Today, it is not a problem to enjoy a vegetable salad in the middle of winter: there is a rich assortment of plant products in stores all year round. But, besides the fact that the price for it is not the most affordable, and the taste leaves much to be desired, the benefits are also minimal, but it is quite possible to “enrich” the body with various chemicals. Therefore, despite the abundance in stores, winter greenhouses, which provide the opportunity to grow environmentally friendly and tasty vegetables or herbs for your family, have not lost their relevance. However, compared to summer greenhouses, winter greenhouses are more complex both in terms of construction and in terms of operation of the structure, and are more demanding in terms of materials. The participants of our portal are mainly engaged in seasonal greenhouses, but they also have experience in the construction and use of year-round greenhouses.

Consider:

- Structural features of winter greenhouses.

- Arrangement of winter greenhouses.

- What to grow in winter.

Infrared heaters

The latest developments in greenhouse heating include ceiling-mounted infrared heaters. They consume a minimal amount of electricity, plus the effect of their action far exceeds any other types of heating devices, including water radiators and even heated floors.

Infrared heaters

The heat from them does not rise upward, but spreads evenly throughout the room. Moreover, it is the soil that warms up most intensively, and not the air, which is very important for plants.

It should be noted that to heat greenhouses it is necessary to use only long-wave devices (preferably ceramic) with heating of the working fluid to 270-300°C. Unlike medium-wave emitters, which heat up to 1700-1900°C, they are not capable of burning plants.

Significant advantages of infrared heating also include:

- environmental friendliness and harmlessness: such heaters do not emit carbon dioxide and other combustion products into the air that are harmful to plant health

- infrared devices do not dry the air at all, since they do not heat it, but any objects and surfaces; no humidification of the room is required during their installation

- no heat loss - the efficiency of such heaters is 95%

- efficiency: since they heat the soil rather than the air, the required volume of thermal resources is reduced by 35%; Plus, such devices consume a minimum of electricity

- installation of systems is simple

- the risk of fire when using infrared devices is minimized

Selecting a greenhouse type

First you need to decide for yourself which type of greenhouse will be preferable. The classification of greenhouses is very broad; there is no point in listing it in its entirety, so we will outline the main characteristics that influence the choice of the type of greenhouse.

- Assigned functions. Depending on what exactly will be grown in the greenhouse, its type largely depends.

- Relation to ground level. The greenhouse can be buried in the soil, located at ground level, or raised above the ground - such greenhouses are often built as a second floor to an existing building.

- Heating type. The most important difference between a winter greenhouse and a regular greenhouse is the heating system. For it, you can use electrical energy, heat from the combustion of solid fuel or gas, and water systems. Or you can arrange an environmentally friendly heat source that runs on biofuel.

- Greenhouse architecture. A heated greenhouse with your own hands can be built with one, two or three slopes, arched, horizontal and almost any other. The choice of architecture depends on the preferences of the master and, again, on what exactly will be grown - for example, for growing tall flowers or climbing plants, the greenhouse should be high, for low-growing plants, for example, for strawberries, a low horizontal greenhouse is quite suitable.

- Materials used. To build a winter greenhouse, you can use a variety of materials, the main thing is that they are frost-resistant and prevent heat loss. Wood, brick, and foam concrete cope well with these tasks. Glazing can be made from polycarbonate sheets; this material retains heat remarkably and allows sufficient sunlight to pass through.

Video:

Also, if you are building a heated greenhouse with your own hands, it is important to position it correctly. Daylight hours in winter are short, so you need to make the most of it

To do this, place your greenhouse along the east-west axis, that is, along the movement of the Sun. Also take into account the prevailing wind directions - if the greenhouse stands across the air flow, the heat will simply be blown out of it. Don’t forget about ease of use; there should be a convenient approach to the greenhouse that will allow you to leave the snow and get into the greenhouse. Therefore, you should not skimp on space.

When designing the internal structure of the greenhouse, keep in mind that you will be working in it in the winter, so provide a vestibule that will separate the warm room from the cold outside. The vestibule must have enough space to accommodate the firebox and installation of heating elements. Take care of reliable thermal insulation of the vestibule - if it freezes, the heating system will be ineffective. And most importantly, understand that a heated greenhouse must be a solid structure, with a reliable foundation, strong walls and a strong roof. Only then will you be able to grow the winter harvest.

