From the author: Hello, friends! Home air heaters create warmth and comfort in the house when there is frost and cold wind outside. After installing a new heating system, apartment owners often do not know how to turn on the gas convector. Of course, you can study the instructions, but the best way is to see everything with your own eyes using a video or get information from experienced users. Additionally, you need to familiarize yourself with the safety precautions and operating rules of the device.

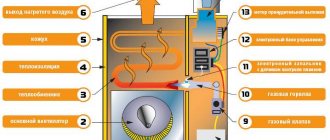

Gas convector device

The operation of the device is based on the law of natural air heat exchange. From the external environment, the device draws in oxygen necessary to maintain the combustion function. Gaseous substances harmful to human health escape through a special adapter.

Weather conditions do not affect the operation of the device. The smell of gas and combustion products is not felt due to the fact that the process takes place in a sealed chamber. A gas convector is a prefabricated structure consisting of a large number of parts:

- back wall,

- sealed housing,

- front casing,

- air exchanger,

- pipes, screeds,

- fastenings and mounting products.

The body is made of cast iron or steel with a heat-resistant coating. The decorative grille protects people from accidentally touching the hot surface of the device. Warm air passes through it, warming the room. The air exchanger is installed on the outside of the wall. The windproof design ensures trouble-free operation of the device.

The safety of the convector operation is maintained automatically:

- if the draft is weak or the ignition burner goes out, the gas supply is interrupted,

- set the desired temperature on the control panel,

- gas flows evenly, regardless of the pressure in the gas pipeline,

- The burner is ignited using a piezo igniter.

Convector control via GSM

Convectors with remote control can operate from commands received via GSM. This module is integrated into smart sockets. Power is supplied to it via SMS.

The kit also includes a temperature sensor. It, together with the built-in thermostat, allows you to set the desired temperature to turn on/off the device. This allows you to save electricity and optimize heating performance.

If necessary, you can configure the device to operate on a schedule. As a rule, these sockets are designed for a power of the connected device within 3.5 kW.

To receive qualified advice on the technical characteristics and selection of heating devices, call the phone number listed on the website, or use the feedback form.

Installation of a heating device

On the wall where it is planned to mount the convector, make a hole corresponding to the parameters of this model. The further actions of the masters are as follows.

- A coaxial telescopic pipe is inserted into the prepared tunnel.

- The wall must be made of material that is not subject to combustion. If the interior is made of wood, drywall or other combustible materials, it must be insulated.

- The pipe is installed perpendicular to the convector with a rigid fastening.

- The back of the device is screwed to it.

- The convector is attached to the wall.

- The telescopic pipe is positioned so that only the fungus is visible from the outside.

- The remaining cracks are sealed with heat-resistant foam and cement mortar.

It is necessary to ensure that emissions from the convector do not fall on footpaths, since the escaping gases have a high temperature.

Preparation for use

Before starting to operate the air heater, you need to check:

- gas burner manifold fasteners,

- tightness of gas connections,

- accuracy of thermostat operation,

- security system in the room and the device itself.

Attention! Never attempt to reset factory programmed settings. They are designed for convector operation on natural gas. To carry out the necessary adjustments (for liquefied gas or other types of fuel), contact a specialized service center.

Conclusion

To summarize, I would like to note that gas heating convectors are advantageous to install in small rooms of a summer house, garage or as an addition to a city apartment. For heating private houses with a large area, a gas boiler and liquid radiators are more suitable.

Mounted units.

Did you like the article? Subscribe to our Yandex.Zen channel

Switching procedure

To ignite the pilot burner, you need to move the main regulator from the “OFF” to “ON” position. Press and hold the control knob for a few seconds until the pilot light comes on. Check to see if the wick lights after you release the control knob. If the light goes out, repeat the operation. To further understand how to turn on and operate the device, watch the video.

Set the temperature control to the desired position - from 13 to 38 degrees. Each of the seven values corresponds to a specific indoor air heating temperature. The gas convector can be left in standby mode when only the wick is lit and the main flame is extinguished. To turn off the device, just press the “OFF” button.

Attention! After the end of the heating season, the gas supply to the device should be completely shut off. To do this, close the valve on the gas pipeline.

