Despite the Internet controversy that has flared up for a long time about the use of foil to retain heat in a bathhouse, the convictions of its supporters and opponents have not been shaken. However, the subject of dispute was initially the physical properties of the material, and in our time there are enough means to make “selection” - to strengthen the necessary properties of the material and weaken the unnecessary ones.

Look at the bathhouse and the mode of its use as a set of factors, each of which can be “for” or “against” insulation with this material. With this approach, harm and benefit cease to be absolute categories, as they are usually presented in disputes.

We will tell you how to place the foil correctly to achieve optimal results, but this will be discussed in other articles.

This article is devoted to the consideration of materials available on the market; both foil and foil bath insulation will be considered here.

Should I use foil for a bath?

As you already know, foil is used as insulation for rooms, mainly bathhouses. In most cases, the choice is made towards aluminum foil. The method of application and types of material are quite varied.

Of course, over such a long period of use, the material has acquired both its supporters and opponents.

- Opponents argue that since aluminum has high thermal conductivity, it does not retain heat. Thus, purchasing and equipping your premises with foil is a waste of effort and money.

- It is impossible not to agree with this opinion, except to slightly paraphrase: “Foil will not keep the room warm if you install it, ignoring all the rules!”

Of course, the foil will not show its properties if you attach it to a bare concrete, brick or foam concrete wall. The wall must be reinforced with a layer of insulation. Remember that foil can rebound heat, but not retain it without additional insulation materials.

By using this material you can save money on heating the room, since the foil will retain and accumulate heat in the heated room.

Useful tips

The cheapest pine wood can be used to build a dressing room, a relaxation room, but not a steam room.

Finishing with wooden clapboard is expensive; to reduce costs, experts give some advice:

- Use slats of short length (up to 1.5 m), which are cheaper, connecting them on a joining strip.

- Hardwood boards should be installed only in the steam room; the remaining rooms should be sheathed with budget-priced softwood lumber.

- Combine types of lining in a steam room, where the quality of the material is important, install extra-class slats, and use class B in other rooms.

- Perform hidden fastening of the lining by driving a nail at an angle of 45° into the groove or tenon. This will prevent metal contact with water and slow down corrosion processes.

- Insulation during the construction phase seems like an extra expense, but it will quickly pay for itself thanks to fuel savings.

A step-by-step plan will allow you to complete all the work yourself.

How to choose the right foil for a bath

Please note that purchased foil may not always fit well on certain surfaces, because of this you must know what little details you need to pay attention to and what criteria to use when choosing.

It must be said that the choice of material should be based on what kind of surface you have and the fastening method you choose.

Let's consider the basic criteria by which you can make a choice:

- Price - pay attention to this, since inexpensive options are most often not of good quality at all, but expensive ones often are. Therefore, to ensure that the foil is of high quality, choose a brand that is manufactured by one of the market leaders.

- Purpose is the most important criterion due to the fact that each material has its own type of foil. Of course, it is allowed to apply foil to any surface, but the service life will be significantly reduced.

- Foil on the crate is the most recommended option. The likelihood of damage to the foil in this case is significantly reduced.

- Environmentally friendly - choose only clean, natural rolls of foil that are not capable of releasing toxic substances when heated.

- Vapor permeability – no higher than 0.01 g/m² per day.

FAQ

Can foil be applied directly to the wall?

This cannot be done, since the material loses its thermal insulation properties. In addition, even a small hole will cause the wall to get wet.

Can I use thin foil in 2 layers?

It is better not to do this, since moisture will accumulate between the layers.

Which option is best?

The most successful is foil fabric, which is difficult to tear or cut. Foil without a base with a width of 100 microns performs well.

There will be holes after using the stapler, should I be afraid of this?

The fastening brackets are sealed with wide foil tape. If the foil is thick, then there will be no problems.

What foil should I use to line the oven?

Foil without a base with a thickness of 100 microns or more is well suited for the oven.

Foil without base

Quite thin material. This foil is used to insulate walls in warm rooms (mainly baths). It must be installed on a previously installed insulation layer.

