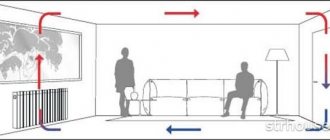

It's no secret that heat loss in a house can be caused not only by poor-quality installation of windows.

Heated, warm air rises upward in the rooms and “evaporates” through the roof. Such losses can reach up to 30%. Therefore, it is very important to properly arrange the roof when building a house.

The right solution would be to install insulation, for example, from the well-known manufacturer Knauf. Let us consider in detail the pros and cons of this material, its technical characteristics, varieties, product line and prices for 100 mm rolls and 150 mm slabs in our article.

Advantages and disadvantages

The popular brand Knauf from Germany offers roof insulation material of the highest German quality. Mineral wool of various modifications, manufactured using modern technologies and at our own factories and equipment, has many advantages:

- long service life - up to 50 years or more;

- contains only natural ingredients;

- hypoallergenic, environmentally friendly - there is no unpleasant “construction” or specific smell;

guarantees excellent thermal insulation of the roof, heat retention in rooms, rooms - low thermal conductivity coefficient;- minimal weight, does not shrink over time;

- maximum noise absorption - indispensable for sound insulation (in noisy areas, or during precipitation);

- excellent water-repellent properties – resistant to changes in humidity;

- better vapor permeability;

- range of material thicknesses;

- perfectly restores its shape after opening the package;

- resistant to slipping;

- versatility;

- biostability - too tough for mice;

- not susceptible to mold, dampness;

- fire resistance – NG non-flammable material;

- the price corresponds to the quality;

- easy to install - soft to the touch and not scratchy, pleasant to work with.

On a note. Short installation time, 2 people are enough to work.

The insulation is very compact (can be strongly compressed) and takes up minimal space during transportation. Mineral wool Knauf guarantees significant and permanent savings on heating a house or building.

The disadvantages of many include the high cost and negative aspects that are inherent in fiberglass - installation should be carried out in overalls, protect the eyes and mucous membranes from microscopic particles of fiberglass.

Insulation materials

0 votes

+

Vote for!

—

Vote against!

In the field of construction, the Knauf company is considered one of the most famous manufacturers of insulation materials. It is the materials from this brand that are in high demand among consumers, which indicates the high quality of the goods and the affordable price of the resources. The range of materials for finishing work from this brand includes a huge selection of various raw materials, divided into special lines, which will be discussed later in the article. Thematic blocks discuss the types of Knauf insulation, their areas of application, as well as detailed technical characteristics of the materials.

Table of contents:

- Areas of application of Knauf insulation

- Types of Knauf insulation

- Technical characteristics of the Knauf Insulation EXPERT line

- Features of the TeploKnauf line

- Characteristics of Knauf Therm

- How to choose the right Knauf insulation

Areas of application of Knauf insulation

Since 1932, products from the German company “Knauf”, specializing in the production of insulation from mineral wool and expanded polystyrene, have been sold on the construction market. Today, this raw material is considered very widespread and in demand, as it is used in the construction of various facilities, commercial, private, industrial, etc. Mineral wool of this brand is valued not only among small buyers, but also in the field of use by large construction companies, since the products are considered absolutely safe for human health. Knauf thermal insulation rolls are manufactured using innovative technologies, which helps make them highly efficient, high quality and durable.

Knauf insulation, the price of which, compared to other insulating raw materials, is quite affordable, is made on the basis of basalt wool and glass wool with various impurities, which allows the manufacturer to sell the product not only in rolls, but also in the form of sprayed and backfilled slabs. These resources have found their application in the areas of organizing thermal insulation for:

- external and internal walls of cottages;

- ventilated house facades;

- pitched roofs and floors of dachas, etc.

We can say that depending on the purpose of use, the choice of the desired material depends on it, which is divided into several varieties, read about this below.

