Lovers of country holidays and avid gardeners who spend half of the spring and summer in nature, and live there until late autumn, cannot do without heating.

Potbelly stove in the country

As a rule, summer cottages do not have a gas supply, and not everyone can afford to build a brick stove or fireplace - this is not a cheap pleasure. But you can always find a way out; a metal potbelly stove with solid fuel is perfect for heating a summer house and banal cooking and hot tea!

Many people will immediately imagine a crudely welded steel structure, but this is not the case at all. There are a huge number of models on the modern market that will satisfy any demand both in price and design. If you need a banal function of heating your dacha, a potbelly stove for 10,000 rubles will cope with this task. Of course it won't look as good, but it will work perfectly!

Historical excursion

The history of the term “potbelly stove” takes us back to the beginning of the 19th century, when their first designs appeared. Initially, the stove was used as a heating device in the apartments of especially wealthy citizens. This is where the name “potbelly stove” comes from.

During the NEP it was also popular. Then each family received a plot of land for use - a “suburban garden” (the same dachas). There, small-sized, unpretentious stoves were used.

Potbelly stoves were produced in large quantities at factories and for the needs of the Red Army. And more advanced designs, artistically designed and decorated, were even exported outside the USSR.

Sawdust firebox

Sawdust is not a high-quality fuel; it burns poorly. But they are easily accessible and popular. The design of a furnace of this modification forms two metal cylinders of different diameters. A pipe with a smaller diameter is placed in a pipe with a larger one, turning into a combustion chamber. A hole with a diameter of 5 cm is created at the bottom.

The chimney is located at the bottom of the outer cylinder. A steel box is welded under the ash. The potbelly stove is equipped with a door. A core of wood up to 60 cm high is inserted into a cylinder of smaller diameter. Sawdust is poured and pressed around it so that it burns as slowly as possible. The core is removed and a fuel chamber is obtained. The stove is ignited through an ash box using shavings and bark. When the fire reaches the top layer of sawdust, the stove is covered with a lid.

So, potbelly stoves have faithfully served people for many years. These unpretentious simple designs still provide heat, although they consume a lot of fuel, which is why they got their name. But modern models have learned to combat the hunger of bourgeois women, giving them a ticket to a long life.

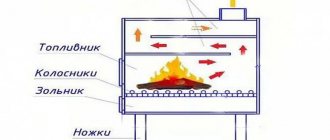

Device

The construction of a potbelly stove is quite simple. It is a rectangular metal box on support legs, equipped with:

- a firebox with a door into which firewood is placed;

- ash pan, which must be systematically cleaned;

- an all-metal chimney pipe (length 5 meters or more: the draft force depends on this parameter).

The main fuel for a potbelly stove is wood.

The furnace operates as follows: the heated flow first passes through the chimney pipe shifted to the side, and then only rushes beyond its limits. The fuel burns, the stove heats up, and the heat is transferred to the room in which it is installed.

The ash enters the ash pan through a special mesh, so the volume of the furnace working area does not decrease.

Safety Recommendations

- The ash drawer can only be cleaned when the stove has completely cooled down. Simply remove it and throw away the contents (remember that the ash can remain hot for several hours).

- It is better to use dry wood for ignition. The volume of the filling is no more than ¼ of the volume of the entire firebox.

- Do not store flammable liquids, objects, or rags near the stove body.

- Hot walls can cause burns - handle the stove carefully and do not leave it unattended for a long time, especially if children are nearby!

- It is better to store fuel away from the stove, and not under it (the temptation is great if the model has legs). This will protect the firewood from sparks hitting it and, as a result, fire.

- The firebox door must not be opened during combustion (except for short moments when you need to work with a poker and immediately close the door).

- By the way, in factory models of potbelly stoves it is taken into account that the door must close very tightly. Most models are equipped with a sealing cord and a high-quality lock.

