Modern convection equipment running on liquefied gas fuel allows you to quickly, efficiently and economically arrange the heating of a private house or cottage. Let's look at what a gas convector using bottled gas is, how it is designed and on what principle it operates, what are its main pros and cons, what number of criteria need to be taken into account when choosing a model for specific application conditions, as well as how to correctly calculate power and fuel consumption.

Convector heater in a residential area, powered by gas Source userapi.com

Gas convector - what is it, device, principle of operation

A convector-type heating device provides effective heating of the room in which it is directly installed, due to the natural circulation forces of the air flows it heats. Heat is produced in it by a heat exchange module, which in turn is heated by the flame of a gas burner.

The hot air flow leaving the device moves upward, thereby displacing the cold atmosphere downward. The latter, in contact with the heat exchanger, heats up and is converted into rising hot flows. Thus, the cycle is repeated - as a result of which the temperature in the room quickly increases to the desired value. If the device is equipped with a fan, the redistribution of air masses will be accelerated, and the air temperature in the room will reach the set level faster.

The principle of heating a room with a gas convector Source bg.by

Principle of operation

Convectors of this type are often installed for heating in private homes or cottages, as they operate on convenient-to-use cylinders or liquefied gas and are somewhat similar to gas boilers, but have a simpler operating scheme:

- Gas from the cylinder enters the burner and is ignited by the ignition mechanism.

- The resulting flame heats the heat exchanger housing.

- A flow of cold air enters the heat exchanger, after which it heats up and leaves the device through a special compartment already heated.

- If the model is equipped with a fan, the heated air first enters its chamber, and from where it is pumped into the room under pressure.

- Fuel combustion waste leaves the device through a special hood equipped with electric motor traction, through a connection to a double-walled pipe that goes outside the house. Through it, the air necessary for the operation of the burner is drawn in.

This is the general mechanism of operation of a standard gas convector. Some additions and differences in the operating scheme may be present in different models, depending on the device, configuration and equipment.

An example of a gas convector connected to a cylinder Source teplowood.ru

Device

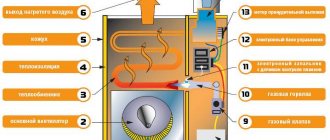

In the standard version, the convector includes the following main components:

- Frame. It contains the main elements and a protective system.

- The combustion chamber. It burns fuel.

- Gas-burner. It burns gas and heats the heat exchange circuit. Located at the bottom of the camera.

- Heat exchanger. Provides air heating.

- Exhaust system. Removes gaseous combustion products outside the room.

- Control device. Provides fuel supply, controls temperature via thermostat and sensors.

Note! Models with fans heat the room faster and more evenly. However, the presence of such an element is an additional energy consumption and a source of noise. On the other hand, thanks to the fan, overheating of the heat exchanger is prevented, which means the service life of the device increases.

The best heaters for the garage: how to choose and what they are like

There are many electrical heating devices, how to decide which option is suitable for the garage:

- a simple fan heater is a simple and cheap option to quickly warm up the garage, but such a device will not be able to maintain the air temperature;

- oil heater – uneven heating of the room, high energy consumption;

- infrared heater – low consumption of kilowatts and quick heating of a certain area. Suitable for quick engine warm-up;

- gas heaters - you must follow fire safety rules, but the option is quite economical and practical. Suitable for garages without electrical connection;

- convectors for the garage are the best choice, as they quickly warm up the entire area of the room, and the automation allows you to set the desired temperature for constant heating.

What car enthusiasts say about each of these options, and how to optimize energy costs.

Advantages and disadvantages

A convector for heating a house, running on liquefied gas from a gas cylinder, is characterized by the following set of positive qualities:

- Profitability – operation using inexpensively available natural fuel.

- Independence from external highways and gas pipelines.

- High performance.

Gas convector is more efficient compared to a conventional radiator Source alsera.ru

See also: Catalog of companies that specialize in autonomous gasification of country houses and related work

- Compact equipment.

- Easy installation.

- There is no need for coordination with project documents.

- Intake of air oxygen from outside the building, and not from inside the room.

- Versatility in the choice of fuel - the unit can operate on both propane and methane - to switch you only need to reinstall the burners.

- Large selection from a range of well-known manufacturers.

Despite the large number of advantages, convectors of this type are not without some disadvantages:

- Low efficiency for spacious rooms.

- If there is a fan, the device can produce a significant level of operating noise, which reduces the level of domestic comfort.

- To install the hood you will need to make a hole in the wall of the house.

- Installation, configuration and initial start-up of the unit requires the involvement of specialists.