Gas supply to the convector

- GOST requires that the pipe leading to the convector run along the street. We will act in accordance with it. If the gas pipe has a pre-installed threaded connection, then screw a gas valve onto it, shutting off the gas supply to the convector. If the pipe does not have such a branch, you will need to make one. Such work should be carried out by a gas welder. Preferably a specialist from Gorgaz or a similar office.

- When the gas tap is installed, a metal-plastic pipe should be routed to the convector. Using a tape measure, we calculate the length of the pipe and determine the presence of fittings.

- We purchase pipe and fittings. When purchasing pipes and fittings, find out if these pipes and fittings have a certificate of conformity for this type of work.

- Now lay the pipe, attach it to clips every meter. To install the clips, drill holes in the wall.

- When installing fittings, lubricate the pipe and fitting with silicone. This will provide additional sealing. In addition, silicone will serve as a lubricant and will facilitate pipe installation.

The result of the work should be a convector hanging on the wall, an exhaust pipe with a hood and a gas pipe laid and connected to the convector.

Precautionary measures

The use of household appliances requires compliance with safety precautions. Be careful and listen to the advice of manufacturers:

- You cannot use a convector that has a damaged viewing window,

- if the device goes out spontaneously, do not re-ignite it earlier than after 3 minutes,

- To prevent burns, the convector is protected with a protective grille.

It is strictly prohibited:

- dry things on a running appliance,

- turn the device on and off for children and people with limited legal capacity,

- operate the device with the outer casing removed,

- repair the device yourself,

- place flammable objects at a distance of less than 1 m from it,

- leave it on if signs of a gas leak are detected.

If there is an unpleasant odor in your home, take immediate precautions:

- turn off the gas supply,

- extinguish all sources of open fire,

- do not touch switches and mobile phones,

- ventilate the room

- urgently call the emergency gas service,

- Contact a gas convector service center.

Criterias of choice

The efficient operation of a gas convector will depend on the correct choice, as with electric heaters, gas devices have their own design differences that must be taken into account when choosing.

Functional features of the heater:

- The remote control allows you to set the temperature and fan speed settings, while some models have both wired and wireless versions, which allows you to control the device from a distance.

- Thermostats make it easier to set the operating temperature.

- Programmable timers will help with energy saving. Most can be programmed to turn on/off within 24 hours.

- Child locks are available on some models.

- Electronic ignition of the burner ensures energy savings.

- Filter cleaning warning function.

When choosing the right model, the specific operating conditions of the unit, the purpose of the room, the geometric configuration of the heating object, for example, for a garage, the heated volume and the required indoor air temperature are taken into account.

Heat exchanger material

The operation of the convector is based on the combustion of fuel in the chamber, so the heat exchanger is exposed to strong thermal effects, and if its metal burns out, this will completely deactivate the convector. An equally important condition for the long-term operation of an internal boiler is its corrosion resistance, which resists the aggressive effects of flue gases. Therefore, it is natural that the boiler material should be as durable and corrosion-resistant as possible. The main materials used in convectors for these purposes are steel, aluminum and cast iron.

The best option is a steel heat exchanger, with increased heat resistance, small dimensions and weight, and a relatively low cost.

Aluminum, despite its excellent thermal conductivity, is an expensive metal and does not have heat resistance. Cast iron has increased fragility; under the influence of sudden temperature changes it can crack, and ultimately damage the heater.

Combustion chamber type

For this type of heater, open or closed combustion chambers are installed. The first option has an exhaust hood that takes air from the room and releases exhaust gases through a vertical pipe into the atmosphere. The simplest gas convectors operate with an open gas combustion system, which has obvious disadvantages - air intake for combustion from the room and the need to install a complex, expensive smoke exhaust system passing through the ceiling.

Therefore, heaters with a closed combustion chamber are better and more environmentally friendly. In such a device, movement in the gas-air duct of the convector is ensured by a special blower fan built into the coaxial chimney. Flue gases are removed through the inner pipe, and air masses are introduced into the chamber through the outer ring.