Types of Knauf insulation

Depending on the dimensions and purpose of the construction project, professionals select the type of Knauf mineral wool required for the job. It is worth noting that the range of insulation products of this brand offers entire lines of insulators for different purposes, with different technical features. In turn, these groups are divided into varieties, see table.

| Types of Knauf insulation | |

| Teploknauf | The materials of this product line are actively used in the process of installing thermal insulation of private houses. They are used for finishing roofs, internal partitions, etc. |

| Knauf Insulation EXPERT | Raw materials of this variety are in demand at large construction sites, where the required quantity is not one or two rolls, but hundreds of square meters. |

| Knauf Therm | This line includes thermal plates designed for insulation of facades, walls, floors, etc. Materials from this group have a high level of strength and are excellent for thermal insulation of foundations. |

It is worth saying that regardless of what variety this or that mineral wool belongs to, there are characteristics that are correlated with any of the above groups. So, all Knauf brand insulation products have the following positive characteristics:

- absorb sounds well, allowing you to equip the room with additional sound insulation;

- have a low level of thermal conductivity, retain heat even during the most severe frosts;

- are not susceptible to damage by rodents, due to which they have a fairly long service life;

- easy to install, do not cause unpleasant sensations on the skin, and are not prickly;

- do not lose their original forms during transportation;

- have a fairly light weight;

- have a standard brown color, since Knauf production does not use a variety of dyes, according to

- This quality material can be recognized by its shade.

It is worth noting that the vapor permeability of mineral wool from a German manufacturer is no more than 0.55 mg/mhPa, while the thermal conductivity coefficient varies from 0.034-0.040 W/mK.

Technical characteristics of the Knauf Insulation EXPERT line

The Knauf Insulation EXPERT line of fiberglass insulation is a range of products designed for consumers who prefer to perform construction tasks themselves. As a rule, it is distributed in all construction stores, and Knauf insulation, the official website of which is easy to find on the Internet, can be ordered via the Internet, with delivery to the post office or to your home. Materials from this line are considered absolutely safe, since they do not contain harmful phenol-formaldehyde substances. You can also add to a number of their advantages:

- comfortable packaging that simplifies transportation and installation of the insulator;

- when choosing a material, the consumer can get acquainted with its main features and characteristics directly on the packaging;

- Rolled insulation from this line, which is intended for roofing, has an improved, increased thickness, which does not require additional thermal insulation.

For attic floors, interfloor ceilings, interior partitions, TEPLOroll 040-15 Expert, TEPLOroll 040-19 Expert, TEPLOroll 040-150-6 Expert, which differ in the area of insulation in the package, the thickness and width of the material, are considered specially developed.

It is worth noting that to ensure thermal insulation of the ceiling along the beams, all materials from the Knauf Insulation EXPERT line, for the production of which glass staple fiber is used, can be used. Using slabs and rolls, you can equip suspended ceilings in rooms, since Knauf mineral wool is considered universal and is characterized by a low level of water absorption.

Features of the TeploKnauf line

The TeploKnauf mineral wool family is usually divided into the following groups:

- Knauf Dacha;

- Knauf Dom and Dom Plus;

- Knauf Cottage.

So, for country dwellings that do not require permanent residence of residents, the manufacturer offers a budget series of materials that are characterized by poor waterproof properties. Raw materials of this quality do not retain heat well in cold weather, so it is better to use it in buildings such as garages, etc.

Mineral wool slabs from the Knauf Dom and Dom Plus series are considered denser. Since their thickness ranges from 5 to 10 cm, the scope of application is considered to be city apartments and private residential properties. The quality indicators of this model can be called average, since the conductivity level of the material is 0.04 W/m∙K. The disadvantages of this raw material include poor sound insulation properties. It is worth recalling that mineral wool is a material that belongs to the non-flammable group.

Knauf Cottage building insulation is characterized by excellent qualities, it has additional water-repellent impregnation, thanks to which it can be used without additional installation with film materials.

An important characteristic of the resources of this group is the high level of heat conservation, which allows the material to be used for insulating roofs, walls, etc. It is equally important to emphasize that the TeploKnauf line is not recommended for use in vertical, loaded structures.

