Booster Summary

This is very rare and expensive equipment. If you intend to buy it, then you will expect expenses in the range of 40,000 - 90,000 rubles. And for everyday tasks this is a rather unprofitable solution.

The booster itself is a container with a built-in pump that provides a change in the flow vector. Because of this, the efficiency of washing increases significantly. The devices are resistant to any reagents.

The most popular models are presented below:

| Booster | A country | Productivity (liters per hour) | Tank volume (l) | Working pressure (bar) | Price tag (RUB) |

| PIPAL PUMP ELIMINATE 20 V4V | Italy | 2600 | 18 | 1 | 38 000 |

| BWT Cillit SEK 28 | Germany | 2400 | 20 | 1,5 | 57 000 |

| TM Aquamax | Italy | 5000 | 30 | 1,2 | 53 500 |

Other nuances for old slabs

When trading in an old stove, you need to know what is valuable about an old gas stove and what parts are not valued. For example, experts do not evaluate any wires, windings and other components that are not used for processing.

How much non-ferrous metal is in a gas stove? Typically, cheap ferrous metals are used to manufacture such devices. Therefore, you can’t count on high prices. The percentage of non-ferrous metals is minimal. In rare cases, they can be discovered during disassembly.

Thus, if you want to earn extra money by selling non-ferrous metals and are puzzled whether there is non-ferrous metal in the gas stove, then this is not the best solution. You're better off looking for objects with a high content of such metals.

How much copper is in an old gas stove? It's no secret that you can make a good profit by selling copper. Especially in villages, significant masses surrender. And often the owners decide whether there is copper in the gas stove and how much cash advance businesses can it contain? In this regard, the answer is negative. And it doesn’t matter what brand of stove.

Often, users of the Idel stove are dissatisfied with its functionality.

This is far from the best model. This is a modest version with limited functions and frequent breakdowns. Even summer residents are increasingly abandoning it. And the fixed annuity interest rate raises a logical question: how much copper is in the Idel gas stove and what is the most profitable way to sell it? In this regard, the stove is also disappointing. It is modest in size, assembled from ferrous metal. You won't get much for it. At best, 3000-5000 rubles.

But in the old Soviet gas financial assistance grants columns and boilers, the situation with copper is much better. For example, in the old column there is a copper radiator. Its weight is 7 kg. The average price of 1 kg of copper is 145 rubles. That is, upon passing this component you can get 1015 rubles.

Classification, principle of operation

There are two media in a gas boiler - gas and liquid. To transfer the air temperature obtained during gas combustion to the coolant, a heat exchanger is used. There are:

- primary;

- secondary;

- biothermal (combined).

Primary

Primary - heat exchangers that receive heat from a source. Included in the heating circuit. They are located in the boiler above the gas nozzles (a coil covered with plates). The coolant, usually water, passes through the tubes. Hot gases passing through plates and tubes heat the water. It is driven through the pump and goes into the heating. Gases are removed through the chimney.

Primary maintenance

Secondary

Secondary heat exchangers receive heat from the heated coolant. They are located outside the combustion chamber. Heating comes from the liquid. The simplest and most commonly used method is to use a plate heat exchanger. The sealed housing is divided into two parts by a thin partition. Heated liquid flows on one side of the partition, and water takes up heat on the other.

Sectional view of secondary plate heat exchanger

There is another way. A coil passes through a large container filled with water. A heated coolant passes through it, giving off heat to the surrounding fluid.

Combined (biothermal)

Installed inside the firebox. Has four pipes. One pair is connected to the heating circuit, the other to the DHW (hot water supply).

Biothermal heat exchanger

The difference is within the design. The heating circuit is heated by hot gases, the hot water supply circuit is heated by the heating gas. Inside the coil tubes there are tubes of smaller diameter. They are fastened with plates located at an angle of 120 or 90⁰.

Cut tubes, slots for contours

During operation of the boiler, the liquid in the primary circuit (heating) heats up and goes into the system. Previously, part of the heat is transferred to the tubes of the second DHW circuit, where the coolant is also heated.

