If anyone doubts whether soil heating is needed in a greenhouse, look at the photo below. Under this bed there was a “return” pipe from the radiator heating. As you can see, the onion feather is twice as tall and better in quality. From this plot it was possible to harvest almost twice as much harvest (by weight). After this result, the next season the owner heated all the beds. Very convincing.

The heating return pipeline ran under this bed. Based on the height and thickness of the feather, it is easy to find out exactly where. After such a clear demonstration of the need to heat the soil, the next season a warm water floor was installed under all the beds

Cable heating system for greenhouse soil

With cable electric heating, local heating occurs near the roots, that is, the part of the soil in which the roots of a heat-loving plant are located is heated. For this, 2 types of heating cable are used: resistive or self-regulating. The most important difference is that the self-regulating heating cable is not afraid of overheating. It can be stacked on top of each other without fear of the area where the cables meet burning out. A resistive wire has a constant power and if during operation the cable becomes blocked and overheats, it will fail.

Heating a greenhouse with a resistive cable

For the purpose of heating the soil in greenhouses, resistive cables for anti-icing systems with a linear power of 10-15 watts per 1 linear meter are often used. Commonly used options include:

- Armored sections 10 TSOE2 – armored single-core heating sections from the manufacturer SST LLC, Mytishchi, Russian Federation. Available cable lengths: from 58 to 218 meters. The main advantage is the twisted armor, which protects against damage from a shovel or other objects during soil cultivation. The disadvantage is the high price and complexity of installing a heavy and elastic cable;

- Single-core heating cable NSKT with a linear power of 10-15 Watts from the same Russian manufacturer SST LLC. The cable is comparatively cheaper than its analogues, because is single-core. This complicates its installation, because... After installation, both ends of the cable must be connected to a single source of electricity;

- Single-core sections ICE FREE O and two-core sections ICE FREE M from another Russian one. These options for heating sections are not inferior in characteristics to analogues, but at the same time they are 10-20% cheaper.

Using resistive heating cables will be the most optimal solution, because... Manufacturers offer a wide table of section sizes and capacities suitable for the most complex and non-standard solutions. In addition, you can select cables for more or less aggressive operating conditions in order to increase the performance of the greenhouse heating system.

Ready-made kits (Green Box AGRO)

The Russian one was one of the first to release ready-made solutions for heating the soil - Green Box Agro kits on two-wire shielded heating sections 14GBA. Linear power of sections 14 Watt per m/linear. In addition to the sections, the kit includes a box and a TP 600 thermostat for controlling the soil heating system.

The cable sheath is made of special polymers that are resistant to aggressive environments (high humidity, exposure to fertilizers). The cable is equipped with a foil shield that meets all safety requirements against electric shock. The model range includes 9 standard sizes (from 200 to 1480 Watt) with a heating area from 2 to 15 m2.

It must be said that GBA kits are one of the most optimal solutions for heating the soil of greenhouses, since a linear power of 14 watts is just enough to warm seedlings and seedlings and at the same time not to dry out the soil or burn the roots. The manufacturer has been developing this system for a long time together with specialized research institutes and has developed the most effective system.

Currently, similar products are produced by other Russian manufacturers: Teplyshko (Kaleo), SNGT from Chuvashteplokabel, Heatline-Grunt from the manufacturer Heatline. They are a little cheaper, but inferior in quality to Green Box Agro.

Heating greenhouse soil with a self-regulating cable

One of the advanced solutions in heating the soil of greenhouses is the use of self-regulating heating cables. The cable is based on a self-regulating nano-matrix, which independently increases heat dissipation if the ambient temperature is low and, conversely, reduces its power if the surrounding temperature is warm.

This cable is ideal for greenhouses for the following reasons:

- Self-regulation. If an air cushion has formed in the ground or the area with the cable is covered with something, it will simply drop the power. At the same time, a regular resistive cable may burn out;

- Energy saving. This cable allows you to specifically reduce or increase the temperature where necessary. Due to this, electricity can be saved up to 70%;

- Sections of any length. The self-regulating cable can be cut to any individual length. The resistive cable comes in strict segments, which are often not enough or, on the contrary, turn out to be too much for your greenhouse.

Tips for gardeners

When choosing a system for heating a greenhouse, it is important to consider the cost of its operation, as well as the existing location. In the case of water heating, it is only advisable if the greenhouse is located near the house, which allows it to be connected to the central system, since the construction of a separate boiler room is financially intensive. Electric heating devices consume quite a large amount of electricity, which will affect your utility bill; in addition, they dry out the air, which negatively affects plants and requires the installation of a humidifier.