The ends of the material are overlapped one on one, and the joint of the sheets is certainly glued using adhesive tape on a metallized base. This way you will create a completely sealed reflective layer of foil.

The limit of the reached temperature is +650°C. That is, foil can provide rapid heating of the room and maintain its temperature for a long time.

Foil without a base is considered resistant to damage and is not capable of releasing dangerous toxic elements when heated.

Bottom line

The process of insulating any room, including a bathhouse, is an important stage in the work. Not only the consumption of energy sources, but also the safety of building structures, as well as indoor comfort, depend on how well the work is done and how effective the materials are selected. Nowadays, materials for thermal insulation can be chosen from a huge number of products on the market. It is important to know that foil for insulating baths is an integral part of the process of creating optimal operating conditions in the future.

Kraft foil

This type of material is produced on a paper basis. Comprises:

- Foil,

- Kraft paper,

- Polyethylene.

This material is quite durable, so you don't have to worry about it tearing while layering. Another distinctive feature is that it can be used without adding insulation.

- Moreover, foil based on craft paper is considered natural, that is, when heated, it also does not emit toxic substances and is considered safe for humans.

- Thickness: 0.03mm-1.0mm.

- Temperatures can reach one hundred degrees.

The ends of the material are overlapped one on one, and the joint of the sheets is certainly glued using adhesive tape on a metallized base.

This material is more convenient to use due to its base and increased strength properties.

Choosing the wood from which the lining is made

Before sheathing the inside of the bathhouse with clapboard, the owner of the room will have to decide on the type of material and wood. First, there are two types to choose from: regular lining and its Euro version. Finishers often prefer eurolining. The reason is the appropriate length of the groove and a wide ridge, which ensures a tighter fit of the elements than when working with ordinary lining. The eurolining is also equipped with holes for ventilation. Their task is to protect the material from the formation of condensation and subsequent deformation. The service life of such lining is many times longer than that of a conventional one, since the highest grade wood is used for its manufacture.

The finishing of the bathhouse with clapboard is carried out taking into account the specifics of the room - high levels of humidity, temperature changes. These factors are taken into account when selecting wood. Species that release resin when heated are not suitable for this, including most coniferous trees.

The following types of wood are suitable for finishing baths:

- Alder. Hygroscopic wood with low thermal conductivity. Used for interior decoration in country houses and baths. In addition to the pleasant aroma, the fumes it produces have a beneficial effect on human health. Medium price material. Sold in pieces up to 3 m in length.

- Oak. This wood is elite and one of the most expensive. Its advantage is that the oak panel does not require additional processing or protective coatings. Oak wood is also considered eternal - the finish will last for decades even with regular use of the steam room, since such wood does not rot. African oak, abash, has similar properties. Its only difference from the usual one is its light brown color and less processing complexity.

- Aspen. The wood is soft and easy to work with. Over time, its strength increases, the material tolerates high humidity and temperature changes without consequences. The only drawback of aspen lining is that over time its surface becomes dull. To return it to its original appearance, you will have to sand the outer surface of the lining with fine-grained sandpaper.

- Linden. The material not only looks beautiful and is easy to process, but also emits beneficial fumes when heated. Therefore, linden is one of the traditional materials for finishing both the dressing room and the steam room. The wood is light, with a reddish or brown tint, does not dry out due to changes in humidity and has its own matte shine. The only drawback is the oxidation of iron when interacting with such lining. Metal parts in the steam room or dressing room will have to be coated with special compounds, or their use will have to be abandoned.

- Cedar. Durable wood in shades from beige to coffee, the color depends on the region where the wood grows. Expensive and resistant to changes in temperature and humidity, it needs to be treated with an antiseptic before use as a finishing material. The disadvantage of cedar lining is the risk that over time the finish will begin to release resin without heating the room.

- Larch. Coniferous wood with antiseptic properties. Lining made from it becomes stronger when used in rooms with high humidity. Lining is in demand, found everywhere, its price is an order of magnitude lower than that of other types of coniferous species suitable for installation in a steam room.