Range of applications

Potbelly stoves are universal and are used:

- for heating cottages, country houses, rooms or garages;

- for cooking in the country: in houses, on verandas or even in the yard;

- as a camp kitchen if the model is compact;

- to provide hot water (if the model has a storage tank).

Read More at pechinfo.ru/material/iz-metalla/konstruktsiya-metallicheskoj-pechi-dlya-bani?preview_id=818&preview_nonce=a837fab63d&preview=true © PechInfo[/box]

Criteria for choosing cast iron stoves for a summer residence, taking into account their technical characteristics

We have compiled a list to help you make your choice, it will show you what you should pay attention to.

The main criteria to rely on.

- You need to evaluate the main style in which the interior of the house is made, and then, using the knowledge gained, select a suitable stove.

- Also an important factor is the base material of the furnace. It is usually made of metal or alloy, the most popular being cast iron. Its composition ensures long-term service, the stove is resistant to damage and is not afraid of any natural phenomena. This material is more suitable than others for making a stove. Therefore, it is the most practical, and therefore the most popular.

- The type of fuel is also an important factor when choosing a stove. The most common fuel is wood. You need to make sure there is a large supply of wood nearby, otherwise this could become a problem. People usually do not pay attention to this factor, despite the fact that it is one of the most important. Therefore, his mention was mandatory.

- The obvious criterion is the size of the oven. It is important to take measurements of the space where the stove will be placed in the future.

Varieties

When choosing a stove, take into account its appearance (shape), design, materials from which it is made, as well as various additional elements that the stove may be equipped with. There are the following varieties:

Classic ovens.

This is a cast iron bunker, which has a firebox with a door and a chimney.

Advantages:

- made of durable cast iron;

- it takes a minimum of time to heat up;

- compact, therefore suitable for any type of premises;

- any solid fuel can be used for kindling;

- no special installation required.

Potbelly stoves with a hob.

Advantages:

- versatility of use: not just a heating device, but also a stove for cooking;

- possibility of use at any time of the year: heated air vapors will go into the chimney and will not create a high temperature in the room;

- mobility: can be installed both in the house and on the site.

Heater furnaces also have advantages:

- retain heat well, unlike the models described above;

- One stack of firewood heats the room for 8 hours. This is ensured by a special design: the furnace body is surrounded by a casing. Unheated air enters this area. While the air rises, it is heated by the walls of the oven.

The disadvantage is the size:

- ovens can be quite bulky.

Gas generator furnaces

have the following advantages:

- the most efficient of all models of potbelly stoves;

- High-strength steel is used for their manufacture;

- Heat-resistant paint is used for coating;

- The special design allows the stove to operate in fuel saving mode. The furnace consists of two chambers: in the lower one, flue gases are formed; the top one is used for afterburning. Fuel can emit gases, but not burn, which reduces its consumption;

- One stack of firewood provides heating of the room for 12 hours.

Army potbelly stoves

These are nothing more than wood-burning cast iron stoves POV-57, designed specifically for use in the army.

Their manufacturer is the Russian Military Industrial Complex. These models are also cast from cast iron.

They are used both as a heating device and as a stove.

Main advantages:

- these are furnaces with high strength and thermal efficiency;

- it also works with wood, but in addition to this, it can be heated with coal, and even with garbage and vegetable waste;

- characterized by maximum heat transfer;

- easy to install and dismantle;

- long combustion furnaces;

- One load of fuel is enough to heat a room for 10 hours.

For all types of potbelly stoves

General disadvantages can be identified:

- there is no automatic operating mode;

- may be a fire hazard;

- To retain heat, some models require additional lining of the stove with bricks, which has a negative effect on cast iron.

Advantages of a potbelly stove

A modern stove-stove, thanks to new developments and improvements, can be an additional or main source of heat. It has its advantages over brick kilns - these include the following:

- It is easy to install a potbelly stove even in an already built house; there is no need to build a foundation for it, since the structure is not very heavy. It is enough to simply lay fire-resistant material under it.

