For boilers with a power of up to 7 kW, it is allowed to place the pipe 25 cm from the window in any direction and 50 cm to the sides if the boiler power is higher. If the boiler is located on the ground floor, then the installation height of the pipe above the ground should not be less than 0.5 m, if there is no passage of people at the pipe outlet, but if there is passage of people, and the boiler power exceeds 7 kW, the height of the pipe should not be less than 2.2 m. Also, the pipe should not go under the supply vent closer than 2.5 m or next to it closer than 0.6 m for boilers with a power of 7 kW and no closer than 1.5 m - if the power of the gas boiler is over 7 kW. Under balconies and other elements protruding by more than 0.4 m, it is allowed to place a parapet-type boiler pipe no closer than 2 m (if the power of the gas boiler is over 7 kW - 3 m), cornices and other elements protruding less than 0.4 m - no closer than 0.3 m (if the power of the gas boiler is over 7 kW - 1.5 m).

Since the coaxial pipe requires periodic monitoring and maintenance, the installation location of the gas boiler should be chosen in such a way that it is possible to organize access to the pipe.

There should be no flammable interior elements (curtains, curtains, draperies) near the gas boiler indoors; furniture and electrical appliances should not be installed close to it or closer than 30 cm.

The controls of the gas boiler itself, the control and shut-off valves of the pipelines connected to the boiler must be accessible for inspection and control, for which there must be a passage at least 1 m wide in front of the front panel.

Boiler structure

Danko gas boilers are manufactured according to standard designs, according to which its main components are a heat exchanger and a burner, combined into a common unit. The device design also includes the following modules and working units:

- circulation pump;

- plate heat exchanger of the second level;

- turbofan in models with forced air supply;

- three-way valve;

- control electronic module.

When the boiler is operating, water first enters the main heat exchanger and is heated there, and then moves to the plate exchange module, which heats it to the desired temperature. After this, the coolant enters the three-way valve, where it continues to heat up, and then is discharged into the heating circuit to proceed to the next round of circulation.

The operation of the system is controlled by a control module, which is installed in volatile boilers. In parapet non-volatile models, this function is performed by mechanical sensors and special valves. A pump built into the system is responsible for the circulation of the liquid; air is supplied to it due to natural draft or forcedly through a turbofan.

Ignition

On the eve of putting the unit into operation, you need to fill the heating system with coolant, preferably soft water. After this, the temperature is brought to 90 C several times in order to extract dissolved oxygen from it as much as possible.

Filling is carried out very slowly without interruptions in order to prevent the formation of air jams in the network.

The procedure for igniting the Danko boiler unit:

- Check the draft in the chimney system and the absence of gas contamination in the room.

- Ventilate the furnace room for at least 10 minutes, the valve at the entrance to the boiler must be closed.

- Check the gas fuel pressure in front of the boiler - less than 3000 Pa.

- Using the automatic “KARE” system, with the boiler valve on the gas pipeline closed, turn the handle of the temperature sensor all the way counterclockwise.

- Open the gas tap.

- Press the start button of the thermoelectromagnetic valve and, holding it, press the piezo button until the burner device begins to burn steadily.

- Heat the water to 80C, while monitoring the pressure in the water network, checking the quality of the burner, the torch should be bluish in color.

Types of Danko boilers

Wall-mounted boilers with a steel heat exchanger have power limitations.

Danko boilers on the heating equipment market are represented by a large assortment of models, differing in the following characteristics:

- according to the type of installation within the premises they have a floor, wall or parapet design;

- according to functionality they are divided into single-circuit and double-circuit systems;

- According to the type of combustion chamber, there are open or atmospheric and closed (turbocharged) types.

Danko floor-standing gas boilers for heating a private home are installed on a special stand made of non-flammable material or directly on the floor. For their wall-mounted analogues, hinged installation is provided using metal support structures (ramps) mounted on load-bearing walls. Parapet boiler samples are products with a hinged installation type. They differ from wall-mounted models in the way they connect to the chimney. In addition, this difference is caused by the need to create a slope for the heating system pipelines, ensuring natural circulation of the coolant.

Single-circuit units are designed only to heat liquid and transfer it to the heating network. Dual-circuit systems simultaneously heat the coolant and prepare hot water used for domestic needs. There are the following differences in the design of the combustion chamber:

- In open (atmospheric) models, to obtain normal combustion, air is taken directly from the room in which the boiler is installed. Combustion waste along with smoke is removed naturally due to the draft generated by the pressure difference.

- In closed-type units, air enters the system and smoke is removed from it through a powerful turbocharger fan.