Power and heating area

In order to choose the right thermal power of the heater, you will need to take into account many factors: the climate zone of your residence, the height of the ceiling and the total heated area, whether adjacent rooms have heating, the state of thermal insulation, whether sunlight enters the room, glazing area. It is almost impossible for a person who does not have a special education to perform such a calculation, therefore, to select thermal equipment, they use the average practical ratio of interrelated quantities:

The required kW power depends, first of all, on the area to be heated and the climatic zone of residence. In order to choose the best gas heater for rooms with ceilings no higher than 2.5 m:

- Northern regions - 1000 W for every 8.5 m2 of area.

- Central region - 1000 W for every 10.0 m2.

- Southern regions - 1000 W for every 16.0 m2.

An example of selecting convector power in relation to the heating area for the central part of Russia:

- Low-power unit, area 29 - 42 m2, load 2.9 - 4.2 kW.

- Medium unit, area 50 – 60 m2, load 5 – 6 kW.

- Powerful unit, area 62 – 82 m2, load 6.2 – 8.2 kW.

For heating efficiency, it is recommended to choose convectors with a margin of heating capacity in order to minimize heat loss. Gas consumption will remain virtually unchanged.

type of instalation

In order to make a choice of device according to the type of installation on the wall or on the floor, you need to take into account the actual conditions of the site. The preferred option is wall installation. It does not take up a large volume, being located under the window and creating a thermal curtain between the cold air coming from the window and the internal air in the room. Despite their many advantages, such devices are limited in power to 10 kW, and therefore are not used for large objects. Wall heaters typically last between 8 and 12 years.

To heat large areas, floor-mounted devices are used. They are large in size and weight and last more than 20 years. The final decision on choice is made taking into account the safety of installation and operation of the heater. The biggest threat to your home when using one of these heating appliances is the risk of fire. Convection technology uses intense heat to heat the air, so you need to place these heaters away from flammable materials and household items that can heat up and burn.

Gas convector KARMA BETA 5

Fuel consumption

Once the power has been determined, you can begin to calculate the fuel. According to current standards, gas is calculated for each object separately, at T outside air in the area where the object is located. This data can be obtained from SNIP for heating.

To calculate gas fuel use the formula:

G = N / (QH x 0.95) , where:

- G – estimated gas flow, m3/hour;

- N – thermal power of the convector, 100 m2 – 10.0 kW;

- QН – lower calorific value of gas – 10.175 kW/m3;

- 0.95 – convector efficiency, %.

Hourly gas calculation:

10 / (10.175 x 0.95) = 1.034 m3/h

Daily indicator:

1.034 x 24 = 24.8 m3/day

Seasonal consumption, with a heating period of -185 days:

24.8 x 185= 4593 m3/season

It should be clarified that this calculation is approximate; the actual consumption will depend on the parameters mentioned above.

Additional functionality

There are several such functions that consumers additionally choose:

- Timer for setting the operating period;

- fan to improve convection;

- control valve to control combustion mode;

- thermostat to support the operating mode and working in tandem with a gas valve;

- an automation and safety system monitors the stable operation of the heater and turns it off in the event of an emergency due to gas pressure, lack of air, or gas contamination in the room.

Features of use

The operating principle of the device is based on the physical phenomenon of convection. Streams of cold air penetrate through the lower grilles, heat up from the heat exchanger and rise to the ceiling. Constantly circulating air quickly heats the room. When installing convectors, there is no need to install heating pipes in the apartment.

Several convectors are installed in a large house. A main gas pipeline must be connected to each of them. One device heats a room with a volume of up to 130 cubic meters. It maintains a given temperature regime with a minimum gas flow rate - from 0.22 to 0.48 m3/hour, depending on the model.

The efficiency of the devices reaches 88%. In comparison, gas boilers operate with efficiency of up to 98%. The performance is improved for devices with fans, but at the same time the noise level in the room increases. When heating and cooling, steel convectors emit a characteristic crackling sound (the metal expands or contracts). Cast iron casings do not produce any sounds.

Gas appliances come in two types: wall-mounted and floor-mounted, fireplace type. They are fastened in the same way, have a common principle of operation, but the latter are larger in size.

Advantages and disadvantages

A gas heater is 50% cheaper to operate than a conventional electric convector, which is a strong argument for its use. It can operate during power outages and reach maximum temperature quickly, almost instantly.

Advantages of a gas convector:

- Portability and mobility, they can be placed in any room, you can take them with you when moving, for example, to the country.