Underfloor heating system

Installation of heated floors

An ideal option for heating the soil in a greenhouse is also a heated floor system. After all, for successful plant growth, it is the roots that need to be warmed up.

Since heating a greenhouse with electric heating elements will cost a lot of money, it is better to install a stove or boiler in it. The heating system can be combined by installing radiators around the perimeter.

- It is better to use polyethylene pipes to heat the greenhouse. They are buried to a depth of about 40-50 cm in the drainage - a layer of crushed stone and sand

- It is not advisable to use metal-plastic for laying in the ground. After all, its fittings (connecting elements) require regular tightening. If you still decide to use such hard plastic, use compensation loops when laying the pipeline

- The first to be laid is a polyethylene film , which serves as waterproofing.

- Next, a layer of thermal insulation made of polystyrene foam or expanded polystyrene

- You can also reduce the thermal conductivity of the soil using compacted sand , which is poured over the heat-insulating layer to a height of 10-15 cm

- The distance between the pipelines should be 0.36 m. To ensure uniform heating, 2 collectors are placed along the edges of the greenhouse. Pipes are connected to them alternately

- To protect the pipeline from damage when digging the soil with a shovel or pitchfork, slate or metal mesh is laid on top of it

- The next 35-40 cm layer is fertile soil

How to make heating in a polycarbonate greenhouse with your own hands

Despite the apparent complexity, you can set up a greenhouse heating system yourself without the help of professionals. You just need to prepare carefully and stock up on the necessary tools and materials.

How to make a brick oven

The installation of stove heating is not particularly difficult; almost any greenhouse owner can handle its installation.

Necessary materials:

- solid ceramic brick - 220 pcs.;

- fireclay brick - 80 pcs.;

- clay masonry mortar - 80 l;

- fireclay masonry mortar - 30 l;

- foundation concrete - 0.25 m³;

- waterproofing material;

- firebox door;

- cast iron grate for grate;

- blower and cleaning;

- smoke valve.

Step-by-step instruction:

- A foundation for the slab is laid: height - 20–30 cm, base size - 70x100 cm. For this, a trench about 45 cm deep is laid.

- Formwork is laid around the perimeter of the trench, reinforcement is installed, and concrete is poured.

- The base area is covered with a 20 cm thick layer of sand.

- To create a firebox for filling and an ash pit for waste disposal, 4 initial rows of the structure are laid out with red bricks on clay mortar.

- A cast iron ash pan door is installed.

- Rows 5–12 are laid with fireclay bricks with fire-resistant adhesion. In row 5 a grate is installed, rows 6–8 are equipped with a combustion door. Rows 9–12 form the arch of the firebox.

- Rows 13–22 are laid with refractory bricks. The furnace roof is covered with rows 13 and 14, and a cleaning door is installed in row 15.

- The chimney channel is rows 17–21. The first smoke damper is installed in row 22.

- Rows 23–27 - continuation of the smoke channel. The narrowing of the channel begins from the 28th row, and in the 29th row another smoke damper is installed.

- The furnace roof is rows 30 and 31. Starting from the next row, a smoke exhaust pipe is installed. It is created with a bandage and is built from 4 bricks.

Heating with gas

Infrared burner

The disadvantages of such heating include the need for mandatory coordination with special services. Moreover, you will not be able to provide gas heating for the greenhouse - the design and installation of such systems is carried out only by specialists. Due to the high risk of ignition during operation, the operation of gas boilers will need to be constantly monitored. Due to the excess carbon monoxide generated during fuel combustion, ventilation .

But still, such devices have much more advantages. The cost of gas is not that high. You will only have to spend money on purchasing a boiler and equipment for it. Such designs ensure uniformity and rapid heating of the greenhouse, plus they are as easy as possible to maintain. But in order for it to heat up evenly, it is better to install heaters or connect several burners at once.

We list the main types of gas equipment used for heating greenhouses:

- convectors: industry produces special devices of this type specifically for heating greenhouses; built-in heat exchanger distributes heat evenly throughout the room; ventilation in it is provided using a coaxial (pipe in pipe) chimney

- heater with two open burners (the second of them serves as a spare) and a vertical chimney; the ventilation system is installed separately

- burners with infrared radiation: they are located in separate zones for local heating of certain types of crops or accelerating seed germination; equipped with a smoke exhauster that throws combustion products into the chimney; their operation does not require the installation of forced ventilation systems - natural is sufficient

In most cases, gas heating in greenhouses is combined with water heating . The principle of its arrangement is similar to that described above.

