The operating conditions of bathhouses (especially steam rooms) are not similar to the usual operating conditions of residential premises. The microclimate parameters of high-temperature spa areas are important not only for creating comfort, but also for prolonging the life of the buildings themselves. In addition, the problem of energy saving becomes more and more urgent every year. “What is the best way to insulate the ceiling in a bathhouse?” - special attention is paid to this issue, since heat losses from upward flows of heated air and steam can amount to up to 30% - 35% of the heat exchange of a steam room.

Foil without base

Quite thin material. This foil is used to insulate walls and ceilings in warm rooms (mainly baths). It must be installed on a previously installed insulation layer.

The ends of the material are overlapped one on one, and the joint of the sheets is certainly glued using adhesive tape on a metallized base. This way you will create a completely sealed reflective layer of foil.

The limit of the reached temperature is +650°C. That is, foil can provide rapid heating of the room and maintain its temperature for a long time.

Foil without a base is considered resistant to damage and is not capable of releasing dangerous toxic elements when heated.

Insulation technology

The choice of a suitable method of ceiling insulation is determined by the design features of the bathhouse building - the presence of an attic, attic, flat or pitched roof.

In practice, the following options for insulating a bath ceiling are used:

- Hemmed - for large baths.

- Flooring – for small-sized buildings.

- Panel - for various types of structures.

The main requirement for arranging ceiling bases is the presence of properly installed waterproofing and vapor barrier - reliable protection of the insulating material from high humidity.

Flat ceiling

The floor ceiling structure consists of 5 cm thick boards mounted on the bath walls. It is used for buildings with a cold roof up to 250 cm wide.

Insulation of the ceiling in a bathhouse with a cold roof, in which an attic is provided, is carried out using sawdust, clay or expanded clay.

All do-it-yourself ceiling insulation work is carried out step by step as follows:

- Sheets of vapor barrier material (film or roofing felt) are laid overlappingly on the ceiling flooring and secured with metal staples or nails.

- Next, install thermal insulation protection - mineral or basalt wool.

- If bulk insulation is used - expanded clay, sawdust with cement or clay, an additional edge should be installed around the perimeter of the ceiling surface. The thickness of the layer of loose insulation is 30 cm.

- The multilayer structure is covered with waterproofing material - polyethylene film or membrane.

- Finally, a wooden flooring made of boards or plywood sheets is installed.

false ceiling

The hemming type design ensures the creation of a practical bath ceiling. The boards are mounted to load-bearing floors from inside functional rooms and from the attic.

Multilayer thermal insulation is installed between the floorings. The installation process includes the following steps:

- A vapor barrier film or membrane is laid on the ceilings with an overlap of 12 cm, overlapping the wall surfaces. The canvases are fixed with thin wooden slats, which are stuffed in compliance with minimal technological gaps. A double layer of vapor barrier and insulation material is laid over the steam room.

- A wooden lining, pre-treated with antiseptic impregnation, is mounted on the ceiling structure to the slats.

- The load-bearing beams in the attic are insulated with expanded clay, basalt or mineral wool. Thermal insulation is laid in a dense layer without gaps or cracks. The height of the insulating layer is 10 cm.

- A waterproofing protection is mounted on the heat insulator with an overlap of 12 cm, with the joints tightly sealed.

- Finally, the installation of wooden flooring from boards or plywood is carried out.

Holofiber

This type of insulation is considered a synthetic material, which consists of a large amount of hollow fiber. There are many types of holofiber with the density you need. It all depends on what specific purposes you need it for. The advantages include:

- Resistance to mechanical stress - it does not change shape. The way you laid it is how it will lie.

- The small springs in your insulation are the fibers that make up the insulation roll.

- Porous, homogeneous surface.

- Protects against moisture penetration.

- No glue is used in production. This makes it more environmentally friendly.

- Thermal insulation - retains heat and will keep warm in the cold season.

- Created under the influence of high temperature.

- It is quite difficult to break randomly, only intentionally.

