Many owners of summer cottages would probably not give up the opportunity to harvest crops all year round. Unfortunately, in most Russian regions the climate is such that this desire looks like a utopia. However, installing a reliable greenhouse equipped with a productive heating system can be a solution to this issue. Recently, gas heating of greenhouses has been considered the most common, which is explained by the appearance on the market of modern equipment - IR emitters and convector heat guns.

How to make gas heating for a greenhouse

Only a properly selected gas heater will cope with the task. The first classification system is based on the use of a water or gas-air heating unit. In the second case, warm air moves in special air ducts. Another classification system is based on the number of built-in heat sources.

For small greenhouses, a 1-phase is suitable, and for larger ones, a multi-phase greenhouse heater is suitable. If we talk about the advantages of both options, then it is preferable to choose the second one.

This is explained as follows:

- Small heat sources are installed along the entire perimeter of the building, which promotes uniform heating;

- If the region experiences sudden cold snaps, then the multiphase version of the heater is supplemented with a catalyst system;

- An IR heater will help smooth out high humidity and a high difference between night and day temperatures.

The retail chain offers a large selection of gas heating devices for use in greenhouses. When choosing, you need to take into account the operating temperature range, humidity level, building area, and so on. The more accurately the calculation is carried out, the less wasteful expenses the gardener expects.

Tips for beginning gardeners: how to install gas into a greenhouse

Lucky are those whose greenhouse is located in close proximity to their home. In this case, you can heat the seedlings with gas with minimal time and effort. The situation is more complicated when it is impossible to install a gas pipeline to the greenhouse.

Mobile sources of gas - cylinders - will help to get out of this situation. Our review will help you choose a gas heater: https://homeli.ru/stroitelstvo-doma/inzhenernye-sistemy/otoplenie/gazovye-obogrevateli. When using them, you must always monitor the concentration of carbon dioxide in the greenhouse.

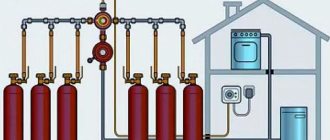

If there is too much of it or vice versa, the seedlings will not grow. You can assemble the simplest gas circuit as follows. First, you need to decide whether gas will be supplied to the house and greenhouse, or whether you plan to heat only the seedlings.

In the second case, the heat supply diagram looks like this:

- Gas sources;

- Heat exchanger;

- Fan;

- Air duct for constant exchange of hot and cold air masses;

- Buffer – equalizing pressure;

- Exhaust gas outlet source.

Depending on the distance of the house from the greenhouse, the gardener chooses one of two methods of supplying a heat source. In the first case, we are talking about direct connection by pipeline, and in the second, about the use of gas cylinders. In order for heating to be as efficient as possible, gas heating is supplied with the obligatory presence of a reverse circuit. Its presence does not allow carbon dioxide to accumulate inside the greenhouse, and also reduces the likelihood of an emergency situation.

Safety precautions when connecting gas

If it was decided to use gas cylinders for heating the greenhouse, safety precautions must be observed when connecting them to devices:

- After connecting the cylinder through the reducer to the equipment and securing the clamps, check for leaks. To do this, cover all connections with soap foam (any kind will do). If the formation of bubbles is observed, then there is a leak, and therefore it is necessary to tighten all connections again and carry out the control act again.

- Place the gas cylinder 1 m away from the heating device.

- Do not check the tightness of connections using burning paper or similar tricks.

- When filling a cylinder, the volume of gas in the container should not exceed 85% of the total in order to avoid an increase in internal pressure.

Gas heating in greenhouses today is an affordable and economical heating option, allowing you to obtain crops all year round. The main thing is to choose the right equipment and observe safety measures during its subsequent operation.

Universal gas gun for heating a greenhouse

The installation of a full-fledged gas-based heat supply system is not always justified. For example, seasonal greenhouses in temperate regions can be managed with the help of mobile portable devices.

Depending on the manufacturer, a heat gun has a power from 4.2 to 10 kW. When choosing a specific model, it is necessary to take into account the area of the building, otherwise increased consumption cannot be avoided. Read tips on choosing a heat gun in the material: https://homeli.ru/stroitelstvo-doma/inzhenernye-sistemy/otoplenie/teplovaya-pushka-na-dizelnom-toplive

From an economic point of view, a heating system based on such guns is justified only in one case. If the device is used at least 10-15 times during the season, the purchase makes sense. The average gun has the following characteristics :

- Average gas consumption: 310-410 g/hour;

- Thermal energy generation: 33 – 50 kWh/m3;

- Heated area: 25 – 65 sq. m.;

- Working volume range: 10 – 25 l;

- Working pressure: 29-35 mbar.