Stone backing for potbelly stove

- Such a stove does not require special maintenance, which is necessary for analogues made of brickwork.

- The cast iron surface with a hob makes it possible to cook food.

- Relatively low cost compared to brick structures.

- Possibility to heat a potbelly stove with several types of fuel: wood, peat, wood briquettes (photo).

- If necessary, the potbelly stove can be moved to another room, in which it is possible to lead the chimney to the street or into a common chimney.

Main manufacturers and cost

Slovenian company Thorma.

It is famous for its simple, fairly cheap, but high-quality models of potbelly stoves. They have a “clean glass” system and secondary combustion of flue gas. Approximate price - 25,000 rubles.

Godin is a French manufacturer.

Manufactures high-tech heating equipment.

The use of innovative technologies allows these furnaces to burn the maximum amount of gases, while reducing the volume of ash and increasing the efficiency of the unit. In addition, the French also value the design of stoves, so their cost ranges from 30,000 to 190,000 rubles.

Guca is a manufacturer from Serbia.

These stoves are distinguished by their low price and simplicity.

The line even includes devices for heating rooms up to 240 square meters. m. Guca also presents models to which a heating circuit can be connected. Price: 16,000 - 85,000 rubles.

In Russia

The production of stoves is carried out by a company that is not inferior to the above listed manufacturers in terms of the quality characteristics of the products. Their price ranges from 4,000 to 80,000 rubles.

Review of products from world brands

There are many potbelly stoves on sale today, ranging from purely utilitarian ones to retro-style products. At the same time, the units differ in appearance, design features and price. Due to the fact that the range of stoves is now huge, buyers are interested in the question: what brands of products are in demand? The most popular potbelly stove brands are:

The Guca Prometej stove has excellent thermal characteristics and a unique design

- “Vermont Castings” – the products of the Canadian company can safely be called a standard. Advanced technologies and the latest materials are used in production, so the efficiency of stoves and their aesthetic characteristics are constantly improving. Potbelly stoves from this brand have many advantages: fire safety, ease of assembly, quick kindling, high productivity. Plus, the units are equipped with a perforated double firebox. In a potbelly stove, more than 90% of the chemical compounds found in flue gases are burned. From this we can draw a logical conclusion: there is no negative impact on the environment and people.

Modern potbelly stoves that burn wood or coal have excellent performance indicators. They look original and effectively complement the interior. But you need to understand that the installation of units must be carried out by qualified specialists. This is the most important aspect that deserves the close attention of owners of dachas and country cottages.

Installation and operation

- When installing, a space of at least 1 meter must be provided between the wall and the stove. In this case, the cast iron stove must be installed on concrete, tin, brickwork or ceramic tiles. It is these materials that will ensure the fire safety of the structure. It is strictly forbidden to install stoves on boards, parquet, floors covered with linoleum, laminate, carpet or plastic. The size of the base for installation should exceed the dimensions of the oven by 20-30 cm .

- The chimney pipe in the room should be installed in one section, without joints. Or the sections should be connected to each other by connecting the bottom to the top. Where the chimney passes through the wall, a thermal barrier made of brick or ceramic can be provided. It is also possible to install a concrete barrier, but concrete may crumble during temperature changes.

- boxes with firewood or other fuel away from the stove doors (at least 80 cm), otherwise there is a risk of fire. This also applies to any other flammable items.

- To ensure fire safety at the dacha, the potbelly stove must be kept within sight. Do not leave the room until it burns out.

- To light the stove , open the firebox slightly, add fuel and light it. You can regulate the strength of the fire by opening and closing the ash pan.

- The ash drawer must be cleaned regularly . To do this, cool the oven, remove the ash pan and empty it of its contents.

- Do not put more than 3 kg of firewood per kindling into the potbelly stove. Always close the doors.