Heat gas gun

Heat gas gunsused for spot heating can be easily connected to both a gas main and a cylinder. Such structures are light in weight and quite mobile; they can easily be moved to any other place. The fuel in them burns completely, so the risk of carbon monoxide poisoning during their operation is minimal. Modern gas-fired heat guns are equipped with a temperature and even humidity control system.

Air heating of a greenhouse

Many gardeners prefer to use air heating. As a rule, this is decided in advance, because the air heating system is installed during the construction of the winter greenhouse.

For those who don’t want to bother, there is one fairly simple method to heat a greenhouse using air. It is used mainly as a backup option in case of force majeure.

To do this, a pipe is laid in the greenhouse, one of the ends of which is led outside. A fire is lit under the protruding end of the pipe. Warm air, heated by the fire, will flow through the pipe into the greenhouse and warm the plants.

Of course, it will not be possible to constantly maintain the desired temperature in this way, but if necessary, this method of heating a greenhouse can save seedlings from death.

For those who need to maintain the desired temperature in the greenhouse for a long time, it is better to choose a more reliable option.

Stove heating for a year-round greenhouse

Many gardeners choose stove heating for heating the greenhouse in winter. This is not surprising, because in cold weather the familiar “potbelly stove” and its modern modifications are capable of maintaining a temperature of about 18-24°C for a considerable time!

The most important advantages of the stove heating method are efficiency and simplicity. The price of fuel for a potbelly stove is not that high, and its installation is easy to do yourself, without the help of specialists. It is important that by heating the stove with firewood, sawdust, packaging materials or rags, you will get an excellent fertilizer for fertilizing the soil - ash.

The undoubted disadvantage of using a stove in a greenhouse is that the air with this heating method is not always heated evenly. As a rule, it is too hot near the stove; plants planted in this area will die from unsuitable temperatures. In addition, we should not forget that a potbelly stove is a fire-hazardous structure, and a number of precautions and safety rules must be observed. And for a potbelly stove to work efficiently, it is necessary to regularly add fuel to it, that is, to be in a greenhouse all the time.

But there is an alternative option - using stove heating to warm the soil. In this case, the heated air will be distributed through pipes laid in the ground and evenly warm the soil, from which the air in the greenhouse will also heat up.

But keep in mind that for regions with very harsh winters, such heating alone may not be enough. To be on the safe side, the air in the greenhouse will need to be heated with any of the devices described above.

Homemade water heating for a greenhouse

Some gardeners recommend using water heating to maintain heat in a winter greenhouse. It can be created using a fire extinguisher (or pipes) and a heating element (heating element) as a basis. This method is considered simple and at the same time quite effective. True, the ability to work with a welding machine will come in handy here.

You will need an empty fire extinguisher, the top of which needs to be cut off. At the bottom of the fire extinguisher, attach a heating element with a power of about 1 kW (you can take a heating element from a samovar). Then attach the cut off top to the body of the fire extinguisher using loops.

Next, connect two metal water pipes to the body of this unit, securing them with nuts and rubber seals. Then install an automation tool (many use a relay circuit).

How does this equipment work? It's simple. If the greenhouse becomes very cold, the sensor will react to this, close the contacts, and the water will begin to heat up. At the same time, it will transfer all the heat generated to the greenhouse. As soon as the water heats up to the desired temperature, the heater will automatically turn off.

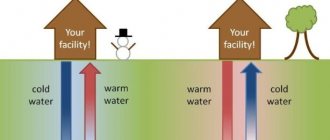

Hot water in such a system circulates in a closed circle. It is supplied through the upper pipe, in which it is slowly cooled and returned to the boiler through the lower pipe.

The optimal pipe diameter is 10 cm. If you install pipes with a larger diameter, a significant amount of fuel will be required to heat them, and if smaller, they will produce an insufficient amount of heat. They need to be located as close to the soil surface as possible.

Owners of small greenhouses can use a gravity water circulation system. For the method to work, the boiler must be installed much lower than the heating pipes. This method is not suitable for use over a large area: due to the fact that the water moves slowly, the inner surface will not warm up properly. To avoid this situation, use a circulating pump. For use in a closed system, a mechanism that is reliable and durable will be sufficient; there is no need to purchase high-power equipment.