Diagram of a gas convector heater Source oboiman.ru

On a note! One of the clear advantages of a convector heating device powered by a cylinder is its inertness with respect to temperature changes - the device does not deteriorate when turned off and left in cold weather - which absolutely cannot be done with any gas boiler for the home, since water is often poured into the system when when freezing, it expands and turns into ice.

Installation recommendations

It is well known that the installation of a gas convector consuming main methane must be carried out by specialists from companies that have the appropriate permits. It is worth clarifying this somewhat generalized requirement: the issue is not installation, but connection to the gas supply network. This operation can indeed be performed by the above-mentioned workers in accordance with previously completed project documentation. This means that you can put the units in place with your own hands, but without connecting to the gas pipeline.

If you nevertheless decide to take bottled gas as an energy carrier, then the situation is simpler. Connecting propane heaters does not require any permits. However, it is strongly recommended to involve a specialist in this work, at least as a consultant. It will help you check the correctness and quality of the connections and carry out the first start-up of the unit.

Before installing a gas convector, you need to make a round hole of the appropriate diameter in the wall. Next, attach the device to the wall or floor according to the operating instructions. In this case, in some heater models, the external temperature sensor with a capillary tube must be moved from the transport position to the working position. After this, all that remains is to connect the fuel supply line to the inlet pipe on the device.

Criterias of choice

When choosing a convector for specific application conditions, the following main characteristics of the equipment are primarily taken into account:

- Installation method.

- Fan.

- Combustion chamber design.

- Power and gas consumption.

- Heat exchanger material.

- Automation.

Let us consider in detail the features of each parameter.

Installation method

Modern convectors are divided into two types according to installation method:

- Wall mounted . Fixed to the surface of the main wall. They are lightweight and compact in size. The exhaust device is equipped with a rigid pipe through a hole in the wall. Maximum power – 10 kW.

Wall-mounted propane convector Source oboiman.ru

Installation Rules

Once the convector has been purchased, it can be installed. Before you do this, you will need to have a certain set of tools:

- drill;

- spatula;

- pipe cutter;

- wrenches and adjustable wrench;

- screwdrivers;

- perforator;

- gas tap;

- special silicone;

- self-tapping screws;

- dowels

It is necessary to choose a place where it will be located. It is best to do this in accordance with GOST. According to it, installation must be carried out under a window. After this, you should prepare the room. That is, the surrounding space around the installation site must be covered. The installation is done according to this algorithm.

- It is necessary to determine the hole for the gas pipe to enter. It is necessary to leave a gap for the pipe and fitting.

- We make a through hole according to the size of the exhaust pipe using a hammer drill.

- We make holes for the fasteners on which the heater will be mounted, and hammer the dowels in there.

- We connect the device to the exhaust pipe and seal the joint with special silicone.

- We fix the heater to the wall using self-tapping screws.

- We seal all holes using foam to prevent cold air from entering the room.

Video description

Video instructions for measuring gas flow with a convector:

- Cast iron. Sufficiently heat-intensive - able to retain heat for a long time after being turned off. Disadvantages: fragility, heavy weight.

- Duralumin. Strong, lightweight, durable. The downside is that it is quite expensive.

- Copper. Durable, plastic, not subject to destruction. The disadvantage is the very high cost.

A convector with a cast iron heating circuit is most optimal for domestic use. It is durable and retains heat for a long time. However, during installation and operation it is necessary to take into account its increased fragility.

Automation

Convector gas heating from bottled gas can be controlled either by a simple automation system based on a relay and thermostat, or by a more advanced software module that sets many operating parameters. The final cost of the device largely depends on the type of automatic unit used. However, the more factors are taken into account in the settings, the more economical the consumption will be and the more comfortable the living conditions will be.

What gas is used

In the original version, the convectors were designed to consume mains gas, which created a false assumption that the installation used only natural gas.

But when using special transition kits, it is very easy to convert it to liquefied fuel. Some device models are already designed for the possibility of transition.

The use of bottled gas has several nuances, including:

- It is economically inefficient to work on liquefied fuel, since the cost is equal to the price of electricity if correctly recalculated.

- There are strict requirements for the installation and operation of equipment. It is better not to deal with the installation process yourself, but to entrust the arrangement to specialists.

Briefly about the main thing

A gas convector, operating by burning natural gas from a cylinder, heats the room through natural or forced air circulation. The device includes the following main components:

- Frame.

- The combustion chamber.

- Burner.

- Heat exchanger.

- Ventilation system.

- Control block.

When choosing a gas convector for heating a private home, a number of parameters are taken into account, such as the installation method, the presence of a fan, the type of combustion chamber, power and fuel consumption, the type of material from which the heat exchange circuit is made, and the capabilities of the control system.