- If any defects are found in the design of the chimney, the use of the stove is prohibited.

- Do not touch the stove with your hands : the heating temperature is extremely high.

The production of stoves is gaining popularity and improving; there are many varieties on the market, but it is more advisable to choose models with longer combustion and double combustion ; they will use fuel more efficiently.

To create a cozy atmosphere around the fireplace, consider designs with thermal glass doors. When choosing a model, consider the purpose of subsequent use of the unit and your financial capabilities.

A potbelly stove is one of a variety of outdoor stoves. What other outdoor ovens are there and, using the example of one of them, how to build a brick oven on the street is described in detail in this article.

The video that we invite you to watch will help you visualize all the intricacies of the construction of a cast iron stove and its installation in the country.

How to make it yourself

Assembled stove

The easiest way to make a potbelly stove yourself is from two metal barrels according to the standard scheme. For this purpose, you will need two barrels, one of which should be smaller. The upper part is cut off from each, and metal handles and locking parts are attached to the remaining part. Before starting work, it is better to rinse the barrels thoroughly to get rid of any unpleasant odor that might remain there. Assembling such a stove according to the rules consists of several stages, performed step by step:

- A rectangle with an area of 25x10 cm is cut out at the bottom of a large barrel; this compartment will become a compartment for a drawer.

- You need to attach two guides measuring 2.5x2.5 cm to the bottom.

- A tray is cut out of a metal sheet along a contour no more than 1-2 cm thick, which will become the basis for the chamber and can isolate it from the ash pan.

- A hole with a diameter of 6 cm is cut out in the central part of the pallet and the bottom of a small barrel, after which the pallet is welded at a distance of at least 15 cm from the bottom of the container.

- At the final stage, a hole is made in the body of the large barrel required for the flue pipe and a convenient damper with a small handle is built into the pipe.

- A small barrel is placed inside a large one so that each hole in them coincides.

To add fuel, make a cone at least 1.5 meters long, which is made of metal or wood. The bottom of such a cone should pass freely through the hole in the pan.

Material options

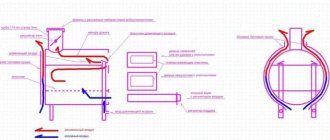

Drawing of a wood-burning potbelly stove.

Basically, potbelly stoves are made from metal barrels or gas cylinders, using additional materials and equipment for this purpose. To make a full-fledged device, it is advisable to first prepare a drawing of the future potbelly stove, brick or cast iron, and stock up on all the necessary materials. The drawing indicates in advance the main and auxiliary parts, for example, a heat exchanger. Stoves from a barrel and a cylinder are assembled according to a similar scheme, following all stages.

A more acceptable option is to build a brick stove; a device of this type has more advantages: it cools slowly and retains heat longer. Also, brick potbelly stoves look quite neat in any room. For a collapsible or conventional stove of this type, there are two construction options; you can build it yourself using bricks according to a standard scheme, or you can line a finished potbelly stove made of metal with bricks. The choice of option depends on the situation and the amount of free time.

How to convert a potbelly stove operating on solid fuel for mining

Sometimes a potbelly stove has already been created with your own hands, but you don’t like the type of fuel it uses. Then it can be upgraded to a universal one. To create such a potbelly stove from a pipe with your own hands, drawings are not required. To do this, you need to make an additional part, similar in design to a potbelly stove in a mining garage, and attach it to the lower part.

A potbelly stove is created from a horizontally oriented pipe (bent at an angle of 90 degrees), and not strictly vertical. The pipe structure is also perforated. Then, attach it to the side of the stove, it will become the final combustion chamber.

When the owner of the potbelly stove decides to weld the stove door and creates a hole in the pipe, the potbelly stove will operate exclusively on oil.

You can make a couple of replacement doors to use both firewood and oil. The standard one is used for heating with wood, and when replacing wood with oil, a modernized one with the necessary hole is used.