In terms of cost-effectiveness ratio, cable heating is considered the most optimal: for a room with an area of 24 m², 92 m of cable with a power of 1650 W is sufficient. The success of the procedure also depends on how long the heat is retained in the room.

Find out how to heat a greenhouse with a heating cable.

To do this, you should think about thermal insulation of both the room itself and the heating elements. Now you know how to make a room warm with your own hands, why thermal insulation is needed in a greenhouse, and also what technology to choose, taking into account the cost-effectiveness ratio. Grow vegetables in the temperature conditions required for them, which will help you fully recoup your costs thanks to high yields.

Soil heating

The reason why we chose electricity rather than water heating of the greenhouse is that the first option is easier to implement with our own hands, purely technically. It is quite difficult to solder water pipes; you will also have to think about whether to power them from a house boiler or one installed in the greenhouse itself.

The first option is without installing a concrete base

Preparing the beds for organizing warm soil in the greenhouse is very simple: remove the soil to a depth of 40 cm, put it in bags, and take it out of the greenhouse. Installation without pouring concrete will be carried out as follows:

- We pour a sand cushion 10 cm thick. In this case, we lay scraps of boards on the sand, a meter apart from each other.

- We lay out the self-regulating heating cable for heating the soil of greenhouses on top, fixing it with special fasteners to the tree.

- We cover everything with polyethylene, the edges of which should be slightly on the walls of the beds.

So, we did the heating of the soil in the greenhouse with our own hands. Now you can fill the soil and begin preparing it for planting.

Please note: for ease of heating regulation, it is better to place a thermoregulation device with switches near the front door. Accordingly, we lay the cable in the ground with this in mind. . Making a warm floor in a greenhouse with your own hands: installation without cement screed

Making a warm floor in a greenhouse with your own hands: installation without cement screed

Organization of soil heating with a cable under the screed

First, as in the first case, we remove 40 cm of soil, then make a sand cushion (10 cm). Along the edges of the heated greenhouse floor we will arrange a 15 cm high border, which will prevent the cement from spreading beyond its boundaries. We compact the sand well, achieving as smooth a surface as possible. Next we work like this:

- We lay a layer of waterproofing material, for example, thick cellophane film.

- We place several metal profiles or wooden beams (30x40) on the film along the length of the greenhouse. The step between elements is 60-80 cm.

- We knit a reinforcing mesh from a steel bar and lay it on the prepared surface. Using knitting wire we attach the mesh to the profiles/beams.

- We lay out a soil heating system in the greenhouse on top of the mesh. We attach the wires to it with plastic clamps.

Installing a heating cable in a greenhouse under a concrete screed

Please note: we make the heating screed using a concrete-sand-gravel mixture. The consistency should be the same as in the photo below. Pre-hardening of the screed will occur in approximately 3 days. If no structures are planned to be built on its surface, after this time you can begin pouring soil.

We set up a greenhouse with heated soil with our own hands: pouring screed

Another option for a warm floor in a greenhouse; the video shows the installation of a carbon cord. The principle of soil heating is the same as when laying an electric heating cable.

Water heating of a greenhouse - design features, choice of pipes

Heating a greenhouse is the key to obtaining a good, timely harvest. Many gardeners use water heating in greenhouses, due to which it is possible to create in buildings of this type the temperature regime necessary for full growth. Such systems are relatively cheap and quite simple to operate. You will learn how to make water heating in a greenhouse yourself from this publication.

Warm bed in a greenhouse made of polycarbonate, biological method

The biological method of heating beds is made using natural biofuel placed in the subsoil layer. Plant residues, sawdust and manure are used as filler, which is spilled with water for the rotting process. Such beds are the most economical design.

Warm beds running on natural fuel are usually divided according to the type of construction:

- In-depth, when fertile soil is removed, a trench is dug, compost is laid and filled with soil on top so that it is level with the total mass of the earth;

- Raised beds, the top layer of soil is removed from the surface and placed in special wooden boxes, which serve as protection against shedding and washing away of the soil during operation;

- A hilly bed, laid without a box on top of the main platform;

- A combined option, when the lower layers with organic matter are laid at ground level, and the fertile soil layer is fixed with a box.

To make a structure for a combined warm ridge, you need to mark out places for future plantings. Then carefully remove the layer of turf, putting the fertile soil aside. Next, you need to dig a trench up to 60 cm deep. To protect against freezing, foam plastic or closed plastic containers are placed at the bottom of the trench. Next begins the first layer of organic matter, consisting of large branches, wooden chocks, and large plant objects.

This layer will play a drainage role. Then a paper backing consisting of waste paper is laid.