Characteristics of Knauf Therm

Highly effective thermal insulation materials include insulation from the Knauf Therm line, which are characterized by a low level of water absorption and at the same time excellent strength. It is worth explaining that this product range is divided into raw materials for insulating walls, floors, facades, flat roofs, etc. Knauf Therm insulation materials are based on polystyrene foam granules, which increase in size tens of times during the foaming process. Knauf thermal insulating polystyrene foam boards have the following positive qualities:

- high level of sound insulation;

- absence of harmful chemical compounds;

- the material is not damaged by rodents, mold and fungal diseases do not form on it, and does not attract insects, which is no less important;

- the slabs are convenient during installation, as they are packaged in compact packages and are lightweight;

- the material can be easily plastered, which cannot be said about mineral wool from this manufacturer;

- due to the fact that the material does not contain phenol-formaldehyde, chromium and other substances, you can work with it without special clothing or other protective elements;

- have a long service life.

Knauf Therm Roof is a polystyrene board characterized by good moisture resistance and strength. They are actively used not only in the process of insulating roofing elements in new buildings, but also as restoration raw materials. They are able to withstand large load-bearing loads, and one person can handle their installation. The standard configuration of this product is presented in packages of 1.2 m³.

For insulation of brick, concrete, and aerated concrete structures, it is recommended to use insulation from the Knauf Therm Façade range. The range of materials from this category is represented by slabs of different thicknesses: some (50 - 80 mm) are intended for internal work on thermal insulation of premises, others (100 - 120 mm) are recommended for external use. Insulation of foundations should be carried out with construction resources from the Knauf Flor group. They are actively used in construction work aimed at organizing reliable plinths, blind areas, heated floors, etc.

For insulation of country houses and repairs of individual areas, it is recommended to use the universal insulator Therm Compak; it not only retains its shape for a long time and withstands heavy loads, but also perfectly withstands a humid environment. However, craftsmen need to remember that Knauf insulation materials based on polystyrene foam are flammable, so they cannot be used to insulate baths, steam rooms, saunas, etc.; it is wiser to use mineral raw materials from this manufacturer for this purpose.

How to choose the right Knauf insulation

As practice and analysis of user reviews show, Knauf insulation is a reliable, affordable raw material that allows you to insulate the required private room or large object at the required level. But those who want to work with this particular material must remember that their choice must be approached carefully. As it turned out from the information presented above, the entire range of construction resources of this brand is divided by purpose, so it is important to select it that way and use it in the future.

That is, before buying mineral wool or expanded polystyrene-based insulation, the owner needs to decide on the purpose of its purchase: to insulate the floor, facade, walls, etc. Based on this, you should move on to the production line of materials, on which their quality and cost depend.

When choosing the best Knauf insulation, the official website of which advertises all products, it is necessary to consult with a competent sales specialist, to be sure, read the product certificates, clarify the thermal conductivity, flammability class, service life, etc.

Thus, we can say that the quality of construction work carried out to organize thermal insulation with the Knauf company takes a leading position, because the products of this brand are in demand all over the world and are characterized by the majority of positive responses from consumers. Thanks to the variety of mineral insulation from the manufacturer, everyone can choose the most suitable raw material for themselves, both in terms of quality and purpose, as well as in terms of pricing. Properly selected Knauf mineral components are a worthy solution for any repair project. More detailed information on the topic is provided in the video:

Specifications

Knauf insulation has proven itself to be one of the main layers of the roofing pie for a ventilated or non-ventilated roof. This material is suitable for arranging all types of roofs, both in residential buildings and in industrial and commercial facilities. It is used for horizontal, vertical or inclined (roof slopes) insulation.

The appearance of mineral wool is natural light brown, without the use of harmful dyes and bleaches, the microdust content is minimal. The material is made from natural ingredients, safe, environmentally friendly. It maintains its original shape and size for 50 years.

The lightness and low density of the material guarantee minimal load on the roof structure. The manufacturer has provided the insulation with protective properties against insects, rodents, and dampness.

Layer insulation

TeploKnauf Premium is the first material developed for use in private households. Does not contain fiberglass. During operation, it does not change its dimensions and does not shrink, which avoids ruptures in the insulation layer.

It has increased heat-retaining capacity and good sound insulation. Resistant to getting wet. It is used for insulation of enclosing structures, including layered masonry walls. The mini-slab has dimensions of 1230x610 mm.