Turbocharged units are much more stable in operation than conventional ones. The reason is the high pressure under which the fuel is supplied to the burner. The flame in it is more stable and does not die out due to drafts or strong gusts of wind.

From the point of view of the reliability of the boiler unit, the user may be interested in models with a steel or cast iron heat exchanger. In addition, it is possible to select samples with different configurations of control systems.

Installation

The thermal power of the unit must be selected according to the design for heating the house in order to ensure a sanitary thermal regime in the premises.

The lowest ambient temperature during operation is not lower than 5 C. When installing the boiler, the circulation speed of the centrifugal pump and the total volume of coolant in the network must be taken into account.

Basic provisions when installing a Danko boiler:

- Before installing the unit, a heat-resistant horizontal foundation is made. The walls are shielded with heat-resistant materials, the gap between the wall and the boiler is left at least 250 mm. The insulating layer should extend beyond the dimensions of the housing by 150 mm.

- In front of the front working wall of the device, free passage is at least 100 cm.

- It is forbidden to wall up the base of the unit into the floor, since the process of air intake into the combustion chamber will be disrupted.

- The boiler unit is placed below the level of the batteries for efficient coolant circulation within the heating circuit.

- The expansion tank is installed at the highest point of the heating network, mainly in a heated place.

- The unit is installed with a chimney more than 5 m from the level of the chimney, which is located in the boiler.

- The height of the pipe above the roof is set above the level of wind pressure, and not less than 50 cm above the roof ridge.

- The main smoke exhaust duct must be located vertically, have smooth internal surfaces, without turns or kinks.

- The design of the chimney must ensure that the temperature of the flue gases at the outlet of the boiler unit is greater than the dew point temperature.

- The connection between the gas pipe of the unit and the chimney is made with a zinc or non-corrosive pipe.

- The unit must be installed and maintained exclusively in rooms with stable supply and exhaust ventilation

- The boiler is connected to the system using easily removable connections: couplings, union nuts or flanges and cannot be accompanied by high pipe tension.

- Sections of heating pipes operating with natural circulation are made with a slope of 10 mm per 1 m in the direction of the battery to collect air and remove it when the system is filled with water.

- The connection of gas appliances to the boiler is carried out by representatives of Gorgaz.

Popular models

Danko Rivneterm heavy-duty model for heating rooms up to 900 sq.

m Floor-standing models of Danko brand boilers are presented in the following series:

- Danko-10 with a power of 10 kW are intended for heating and hot water supply; they require a chimney.

- CP or VSR refer to single- and double-circuit models with a stated power from 8 to 24 kW. Equipped with metal heat exchangers with a wall thickness of 3 mm.

- SN and VSN are units with increased power from 30 to 48 kW with the same steel heat exchanger.

- Rivneterm belongs to a series of ultra-high power units and is designed for heating large areas.

The latest models are represented by single- and double-circuit boilers with a declared power of 30 to 96 kW, having a steel heat exchanger and capable of heating rooms up to 900 m2.

The series of wall-mounted boilers from the same manufacturer includes products with the indices US and UVS - single- and double-circuit boilers with a power from 7 to 18 kW. They have the same steel heat exchanger with three-millimeter walls. A separate series includes floor-standing boilers with a capacity of 16-50 kW, equipped with a cast iron heat exchanger. They have large dimensions and weight, which is explained by the different sizes of individual components and assemblies.

Cost and completeness

Automation for boilers is produced in Italy, Poland, and the USA.

The cost of Danko boilers is determined by the type of design, its functionality and ranges from 8 to 109 thousand rubles. The delivery set traditionally does not include a chimney and other components. Each series of products differs in its configuration, so before purchasing, the user will need to clarify its composition and purchase the missing elements.

The following sets are common on the domestic market of components for such boilers:

- A set of parts from Kare (Poland), manufactured specifically for Danko: valves, thermostat, reducer and a set of pressure and draft sensors.

- A selection of components from Honeywell (USA): electromechanical flow control units installed in particularly “advanced” models.

- Components from Sit (Italy): automatic units used in models of gas boilers made in Europe.

The range of products themselves and components for them is very wide. The user can always choose the best option taking into account the specific conditions of their operation.

Basic problems

Potential breakdowns in the boiler unit and methods for eliminating them are described in the instructions for use included in the delivery kit. List of probable defects. Why the boiler may not turn off and methods of correction are included in a special table.

The wick goes out

For boilers equipped with “SIT” automation, when, when the boiler is fired up, the pilot burner device goes out, and turning it on again does not produce results, then one of the likely causes of the failure is poor contact between the power terminals and the primary draft sensor.

