When there is no central gas supply in the area where they live, people start looking for other sources of heat. One of the most popular options is a gas boiler running on liquefied gas. The main difference between this type of heating installation is the ability to connect it to gas cylinders or a gas holder.

Heating a private house using liquefied gas

Choosing a liquefied gas boiler

An important criterion is power, measured in kW. The heated area is usually 9-10 times larger than this value. That is, by choosing a boiler with a capacity of 11.3 kW, you will heat a room of about 100 m2.

However, it is necessary to make an allowance for the fact that during prolonged and severe frosts, equipment of such power will not be able to maintain the set temperature. Therefore, experts recommend choosing a boiler unit with a reserve.

Other options:

- Boiler type. According to the method of installation, there are wall-mounted and floor-standing models, and according to functionality - single- and double-circuit (heat + hot water), with an open or closed combustion chamber.

- Efficiency The higher the indicator, the more economical and efficient the installation will be. The parameter varies in the range of 90-94%.

- Pressure. A unit operating on liquefied fuel must operate at low pressure (3-5 mbar). A low value will ensure that gas is produced from the cylinders without any residue.

- Gas consumption. The figures indicated by the manufacturer are conditional and depend on the power and efficiency of the unit, the set temperature in the room and outside the window, heat loss of the building and other factors.

When planning to build a house, you also need to pay attention to the design of the heating system.

The right solution is to delegate the task to experienced designers who

:

- calculate the amount of heat load;

- will develop recommendations regarding the selection of heating equipment and related materials.

Knowing the required parameters of the boiler, all that remains is to choose a device based on appearance and price. Russian boilers are the cheapest. Popular Japanese-made models are twice as expensive. And the “Germans” will cost even more.

LPG boiler

How to calculate fuel consumption

When choosing, the question arises: how much propane is needed to heat a house? The operating instructions, which indicate the characteristics of your model, will help you make accurate calculations.

It turns out that devices running on butane emit three times more energy. In this case, the gas is not necessarily stored in cylinders. These can be large tanks with a capacity of several thousand kilograms. They are installed in basements.

Let's take the averages. To heat an area of 100 m² with normal thermal insulation, the consumption of propane gas will be 2 cylinders for 7 days. For one month you will need 9–10 cylinders. To avoid frequently changing containers, a two-arm collector is used. 10 containers are connected to it simultaneously.

Principle of operation

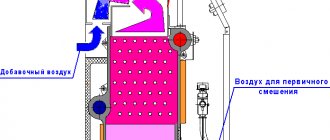

Comparing conventional gas boilers and liquefied gas heating boilers, we can highlight the following differences in operating principles:

- Less pressure is required for normal operation. The gas-air mixture is supplied under pressure not exceeding 3-4 mbar. The main gas is supplied at a pressure of 0.8-1 bar.

- Converting liquid fuel into gaseous fuel. The propane-butane mixture is transported as a liquid. It turns into a gas under certain conditions. Constant pressure in the pipeline is one of them. Creating the necessary conditions and ensuring stable operation are the tasks of the gearbox mounted between the boiler unit and the fuel tank.

- Efficiency Heating boilers using liquefied gas operate with an efficiency of 92-95%.

- Injectors. They have a different (smaller) outlet diameter. This ensures a low supply rate of the gas-air mixture, approximately 0.86 kg/hour.

Operating principle of liquefied gas boilers

What volume of gas cylinder to choose

| Weight and internal volume of gas cylinders | ||||

| Volume (l) | 5 | 12 | 27 | 50 |

| Empty cylinder weight (kg) | 4 | 5,5 | 14,5 | 22,0 |

| Weight of propane cylinder (kg) | 6 | 11 | 25,9 | 43,2 |

| Gas mass (kg) | 2 | 5,5 | 11,4 | 21,2 |

| Cylinder height (mm) | 290 | 500 | 600 | 930 |

| Cylinder diameter (mm) | 200 | 230 | 299 | 299 |

| The volume of gas in the cylinder depending on the capacity | ||||

| Cylinder capacity (l) | 5 | 12 | 27 | 50 |

| Gas capacity (m³) | 0,95 | 2,59 | 5,38 | 10,01 |

| Liquid propane volume (l) | 4,3 | 10,2 | 22,9 | 42,5 |

How to connect a column to a gas cylinder

- cylinders are connected via a ramp, several at a time, from 2-4 pcs.;

- To normalize the pressure, an adjustable reducer is installed.