"TechnoNIKOL"

Insulation for baths "TechnoNIKOL". Russian mineral wool goes on sale in a wide range. In private construction, three lines are used: “Rocklight”, “Technoblock”, “Technoacoustic”. All three types are suitable for both internal insulation, performed by specialists or with your own hands (using a vapor barrier), and for external work under siding.

Of all the types of fire-resistant wool produced by this manufacturer, TechnoNIKOL stitched mats (basalt insulation for baths), which do not contain phenols, are best suited for bath insulation. In the manufacture of other types of products (TECHNO 03B, 03D, 03M boards), a low-phenolic binder is used.

Kraft foil

This type of material is produced on a paper basis. Comprises:

- Foil,

- Kraft paper,

- Polyethylene.

This material is quite durable, so you don't have to worry about it tearing while layering. Another distinctive feature is that it can be used without adding insulation.

Moreover, foil based on craft paper is considered natural, that is, when heated, it also does not emit toxic substances and is considered safe for humans.

- Thickness: 0.03mm-1.0mm.

- Temperatures can reach one hundred degrees.

- The ends of the material are overlapped one on one, and the joint of the sheets is certainly glued using adhesive tape on a metallized base.

This material is more convenient to use due to its base and increased strength properties.

Heat resistant cables

Choosing a non-flammable cable for steam rooms is a fairly responsible procedure that affects not only the operational reliability of the installed wiring, but also the safety of people in the bathhouse.

Since the temperature inside the steam room can reach plus 170 degrees (with a humidity level of up to 90 percent), the cable products installed in it must have the appropriate characteristics. For these purposes, it is recommended to select special samples of waterproof and heat-resistant cable products in a non-flammable sheath, the quality of which is confirmed by certificates.

Mineral wool

The abbreviation (minvata) is often used. It is considered the cheapest insulation option. But the downside is that they can only insulate façade elements. Excellent for insulating houses.

So if you need to insulate your house, then opt for mineral wool. As for the cons:

- When compressed, the insulation quickly loses its thermal insulation properties.

- Mineral wool practically does not absorb moisture.

The disadvantages are especially noticeable when you insulate the bathhouse. So this insulation is not suitable for insulating baths and saunas.

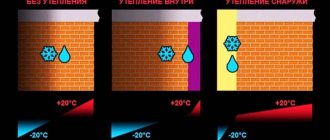

Features of the arrangement of vapor barrier and waterproofing layers

The presence of a vapor barrier layer is not a whim, but a real necessity. Especially when it comes to rooms such as a bathhouse, where hot air is an integral part of using the room for its intended purpose. Rising in the form of steam, moisture can have a destructive effect on the insulation and contribute to the formation of mold and mildew on the wooden elements of the bathhouse frame.

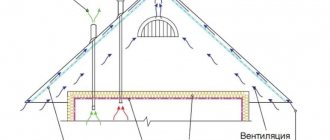

Scheme of insulation and insulation of a bathhouse roof

In order to avoid problems that may arise as a result of moisture accumulation on the ceiling and walls, special films and coating materials are used, for example, anti-condensation membranes. When choosing a suitable material, it is advisable to purchase one that has a foil layer.

Helpful advice! During the installation of a vapor barrier film, it is very important to pay attention to its integrity. It is necessary to prevent the occurrence of tears, as this will greatly affect the technical characteristics of the coating.

To ensure waterproofing, special films are used, which can be purchased at hardware stores. Sometimes the most ordinary polyethylene of sufficient density or cheap roofing felt is used.

To protect the bath frame from moisture, it is recommended to use a waterproofing membrane, which can be mounted in contact with the insulation without losing its properties

Folgoizolon

This foil is polyethylene foam with foil as a cover.

- You can find it in stores in roll or sheet form. Depending on what thickness of the product you personally need.

- The product has high strength, shock absorption and sound insulation characteristics.

- This fact means that it can be laid on the surface without additional insulation.

- Most often it is used as insulation for wooden surfaces.