- Efficient, more than 90% of the energy contained in the gas is converted into heat.

- Instant heat transfer. The lower limit for heating output for such devices is 25 MJ/h, which is equivalent to 6 kW of electric heating, so one standard gas convector produces the same amount of heat as three 2 kW electric heaters.

- Low specific costs for the production of a unit of thermal energy, 1 Gcal.

- Modern level of security. The protection system turns off the heater based on an oxygen depletion sensor if its level in the room becomes too low, as well as in the event of a flame breakout or the heater overturning.

- Carbon monoxide protection.

- Automatic temperature maintenance using a thermostat.

Disadvantages of a gas heater:

- There is no chimney, in designs with natural circulation, so emissions from the combustion process flow back into the room.

- They should not be installed in bedrooms, bathrooms or other small or poorly ventilated areas.

- Water vapor from the combustion process can condense on walls and ceilings and cause mold to form.

Gas convector Alpine Air NGS-50F

LPG convector

The air heater can be converted to operate on bottled (liquefied) gas. For this purpose, special nozzles and a gearbox are purchased. If there are several such convectors in the house, then a special room will be equipped on the outside of the house for storing propane cylinders.

A comfortable temperature in the house is achieved using the built-in thermostat. It prevents the air in the room from overheating, while gas is consumed more efficiently.

Important! Gas combustion products will not enter the airspace of the room if they are vented into the chimney.

Before buying an air heater, calculate the required power to heat the volume of the room in which you plan to install it. Be sure to take into account the height of the ceilings, otherwise the device may not meet your expectations. The best location for convectors is under the windows. In this case, cold air does not have time to penetrate into the room.

Sometimes these devices are used as an additional source of heat in severe frosts. Approximately 0.095 kg of liquefied gas is burned per 1 kW of heat transfer power per day. Keep in mind that a cast iron heat exchanger in a gas convector lasts much longer than a steel one. Its service life can last up to 50 years, but such a device costs much more. Manufacturers provide a factory warranty of up to 5 years. Make sure that when purchasing the device in the store, all documents are filled out, including the warranty card.

Switching on and operating modes

Modern convectors have thermostats that regulate the temperature of the heating element and, accordingly, the exhaust air.

Electronic installations carry out control with high accuracy (up to 0.1ºС) to achieve a comfortable microclimate. This is suitable for objects where there is a need to maintain a certain temperature regime. You can also adjust the temperature automatically, which also increases efficiency. The process of turning on an electric convector manually

simple enough. There is a switch on it that supplies voltage to the heating element. In high power convectors there may be several heating elements, and in this case the switch provides several possible positions. Accordingly, when the switch is set to the first position, one heating element will be turned on, in the second - two, and so on until full power. Thus, a high-precision thermostat allows temperature control over large ranges.

In addition to manual, there is the possibility of remote

convector control. Modern technologies allow you to use the Internet and a smartphone to remotely control the heater.

The Norwegian company Nobo offers two systems for remote control of heaters: Orion 700 and Energy Control. Using these systems, you can control convectors (and other electrical appliances) through special receivers, similar to a “smart home”.

This allows the user to remotely control the heating of, for example, a country house so that it does not freeze in cold weather.

The convector operates from the Orion 700 system and the GSM module using SMS commands. A regular SIM card is pre-installed into the module, to which a command is sent from any mobile device, and the module, in turn, communicates with the Orion 700 control unit and configures the operation of the heater via a radio signal.

It is also possible to create a work program for a week in advance, indicating the temperature parameters that need to be maintained. It will repeat cyclically, maintaining the optimal set temperature. The heater can operate for an unlimited amount of time. This is convenient, as it allows you to heat, for example, a country house in winter, when there are no residents in it. All Nobo convectors have an anti-freeze mode, which allows you to maintain a minimum positive temperature in the room (to maintain the operation of communications) with minimal energy consumption.

The second control system is Energy Control. It controls via the Internet using the Eco Hub control unit and router. By analogy with Orion700, here you can also configure convector operating modes, configure programs, turn on heating, and so on. It is possible to control from several smartphones simultaneously.

Today, this technology from Nobo is an advanced development in the field of remote control of space heating.