After this comes a layer of finer organic matter, food waste, tree leaves, and small grass stems. Next, add ready-made compost, or semi-rotted manure, to begin the rotting process. We install a pre-prepared box into which we will pour fertile soil. Each laid layer must be thoroughly watered. We cover the last layer with fertile soil. Soil enriched with organic matter is perfect for planting tomatoes, pumpkins and cucumbers. The rotting process can warm the earth for 2 months.

Insulation with polystyrene foam

A lot of heat goes directly into the floor of the greenhouse - into the concrete base (if the structure is placed on a foundation) or into the ground. Therefore, even if you use the most powerful heating systems, the greenhouse floor must be carefully insulated.

This can be done using a thermal insulator, such as polystyrene foam. The material is sold in the form of sheets of different thicknesses. For laying on the foundation itself, you can use the material in a layer of 50 mm. Expanded polystyrene is placed on the surface and fixed with a special adhesive for thermal insulation (Penoplex). After this, apply sand (2-3 cm), level it and lay a productive layer of soil 25-30 cm in height.

Expanded polystyrene boards have excellent thermal insulation properties, so a layer 50 mm high will be sufficient

Important! The insulation can even be laid on the ground, i.e. This method is suitable for both mobile and stationary greenhouses.

Advantages and disadvantages of heating soil with cable

Previously, summer residents had to use “potbelly stoves” as additional heating. Thanks to the rapid development of modern technologies, farmers abandoned this archaic method, preferring new devices.

Since the temperature of the soil, rather than the air, is more important for plants, special cables began to be used to heat it.

Such a system allows you to turn on the heating as needed, regulate and maintain the desired temperature.

Heating can be carried out locally or spread throughout the entire greenhouse. Thanks to the possibility of local heating, farmers can grow several crops with different temperature requirements in one greenhouse.

Heating the soil is accompanied by several advantages:

prevention of soil freezing; reliable protection of plants from frost; acceleration of plant growth and fruit ripening; increasing the fruiting period; accelerated seed germination; growing heat-loving varieties of vegetables (this is especially important for regions with cold climates).

The advantages of such a system are reflected not only in the growth and development of plants. Farmers also welcome the proposed method for its following properties:

- safety (when using water, in the presence of branches and other foreign objects in the ground, accidental overlap of cables, the system will not fail or create conditions that pose a danger to humans);

- efficiency (low power consumption);

- convenience and the possibility of specific installation (cables of various cross-sections and power can be laid in one greenhouse).

Benefits of rising ground temperatures

Growing cultivated plants indoors is a rather complex process.

The articles on our website describe its main aspects in sufficient detail:

- Natural and artificial lighting.

- Regulation of humidity conditions (watering and drainage).

- Ventilation of premises.

- Air and soil temperature control.

It is the latter aspect that we will focus on today.

Warming the soil promotes more active growth

Warming the soil in a greenhouse is an integral stage of the thermoregulation process. Together with an increase in air temperature, it ensures the formation of a comfortable microclimate, which promotes the active growth and development of plants.

At the same time, soil heating has very significant advantages:

- An increase in substrate temperature leads to an acceleration of the development of underground organs (roots, rhizomes, tubers, etc.). This contributes to the overall strengthening of plant organisms.

Note! Many devices that are used for warming also have a slight bactericidal effect.

- When growing root crops (carrots, radishes, etc.), the time until obtaining marketable products is significantly reduced.

- Energy is consumed extremely economically: modern ground heating systems have an efficiency of 90 to 95%.

- The operation of soil heaters does not lead to a decrease in the oxygen content in the air, which can significantly reduce ventilation costs.

Thus, by choosing soil heating, we not only get the opportunity to grow the most heat-loving plants, but also significantly reduce the cost of maintaining a greenhouse.

A simple greenhouse with heated soil with your own hands

Water heated beds also have a number of advantages. Firstly, the condensate formed on the pipes additionally moistens the soil. This design provides uniform heating of the air in the room. To heat the greenhouse, you will need a gas or electric boiler; you can also use a small wood-burning stove made of brick or metal.

You need to purchase a smoke outlet pipe for it. The choice is made in accordance with the configuration of the heater.

To install a furnace or boiler, it is necessary to prepare a foundation; for a brick structure, a concrete foundation. A metal boiler can be placed on a sheet of asbestos and cement mixture. Next, the structures provide stability and attach the chimney, hermetically sealing the connection points.

Insulation of beds with pipes, necessary work:

- Remove soil 35-40 mm thick;

- Material for thermal insulation is laid at the bottom of the resulting trench; foam plastic is usually used;

- Water pipes are placed on top and connected to the heating system;

- Fertile soil is laid on top of the pipes.

This heating method is considered optimal, but it is necessary to ensure that the temperature of the water in the pipes does not exceed 45 ° C, otherwise you can burn the roots of the plants.