Features of operation

When choosing a boiler that runs on liquefied fuel, you should remember to comply with the operating rules for these installations

:

- It is prohibited to install boiler rooms in basement or semi-basement premises. Propane-butane mixture is fire hazardous. When mixed with air it becomes explosive. And since the gas is heavier than air, if there is a leak, it does not evaporate through the windows and ventilation, accumulating on the floor.

- If there is an underground storage facility for cylinders or a gas tank, it should be located no closer than 10 meters from the house.

- When installing a storage facility in the depths of the site, there will be a problem with getting a gas station to it. There is also a huge list of requirements that must be met. In connection with this, design and installation must be carried out by a specialized organization.

- It is mandatory to have a maintenance agreement for the installation.

- A double-circuit liquefied gas boiler costs much more than a single-circuit boiler. It is recommended to use the second option complete with a geyser. This way you will save money and will not be left without hot water if the boiler unit breaks down.

Outdoor installation of propane cylinders

Gas cylinders in winter

If gas cylinders are located outside the house, then in winter at subzero temperatures the pressure of liquefied gas decreases and the boiler may simply turn off. To prevent this from happening, the cylinders are installed in a special cabinet with good ventilation, insulated with non-flammable materials. Also suitable for this purpose are detached non-residential buildings with minimal heating. When using cylinders, safety precautions should be observed:

Special cabinet for installing cylinders

- It is prohibited to heat containers with gas using open fire;

- There should not be a basement or cellar near the cylinders, since liquefied gas sinks down when leaking, has no odor and can accumulate to an explosive concentration;

- It is advisable to install a gas leak sensor;

- Storage of full containers is allowed at a distance of 10 m from the living space;

- Storing empty cylinders in the house is prohibited;

- Once every 4 years, it is necessary to check the cylinders for integrity and tightness.

Situation with lack of energy resources

When choosing heating equipment, you should take care of the possibility of using other types of fuel.

Main reasons

:

- To heat a 100 m2 house with a boiler with an efficiency of 92%, you will need 18 liters of liquefied gas per day, i.e. one 50 liter cylinder is enough for 2.5 days. To ensure uninterrupted operation, 3 main tanks and 3 spare tanks are required.

- Replacing cylinders involves paying the costs of transporting and filling them.

- Frequently changing cylinders entails the risk of negligence in this procedure. As a result, leakage, fire, or explosion may occur.

- Equipping a gas tank requires compliance with a large list of requirements, preparation of design documentation and obtaining permits.

Location of the gas tank for supplying liquefied gas

Taking into account the above, it is recommended to find additional types of fuel (wood, coal, electricity). This will allow you to choose a combined heat generator capable of operating on 2-3 types of fuel.

Choosing a storage location for gas cylinders

Cylinder connection diagram

Before deciding on the method of storing gas cylinders, it is necessary to correctly select their capacity. Currently, containers with a capacity of 5, 12, 27 and 50 liters can be used. If heating a private house with bottled gas will be regular, it is best to purchase containers with a maximum volume of 50 liters.

To supply gas, a line is made from the place where the cylinders are stored to the boiler. You can use several containers at once by installing a gas reducer on each. It should include two pressure gauges. One of them is necessary to verify the pressure inside the cylinder, and the second shows this value at the outlet. Using the shut-off valve, the intensity of the fuel supply is regulated.

Reducer for cylinders

The location for choosing their storage directly depends on how many cylinders are needed for the heating boiler. The estimated number of containers depends on the following indicators:

- Total area of the house;

- Heat losses in the building;

- Minimum temperature in winter.