In addition, the Nobo electric convector can remain turned on for an unlimited period of time, as it has reliable protection against overheating. Thus, this system allows you to control the convector as needed in each specific case. For example, you can remotely turn on the heater a couple of hours before arriving at the dacha to warm up the house, or, without fear, leave it running for the whole season to maintain the temperature, without having to come. This ensures detailed control of operation, efficiency and maximum comfort in use.

Distinctive features

Convectors operating on liquefied gas have a horizontal or vertical chimney. Vertical systems have more power, but have installation limitations - they cannot be installed everywhere. Models with a fan provide accelerated air circulation in the room.

Installation of the device follows the same principle as in the case of natural gas, but it is necessary to provide an additional hole to connect it to a cylinder located outside the room.

Important! During the first hours of operation of the convector, an unpleasant odor is felt in the room. This burns the lubricating oil. Ventilate the room and the air will be refreshed.

To start the device, the operations described above are carried out sequentially. The only difference is that instead of a tap on the gas pipe, they open a valve on the propane tank. An important distinctive feature of liquefied gas appliances is the ability to heat rooms located away from gas pipelines.

Principle of operation

The Nobo electric convector operates based on air circulation through the device.

It has a heating element inside and a thermostat outside to control temperature conditions. Entering the convector, the air exits in the form of a directed heated flow, heating the room. This ensures fast and uniform heating of the air. Thanks to the use of a special alloy for the manufacture of the heating element, it begins to work for heating almost immediately after connection. The convector can be installed in different rooms and near any surfaces, since fire safety is guaranteed due to the low temperature of the housing. At the same time, with the small size of the heating element, the convector has sufficient power to heat any area.

Thus, this type of heater guarantees efficient operation, reliability, as well as cost-effectiveness and ease of operation.

How to fix the problem

Malfunctions in the operation of the devices occur very rarely. The main reasons for unstable operation of the device:

- burner contamination,

- clogging of jets,

- dampening of contacts.

Experts advise carrying out preventive measures at least once every 24 months. Craftsmen carry out the necessary repair work:

- weld the damaged body,

- restore the automation system,

- switch the device to liquefied gas.

Attention! Only a certified technician from the gas industry or service center can carry out repairs on gas convectors.

The main task of the specialist is to eliminate the cause of the problem. To do this, replace the damaged node or block. Such repairs are done quickly at a low cost. At the final stage, the operation of the equipment is tested in different modes and the functioning of security systems is checked. Experts inspect the gas pipeline to prevent gas leaks.

Main characteristics of the device

Gas convectors have many advantages that allow them to be used in residential buildings, factories and shops. This:

- moderate cost,

- can be turned on only in one room if there are several devices installed in the house,

- The device provides significant gas savings,

- uniform distribution of warm air,

- ease of operation,

- reliability and long service life,

- can be used during a power outage,

- no installation of additional sources required,

- affordable installation and maintenance of the convector.

When choosing a heating system for a new apartment, consider installing gas convectors using natural or liquefied gas. Let your home be warm and cozy.

Installation recommendations

It is well known that the installation of a gas convector consuming main methane must be carried out by specialists from companies that have the appropriate permits. It is worth clarifying this somewhat generalized requirement: the issue is not installation, but connection to the gas supply network. This operation can indeed be performed by the above-mentioned workers in accordance with previously completed project documentation. This means that you can put the units in place with your own hands, but without connecting to the gas pipeline.

If you nevertheless decide to take bottled gas as an energy carrier, then the situation is simpler. Connecting propane heaters does not require any permits. However, it is strongly recommended to involve a specialist in this work, at least as a consultant. It will help you check the correctness and quality of the connections and carry out the first start-up of the unit.

Advice. When purchasing a heater, you should make sure that the length of the coaxial channel included with the product will be sufficient to pass through your wall.

Before installing a gas convector, you need to make a round hole of the appropriate diameter in the wall. Next, attach the device to the wall or floor according to the operating instructions. In this case, in some heater models, the external temperature sensor with a capillary tube must be moved from the transport position to the working position. After this, all that remains is to connect the fuel supply line to the inlet pipe on the device.

Important. Floor and wall convectors must be supplied with gas at a certain pressure specified in the technical data sheet for the product. Therefore, the supply of fuel from the cylinders should be organized through a reducer configured for this pressure.