Advantages of heating the soil with a heating cable

Such a system is ideal for Belarusian climatic conditions; it will not only protect the soil from severe frosts, but also preserve its fertility and quality. Depleted soil is unable to produce the desired harvest; if you take care of it, then it will take care of us. Frost does not allow the soil to be saturated with moisture, heat, or useful minerals, and the heating system will provide the soil with the opportunity to feed and produce fruit at any time of the year.

Thus, we can highlight the following advantages of purchasing a cable heating system for plant soil:

- Early sowing. Thanks to the warm soil, you can plant seedlings in a greenhouse about 1-1.5 months earlier than usual and harvest until late autumn. This way you can get 2 harvests in 1 year;

- Comfortable and safe growing conditions. Seedlings and seedlings will not freeze in case of frost and will grow and bear fruit more intensively;

- Relatively inexpensive components. The price of the entire system, depending on the size of the greenhouse, will cost $100-300;

- Economical consumption of electricity. We are not required to heat the entire greenhouse. The cable warms the soil and plant roots. To do this, for 1 sq. meter of beds the power is about 80 Watt/m2. The use of thermostats reduces energy consumption by another 30-70%;

- Quick installation. Unlike boiler water heating, the system can be installed in 1-2 days. If you use water boiler heating, then its installation will take more time and money.

Electric soil heating systems equipped with thermostats monitor the temperature in the greenhouse and will become indispensable assistants for every landowner. Previously, much more effort and time was spent on providing plants with a comfortable existence even in cold seasons. Thanks to soil heating systems, you can easily manage your site and vegetation. Heat, moisture and mineral decomposition are the main elements that provide the earth with vital force; this issue is resolved much faster today thanks to these systems.

Generally speaking, this whole system is something like heating for the soil and plants during the cold season. Why not allow nature to exist even in frost, taking into account the needs of each plant and the ability to provide complete comfortable conditions? If modern technologies can provide warmth to the soil and plants in the cold winter, then all that remains is to choose the most optimal option!

What are the ways?

There are three ways to heat the soil in a greenhouse:

- Natural;

- Biological;

- Technical.

Natural heating of the soil in greenhouses occurs due to solar radiation. The sun warms the soil and air. But, having become warm, they do not disappear anywhere and cannot mix with the cold soil and air outside. It is suitable for increasing the temperature and humidity of the air, but the earth warms up poorly. Another drawback is that the method only works in summer.

Summer residents will appreciate the biological heating of the soil in a greenhouse with their own hands. The method involves burying material under the soil, which, when biologically decomposed, releases a lot of heat and carbon dioxide. And this is an essential substance for plants, which they use to carry out photosynthesis. The only drawback of this method is the inability to regulate the temperature.

Technical heating can be realized using water, electric, stove or gas heaters. Today we will consider only the most effective methods: heating the soil of the greenhouse with a heating cable and pipes with warm water circulating through them. With their help, it is easy to control the soil temperature and maintain it in the desired range all year round.

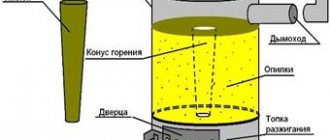

Biological heating device

To heat the soil in small greenhouses in this way, you need a biological material that, when decomposed, releases a lot of heat - manure (the list is arranged in descending order of the heat released during decomposition):

- Horse;

- Pork;

- Bovine;

- Goat and lamb.

You can improve heat transfer for better heating of the soil in a greenhouse by mixing manure with sawdust, straw or dry leaves. The best ratio of manure and additive is 1 to 1. If you are interested not so much in soil temperature as in the duration of heating, then mix manure with peat, which will prolong the rotting process.

Start preparing manure for heating greenhouse soil in the fall:

- Dry the collected (purchased) manure;

- Mix with straw, leaves or sawdust;

- Add nitrogen fertilizers (additives to manure during rotting take away a lot of the nitrogen needed by plants);

- Place in piles so that the manure does not begin to rot ahead of time;

- Cover the top with a layer of peat, soil or dead wood collected in the fall.

Then work in the greenhouse to heat the soil is postponed until early spring:

- A week before the intended planting of plants (in the first or early second month of spring), scatter the manure over loose piles to start the warming up process;

- After 2-3 days you will see ammonia fog over the piles with a corresponding smell. This means that it’s time to dig a pit, the area of which should correspond to the area of the greenhouse;

- Fill the bottom of the pit with rotting manure and leave for 2-3 days for it to settle;

- Sprinkle lime on top (rotting manure makes the soil acidic - this is exactly the environment that pathogenic fungi love);

- Complete the work by filling the remaining space of the pit with fertile substrate.