Rationalization ideas: how to heat a greenhouse without gas and electricity

Continuing the topic of saving, it is necessary to dwell on one more point. In some cases, heating can be carried out from natural heat sources. At the same time, electricity, water and gas are completely abandoned. One such example is the use of solar energy. At first glance it may seem that this is not entirely economical, but the secret of success lies in proper preparation.

The following recommendations will help you avoid common mistakes during the installation of solar panels:

- The panels are installed on the sunny side. Slopes are installed on the opposite side of the greenhouse. They play the role of a vehicle that transfers and dissipates heat so that heated seedlings do not experience temperature shock.

- An excess heat accumulator is built under the structure. Here it is important to emphasize that it is better to do the installation before the actual installation of the greenhouse.

- Air heating from a natural source reduces the economic component of the project. It must be remembered that it can only be used in certain months, depending on climatic conditions.

Economical gas heater for a greenhouse (video)

Heating for a greenhouse based on a gas cylinder is an opportunity to create comfortable conditions for seedlings in cases where electric or centralized heating cannot be supplied. Before installation, a project should be developed, taking into account the area of the structure, duration of operation and the nature of the planted crops. During direct installation, all manufacturer's recommendations must be strictly followed.

In its traditional form, gas heating of a greenhouse involves the installation of a conventional water heating system, where the heat source is a natural gas boiler. This option is feasible in a very small number of cases, since installation of a boiler and heating requires ordering a gas supply diagram, obtaining permission for such work and installation of heating by a licensed company.

Natural gas heaters for greenhouses allow you to do without such great difficulties.

Greenhouses heated with wood

Modern vegetable growers tend to heat their greenhouses with gas boilers, infrared heaters, and cables laid under a layer of soil. However, wood stoves for heating greenhouses have not lost their relevance, although they are no longer used so often. Contrary to the popular belief that such a system is cumbersome, we hasten to assure you: a wood-burning stove can be created in a small size, so it will not take up much space in the greenhouse. In addition, constant monitoring is no longer necessary.

The choice of type of wood-burning oven depends on the capabilities and needs of the vegetable grower. This could be the well-known central oven, made of brick or welded from metal. Such stoves belong to long-burning systems. Components of the device: a fuel compartment, a second bottom under the compartment, a blower, an opening with a door, a chimney with a steel valve and a lid. Heating a greenhouse with wood involves loading the firebox to ⅔.

Install the stove in a shelter away from flammable substances. Place it away from delicate plants, as the heat from the hot iron surface can damage the crops. Please note that this heating method reduces air humidity, which can cause plants to wither.

Gas heating systems: types

Today, there are quite a large number of heater models operating on natural or liquefied gas, which are capable of supplying heat to the required area. From these devices you can organize several different types of heating, equally suitable for greenhouses covered with polycarbonate and glass.

- Systems with one heat source are, one might say, traditional, judging by the reviews:

- gas-water heating with appropriate heating devices - pipes and radiators;

- gas-air heating - in this case, the air mixture is heated in a gas heat generator and distributed through polyethylene air ducts. In this case, the boiler power is calculated based on the required amount of heat per 1 m2.

- Gas-air heating can be organized on the basis of one mobile gas heat generator.

- Gas-air system with several heat sources - there may be several options:

- Convectors can be used as basic devices. The latter are fixed on the walls. The housings of the devices do not heat up, so these gas heaters for polycarbonate greenhouses are quite suitable;

- The system is based on floor-standing or mounted devices of various types - with an open burner, with injection, infrared.

Do-it-yourself installation of any gas-powered systems is prohibited. Installation of the system is quite possible, but connection to the pipe, debugging and startup must be carried out by a specialist with the appropriate license.

Types of gas heaters

Modern models are, of course, as safe as possible and are equipped with sensors that prevent the release of gas during attenuation, when overturning, and so on, which is confirmed by expert reviews. But we are still talking about such an explosive substance as gas, so you cannot install convectors of any kind with your own hands, no matter how simple this work may seem.

Features of modern products - a hidden threat

What is the reason? I think, first of all, in the recent publications on the pages of newspapers and magazines, as well as on television screens, about what modern sellers of “healthy” products feed us. As it turned out, for the most part, all these beautiful and appetizing delicacies do not always bring the desired benefits to the human body, and in some cases they can cause serious harm to the body, even death. In addition, it is much more pleasant to see vegetables and berries on your table that were picked just a few minutes ago from the garden, without pesticides or other chemical additives. The benefits of such products are undeniable.