If you need it just for yourself

For ease of use and transportation, TeploKnauf House Mini is produced. The length of the slab is 1 m. No glass wool is used in production. The main purpose of Knauf House Mini is the insulation of small-area enclosing structures or even parts thereof.

Roof product line

For maximum efficiency and convenience in arranging thermal insulation, the German brand has developed a highly specialized line of thermal materials: Insulation Pitched Roof. This option is in the form of mats/slabs, created using the patented Aquastatik technology. The ability of the insulation to absorb moisture is practically zero, this is a very valuable argument for the roofing pie. The material is suitable for arranging pitched roofs (with wooden structures) of residential buildings, offices, manufacturing, and government institutions. But insulation can also be used for arranging floors (on joists) in the attic. This line includes four types of insulation material (with different thicknesses):

- Thermo Plate 037A.

- Thermo Plate 034A.

- Thermo Roll 037A.

- Thermo Roll 034A.

Thanks to the wide range, you can choose the most suitable insulation for each specific case. The material can not only preserve heat during the cold season, but also protect against the summer heat.

Knauf insulation

The company has developed several lines for professionals and for those who want to insulate themselves. The materials in the Knauf insulation line show the maximum insulation and sound insulation characteristics for basalt wool.

Knauf insulation technologies are based on creating the thinnest and longest fiber. This type of fiber not only provides premium insulation quality, but gives additional strength to the material, and also enhances the effect of 3D elasticity: the wool returns to its original appearance and volume after any compression.

Knauf insulation for insulating a frame house.

The high standards of the manufacturer allow us to talk about the safety and environmental friendliness of the insulation; in particular, the materials do not contain harmful phenols and other volatile compounds that could negatively affect health.

Application and functionality

Knauf insulation should be correctly placed into the roofing pie. A preliminary calculation of the required material is made. Next, installation is carried out step by step:

- Measure the distance between the rafters.

- Measure and cut the width of the insulation with an allowance of 10 mm more. This is necessary for a stronger and tighter fit of the material to the structure. With a rafter width of 600 mm, the width of the insulation mat will be 610 mm.

- Laying is carried out from the bottom of the roof upwards, be sure to avoid through joints between the mats.

- The thickness of the insulation should not be thicker than the cross section of the rafters.

- When the insulation is completely installed, a frame is built to accommodate drywall or gypsum fiber sheets (inside the premises).

- To avoid the appearance of cold bridges, professionals recommend laying an additional layer of thermal insulation in a horizontal position, overlapping the first layer on the rafters.

- Next, a vapor barrier membrane is laid; it will prevent the formation of condensation inside the structure.

Note! Knauf insulation is practical and maximally functional. It is easy to work with and is safe for health. The material will preserve warmth and comfort in the house, and also improve the environmental atmosphere.

Insulation technology

At the first stage, the facade is cleaned and freed from unnecessary elements. There should be no metal pins on the wall, as they will become rusty. If it is not possible to get rid of metal, then decorative plaster should not be used to decorate the house. Before installing mineral wool on the walls, you should install profiles

It is important to ensure that the planks are securely fastened. Using special glue, mineral wool is installed on the surface

The thermal insulation should additionally be covered with a reinforced layer, which will prevent deformation of the insulating materials. Using a spatula, an adhesive layer is applied to the surface, onto which a reinforced mesh is attached.

Prices for TeploKnauf

The price range for Knauf roof insulation products depends on the purpose, type, width and length of the material.

The cost of products in the central region may be lower than prices in remote areas of Siberia, the Urals, and the Far East. For example, TeploKnauf heat insulator for a roof:

- roll (150x1220x5500mm) 6.71 m2 – from RUB 5,400;

- slab (100x610x1230mm) 6.00 m2 - from 2,990-3,000 rubles;

- roll per cut - from 420-450 rubles. for 1 m2.

Purchasing this material at wholesale outlets or directly from the manufacturer’s stores will significantly save money.

Selection rules

If you are purchasing Knauf insulation for the first time, it is recommended to seek the help of experienced consultants who will help you choose one option or another, as well as calculate its quantity.

The cost of insulation depends on the following:

- his type;

- number of slabs;

- their size;

- loads;

- equipment locations.