After a week, the temperature of the manure will reach 60-70 degrees Celsius and will last up to two weeks. If the thickness of the soil heated in the greenhouse is small, then planting plants during the period of active heat generation can be dangerous. But after those two weeks, the soil temperature will remain in the range of 20-30 degrees for up to 2-2.5 months.

The advantages of a biological soil heating system in a greenhouse are accessibility, simplicity and environmental friendliness. You can plant heat-loving plants as early as mid-April. By the end of the summer season, manure turns into humus - a fertile substrate that is used to fertilize vegetables, berries and flowers. But the preparation of fresh manure will have to be done again.

Cable heating device

The newest and most effective method is cable heating of the soil in greenhouses. But it is already actively used by experienced summer residents and commercial organizations, because its advantages are undeniable:

- Possibility of growing any crops in a greenhouse, including those that grow in the subtropics;

- Plants grow faster, begin to bear fruit earlier and do so for a long time;

- Productivity increases;

- Heating is adjusted automatically;

- The service life of electric heating is half a century;

- Easy installation of the heating system;

- The cost of the system is low.

To install a soil-warming system you will need:

- Fine river sand;

- Safety net;

- Electric cable for heating the soil in a greenhouse;

- Thermal insulation material (expanded polystyrene, polystyrene foam, penoplex);

- Fertile substrate or simple soil.

Work on installing an electrical heating system for greenhouse soil is carried out in the following order:

- Remove a layer of soil from 3 to 4 dm;

- Place heat-insulating material on the bottom so that heat is not wasted on heating the lower layers of the soil;

- Sift the sand and make a cushion on top of the thermal insulation with a thickness of at least 5 cm;

- Compact the sand cushion by pouring water on it and patting the surface;

- Place a metal mesh to protect the cable from rodents and other damage from below;

- Place the heating cable on the mesh so that it forms a “snake” pattern. There should be no breaks; the distance between adjacent cable lines (laying pitch) should be 2 dm;

- Secure the cable to the mesh using clamps;

- Place the same sand cushion with a thickness of 5 cm on top. It also needs to be compacted by pouring water;

- To prevent mechanical damage to the cable during future excavation work, place another layer of protective mesh on top of the second sand bed;

- Place at least 30 cm of soil on top.

Cable heating of the soil in the greenhouse allows you to cultivate the soil all year round. But do not forget that in addition to heat, plants need additional feeding (the soil is quickly depleted). And in the period from the 10th calendar month to the 4th, plants will need additional lighting. But in return, the greenhouse will reward you with continuous fruiting and high yields.

Water heating device

A water heating system for soil in greenhouses is a universal method that allows you to maintain the temperature of both the ground and the air within normal limits. Its other advantages are:

- The soil and air are heated evenly (there is no division into overly and poorly heated zones);

- The system does not affect air humidity;

- Condensation collects on the pipes, which additionally moistens the soil, which is beneficial for cultivated plants;

- The cost of maintaining a water heating system is the lowest.

To organize water heating of greenhouse soil:

- Remove a layer of soil 2.5-3.5 dm thick;

- Place thermal insulation material (foam plastic, penoplex and others) at the bottom of the dug trench;

- Lay plastic pipes and connect them to the heating system;

- If there is not enough traction and the water does not circulate, the soil will remain cold. To fix this, you will need to install a water pump;

- Place fertile substrate on top of the pipes.

This method of heating the soil in a greenhouse is considered optimal if it is located near the house. The only difficulty is the need to maintain the water temperature inside the pipes no more than 40 degrees Celsius. Otherwise, the roots of the plants will receive numerous burns, and the above-ground part will begin to wither.

All you have to do is choose the most suitable method of heating the soil in your greenhouse. Consider not only the cost of the heating system, but also the costs of its further maintenance, as well as the possibility of year-round or seasonal cultivation. In any case, your diligence will pay off with a high harvest, and if you are a private entrepreneur, then also with increased income.

Popular posts

- Greenhouse 2 DUM Overview of the 2DUM country greenhouse or what the “polycarbonate pioneers” are remembered for 2DUM country greenhouses - comfortable, durable,…

- What kind of lighting should be in a greenhouse? What kind of lighting should be for plants in a greenhouse? Most plants require 12-16 hours of light per day…

- Heated inflatable Jacuzzi Inflatable Jacuzzi pool in Russia Do you need clients? To add products and services to the Tiu.ru catalog,...