Differences between a biothermal circuit and one with two separate heat exchangers

When water is drawn from the second circuit, the first circuit is closed so that the heat received from the boiler is transferred to the hot water supply. When the collection of water from the hot water supply stops, the first circuit is connected and the heating starts working.

Schemes in two modes

Circular pump factor

Don't forget about the circulation pump factor. More precisely about the final brand that produces these pumps. For European boilers, everything is quite simple: most often they install Grundfos and Wilo brand pumps into their boilers. Other manufacturers equip gas boilers with incomprehensible pumps. And there are such pumps in gas boilers that are quite good, but there are others that are not so good. Grundfos have proven themselves well; their pumps are very durable. A Grundfos brand pump is an indicator of a good quality gas boiler boiler. If you see a pump of an unknown brand in a boiler, it is worth considering whether you need such a boiler, but again you need to take into account the other factors that we are talking about.

The Italtherm City Class boiler uses a hydraulic group with a Grundfos pump

Malfunctions and repairs

Let's look at what malfunctions are typical for heat exchangers of gas boilers, and also figure out how to fix them yourself:

- A crack may appear on the heat exchanger. You can solder it yourself. Solder must be selected depending on the material from which the part is made.

- When the TO burns out, it can be “glued” with a copper or tin patch. Less commonly, people use can lids and other homemade items. The patches are secured using a riveter.

- If the unit is leaking, you can turn to cold welding to repair the damage.

- The unit must be periodically descaled so as not to cause problems with the operation of the unit. A hydrochemical cleaning method, manual or chemical, is used. The heat exchanger will need to be removed from the equipment before cleaning.

- To completely replace the heat exchanger, it is recommended to contact experienced specialists.

For a video review of a boiler with a cast iron heat exchanger, see the video below.

Branding is an important point

Look at the specific branding of the boiler itself. It is a rare manufacturer that makes a specific product from scratch to the final result. Usually he orders some specific parts from outside. So, almost always wall-mounted gas boilers are made entirely from some third-party components. Then the manufacturer himself assembles everything into a single design at his factory, finalizes the software, arranges everything as needed and releases everything in a beautiful form. A good manufacturer will always show what his gas boiler is made of. He can write about this in his brochures, sketch out what the boiler is made of, but sometimes he remains silent. But in this case, looking into the boiler, you will definitely see what the boiler is made of, everything will be written on every detail. If you see a branded wall-mounted gas boiler, you can consider purchasing it. This is a good option for your home. If you look into the boiler and do not understand what it is made of, the manufacturer is trying to hide what parts are used. In such cases, simply write the part marking, production date and serial number. It is better not to buy such gas boilers. If the boiler is made of good parts, the manufacturer will always want to say so.

Branding example. The fan has a label from the Polish manufacturer Fime.

These five points should help you choose a gas boiler that will delight you in your home for many years, will not create problems and will last long enough.

Source

Which material is better

Boiler heat exchangers are made of different metals, the selection of which is made by the manufacturer during the design of the heating source.

Basically, modern devices are equipped with heat exchangers made of steel, cast iron, copper and aluminum. They have different heat transfer coefficients, permissible temperature environments and resistance to corrosion processes. A floor-standing gas boiler with a cast iron heat exchanger is the most economical and durable.

Steel

A stainless steel heating apparatus is technologically the simplest, both in manufacture and in operation. Therefore, it has the most affordable price, which affects the overall cost of the boiler.

Steel has good ductility, so this design in an environment of high-temperature hot gases is less susceptible to temperature deformation.

Aluminum

Many Western models are equipped with aluminum heat exchangers, to which experts attribute a great future in household heat and power engineering.

With high ductility, they have thermal conductivity 9 times higher than that of steel. In addition, they have high functionality with low weight.

In such structures, stress zones are not created during a welded joint, like stainless steel devices, and, therefore, there will be no corrosive hazardous areas.

Aluminum components are characterized by strong chemical resistance, which is used in low temperature applications or condensing type boilers.

However, aluminum structures will last less if they use hard tap water; they become clogged with scale almost immediately.

Copper

Copper surfaces in boiler heat exchange devices are compact and lightweight, so they are installed on a Navien gas boiler.

Copper is essentially non-corrosive in aggressive acidic environments. Boiler units with similar devices are compact and easy to use. Due to their low inertia, copper devices quickly heat up and cool down.