Solar batteries

The principle of operation of a solar battery

Collecting and accumulating the heat given off by the sun's rays will help to get an early harvest in the spring. Heating a greenhouse using solar batteries can also be used as an additional option. For the winter period, the heat received only from them will not be enough.

To accumulate solar energy, the greenhouse must be installed in the most open place and located from east to west. It has been proven that arched polycarbonate structures are capable of “collecting” the maximum number of rays. Plus, the air in the cells of this material will serve as a natural heat insulator.

Solar batteries are divided into:

- water : the heat storage in this case is water containers (barrels or pools); Moreover, several small containers have a higher efficiency than one large one, because water always warms up better closer to the surface; they are distributed evenly throughout the room

- stone : this material is capable of retaining heat for a long time, so it makes sense to line the walls of the greenhouse with stone or cover it with a sufficiently large layer around the perimeter of the structure

- air : are among the most efficient battery devices (see photo); for efficient heating, heat exchangers are positioned perpendicular to the direction of the sun's rays; heated air enters the greenhouse through pipes; cold air is taken in through the second duct

When installing an air heating system in a polycarbonate greenhouse, it is advisable to use fans to ensure rapid air exchange. The inlet pipe of the air duct is located as close to the ground as possible. The pipe through which heated air enters the greenhouse is placed in the upper part of the room.

What should a winter greenhouse be like?

Winter greenhouses are permanent structures built on a foundation that can withstand both wind and snow loads. These can be either free-standing buildings or extensions with one blank wall. For example, to the utility block, if the orientation of the structure allows.

Foundation

The foundation of a greenhouse can be strip or made of separate blocks; columnar and slab foundations are less common. USPs are usually not made under free-standing greenhouses, but if this is a winter garden within a permanent building, then such a foundation is quite justified. In terms of cost, a slight expansion of the building area against the general background is not critical, and the heating circuit installed when pouring the slab will simplify the further arrangement of the greenhouse.

To prevent the outflow of far from free heat through the base of the greenhouse, extruded polystyrene foam can be used when building the foundation. The most effective is comprehensive insulation of both the foundation strip and the soil under the greenhouse, on the site of future beds. The use of insulation is especially important if soil heating is planned; EPS will prevent unnecessary consumption of thermal energy for heating the lower, unused layers of the soil. You can also use insulation to protect the north side.

Frame

Like seasonal, year-round greenhouses, mainly of the frame type, the frame comes in two types:

- metal;

- wood.

These materials are comparable in strength; In addition, wood does not overheat in summer and gives off much less heat to the outside in winter. Considering that winter greenhouses are built on a foundation, and there will be no direct contact with moisture at the racks, the service life of the wooden frame is quite decent. Naturally, when calculating the parameters of all elements, the expected loads must be taken into account.

Alla Ivanova

I prefer to build only wooden winter greenhouses - cheaper, simpler, and simple - I love wood. In our steppe there are such hurricane winds - don’t worry, mother, but nothing has ever been torn down, we always do it conscientiously.

A frame made of HDPE (low-density polyethylene) pipes is increasingly in demand for seasonal greenhouses; if used for winter ones, it is in regions where heavy snowfall is very rare.

The shape of the greenhouse largely depends on the frame material, climatic conditions and personal preferences. Most often they build:

- arched;

- single-pitched;

- gable.

Due to the shape, it is problematic to make a wooden frame for arched structures; technically this is possible, but it will require much more effort and time than rectangular options. Therefore, such greenhouses are usually on a metal frame, while a wooden one is more in demand for single-pitch or gable structures. Although some still prefer to combine wood with the arch.

Sheathing

As for the frame sheathing, the era of polyethylene film in several layers is gradually disappearing; today, in most cases, cellular polycarbonate (SP) is used. Glass, also used as cladding for winter greenhouses, is significantly inferior in thermal conductivity, although it is superior in durability (if treated with care) and light transmittance. From the point of view of heat conservation, the optimal greenhouse-thermos for cold regions is considered to be double cladding with SP sheets with an air gap, similar to double-glazed windows. In this case, the thickness of the outer layer is at least 6 mm; for the inner layer, a thickness of 4 mm is acceptable. But the thicker the sheets in the layers, the lower the thermal conductivity, therefore, when creating a sealed circuit (using end caps), the lower the heat outflow. In the summer months, the effect of a thermos will help prevent overheating without the need for partial dismantling of the casing.