An important point is the place where the gas heating boiler using bottled gas will be installed. The length of the supply line should be minimal in order to reduce the likelihood of its depressurization and optimize gas consumption.

Separate room for cylinders

Storing gas cylinders at home

The best way to store gas cylinders for heating is to prepare a separate room. The rules for arrangement and requirements for it are described in detail in SNiP 2.04.08-87. Therefore, before installing heating using gas cylinders, you must read this document.

The best option is if the storage room is located in close proximity to the boiler installation site. In this way, the supply line can be made as short as possible. It is also necessary to ensure the following storage conditions for containers for heating a private house from gas cylinders with your own hands:

- No flammable or lubricants should be stored in the premises;

- It is prohibited to use any heating devices - convectors, heaters. The exception is pipes and radiators for water heating;

- Providing fresh ventilation. The average air exchange rate is 12 m³/hour per 1 m² of room;

- Each cylinder must be placed on a pallet. This is necessary to maintain stability in case of possible fluctuations in the capacity during gas release.

To ensure safety, the premises must be locked. Fuel supply for heating a private house with bottled gas occurs via a pipeline. If flexible hoses are used for this, kinks must be avoided during installation.

Requirements for a cabinet for storing gas cylinders

Storing cylinders in cabinets

An alternative to the method described above is the use of special metal cabinets. This is relevant for heating a dacha with gas cylinders with low fuel consumption.

It is recommended to purchase a ready-made design, since it will take into account the requirements from GOST 15860-84. They are as follows:

- Ventilation. To do this, the cabinet design must have ventilation holes;

- Eliminating the possibility of sunlight hitting gas cylinders. This can lead to an increase in temperature on their surface;

- All elements of individual heating from gas cylinders must be made of non-combustible materials. The same applies to storage cabinets;

- Presence of warning signs and inscriptions.

How long does a 50 liter gas cylinder last for heating? It all depends on the nominal consumption of the boiler. But despite this, you can only store two cylinders in one cabinet. The optimal dimensions of the structure in this case will be 2000*1000*570. Before installing the cabinet, it is necessary to make a separate foundation. Its dimensions should exceed the dimensions of the structure by 15-20 cm.

The installation rules for heating a private home from gas cylinders with your own hands are also observed:

- The minimum distance from doors and windows should be 5 m;

- The wall to which the cabinet will adjoin is made of non-combustible materials.

Be sure to make special ventilation gaps on the surface of the foundation. Experts recommend grounding the structure to remove possible static voltage.

Small buildings

Cases when a boiler is the best option and the search for alternative heat sources is not important:

- Building area up to 50 m2.

- If there are no people in the room, the temperature is maintained at 5-10 degrees.

- Operating the boiler at full power is necessary periodically.

Advantages of choice

:

- There is no need to prepare project documentation and obtain permits.

- It is permissible to install a low-power boiler unit of any type (wall-mounted, floor-mounted). It is important to have the ability to switch to liquefied gas. There are no devices designed to operate exclusively on propane. All models of equipment on the market can operate on natural gas and liquefied propane.

Advice! To fill the system, choose a non-freezing liquid, which will avoid an accident.

This is important to know

Only professionals can install a heating system

The safety and reliability of a gas-powered system is more important than imaginary savings. It is necessary to comply with the maintenance of the gas boiler and chimney in a timely manner; if the instructions are poor, then you can find maintenance tips and videos demonstrating maintenance on the Internet. It is important to choose not only the boiler that is optimal in terms of power, but also to properly arrange the chimney so that the entire system works efficiently and without failures; chimney problems reduce the efficiency of the heating system and the durability of the boiler. You cannot install a computer UPS on gas boilers. If the water is hard, be sure to equip the inlet into the house with a filter to soften the water, this will extend the life of the heat exchanger. The manufacturer's warranty is valid only if several requirements are met: first commissioning by service center specialists, provision of a UPS for the boiler, repairs only by licensed craftsmen.. https://www.youtube.com/embed/T7t5BqyUvhk

How to convert a heating boiler to liquefied gas

Problems to be solved

:

- Changing the fuel mixture feed rate.