The main advantages of a convector running on gas from a cylinder are its economy, ease of installation and maintenance, compactness, and independence from gas mains. Disadvantages - low efficiency for spacious rooms, operating noise in fan models and the need to call a specialist for installation.

When is the heater effective?

It is imperative to ensure the garage door is sealed and insulate the floor and roof. If you carry out repairs in the garage in winter, then you can insulate the floor using foam screed or lay a board over the sheathing.

An infrared heater will help to quickly warm up the garage and car, rather than maintaining the temperature; it heats locally.

Prices: summary table

| Model | View | Available nominal powers, W | Input voltage range, V | price, rub. |

| CyberPower SMP550EI | Off-line | 200, 300, 375 | Advanced: 100-280 Normal: 190-260 | 6 900-7 900 |

| Exmork NB-Y300W LCD DC12V | Line-interactive | 300, 600, 800, 1000 | 140-280 | 6 100-6 500 |

| POWERMAN ONLINE 1000 | On-Line | 900, 1800, 2700 | 115-295 | 15 900-17 500 |

| SibKontakt IS2-12-300 | Off-line | 300 | 220-300 | 3 900-5 000 |

BoilersEquipment for boiler room

Hosseven HP-8

It is characterized by a very high efficiency, which for this convector is 90%.

This quality ensures minimal heat loss and accelerated heating of the room. The product has a unique design that transfers heat directly into the air rather than onto the coolant. The temperature range is from 13 to 38 degrees. The device has a very accurate thermostat. It comes complete with a special adapter for connecting to cylinders, so the device is often purchased by residents of non-gas supply areas and owners of country houses. There is a chamber installed here that ensures a closed combustion cycle; there is a coaxial chimney, so all exhaust gases will go outside. The design has compact overall dimensions and a stylish appearance.

Advantages:

- The dimensions of the case allow the heater to be installed even in a small room;

- There is everything you need for comfortable use;

- Very high efficiency;

- Chamber with a closed fuel combustion cycle.

Flaws:

- Quite expensive.

Karma BETA 2 Comfort 02

If necessary, this device can be easily integrated into a smart home system.

The design includes an electronic thermostat, thanks to which the temperature is maintained with an accuracy of one tenth of a degree. The creators tried to give this device maximum resemblance to a real fireplace. In particular, they equipped it with a window made of heat-resistant glass through which the flames can be observed. The power of the device is only 2 kW, however, this indicator is quite enough for high-quality heating of a room up to 40 square meters. m. The convector is very technologically advanced, equipped with a GSM module. Through it, up to three similar devices can be connected to one thermostat. The design does not have an igniter, which makes it possible to reduce the amount of fuel consumed by approximately 30% when comparing the products with standard mechanical devices.

Advantages:

- Low consumption of natural gas;

- Stylish appearance;

- High quality assembly and workmanship;

- Able to fit into any interior of the room;

- Long period of operation.

Flaws:

- A power of 2 kW is not enough for all consumers.

Timberk TGH 4200 M1

- Characteristics

- Average price: 5,890 rub.

- Country: China

- Power: 4.2 kW

- Heating area: 20 – 60 sq. m.

- Gas consumption: 0.31 kg/hour

- Heat exchanger: no

- Chimney diameter: no

- Ignition: piezo

Timberk TGH 4200 M1 has a strict classic design and mobile design. Powered by bottled gas. The heater has three power levels and is suitable for heating rooms with an area of 20 to 60 sq.m. According to customer reviews, the device heats up quickly and heats economically: the bottle lasts for about 50 hours of continuous operation at maximum power. The convector is equipped with a fuse for insufficient oxygen levels in the air, and in the absence of a flame, the gas supply automatically stops, which makes the model safe to use. But for some reason the manufacturer did not take care of the shutdown button - you can turn off the convector only by turning off the gas.

Termotechnik AKOG-4

This device is ideal for a garage or country house.

The design is distinguished by the most accurate factory settings and compact overall dimensions. It is very easy to install, and it practically does not require any additional wiring. Such a convector is often installed even in industrial or industrial premises, the area of which does not exceed 40 square meters. m. The heater is absolutely independent of water and gas supply, since, if necessary, it can be connected to an ordinary gas cylinder - this is quite convenient, because centralized gas is not found everywhere. Combustion products will not penetrate into the room, which makes the device absolutely safe. Maintains the set temperature independently. The device's gas consumption is low, and the convector itself can last for quite a long time.

Advantages:

- It is a completely autonomous heating device;

- Lightweight and very compact device;

- Low fuel consumption;

- Operational safety.

Flaws:

- Some users feel that the control buttons are not very convenient;

- The convector is sensitive to changes in gas pressure.