When choosing one or another insulation option, consider the following:

- thickness of the slabs - walls need structures that are thinner than those for the floor;

- for pitched roofs, choose products based on fiberglass or basalt;

- polystyrene foam with a water-repellent effect is best suited for the foundation.

When insulating, do not forget to provide waterproofing, vapor barrier and windproofing. To fix the insulation, be sure to use dowels or polyurethane foam.

Products of the Knauf brand are much more expensive compared to analogues, but the high price is due to the excellent quality of the products and their long service life. Accordingly, you will not have to spend additional money on unnecessary repairs during use.

New development

Monolithic materials are used for thermal protection of houses, cottages, walls, facades, roofs, floors, foundations.

The newly developed Knauf Therm Floor is a durable material for insulating plinths, foundations, and blind areas with a load of up to 12 tons per m2. Flor foam has moisture absorption of up to 0.8% of the volume of insulation. Used in the installation of “warm floor” systems.

If you need an effective, convenient, innovative material to protect your home from heat loss and noise penetration, choose Knauf products. It meets all the stated characteristics and will help you forget about the cold and noise in the house for a long time.

Installation features

The system for assembling walls and partitions using this technology has its own nuances that must be taken into account to achieve an optimal result:

- To ensure high strength, individual frame elements are reinforced by nesting one profile into another.

- The guides are attached to dowels at at least three points. The profile plane adjacent to the base is preliminarily covered with damper tape.

- Often it is necessary to join elements of metal structures that are not long enough. In this case, the connection points should be spaced, for example, placed in a checkerboard pattern. This will reduce the likelihood of vibrations or various deformations of the structure.

- The racks are placed at a distance of 600 mm from each other. Thus, each sheet will be fixed on three profiles. If necessary, the step between the racks can be reduced.

- The profiles are fastened together using a cutter or branded self-tapping screws. Crab connectors are used at intersections.

- Sheathing elements made of gypsum plasterboard are attached end-to-end with the necessary gaps to compensate for the thermal expansion of the material. Subsequently, they are filled with a special composition produced by the same company.

- When constructing gypsum plasterboard partitions that have window niches or doorways, it is prohibited to join the sheets above them. Otherwise, there is a risk of seams coming apart due to vibrations that occur when using windows and doors. The elements are joined closer to the corners of the room.

TechnoNIKOL is a reliable Russian brand

This is an exclusively Russian brand that has 53 factories in 7 countries. Among them are Germany and Great Britain, Italy and Lithuania. Official representative offices are located in 18 countries. The company's training centers are also located there. TechnoNIKOL has its own Research Centers for the development of new technologies for heat and sound insulation. The products of this concern are very popular due to competitive prices and are sold in 95 countries.

TechnoNIKOL general building thermal insulation based on stone wool

An inexpensive way to perform thermal insulation on any construction site is with materials based on stone wool with a universal purpose. At TechnoNIKOL such products are represented by the BAZALIT series. All brands can be mounted horizontally or vertically.

- BAZALIT L-30 - has a density of 25-35 kg/m3 and a thermal conductivity of 0.032 W/(m*K) at an outside temperature of 10 degrees. Well suited for a base layer followed by cover.

- BASALIT L-50 - denser slabs (36-50 kg/m3), designed for installation in any spatial position. Particularly good for the bottom layer when insulating floors and interfloor ceilings.

- BASALIT L-75 is the most dense material based on stone wool with an indicator of 51-75 kg/m3. Vapor permeability of 0.5 mg/(m.h.Pa) allows its use in the middle layer on walls with light masonry.

TechnoNIKOL stone wool for insulation of all types of roofs

For all types of roofing, the TechnoNIKOL company has developed a line of TECHNORUF insulation materials. The TECHNORUF N EXTRA brand is produced in the form of a basalt slab with a density of 90-110 kg/m3 and can withstand pressure up to 3000 kg per 1 m2. It is optimal for arranging a sloping roof. TECHNORUF N PROF is next in class and has a density of 110-130 kg/m3. With a deformation of 10%, it is capable of carrying a load of up to 4000 kg per square meter, which is also not bad for insulating a roof of complex shape.