- Replacing injectors by installing special jets.

- Changing operating parameters, setting up automation for them.

Most models of modern single- and double-circuit boilers are designed to operate on both main gas and liquefied fuel. It is enough to replace the nozzles and select a different operating mode.

Converting the boiler to liquefied gas fuel

When the heating device is not designed to operate on liquefied gas, converting the boiler to this type of fuel is somewhat more difficult. It is necessary to carry out work to reconfigure the control valves and automation.

It is important that all work on reconfiguring the equipment is performed by a licensed specialist!

What is the liquefied gas consumption of the boiler?

You can find out this information by studying the technical documentation. Each model has different consumption, as it depends on a number of factors

:

- Burner type.

- Selected settings.

- Performance.

On average, to power a boiler with a power of 10-15 kW you will need 2 cylinders of fuel. Thus, it is more profitable to use main gas.

Heating system using liquefied gas based on the area of the house

Converting the boiler to liquefied gas is only necessary in a number of cases

:

- Temporary transfer. Registration of a new boiler, preparation of design documentation, connection of the installation to the main line - operations that can take six months. During this period, it is economically profitable to use an already purchased boiler in a different operating mode.

- Using a gas holder. This technique is more economical than using firewood, diesel fuel or electricity for heating the room. An important nuance: the result of incorrect settings is an increase in fuel consumption by 15%. You should seek help from a qualified professional.

Short description

The heating units in demand today using available propane are more reminiscent in their design of a unit that is used for the main gas supply method. Such equipment consumes a minimum of fuel, and the entire operating principle of the burner is controlled automatically. Multifunctional computer elements and built-in modules monitor important boiler parameters. Thanks to this, all residents of the house are completely safe. The traditional design of the unit consists of the following elements:

- Water jacket".

- Burner with spacious combustion chambers.

- Automatic control system.

- Universal devices for smoke removal.

Powerful heating system

Therefore

It is advisable to use gas boilers for heating a private home, capable of running on liquefied fuel, for the following reasons:

- Economic component.

- High operational safety.

- The ability to switch equipment to one or another operating mode.

At the same time, operating the boiler in this mode is not comfortable, since it involves constant material costs for refilling the cylinders, and the consumption of physical effort and time for connecting the containers.

To heat an apartment, it is more profitable to use a conventional wall-mounted boiler connected to the central line.

Video on the topic:

The best manufacturers and models: characteristics and prices

The country of manufacture determines the functionality and quality of the unit: given that it is purchased for many years to come, you should not waste your money on dubious equipment offered by the Chinese market. It is better to opt for proven options from European or Russian manufacturers.

Protherm Gepard 23 MOV

Well-known two-circuit mounted model with a power of 23 kW. It has an open combustion chamber (natural draft) and a copper plate heat exchanger: more thermally conductive and resistant to corrosion. Excellent, considering the price category, the automation allows you to fine-tune the operation of the boiler and efficiently consume fuel (max 1.9 l/h).

Cost: 39,870 – 42,480 rubles.

Manufacturer: Protherm (Proterm), Slovakia.

Bosch Gaz WBN6000-24C RN S5700

The German BOSCH with a power of 24 kW is made of higher quality materials and is not demanding on the quality of fuel and coolant. It is fully adapted to Russian conditions: it is resistant to changes in voltage, pressure and sudden cold snaps (down to – 35 °C). Economical gas consumption (max 1.5 l/h) is ensured by a modulated fan, a three-speed pump, and thermal insulation of the housing.

Cost: 36,900 – 38,460 rubles.

Manufacturer: Bosch Thermotechnik (Bosch Thermotechnik), Germany-Russia.

Buderus Logamax U072-18K

We can say that this inexpensive single-circuit boiler unit is one of the best liquefied gas boilers for heating a private home: with a power of 18 kW, it consumes fuel very moderately (max 1.5 l/h). And the built-in membrane expansion tank and three-way valve make it easy to convert it to domestic hot water. At the same time, the model is known for its high reliability, character

Cost: 26,200–31,840 rubles.

