In order to maintain a comfortable temperature in the main rooms of the bathhouse and ensure hot water supply, it is important to properly organize heating in the bathhouse from a heater located in the steam room, or use alternative sources. At the same time, each bathhouse owner can create an autonomous heating system independently, without involving outside help.

Need for additional heating

The classic option for heating a steam room for bathing procedures is a brick or metal heater. In this case, additional equipment is used to maintain a given air heating temperature both in the steam room and in other rooms.

It is impossible to ensure fast and uniform heating of the dressing room and rest room from a sauna stove.

And if in summer this does not cause problems, then in winter such a situation can lead to a decrease in comfort when organizing a bathing holiday. In this case, all the heat produced will be accumulated in the steam room, and the dressing room and other rooms of the bath will remain unheated.

Installation of additional heating equipment will ensure the maintenance of a comfortable temperature necessary for a long stay in the dressing room.

Construction of a brick stove

The main problem that arises when installing a brick heater is the massiveness of the structure. This requires the construction of a reinforced concrete foundation. For those who do not have experience in building sauna stoves with their own hands, the following tips may be useful.

If you put a thick layer of mortar between the brick joints, then under the influence of high temperatures it will begin to collapse and the heater will become leaky. On the contrary, a thin layer of mortar between the brick joints will negatively affect the life of the structure.

Each vertical layer of masonry must be covered with a top brick. It is advisable to make the ceilings in half a brick.

https://youtube.com/watch?v=cJLIxnSHc68

There are other nuances. So, if cut bricks are used, then the whole side should be turned inside the furnace. To ensure uniform linear expansion, cast iron elements are installed with a gap. To secure the upper part of the stove door, it is better to use a metal clamp.

Heating by stove-stove

For small baths, a traditional heater remains a viable heating option. In this case, it is enough to purchase or manufacture a heating unit of the required power.

Calculation of equipment power is determined by the formula: 1 kW of power per 1 sq. m of premises. To ensure a comfortable stay for visitors in the steam room, a thermal power reserve of 35 to 55% is additionally taken into account.

The popularity of the heating heater is explained by the following advantages:

- ease of installation and maintenance;

- accessibility of operation;

- using available fuel.

When giving preference to a sauna stove, do not forget about some of the disadvantages of the device:

- impressive dimensions and weight;

- inability to automate the process of heating rooms;

- high fire hazard;

- formation of fuel combustion products.

Modern heaters operate on wood, electricity, liquid and gaseous fuel. The choice of the appropriate option depends on the financial capabilities and technical capabilities of the equipment.

To ensure effective heating of the room, heating the bath from the stove in the steam room is done as follows: the firebox is placed in the dressing room, the heater is in the steam room, and the tank with warm water is in the washing compartment.

Choice

What are the characteristics of gas stoves intended for baths?

Stones

The traditional stove for a Russian bath - a heater - is distinguished by a large number of round stones placed in a tray. The tray is located above the firebox and, after lighting the stove, heats up quite quickly; the stones heat up to temperatures of 200 degrees or more.

They perform a dual function:

- By accumulating heat, the stones maintain a high temperature in the steam room after the wood burns out.

- The very name “steam room” implies the presence of steam. The traditional mode for a Russian bath is 60 degrees with very high humidity. To add steam, just splash water from a ladle onto the stones.

Gas heater Ermak.

If you are a fan of the Russian bathhouse, a heater is your obvious choice. If you want to use a sauna with high temperatures and minimal humidity, you don't need stones. Heat accumulation in the case of gas, you understand, is of no value.

Water tank location

It may be located in the stove body or around the chimney. In the first case, the heat source for heating water is the burner flame, in the second - combustion products. In the author’s humble opinion, the second option is preferable: the tank additionally cools the combustion products, increasing the efficiency of the device.

Gas stoves

If you use bottled gas, a stove that combines two types of fuel would be an excellent solution for you. When the cylinder runs out, you can light the stove with wood.

Burner

Often it is purchased separately.

What should you pay attention to when purchasing?

- With a steam room volume of 18 m3, the reasonable maximum gas consumption by the burner is 1.5 m3 per hour. It is easy to recalculate the required productivity for your volume.

- The registration certificate and markings must be present. Automatic shutdown when the flame goes out is mandatory (in fact, now it is available almost everywhere).

- Any damage, even seemingly uncritical, puts an end to the device. Big and fat. We are talking about people's lives and health.

Domestic burner Teplofor.