- Hemlock. The second name of the tree is Canadian hemlock. It is resistant to temperature changes and increased humidity, and is also much higher in mechanical strength than pine. Like cedar and linden, it releases essential oils beneficial to human health when the room is heated.

Pine is used with reservation. You have to be careful when finishing the inside of the bathhouse with it - the wood releases resin when heated. This substance stains things and sticks skin to wooden surfaces. Can cause burns if heated too much. Therefore, only the dressing room and dressing room are upholstered with pine clapboard, choosing other types of wood for the steam room.

Folgoizolon

This foil is polyethylene foam with foil as a cover.

- You can find it in stores in roll or sheet form. Depending on what thickness of the product you personally need.

- The product has high strength, shock absorption and sound insulation characteristics.

- This fact means that it can be laid on the surface without additional insulation.

- Most often it is used as insulation for wooden surfaces.

It is also worth noting that the material cannot be deformed.

Megaflex

This is bath foil that has higher quality parameters compared to its competitors. Megaflex can be used at temperatures above 300 degrees. Bath foil is highly reflective. If the installation technology is followed, this product will help create a sufficiently sealed system, which prevents the spread of steam outside the bathhouse.

PIR boards

These slabs are ideal for insulating saunas and baths. The inside of the slabs is porous, but the cells inside are closed, which is why they do not absorb water.

- This is the most important indicator that you should pay attention to when choosing insulation for baths and saunas, where humidity will always be present.

- The stove is able to withstand large temperature changes without emitting toxic substances. PIR boards are used to insulate various surfaces: walls, ceilings or floors.

There are many types of slab coatings, but aluminum foil is the most popular.

This type of insulation is a strong barrier not only to heat, but also to vapors emanating from water. In addition, you can save on heating the room. By heating it once, you will not have to frequently add firewood to the stove or increase the heating time of the boiler.

Additional protection - special compounds and impregnations

Wood is a pleasant-smelling, natural material, which, in addition, gives the bathhouse the appropriate atmosphere of a rustic steam room. Using wood clapboard simplifies the procedure for finishing a bathhouse, and also saves material and costs - covering the walls and ceiling with clapboard will ultimately be cheaper than making a bathhouse from wood or covering it with untreated boards. But the finished finish has a significant drawback - without treatment with waterproofing compounds it will not last long: moisture passes through the connecting seams, settles in the grooves, reaches the vapor barrier material, accumulates on it and provokes the development of mold. To avoid this, you will have to treat the walls, floor and ceiling after finishing with a waterproofing solution.

Protective impregnation will extend the service life of both the finish and the bath itself. The main thing when applying it is to read the manufacturer’s instructions on the packaging and act in accordance with the algorithms specified therein. The safest and most effective waterproofing agents for baths are those containing wax. Water-based impregnations can also be used.

Photo of foil for a bath

The main requirements for materials and raw materials: insulation for a bathhouse on the ceiling, which is better and more reliable

When the entire structure has already been built, and all systems have been well thought out, it is worthwhile to take up insulation, especially if you plan to use the bathhouse throughout the year, regardless of the season. Moreover, in the sultry summer and cold winter, this will be equally useful and simple if all the calculations for insulation are correctly made, especially the ceiling, from where the lion's share of the heat from inside the room can be ventilated. To begin with, before you figure out how you can insulate the ceiling in a bathhouse, you need to understand that this material must meet special requirements, otherwise it’s simply not worth taking it, it will be wasted funds, and now is not the time to risk your own money.

Important

It is worth understanding that, first and foremost, the insulation in a bathhouse on the ceiling, the builders forum is replete with similar statements from real professionals, must be moisture resistant, since all the hot steam first rises. Moreover, you should not hope that vulnerable material that absorbs water can be reliably hidden under a vapor barrier. It will, of course, help a little, but such an insulator can still become unusable and completely lose its properties in just a couple of years, due to the regular appearance of condensation, which is inevitable with temperature changes.