Classic version

The traditional approach to using gas to ensure an optimal microclimate in greenhouses involved the creation of a heat circuit based on a gas boiler. This method is effective and reliable, but it is not very suitable for a small private greenhouse; the financial investment turns out to be impressive; it is necessary to create complex pipe routings and install shut-off valves for fine tuning and adjustment of functioning. In addition, this method of gas heating requires obtaining numerous certificates and permits; the equipment is classified as potentially dangerous, and therefore requires approval from regulatory authorities.

As a result, this scheme is relevant only if we are talking about a large commercial greenhouse with an area of several hundred square meters. Then we can talk about the justification of all investments, they are quickly compensated. Creating a separate heating circuit for a small agricultural structure is only appropriate if the owners use a gas boiler to heat the main cottage; it is possible to make a branch to the greenhouse.

Basic Rules

In greenhouses with a large area, it is necessary to connect to a common gas pipeline network; small greenhouses can be heated with gas cylinders.

To heat a room with gas, you can use various heating equipment: gas burners or air heaters. Each of them has its own characteristics. Using burners is more dangerous. However, provided that there are no wooden elements in the greenhouse structure, you can resort to burners. In this case, the burners simply need to be connected to cylinders and placed throughout the entire area of the room requiring heating. Installing a heating system requires a lot of expense and effort, but this option will prove to be more convenient to use in the future.

Particular attention must be paid to the uniform distribution of heat in the room, as this represents the greatest difficulty when organizing gas heating. To do this, you need to connect a sufficient number of burners to the gas cylinder, which will be distributed evenly throughout the room. At the same time, providing gas heating to a greenhouse requires compliance with certain safety measures. For example, access to gas burners should not be hampered in any way. If any problems occur in their operation, it should be possible to turn them off immediately. In addition, gas equipment requires constant preventive maintenance.

Heating using gas requires an efficient ventilation system. A hood may need to be installed. This is due to the fact that gas heating leads to a lack of oxygen over time.

The advantage of air heaters is that they are able to provide a sufficient amount of heat and at the same time mix the heated air. Their only drawback is their high cost. First of all, costs will be required for the installation of polyethylene perforated pipes, which should form an entire system. In addition, it is necessary to install a chimney that will ensure the removal of combustion products from the room.

Traditional mobile equipment

Heating a private greenhouse with gas is more economical if the owners use portable devices.

- Heater with open type burners. The design assumes the presence of a thermostat, a main burner and an auxiliary device. Both the cylinder and the mains are used as a power source. The burner flame heats the air, which naturally begins to rise to the roof, after which it settles evenly, increasing the temperature in the ground zone, that is, exactly where the plants are located. The main disadvantage of the technique is that the combustion process reduces the oxygen content in the air, and this is detrimental to agricultural crops. This phenomenon can be compensated for by installing a simple ventilation system. Not far from the heater, a hole is punched in the wall with a diameter of at least 5 centimeters. A PVC pipe is inserted into the hole. To protect against insects and rodents, it is recommended to install a metal mesh with small cells.

- Heating with gas convectors. Installation of this equipment is carried out on walls; the design implies the presence of a sealed combustion chamber based on steel or cast iron. Inside the chamber there is a main burner, as well as a closed heat exchange circuit. The operation of the device is controlled automatically; main or bottled gas enters the main burner, due to which the internal heating of the housing occurs. The heat exchange circuit transfers energy inside the greenhouse. Compared to a conventional open heater, this device independently takes in air and releases combustion products, that is, the oxygen level in the agricultural building does not drop, eliminating the need for additional ventilation pipes. The device automatically adjusts the temperature in accordance with the set values, safety is guaranteed by a locking mechanism that cuts off the fuel supply in situations with a drop in draft or pressure. Such a heating device is sometimes additionally equipped with a fan. Modernization increases efficiency, the air in the greenhouse warms up much faster, but there is a dependence on the power supply.

Biofuels for heating

Horse manure has a high heat transfer rate; it heats up within a week and throughout the growing season maintains a favorable temperature in the soil environment where the plant roots are located. Summer residents often use cow, pig, sheep and other types of manure. Their heat output is somewhat lower, but is also suitable for heating a greenhouse.

Wood leaves and debris can be used as biofuel. The mixture is especially good, the third part of which is rags and paper.