TECHNORUF V PROF is designed for all types of flat roofs. It has a pronounced hydrophobic effect. It can act as the top durable layer in three-layer structures. Its density is 175-205 kg/m3, and its strength can withstand up to 8000 kg of pressure per m2. To quickly create a slope on a flat roof for precipitation, use TECHNOROOF WEDGE 4.2%, which automatically forms a slope contour. At the same time, cotton wool itself effectively combats cold retention and has a thermal conductivity index of 0.038 W/(m*K).

TechnoNIKOL TECHNORUF N EXTRA.

TechnoNIKOL stone wool for insulation of ventilated facades

For ventilated facades, the manufacturer offers a whole line of basalt wool from the TECHNOVENT series. TECHNOVENT EXTRA brand is quite suitable as a base layer or in combination with another insulator. Its breathability is 35 m*s*Pa.

There is another type of this material - this is TECHNOVENT N PROF, the air permeability of which is 80 m*s*Pa. The insulation is intended for use in industrial and civil construction during new construction and reconstruction of buildings and structures for various purposes as an inner layer with two-layer thermal insulation in curtain wall systems with an air gap.

TechnoNIKOL stone wool for insulating a wet facade

TECHNOFAS EXTRA insulation, designed to retain a thick layer of plaster, is well suited for wet facades. The density of the slab is 80-100 kg/m3, and the thickness is from 50 to 150 mm.

When a thin layer of plaster is planned, you can save money and choose TECHNOFAS EFFECT, which, with a smaller cross-section, has an increased density of 125-137 kg/m3, which will provide the required strength. TECHNOFAS DECOR is produced for insulating facades on balconies and loggias, therefore it has an increased tensile strength of 25 kPa.

TechnoNIKOL TECHNOFAS EXTRA.

TechnoNIKOL stone wool for use in frame buildings

Frame buildings have a dilemma: the insulation must be dense enough so as not to sag over time, and at the same time not heavy so as not to overload the structure. For this purpose, the TECHNOBLOCK series is best suited, which is designed for installation in frame walls and subsequent cladding. The STANDARD brand has a density of 40-50 kg/m3, and PROF 60-70 kg/m3. The thickness of the slabs ranges from 50 to 150 mm and they are suitable for any walls of a frame house.

In order not to burden the structure with massive insulation in the partitions inside the frame house, the manufacturer produces a lightweight version - the TECHNOLITE line. It has three types (EXTRA, OPTIMA, PROF) and density from 30 to 46 kg/m3. The thickness varies from 50 to 200 mm, which is suitable for any type of partition.

TechnoNIKOL TECHNOBLOCK.

Basalt wool

It is often called stone wool, hinting at the origin of this material. It is obtained as a result of melts and extrusion of mountain dumps, slags and slag mixtures.

- Knauf basalt insulation is available in the form of rolls, slabs, pipes and even lamellas glued to metal foil.

- The density of the proposed types of insulation is different. Thus, the Knauf Insulation LMF AluR product, which is designed for insulation and insulation of air ducts, external walls and facades, has a density of 35 to 90 kg/mK. Roll insulation has density parameters from 80 to 100 kg per cubic meter. And the materials intended for insulation of roofs and facades of buildings, Knauf Insulation DDP slabs, have a density of 150 to 200 kg per cubic meter. In terms of density, only some types of rigid polyurethane foam approach basalt insulation with an indicator of 100 kg/mK.

- The thermal conductivity coefficient of this type of insulation ranges from 0.04 to 0.045. This indicator is not the minimum; for example, it is somewhat less for fiberglass, and even more so for liquid insulation. Approximately in the same group with basalt wool is polyurethane foam with an index of 0.04 to 0.05. However, this low degree of thermal conductivity makes stone wool one of the most effective thermal insulation materials.

- Knauf basalt insulation has such valuable qualities as excellent sound insulation, fire resistance, and a wide range of uses.

- In the manufacture of Knauf basalt insulation, artificial resins are used as a binder, which reduces the environmental friendliness of the final product. But this material is produced using hydrophobization technology, which increases its water resistance.

- Basalt wool, like fiberglass insulation, has biological and chemical neutrality, which increases the safety of its use for insulating residential premises.