- Also, the insulation for a bathhouse on the ceiling must be completely harmless and not dangerous to human health and life. That is, it should not release toxins, aldehydes, or other dangerous substances, even under the influence of high temperatures that will regularly occur in the bathhouse.

- Fire safety is another important factor that insulation for the ceiling in a bathhouse must have, and which one is better under this criterion, they will help you figure it out, for example, in a store.

- We should not forget about sudden changes in temperature, which the thermal insulation indoors must withstand without much reaction, and over a long period of several years.

- Biological and chemical inertness, as well as resistance to the development of various microorganisms, fungi and other “living creatures” of the material for bath insulation is also extremely important.

Among other things, I would like to definitely note that the heat-insulating layer must be sufficiently tight and elastic, but such that, for example, it itself will not sag over time. Therefore, in order not to be too tormented by the question of which insulation to choose for the ceiling of a bathhouse, it is worth purchasing one that is relatively inexpensive, but in terms of performance and properties is at its best. Moreover, it is worth understanding that this can be done using natural materials, or you can choose synthetic ones, which also “work” quite well.

Peculiarities

Most of the time, the bathhouse was used only as a special room for hygiene procedures. Retaining heat in wooden buildings during the winter season was quite difficult. In Rus', with its harsh climatic conditions, the bathhouse served purely for washing. However, the ancient Greeks spent time in their baths discussing issues of politics and art, war and peace. Turning to modern times, we can conclude that our attitude towards baths has adopted the features of ancient times. A shower allows you to simply maintain hygiene, while a bathhouse has a predetermined recreational role. With modern technologies and materials, it is easy to set a comfortable temperature on any day, despite the cold weather.

The most important function of the bathhouse is the steam room. The temperature in it is traditionally defined as 90°C and 130°C.

“Pie” insulation technology

It got its name due to the fact that upon completion of the work the surface looks like it is packed in several layers:

- Thermal insulation;

- Vapor protection;

- Facing finishing.

You need to start work by installing the bars on the wall surfaces, placing them at a distance of the width of the mineral wool, removing 1 cm for packing density.

The basalt slabs are installed into the created frame, very carefully, out of the way, creating a tight fit. The formation of gaps is strictly prohibited - moisture accumulates here and a “cold bridge” is formed.

The created layer is covered with a vapor barrier so that the heat-reflecting foil part is on the outer surface and looks inside the steam room.

Next, you need to seal all joints of materials with auxiliary tape. The next step is to make a sheathing along the protruding bars of the base, leaving a buffer zone of 5-10 cm. It will protect the lining from rotting, since the condensate will not linger, but will drain without touching the cladding, which completes the “Pie” design.

Advantages of insulating walls from the inside

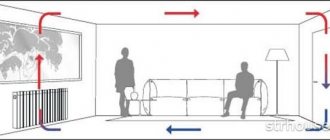

Thermal insulation guarantees several positive effects that are beneficial to owners of washing facilities and all lovers of bathing holidays:

- Reduces fuel consumption and warm-up time;

- Creates a favorable atmosphere in the steam room;

- Forms a circulation of hot air, preventing moisture from settling on surfaces, keeping the wall cladding dry. Thanks to this microclimate, fungus and mold do not grow, the cladding looks great and lasts a long time without destruction;

- Provides noise and vibration insulation, a convenient basis for finishing materials;

- Increases the service life of the structure.

Application of foil vapor barrier

Izolon

If you decide to use such material when building a bathhouse on your summer cottage, this does not mean at all that you need to incur significant expenses. You don't need to invest a lot of money to insulate the entire building. The optimal solution is installation exclusively in the steam room and shower room. The foil layer effectively accumulates heat, and the polymer inside reliably protects the structure from moisture and steam. For other rooms, you can simply purchase simpler and cheaper material.

In addition to insulating the walls, foil material must also be installed on the ceiling, under which hot air and steam collect in the steam room. It is advisable not to forget to use it on doors. But it’s not worth laying any foil insulation on the floor, since its construction here usually consists of a concrete screed with a wooden deck on top. The exception here is warm water floors.