Biofuel harvested in the fall requires proper storage. Manure is placed in stacks up to 2 meters high, compacted with a shovel, and insulated with peat, sawdust, and leaves.

A week before planting in the greenhouse, biofuel must be heated. Shake it with a pitchfork to make the mass loose. Hot stones or quicklime are placed inside. Another option is to build a small fire, which should be loosely covered with a tin sheet. When only coals remain, you need to throw manure on top of the sheet. When heated, it will emit an ammonia smell.

If stored properly, manure will not lose its quality during the winter.

Important! After placing the biofuel on the sheet, it is necessary to leave a hole for traction.

Before heating, the greenhouse must be cleared of snow. Sawdust is placed at the bottom of the structure or in prepared recesses, then heated manure is poured loosely. If it burns weakly, then you can put hot stones or pour lime in several places. After a few days (usually 4-5), the fuel will settle, after which it is necessary to add a new portion. Approximately 15 cm of soil is poured on top. With such heating of the greenhouse, evaporation will occur and the seedlings will need to be watered less frequently.

Important! The manure should be sprinkled with lime to prevent mushrooms from growing.

For more intense heating, you should take up the construction of a stove with your own hands. This won’t be much of a problem for a summer resident – just pleasant troubles.

Modern approach

Heating with infrared burners is considered the most advanced, gentle and economical method. The operating principle of IR technology is based on electromagnetic radiation produced by heating elements that heat up during the combustion of fuel.

- “Dark” units are equipped with tubular heating elements, the maximum temperature of which is 600 degrees;

- “Light” devices are equipped with mesh heating elements or ceramic-based plates, the temperature of which can exceed 600 degrees.

Do not forget to familiarize yourself with the material on heating greenhouses with your own hands.

The reason for this division into groups is the ability of “light” burners to produce light in the visible spectrum, similar to ordinary incandescent lamps. However, 60 percent of the total heat flow comes from infrared radiation.

If we consider the design features, then “dark” devices are based on an element elongated in one direction, which is explained by the tubular shape of the heating element. Additionally, a pipe is installed to remove combustion products. “Light” IR analogues do not have their own chimney; combustion products are emitted inside the greenhouse, and therefore it is necessary to additionally equip the structure with ventilation ducts.

The advantage of technology operating in the IR spectrum is that it makes it easy to organize local heating zones and control the temperature in areas where the most heat-loving crops grow. Practice shows that devices are most effective when germinating seeds that also require an abundance of thermal energy.

Sawdust stove

Wood processing waste is an excellent fuel

The next type of stove for heating a greenhouse is suitable for those owners who have a workshop and sawdust as waste. Thus, the vegetable grower will not need to dispose of waste, and the plants will be kept warm. Sawdust as an ecological fuel for a greenhouse is extremely effective (it burns well and, what is important, for a long time) and is economical. They are sold in briquettes and pellets. Heating greenhouses with sawdust stoves involves using a tank of water. This step will allow maintaining the required level of humidity in the greenhouse for the plants. In addition, warm water from the tank can be used to water plants in cool weather.

Conclusion

Thus, heating a private greenhouse with a gas gun is not the only scenario when using this type of fuel. A competent approach to the formation of a scheme, taking into account all kinds of factors, attention to modern devices - all this will help to establish a system that will not have any weaknesses. Taking into account the fact that gas in Russia is significantly cheaper than electricity or solid fuel, a well-equipped scheme can pay for itself in just a couple of seasons.

Some features

When heating a greenhouse with gas, oxygen burns out and burns out, which is dangerous for plants, so ventilation/air supply systems must also operate simultaneously with gas heating.

Heating a greenhouse with gas means turning to specialists for help. Do not neglect this, as gas is a flammable and explosive substance. Failure to take the necessary safety precautions can pose a threat to your health and even your life. If you contact a specialist in this matter, he will help you determine the optimal number of burners or heaters that will provide heating for a greenhouse of a certain size for growing certain crops.

So, the undeniable advantages that heating a greenhouse with gas have:

- efficiency;

- efficiency;

- safety (subject to professional installation by a specialist in this field, who will give recommendations on the safe operation of heating devices).

Thus, you know the basic principles of arranging a heating system using gas. Compared to other methods of heating a room for growing plants, the use of gas has significant advantages. Most gardeners prefer it. However, the heat obtained in this way may not be enough if you need to heat a large greenhouse throughout the year.

In order for the plants in the greenhouse to bear fruit all year round, it needs to be equipped with a heating system. One such method is gasification. How feasible is this approach to heating a greenhouse space and how the system itself can be designed, read below.