- Greenhouse heating in winter Heating a greenhouse: types of heating, step-by-step recommendations for arranging it yourself (20 Photos & Videos) + Reviews 1396…

Installation

Installation of a cable electric soil heating system in greenhouses consists of the following steps:

Under the greenhouse it is necessary to remove a layer of earth approximately 40 cm deep; Sprinkle the bottom of the hole with a 5-centimeter layer of sand. Sand needs to be spilled and compacted to make the base stronger; We place a reinforced mesh with cells of approximately 10 cm on the sand and lay out the heating cable on it. The cable should be secured to the mesh with plastic ties so as not to damage the outer sheath. The wire is laid out like a snake with a laying step of approximately 12-15 cm; Between the turns of the heating cable we install a temperature sensor, which it is advisable to place in a corrugated tube; Sprinkle the mesh with the cable with a 5-7 cm layer of sand and again spill and compact it; We put a fine-mesh reinforced mesh on top to protect the cable from mechanical damage with a shovel or other objects; We fill the system with a fertile layer of soil on top; Install the thermostat and connect the cable to it

Attention! It is advisable to install an RCD in front of the thermostat to ensure safety precautions against electric shock.

After completing all installation stages, you can safely plant seedlings and connect the plant root heating system in your new greenhouse.

How to make heating?

Installation of the systems is carried out according to a single principle - the heating element is placed underground, according to the following algorithm:

- Remove the top layer of soil, approximately 40 cm.

- Level the bottom, then add 5 cm of sand and compact it.

- Spread a thermal insulating film on top, for example, polystyrene foam - thanks to this, it is possible to retain heat and prevent it from escaping deep into the soil.

- Fill in 5 cm of sand.

- Lay a stainless mesh with 5–10 cm cells.

- Laying of heating elements.

- Cover with wet sand - a layer 5 cm thick.

- Cover everything with a net - both plastic and stainless steel are suitable for this purpose. This layer is necessary in order to protect the heating source from any damage.

- Finally, we fill the structure with fertile soil - for this, the initially removed layer is mixed with fertilizers.

Making warm beds in a greenhouse types of heating

Solar heat warms the beds only by the beginning of May, in some regions and by the end of May. Artificially heated soil is suitable for planting plants as early as March, while the root shoots are in comfortable conditions, which contributes to their strengthening and plant growth. In addition, the heat generated by the earth helps warm the air in the greenhouse.

Advantages of warm beds:

- Early planting and achieving maximum yield in the first summer months;

- Getting good results even on relatively fertile soil;

- Reducing the need for plant nutrition;

- Increasing the fruiting period;

- Reducing water consumption during irrigation;

- Weed control.

Preparing a warm bed in a greenhouse is carried out in autumn or early spring. There are several options for heating the bed: electric cable, water pipes, biological compost. When using a cable, it is laid under the soil in advance and heated using electricity. These designs are highly efficient, but expensive to maintain.

Water heating is used using special pipes made of polymer material, which are laid under the ground.

Hot water flows through the pipes, capable of heating the earth. For biological beds, plant residues and manure from livestock farming are used. The heating element is the rotting process, as a result of which the soil temperature rises. This is the most economical way to heat beds. Each method has its pros and cons. The gardener selects the most appropriate option based on his own views on growing plants.

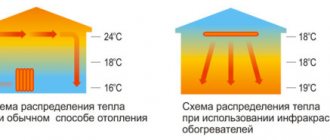

IR heaters and convectors

There are also more modern types of heaters for polycarbonate greenhouses:

- Infrared heaters (IR).

- Convectors.

IR heaters convert electricity or gas energy into infrared (thermal) radiation, which warms not only the air, but also surfaces (ground, walls). This equipment is divided into two main classes:

- IR light heaters - they get very hot and give off a lot of heat. Such equipment is suitable for relatively large greenhouses with an area of 30 m2 or more.

- Long-wavelength ones give off less heat and are well suited for small greenhouses, which are most often used on private farms.

The source of IR radiation can be placed on the walls or ceiling and direct the heat flow in any direction.

Convectors can also operate on electricity or gas. In the latter case, they are a sealed combustion chamber made of cast iron or heat-resistant steel. Inside it there is a burner, the operation of which is controlled automatically.

This is a more efficient option, since there is no longer a need to install a ventilation system in the greenhouse

Operating principle of a convector for heating

The stove (1) warms up the air in the greenhouse (2). It rises upward, where it cools, then settles down and heats up again. In this case, combustion products, which also heat the air, escape through a special pipe (3) into the atmosphere.