It is also worth noting that the material cannot be deformed.

Preparatory work

how to properly insulate a ceiling

For baths without an attic, it is enough to use aluminum foil for vapor barrier. You can use wax paper or thick cardboard. The material must be pre-treated with drying oil.

If the bathhouse is equipped with an attic, then it is better to apply a layer of clay (3 cm). You can purchase industrial materials:

- Polyethylene film. But during operation it will be necessary to make a small gap to get rid of condensation.

- Polyethylene vapor barrier film. It is equipped with fibers that retain condensation.

- Vapor barrier membrane. The vapor barrier will create conditions under which wet vapors will not settle on the surface of the thermal insulation. This will prevent damage to the material and walls, increasing the weight of the ceiling and its deformation.

https://youtube.com/watch?v=xCCC_y1f810

Felt

Most often, the combination of jute and flax is very popular.

- It is quite reliable among all other insulation widows.

- Thanks to jute, felt becomes resistant to negative factors.

- By the way, this combination is called “Eurolen” in professional circles.

You should know that jute can provide you with good performance.

When you buy felt, pay attention to its condition: the fabric should not have tears or protruding threads.

PIR boards

These slabs are ideal for insulating saunas and baths. The inside of the slabs is porous, but the cells inside are closed, which is why they do not absorb water.

- This is the most important indicator that you should pay attention to when choosing insulation for baths and saunas, where humidity will always be present.

- The stove is able to withstand large temperature changes without emitting toxic substances. PIR boards are used to insulate various surfaces: walls, ceilings or floors.

There are many types of slab coatings, but aluminum foil is the most popular.

This type of insulation is a strong barrier not only to heat, but also to vapors emanating from water. In addition, you can save on heating the room. By heating it once, you will not have to frequently add firewood to the stove or increase the heating time of the boiler.

Conclusion

We have given enough information on the issue of how to insulate the ceiling of a bathhouse. When choosing insulation for the ceiling, we recommend that you rely on data on the safety of materials, taking into account the capabilities of your budget. And, of course, the purpose of the bath - for yourself or for commercial purposes. You should also take into account the type of material from which the bathhouse is built; for each there are some nuances of insulation: wood: timber and logs, brick, blocks (slag, expanded clay and foam concrete, gas silicate), frame.

Lnovatin

This material is a material that is made by a needle punching machine. It's important to note that this is not fabric.

- To create it, they take flax fiber, which is carefully combed, folded into several layers and the fibers of which are intertwined with each other.

- It is worth noting that there is also a sewn version of this material; it is quilted with cotton or polyester threads.

The disadvantage of this material is that it is not dense and has low thermal insulation properties. In addition, cotton tends to rot quickly.

How to choose the right insulation for a bath

Please note that the purchased insulation may not always be well suited to certain surfaces, because of this you must know what little things you need to pay attention to and what criteria to use to make your choice.

It must be said that the choice of material should be based on what kind of surface you have and the fastening method you choose.

Let's consider the basic criteria by which you can make a choice:

- Price - pay attention to this, since inexpensive options are most often not of good quality at all, but expensive ones often are. Therefore, to ensure that the insulation is of high quality, choose a brand that is manufactured by one of the market leaders.

- Purpose is the most important criterion due to the fact that each material has its own type of insulation. Of course, it is allowed to insulate with any insulation, but the service life will be significantly reduced.

- Environmentally friendly - choose only pure natural insulation materials that are not capable of releasing toxic substances when heated.

- Vapor permeability – no higher than 0.01 g/m² per day.

- Resistance to rotting - the material must be resistant to the growth of fungi and harmful bacteria.

- Thermal conductivity - the ability to retain heat must be present.

- Shape retention - a high-quality filler should not be able to deform under influence.

- Low fire hazard - the material should not have the ability to burn.

- Soundproofing properties - the insulation must have them, but this item is not required.

- Hypoallergenic parameters - this material should not have the ability to absorb dust, which will be very suitable for people with dust allergies.