Anchor PlusModerator FORUMHOUSE

Possible combinations of layers (external plus internal, distance everywhere - from 20 to 50 mm):

- 6/4 – 1.8 W/(m•⁰С);

- 10/6 – 1.61 W/(m•⁰С);

- 16/6 – 1.42 W/(m•⁰С);

- 16/10 – 1.27 W/(m•⁰С);

- 20/6 – 1.19 W/(m•⁰С).

However, you should not get too carried away with thicknesses, especially when the greenhouse is of an arched type. The thicker the sheet, the greater the minimum permissible radius with which it can be bent without loss of characteristics. Yes, and problems may arise with the purchase of components, since for sheets thicker than 16 mm they are rarely found on sale, and if they are, the price is prohibitive. While for most regions, 10 mm on the top layer is sufficient for snow loads, the main thing is to correctly calculate the pitch of the racks.

One of the portal users has a winter garden (extension), on USP, with two layers of joint venture cladding.

Arkhipov I

I plan to install a greenhouse as an extension to the boiler room on one USHP - a wooden frame, polycarbonate walls in two layers, with an air gap. Height – 2.5 m, covering – single-pitched polycarbonate roofing.

Biological heating

Biofuel (self-heating substrate) has been used to heat plants since ancient times. Any summer resident knows that cucumbers get sick less and grow better not in open ground, but in warm manure.

Biofuel can also benefit a greenhouse. It can be used not only manure, but also plant residues, household organic waste (paper, rags, plant food residues), sawdust, leaves, straw. Later, when it completely rots and turns into humus, it is used as fertilizer. The best biofuel is obtained by mixing cow manure (1 part) with peat (3 parts). The mixture of conifer bark, sawdust and droppings heats up more slowly, so its heat lasts for a long time.

Biological heating

To heat a greenhouse using this method, it is necessary to remove the top layer of soil, lay a 15-centimeter layer of biofuel, and pour warm water over it. After a few days, when the organic mass begins to generate heat, it is again covered with removed soil and the beds are arranged.

When using straw, bales are placed in shallow ditches so that it rises slightly above the ground. To start the rotting process, the substrate is spilled with water, infusion of manure or chicken droppings. The seedlings can be planted after 2-3 days, when the temperature begins to rise.

Recommendations

When choosing an IR heater, it is important to pay attention to its power. Devices should be selected taking into account the size of the room. Usually, to heat 10 m2, a device with a power of 1000 W is required, but it is better to purchase units with a reserve

If a wall-mounted heater is selected, it is important to find out the thickness of the foil layer of the emitter. Its indicators must be at least 120 microns. Otherwise, a significant part of the energy will be spent on heating the ceiling

Usually, to heat 10 m2, a device with a power of 1000 W is required, but it is better to purchase units with a reserve

If a wall-mounted heater is selected, it is important to find out the thickness of the foil layer of the emitter. Its indicators must be at least 120 microns

Otherwise, a significant part of the energy will be spent on heating the ceiling.

Manufacturers produce heater models with various functions. You need to think in advance whether they will be used during operation, otherwise there is a high risk of overpaying for something that will not be useful in the future.

Devices may have the following options:

- regulation of temperature parameters;

- automatic shutdown of the device when it is turned over (mobile variations);

- shutdown of equipment in case of possible overheating;

- turning the unit on or off at the right time.

Before purchasing a device, you should carefully inspect its case. It can be made of steel or aluminum. The first options are more durable, the second – stylish design. There should be no traces of mechanical stress or rust on any of the housings. Corrosion can reduce the service life of the device declared by the manufacturer.

How to heat a greenhouse with candles and bottles

This method can be useful in the event of return frosts. It allows you to increase the room temperature by several degrees in a short period of time.

When the temperature drops slightly below 0 °C, 4 candles are enough to heat a 6x3 m room . To prevent heat from immediately escaping upward, they must be covered with metal buckets, leaving a small gap between it and the ground for oxygen to enter. Buckets heated with a flame will begin to quickly heat the air.

You can replace metal buckets with ceramic pots, inserted one into the other and strung on a metal bolt. It will serve as a heat conductor.

Heating with a candle

You can also use regular water bottles to heat the greenhouse. Experienced gardeners stock up on large plastic containers and use them throughout the season. During the day, the bottles heat up in the sun, and at night, when the temperature in the greenhouse drops, they begin to release the accumulated heat into the air. Plus, in hot weather, containers with cold water save plants from excessive overheating and burns.