Heating by furnaces with heat exchangers

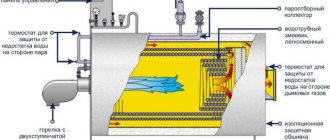

Stoves with heat exchangers are an alternative option to conventional heaters, which provide space heating, hot water supply and steam generation.

Heating in a bathhouse from a stove heat exchanger can be organized both for the main premises - steam room and washing room, and for auxiliary ones - dressing room, relaxation room, billiard room, shower room, swimming pool.

At the design stage of heating equipment with a heat exchanger, the following data is taken into account:

- dimensions of the building and area of premises;

- design features of the furnace;

- weight of heating equipment;

- number of heat exchangers;

- coolant volume;

- length and diameter of the chimney pipe.

The following options for connecting heating equipment using pipes are possible:

- to the expansion tank for hot water supply in the washing compartment;

- to heating radiators installed in functional rooms;

- to hot water supply and water heating system in the main premises of the bathhouse and residential building.

Heating stoves are equipped with internal and external heat exchangers. The internal element is located in the firebox, the external element is located around the chimney pipe.

If the bathhouse is multi-story

The appearance of private households has changed significantly over the past few centuries. The same applies to the bathhouse. Today it is not uncommon for baths to have, for example, two floors.

The presence of more than one floor requires the organization of heating of both the first and second floors. Existing systems are conventionally divided into a number of categories:

- integral or single heating;

- separate heating.

In the first case, it is assumed that the stove is installed directly in the steam room or behind its wall. The pipe through which the smoke will be exhausted is fixed to a special outlet on the equipment. It passes the perimeter of the first and second floors and only then leads out onto the roof.

It is important to remember that single heating requires that the stove be heated constantly, even if the steam room is not in use. In addition, the complex path of hot air circulation results in a long heating period for the room.

In this case, in the area where people steam, a standard set is installed - a stone, a vertical pipe and the stove itself. The remaining rooms are heated by gas, electricity and other sources.

In order for the heating of the steam room to give maximum effect, you must adhere to certain rules.

- First of all, this concerns firewood. They must be dry; the presence of even a small amount of moisture in them will slow down heating.

- The firewood must have the correct size: the diameter does not exceed 9 cm, but not less than 6 cm. Average values will allow the fuel to burn for a long time, give the required heat and, accordingly, temperature.

Experienced users claim that high-quality heating is also determined by the use of a certain type of raw material. If the question is how to make heating in a bathhouse with several floors, it is better to give preference to birch. This wood does not have a large diameter. However, the high tar content ensures long-term smoldering, due to which a high combustion temperature is achieved in comparison with other materials.

https://youtube.com/watch?v=Kj2xVG2VRbs

Additionally, to increase the time of maintaining high temperature, coal is used. Oak and linden also performed well when solving the problem of heating a bathhouse with several floors. Poplar and aspen emit less heat, so much more of them will be needed.

If the bathhouse is equipped with an attic, it is better to use a fireplace to heat it. When installing it, be sure to take into account the weight of the device, which requires mandatory strengthening of the area. The weight of the fireplace depends on how often you plan to use it. It is known that intensive heating requires a large firebox. To make installation and operation easier, it is better to give preference to an electric fireplace. This will also reduce the cost of estimated repair work.

Electric heating system

Electric heating is the simplest and most affordable option for organizing an autonomous bath heating system. When organizing it, it is worth taking into account the electrical wiring diagram, the total load on the network and the cross-section of the wires in order to carry out high-quality installation work.

The electric heating system involves the use of the following types of equipment:

- electric boiler;

- electric stove;

- electric convectors;

- infrared film;

- electric heating cables.

Modern low-power electric boilers are equipped with automation that can maintain a given temperature in bath rooms. To heat the bath, it is allowed to use induction, electrode and stepped boilers with heating elements.

An electric heater for a bath can be used as a main and additional source of heating. If possible, it is most convenient to use electric convectors. As with boilers, convectors are equipped with thermostats to maintain the optimal temperature automatically.

The electrical system can be operated year-round without the need for preparation and storage of fuel material. A significant drawback is the high electricity consumption.

Don't forget about safety

But it is not advisable to install electric heated floors in the steam room itself. Yes, this will make going to the bathhouse more comfortable. After all, true connoisseurs of baths know that it is the floors, especially in winter, that can remain cool even after heating for many hours. All the heat rises, and near the ceiling the temperature can reach 70-80 degrees, but the floors will remain cool. This definitely won’t happen when using electric heated floors - they will heat up much faster than the bathhouse will heat up.

Gas heating system

When connected to a gas main, heating a bathhouse with gas is the fastest and most efficient option for the system.