Manufacturer: Buderus (Buderus), Germany-Russia.

BAXI SLIM 1.150 I

The famous Italian floor-standing boiler of low power (15 kW) is known for its minimal gas consumption (max 1.1 l/h). It is already equipped from the factory with weather-compensating automation, a cast iron heat exchanger and a control module, with an integrated self-diagnosis option. And another important plus is its modest dimensions: for example, its width is only 35 cm.

Cost: 62,090 – 71,300 rubles.

Manufacturer: Baxi (Baxi), Italy.

Wester Lemax Clever-30

A domestic single-circuit wall-mounted device with a power of 30 kW, which does not depend on the availability of electricity. It can work in a system with both forced and natural coolant circulation, and continuous smooth flame modulation from 30% to 100% can significantly reduce fuel consumption (max 1.7 l/h). With such high efficiency, it is also distinguished by reliability close to European manufacturers.

The only significant drawback is the steel heat exchanger, which has a limited resource (10-14 years).

Cost: 34,250 – 40,500 rubles.

Manufacturer: Lemax (Lemax), Russia.

Quick estimate

It is quite simple to estimate by eye how much gas will be consumed by your gas boiler.

We will start from either the volume of the heated room or its area:

- in the first case, we use the standard 30-40 W/cubic meter. m;

- in the second case - 100 W/sq. m.

The standards are taken taking into account the ceiling height in the room up to 3 meters. If you live in the southern regions, the numbers can be reduced by 20-25%, and for the north, on the contrary, they can be increased by one and a half times or doubled. Those. take in the second case, for example, 75-80 W/sq.m or 200 W/sq.m.

By multiplying the corresponding standard by the volume or area, we get how many watts of boiler power are needed to heat the room. Next, we proceed from the standard statement that modern gas equipment consumes 0.112 cubic meters of gas to generate 1 kW of thermal power.

We multiply again - this time the gas consumption standard (number 0.112) by the boiler power obtained in the previous multiplication (do not forget to convert watts to kW). We get the approximate gas consumption per hour.

The boiler usually works 15-16 hours a day. We calculate the daily gas consumption. Well, when the daily consumption is already known, we can easily determine the gas consumption for the month and for the entire heating season. The calculations are approximate, but quite sufficient to understand both the principle of calculation and the expected gas consumption.

A regular calculating machine is sufficient to calculate gas consumption. If you don’t want to delve into calculation formulas, use online calculator programs online. Enter the initial data and immediately get the result

Example.

Let's say the area of the room is 100 m².

Let's calculate the boiler power: 100 W/sq. m * 100 m² = 10000 W (or 10 kW).

Let's calculate the gas consumption per hour: 0.112 cubic meters. m * 10 kW = 1.12 cubic meters. m/hour.

Let's calculate gas consumption per day (16 hours of operation), per month (30 days), for the entire heating season (7 months):

1.12 cu. m * 16 = 17.92 cubic meters m 17.92 cu.m. m * 30 = 537.6 cubic meters. m 537.6 cubic meters m * 7 = 3763.2 cubic meters. m

Note: you can immediately determine the monthly and seasonal power consumption of the boiler in kW/hour, and then convert it into gas consumption.

10 kW * 24/3*2 * 30 = 4800 kW/hour - per month 0.112 cubic meters * 4800 kW/hour = 537.6 cubic meters. m 4800 kW/hour * 7 = 33600 kW/hour - per season 0.112 cubic meters * 33600 kW/hour = 3763.2 cubic meters. m

All that remains is to take the current gas tariff and convert the total into money. And if the project involves installing a double-circuit system that will not only heat the house, but also heat water for domestic needs, add another 25% to the power of the equipment and, accordingly, to the gas consumption of floor-standing gas heating boilers.

The simplest thermal imagers cost at least $300, and the price of professional ones starts from several thousand, but these devices show all the places through which cold air enters the house and heat escapes out