To eliminate the failure, you need to disconnect the connection from the sensor, carefully tighten the terminal, having previously cleaned the contacts, connect the wire and turn on the burner again.

Reasons why the burner may go out:

- Gas output to the boiler unit is blocked.

- Low gas pressure in the network.

- Airiness of the pipe section in front of the boiler.

To purge the gas pipeline, you need to press the button on the gas shut-off valve and hold it for 60 seconds, after which the device is started again.

Igniter does not light

If the pilot burner goes out after the user releases the start button or the igniter does not light, you need to check the operation of the thermocouple, which may be located outside the combustion zone or there is a leak in the thermocouple junction at the inlet to the thermocouple.

In this case, you will need to adjust the location of the thermocouple in relation to the pilot burner flame; it must wash at least 4 mm of the thermocouple sensor.

It is recommended that before starting the boiler, blow out the ignition pipeline, injector and adjust the air supply with the nut to the KARE ignition mixer.

To do this, clean the connection point between the thermocouple and the thermoelement, tighten the nut until it stops by hand and tighten it 1/4 turn with a gas wrench.

Features of operation and setup

Annual cleaning of the chimney is recommended so that the quality of work does not decrease.

The requirements are set out in the user manual, which should be carefully studied before starting to work with the unit. During the operation of boilers, the following unforeseen situations are possible:

- The product does not turn on.

- The boiler starts to turn off randomly.

- In strong drafts, the burner may go out.

- The draft is noticeably reduced (for products with natural ventilation).

To eliminate the first two malfunctions, you should invite specialists. During operation, it is important to remember the need to periodically clean the chimney, which over time becomes clogged with combustion waste.

The need to adjust the boiler’s functionality may be required when it is necessary to increase the efficiency and stability of its operation. To do this, you will have to invite a service center specialist or representatives of the warranty workshop. Self-tuning can lead to complete failure of the equipment.

Design and main characteristics of a parapet boiler

There are several types of parapet boilers; the following classification will help you choose the right model:

- by installation method: floor and wall, left- and right-handed;

- by number of circuits: single- and double-circuit;

- by the presence of automation: energy-dependent or not.

A few words about the second classification. Single-circuit boilers perform only one function - heating the room; double-circuit ones, in addition, heat the water. The device body has special convection holes that allow you to maintain heat in the room without installing additional radiators.

A parapet boiler can operate either using a portable cylinder or from a conventional gas pipeline. The device body is made of steel; the minimum thickness is 3 mm, and a special powder coating prevents rust, even if the boiler is located in the kitchen, where there is usually high humidity.

The parapet boiler consists of the following parts:

- steel housings;

- closed combustion chamber;

- pilot burner, piezo ignition and thermocouple units;

- exhaust systems in the form of a coaxial chimney facing the street;

- heat exchanger;

- electrical sensors that control the operation of the device.

The chimney allows you to collect combustion air not from the room, but from the street. Combustion products, on the contrary, are released from the apartment. Safety is ensured by the operation of the following components: thermometer, thermocouple and draft sensor.

Design and operating principle

A distinctive feature of this type of gas equipment is a closed combustion chamber. The convenience of this design is obvious:

- There is no need to arrange well-functioning ventilation. This will be especially true in old buildings.

- There is no need to take care of the chimney, which must be taken outside the roof of the house. In this case, a coaxial type chimney is used. In order to install it, a hole is made in the wall to match the diameter of the coaxial pipe. By the way, it will not be visible from the side of the room, because the output is made behind the boiler in a horizontal direction. Experts recommend installing a parapet boiler near a window so that it is possible to inspect and repair the chimney.

- The design of the heating device contains convection holes. With their help, the heating of the room where the boiler is installed is carried out. That is, it turns out that the unit works both as a device for a water heating system, heating the coolant, and as a regular oven or convector.

If we talk about technical characteristics, it should be noted that parapet boilers operating on gas are produced with a fairly large power range, where 7 kW is the minimum, and 40 kW is the maximum. True, today manufacturers have also offered more powerful units that can be used to heat a very large multi-story building. But statistics show that the most popular are boilers with a power of 7-15 kW. Such units are most often installed in small cottages and city apartments.

Device and design

Let's add to all of the above that this type of heating units includes both single-circuit and double-circuit options. All manufacturers, without exception, in the second type use heat exchangers made of 3 mm thick stainless steel or copper to heat the coolant. The second option is more effective, this must be taken into account when choosing.