What are the advantages

The main arguments why it is not advisable to use heating systems for soil in a greenhouse are the weak effect in small areas and the high cost of the equipment. Many believe that the greatest benefits from heating the soil in protected soil conditions will be obtained by farm greenhouses in which vegetables are grown throughout the year. However, warming the soil in regular, seasonal structures is beneficial for the following reasons:

- Heat loss through the soil is eliminated;

- Planting seedlings can be done at any time of the year in order to get a harvest by the time the price for it increases as much as possible;

- In warm soil, the root system of the crop develops well, which is why the above-ground part forms and grows even better;

- The yield increases, expressed in kilograms of fruit collected per unit area;

- The fruiting period increases;

- The constant soil temperature in the greenhouse prevents the death of plants during frosts.

Conclusion

Despite the cost of the procedure, heating the soil in a greenhouse pays off: the seedlings are of higher quality, and adult plants gain green mass faster, bloom and bear fruit more actively. That is why it is worth taking care in advance about the optimal temperature of the substrate used. Fortunately, there are many ways to do this (see also the article Underground greenhouse - a new trend or a forgotten technology).

You can clearly study this topic using the video in this article.

Greenhouse kits

Many companies produce ready-made kits based on thermal cables.

For example – Green BOX Agro. The set consists of a resistive two-core cable with a specific power of 14 W/m, the range ranges from 200 to 1480 W with a section length from 14 to 102 m. The product is adapted for use in greenhouses, the insulation is made of environmentally friendly material that retains its properties in any soil conditions exposure to various fertilizers. The soil temperature is adjusted using a TR-600 thermostat. The thermostat includes an external temperature sensor, with which the ground temperature can be maintained in the range from +18 to +27 with an accuracy of 1 °C. The product is designed to work in conditions of high humidity. The maximum current is 16 A at a supply voltage of 220 volts. Thus, several heating sections can be connected to the product within this current value. The cost of a thermostat is about 3 thousand rubles, heating sections - from 2 to 6 thousand rubles.

The South Korean company Lavita offers a similar system. The products are equipped with sections based on thermal cables with a linear power of 20 W per meter. The range is from 200 to 2800 W with a section length from 10 to 140 m. The cost of a section is from 1.5 to 15 thousand rubles. In addition, this company offers two types of thermostats: regular and programmable, which allows you to program the operation of the regulator for a week. The price of regulators is 1100 and 2300 rubles. respectively.

All regulators are supplied separately and can also be used to configure a heating system based on self-regulating thermal cables.

The following materials:

- 04/12/2016 15:27 — Construction and design In order to properly build a greenhouse or hotbed, you must first decide on their main practical advantages...”>Greenhouses and greenhouses: secrets of construction and maintenance, planting and caring for various crops

- 07/27/2016 00:00 — About the influence of the color of the shading net on plants in a greenhouse As soon as shading nets appeared in greenhouses, the desire immediately arose ... ">Colored nets for greenhouses

- 02/27/2016 22:18 — The mention of nonwoven materials immediately evokes an association with spunbond. This is already a common noun not only for a whole class of materials, but also for t...”>Nonwoven materials in agriculture: varieties, properties, applications

- 02/08/2016 22:53 — Agree, high-quality, long-term greenhouse film means no costs and no worries for several years. However, failure to follow simple rules can lead to…”>So that the greenhouse film lasts a long time

- 01/24/2016 23:14 — Covering film materials for greenhouses In recent years, there has been a noticeable interest in greenhouse forms of management, both amateur and…”>Modern films for greenhouses

Previous materials:

- 05/01/2016 22:30 — Unlike furnaces, pyrolysis hot water boilers are more convenient in that they allow you to organize not only uniform heat distribution throughout the greenhouse, but also throughout...”>Pyrolysis hot water boilers for greenhouses and outbuildings

- 11/28/2015 08:20 — There are quite a few ways to heat greenhouses. From the simplest, for example, put 1-2 buckets of boiling water in the greenhouse so that the seedlings do not get caught at night...">Heating of greenhouses and hotbeds: traditional and modern methods

- 09/30/2015 22:44 — Flexible translucent polycarbonate panels are great for building a greenhouse. This polymer material is very popular among consumers for its high...">Which polycarbonate to choose for a greenhouse

- 05/19/2015 11:35 — Economic sanctions against our country, which followed from abroad from former partners, served as an impetus for inflating prices for many industrial and other ... ">Private greenhouse farming using a real example

- 04/30/2015 12:58 — Greenhouses: what, for what and why

Next page >>

How can you heat a greenhouse at your dacha?

When choosing how to heat a greenhouse in the country, vegetable growers consider the following sources of thermal energy:

- solar radiation based on the “greenhouse effect” (the greenhouse, or greenhouse, effect is the increase in air and soil temperature in cultivation structures due to the conversion of short-wave solar energy entering through glass or film into thermal (infrared) energy, which does not pass back through the translucent fence);

- biochemical reactions during the decomposition of organic materials by microorganisms (biological heating);

- heating water and air when burning fuel (water, hot air heating, direct combustion of gas in greenhouses);

- geothermal waters (water and hot air heating);

- electrical energy (electric heating).