The system has two implementation options:

- traditional heater equipped with a gas burner;

- gas boiler with installation of heating radiators and water pipes.

The undoubted advantage of such heating is the absence of unpleasant odors, the formation of soot and soot. At the same time, gas equipment has a compact body, low weight and does not require much space during installation. The power of a standard boiler reaches 45 kW, which is enough to heat a room up to 280 square meters. m.

Installation rules

To heat a bathhouse using a heater, you need to follow some rules:

Steel furnace

Metal stove equipment for baths

- The base under the stove must be made of non-combustible material. Suitable for this purpose: fireclay bricks, sheet iron or concrete.

- The firebox door should face the opposite corner.

- It is advisable to cover the body with brick. This way you will protect people using the steam room from getting burned by the hot body and give the structure a more aesthetic appearance.

Brick oven

First of all, lay a reinforced concrete foundation that can support the weight of the future structure.

Foundation for the stove

Then work with brick begins:

- The layer of cement being applied should not be very thick, as in this case it will quickly collapse under the influence of heat. (See also the article Double-bell heating and cooking stove: features.)

- Each vertical seam must be overlapped with brick, thus forming a checkerboard pattern of masonry.

The process of constructing a heater from bricks

- Install cast iron elements in compliance with the technical gap, which compensates for possible thermal expansion of the materials.

Water heating system

A practical and affordable way to organize heating of a bathhouse in winter is to install a water system.

Water is used as a coolant, gas, electricity, liquid and solid fuel are used as fuel, and a stove or boiler is used as heating equipment.

Water heating provides quick and uniform heating of bath rooms with the ability to automatically maintain the set temperature.

There are the following options for arranging water heating:

- Radiator heating. Provides for laying pipes along the walls to which water radiators or convectors of the appropriate size and power are connected. The hot coolant from the boiler moves inside the system, providing space heating.

- Underfloor heating. Its operating principle is similar to that in the previous version. The only difference is that the installation of pipes is carried out in a concrete base after its preliminary insulation and waterproofing. This design is of a non-removable type, and therefore requires compliance with installation technology.

Pellet boilers

This type of heating is used in almost 50% of European homes, and they can count. This popularity is based on the possibility of automatic fuel supply. Fuel is loaded into the bunker (it can be of any size from an ordinary box to a large room), which is supplied to the burner using a screw controlled by the boiler. In this mode, the system operates as long as there is fuel and the ash pan is not full. If the fuel is of high quality, the ash needs to be removed once every month and a half, and the pellet bunker, as mentioned, can be of any volume. The only thing: to ignite and maintain the operation of the equipment, guaranteed power is required (the consumption is very small). But modern heating systems, it seems, cannot work without electricity. Here, too, if you wish, you can find a solution - diesel engines, batteries, etc. Pellets are not that expensive; the only significant drawback is the cost of the boiler itself. Not everyone will decide to invest this amount in heating a bathhouse.

Pellet boilers are reliable and promising, but the equipment is expensive

As you can see, there are many ways to heat a bathhouse, but all of them are imperfect. You will have to weigh the pros and cons more than once and calculate the options.

Heating system with heated floors

Modern underfloor heating systems are represented by electric and water heated floors. Water floors are an economical and affordable way to heat rooms, requiring high-quality installation, since repairing such a system is quite difficult.

To heat a rest room, dressing room or washing room, it is enough to install heated floors. All work can be done with your own hands. To do this, it is necessary to select pipes of a suitable diameter, calculate the operating resistance of the heating circuit and the required pump power, taking into account the area of the room.

Warm floors can be combined with radiator, electric and air heating.

Heating system from the heating main

A private bathhouse can be directly connected to the central heating main. To organize a similar heating option for a bath, you will need to install an additional circuit.

The connection of the circuit to the heating main is carried out in accordance with the design documentation and permits obtained from the relevant authorities.

Choosing this option involves some difficulties:

- the likelihood of accumulation of groundwater in places where pipes are laid;

- the need for additional insulation of the heating main;

- the need to attract professional installers.

Alternative and mixed heating options

Alternative options for heating baths are becoming in demand. These include the following types of equipment:

- heaters – ceramic and infrared;

- boilers – pyrolysis, pellet, diesel, long-burning;

- baseboard and ceiling heaters.

In cases where the bathhouse is rarely used, a good option is to install a mixed heating system: a wood-burning stove combined with electric heating; pellet boiler with electric convectors. One type of equipment provides heating of rooms for bathing procedures, the other provides hot water supply and additional heating.