Application:

- Knauf stone wool slabs are used for insulation of flat roofs, facades, and external walls. Knauf Insulation HTB boards, reinforced with canvas or foil, are successfully used for pipelines.

- Rolled basalt-based insulation is used for insulating pipes and other engineering structures and equipment.

- Mineral wool cylinders are used for thermal insulation of pipes. Additional reinforcement with foil enhances the waterproofing of structures.

- Another type of roll material - LMF AluR - consists of lamellas glued to a foil base. This product does an excellent job of insulating air conditioning and heating systems. It is great for baths, saunas, and any wooden structures.

Price:

Calculation

Every master and even the customer should know the rules for calculating insulation. Sometimes repair crews deliberately inflate the indicator. To avoid becoming a victim of deception, you can use an online calculator. However, you can do some simple calculations yourself. The fundamental factors are density and approximate area covered.

To make it clearer, we can take a clear example as a basis. It is planned to use 5 cm thick insulation. In this case, the size of the material is not yet taken into account. We need to find its total quantity. The planned height of the facade is 3 m, its perimeter is 24 m.

Calculate the area: 3*24=72 m2.

The thickness of the insulation is converted into meters: 50 mm = 0.05 m.

Multiply the resulting quadrature by the thickness: 72 * 0.05 = 3.6 m3.

After this, all you have to do is look at the packaging labeling. Usually the volume is written on it in cubic meters. All that remains is to divide the resulting indicator by this mark. For example, it is equal to the standard value of 0.36 m3. Then the number of packs is: 3.6: 0.36=10.

Thus, for 72 m2 with a material thickness of 5 cm, 3.6 cubic meters will be needed. m or 10 packs of insulation. The same method is used to calculate the consumption for multi-layer insulation.

Installation features

Preparing the frame for external wall insulation

When installing Knauf Cottage brand mineral wool, you must follow the manufacturer’s recommendations and basic rules so that the result is as ideal as possible. The installation process consists of several stages and includes installation of the frame, the insulation itself, and the application of a vapor barrier film. You can handle this process yourself if you have skills in the field of construction and finishing work, or you can entrust the installation to professionals.

Frame

A primary wooden frame is necessary for direct installation of insulation on the walls. Without it, the material will not hold up. Before installation, the walls are cleaned of unnecessary elements and wooden blocks are prepared, which are treated with a fire-resistant compound. They are fixed horizontally and vertically to the walls from one corner to the other; in the presence of unevenness, special substrates are made from various materials.

The beams are secured using 75 mm self-tapping screws, each fastening is installed at a distance of at least 40 cm from each other. After installing the first beam, you need to measure 58 cm from it, since the width of the slab is 61 cm, then fix the second and subsequent beams while maintaining this distance. The windows are framed with bars horizontally and vertically, taking into account the plane of the wall.

Installation of insulation

Installation of insulation

The slabs are installed starting from the corner, they are slightly compressed and placed between the beams, then fixed to the wall using special mushrooms. For one slab you will need at least 3-5 mushrooms, taking into account the material in one package, each of them is mounted in a through hole with a diameter of at least 6 mm, made with a hammer drill or drill. The insulation can be cut to fit the spacers using a paint knife. After filling all the cells between the bars, they proceed to installing the film.

Installation of vapor barrier film

Vapor barrier of attic roof

The film is necessary to prevent the formation of condensation inside the insulation; if it is present, the steam particles simply come out to meet the cold air. It must be installed with the smooth side up, taking into account the instructions, each strip is placed from bottom to top, taking into account an overlap of 10 cm or vertically from the corner. For the most reliable fastening, the film is sewn to the wood blocks using a construction stapler. The seams must also be taped with double-sided tape to prevent them from coming apart. After the walls are covered, you can begin installing the siding.

Siding

For siding, bars measuring 25x50 or 25x100 mm, special screws with a length of 35 to 55 mm and a screwdriver are used. The frame boards are impregnated with a bioprotective solution and cut to the required length, which must correspond to the length of the boards for the first frame. Next, you will need to form the corners and screw them to the horizontal bars on the first frame vertically, the next boards are attached at a distance of at least 25 cm from each other. Following these rules helps make the structure more durable in addition to the standard insulation procedure.