The best designs for greenhouse heating systems can be easily found online. For example, the author of the following video shares his own experience of heating such premises:

Solar method of heating a greenhouse in winter and early spring

The easiest and most natural way is with the help of the sun. To use the energy of the celestial body to the maximum, the greenhouse should be placed in the place where the most sunlight reaches - this way the plants will receive the maximum amount of heat and light.

Gardeners have experimentally found that a greenhouse in the shape of an arch or hemisphere heats up best in the sun.

For solar heating to work effectively, the roof of the greenhouse must be completely transparent. Then the sun's rays will be able to freely pass inside and heat the plants and soil, which will give off heat, thereby heating the air in the greenhouse.

The undoubted advantages of the solar heating method are efficiency and environmental friendliness, but a significant disadvantage is the fact that this option is not suitable for northern regions.

IR heaters under close review

Not everyone is familiar with this system, so let's talk about it in more detail, consider the pros and cons, and consider how to choose the right heaters and place them in the greenhouse.

Operating principle and advantages

IR rays.

We have already said that IR heaters are in some ways very similar to the work of the sun. They emit rays, which in turn are absorbed by the soil and other objects. When objects heat up, they give off excess heat to the air, heating occurs.

Due to this, it happens:

- The most efficient heat distribution indoors

- Economical energy consumption

- No drafts

Why is it beneficial?

Having said it sparingly and without explaining why, our resource will begin to resemble an ordinary advertising one that offers to buy something and promises a lot of benefits of unknown origin for this. We try to help our readers, so having said A, we will definitely say B.

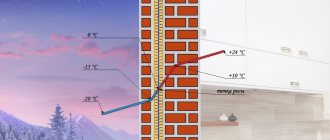

- A conventional heating system heats the air.

- Warm air rises and accumulates under the ceiling.

- To achieve the required temperature below, that is, where plants grow, it is necessary to warm up the air more, which in turn gives off heat to all surrounding objects.

From the above, it becomes clear that in this situation, quite a lot of time passes in order to achieve the required temperature and subsequently maintain it at the desired level.

It is worth adding to this that in convective heating systems, heat is distributed unevenly and this must constantly be monitored and adjusted, and this, as you understand, requires special devices and, as a result, additional costs.

Our information is that with the correct placement of IR heaters and their correct operation, it is possible to achieve about 40% energy savings.

With IR heating, all these disadvantages are eliminated.

- The heated soil releases heat and the highest, controlled temperature is created where the plants are located.

- Due to this, energy costs are minimized.

Experience shows that there are advantages

- When using IR heaters, they can be located in places with reduced thermal insulation, near doors and windows, due to this, heat loss is reduced.

- At the same time, the movement of air masses due to temperature changes is completely absent, therefore there are no drafts, to which some plants are very sensitive.

Experienced gardeners know and can confirm that all these components have a positive effect on plant germination. The absence of dry air, and in this case this is excluded, allows us to achieve good harvests compared to other types of heating by 30-40%.

Our information is that IR heaters warm the soil to a depth of 50 – 70 mm. Due to this, the root system is in the most comfortable mode for the growth and nutrition of the plant.

You need to know that at the moment when the soil warms up to 25 - 28 ˚С, the air temperature in the greenhouse does not exceed 20 - 22 ˚С.

As you can see, the most comfortable conditions cannot be achieved with any other heating system. To do this, you will have to install several heating circuits for soil and air, and the systems must operate in a strictly controlled mode. As a result, the cost of the entire system increases and operating costs increase.

Foundation

The greenhouse building has a heavy structure and requires laying a foundation for strength. There are 4 ways to base it:

- tape;

- brick;

- squared;

- stone foundation.

Practice shows that the most common is a strip foundation.

Work order:

- Construction site marking;

- digging a ditch about a meter deep;

- covering the bottom of the pit with waterproofing;

- production of reinforcement to strengthen the foundation;

- filling the ditch with cement mortar;

- coating of thermal insulation material on a completely hardened foundation.

Next, bolts are attached to the prepared foundation to construct the frame. When deciding how to build a winter greenhouse, some craftsmen lay one layer of brick on the foundation. With this method, the bolts must pass through the brickwork and penetrate the fabricated foundation.