The most economical heat sources for heating a greenhouse are thermal waste from industrial enterprises and geothermal waters.

The economic efficiency of heating systems is determined not only by the cost of thermal energy sources, but also by their location, period of use and other factors. As the temperature of the coolant decreases and it moves away from the greenhouses, the economic efficiency of heating greenhouses decreases.

In winter greenhouses, where 30-50% of all operating costs for growing vegetables are for heating, the economic efficiency of heating systems is mainly determined by the cost of the coolant. In spring film greenhouses, the costs of maintaining optimal temperature conditions are much lower, and their main component is the costs of depreciation, maintenance, and routine repairs of heating systems. Under these conditions, the electric method of heating greenhouses is no less effective than other methods.

Which boiler to use

Since it is important to maintain a constant temperature in the greenhouse, the best option is automatically controlled boilers paired with a thermostat inside the greenhouse. But it's a matter of means. All these units are not cheap at all. However, if possible, buy automated ones. In addition to maintaining a stable temperature, they also save fuel. How? They produce the amount of heat that is currently needed to maintain the set temperature. That is, they will not allow your plants to freeze (if there is fuel) when the temperature suddenly drops, delivering their maximum power. But they will not produce excess heat during an equally sudden warming. In this case, they will simply switch to circulation mode and drive water through the pipes without heating (or with minimal heating - depending on the type of fuel) until the temperature drops below the set one. Then the active mode is turned on again, but only until the specified thermal mode is reached.

If you are going to heat with wood or coal, pay attention to pyrolysis boilers. Although they are expensive, wood in them burns for up to 8 hours, and coal lasts for 24 hours. And you don’t need to “live” in a greenhouse or keep a stoker.

Boilers with automated controls performed best in the greenhouse, and you need to choose any fuel that is available and at the same time inexpensive

How to calculate the boiler power for a greenhouse? In general, the surface area of the greenhouse is multiplied by the heat loss coefficient for the material with which the greenhouse is covered, and all this by the required temperature difference.

The temperature difference is considered to be between the minimum during the heating period outside and the required one in the greenhouse.

For example, we will be heating from February to April. The lowest temperature, even -18°C, will be maintained inside at +20°C. Total delta (difference) 38°C. Now let’s calculate the boiler power for such conditions in a greenhouse 10 x 5 x 2.5 m. Covered with double film. The area of all “film” surfaces of the greenhouse is approximately 150 m2, the coefficient of heat loss through the double film is 3.5. Total we get: 150*3.5*38=19950W. Rounding up we get 20 kW. For reliability, you can take a slightly more powerful boiler, approximately 24-25 kW (in case of expansion or abnormal cold).

Owners' opinion

If you look at the reviews of owners of warm beds, you can see a truly rosy picture. A larger number of authors argue that growing seedlings in warm beds, and even in greenhouses, only has a better effect on the harvest. Those who use organic warm beds claim that in any climatic conditions the yield increases several times. They note the ease of formation of such beds, the possibility of early planting of seedlings and, accordingly, earlier harvesting. Many also point to the cost-effectiveness and durability of this method. On any site there will always be the ingredients to create this type of beds. And even a woman can build it with her own hands.

Owners of electric heated beds point to the ease of installation if you follow the instructions exactly, and the durability of such a structure. The only downside is that you can’t find such a system in stores everywhere. Some users order installation kits online. Increased productivity, early fruit ripening and full automation of this method are noted if you install a thermostat.

Many gardeners prefer the water method of heating beds. Among the advantages, in addition to high yield and early ripening, is the possibility of self-assembly of this type of heating. Any man is able to install pipes of the required size and diameter, connect a water pump and install a furnace to heat water. In addition, this method, as the authors note, is more economical than electrically heated beds.

How to maintain the temperature at the desired level

The optimal temperature for many greenhouse crops is 15 - 20 degrees. If the greenhouse is intended for growing seedlings and then planting them in the soil, then a temperature within the aisles of 30 degrees is required.

To maintain the desired level of heating in the greenhouse, a thermostat is used. It can reduce energy costs by up to 30% in electric floors. This is achieved due to the intermittent operation of floor heating. The regulator turns on when the temperature drops below the required one, and turns off when it reaches the set level.

In water systems, temperature control is carried out by the mixing unit. The cooled coolant will be mixed into it until the desired heating degree is reached.

To avoid sudden temperature changes and increase the heating intensity, the Tichelman scheme is recommended - it implies the presence of a heat accumulator. Then there is no need to install a collector group.