Copper heat exchangers have more advantages than negative qualities. The copper structure is lightweight, compact, and has a small capacity.

It is not afraid of corrosion processes and requires less gas consumption to heat the coolant. Disadvantages include high cost and unreliability under non-standard cold start-up conditions.

Gas boilers with cast iron heat exchanger

A cast iron boiler heat exchanger is considered the most efficient and durable because it is not subject to corrosion. Moreover, since the material is very fragile, it requires proper use.

Uneven heating of the structure, which occurs at the time of start-up from a cold state or in places of scale formation, leads to the appearance of various cracks in the walls of the structure.

Users of such a device will need to monitor the quality of the feed water, install a cleaning system, and if scale appears for gas boilers with a cast iron heat exchanger, flush the heat exchanger.

Usually it is performed once a year before the start of the heating season. If the feed water is pre-cleaned before being supplied to the boiler, then the flushing frequency is once every 4 years.

Heating devices made of steel and copper alloys

Since mass production of household appliances is focused on the production of heat exchangers made of ferrous metal, gas boilers with a copper heat exchanger are considered a prestigious product. Copper has high heat transfer characteristics. Therefore, to heat a large house, you can use small boilers with a small amount of coolant. As a result, the devices are very compact.

Important! Buyers are often interested in which heat exchanger to choose – steel or copper. It is necessary to proceed from the physical and chemical properties of ferrous and non-ferrous metals. The specific heat capacity of copper is lower than that of steel.

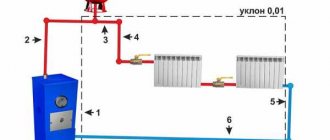

That is, to heat an equal amount of a substance, copper needs to transfer less heat than steel. Accordingly, the inertia of the heating system, where there is a steel heat transfer unit, is greater. The boiler automation, working with a copper heat transfer block, responds faster to an increase in coolant temperature. This ultimately leads to fuel savings. An even greater reaction of the heating system to heating occurs when the pump is running. In addition, it ensures improved circulation even with broken pipe slopes and prevents water from boiling.

Comparing copper heat exchangers for boilers with steel ones, we can say that the latter are more ductile. This factor is important because there is a constant process of interaction with open fire. As a result, thermal stresses in the metal develop and cracks appear. Steel is more durable in this regard and can withstand a large number of cycles: heating - cooling.

The note! The disadvantages of steel, in addition to inertia and increased specific heat capacity, include: • susceptibility to corrosion; • increased volume of the heater surface; • large amount of coolant; • a significant mass of heating devices.

Steel gas boilers weigh from 70 kg and above. The greater the power, the larger the dimensions. A very important parameter of the boiler is the thickness of the metal wall.

The manufacture of copper heat exchangers compared to steel ones is advantageous even from the point of view of their maintenance. The roughness coefficient of copper is 130 times less than that of steel. Due to this, the hydrodynamic resistance of copper products when liquid moves through them reduces the degree of contamination and scale formation.

Important! Today, manufacturers save on metal and reduce the thickness to the limit. This increases the likelihood of rapid burnout. Therefore, when purchasing, you need to focus on the wall thickness of the heater being at least 3 mm.

Types of secondary heat exchangers

When choosing a double-circuit gas boiler, it is important to pay attention to the design features of the circuits. They are divided into two types:

- lamellar;

- shell-and-tube.

Plate and shell-and-tube types are used for separate heat exchanger designs.

In addition to the separate one, there is a bithermic heat exchanger, which implies a combined arrangement of water and heating circuits.

Lamellar circuits

A plate heat exchanger consists of several metal plates with extruded passages. They are assembled in mirror image to create isolated channels for fluid movement. The plates are produced by stamping sheet metal 1 mm thick. Channels are usually equilateral triangles with angles of different sizes. The sharper the angle, the faster the water moves. The dumber it is, the slower the circulation.

According to the flow pattern of the media, the plates are multi-pass and single-pass. In the first option, the coolant can change direction several times, which allows for a fairly high efficiency. In the second case, the direction of movement of liquids does not change.

According to the connection method, plate heat exchangers are either collapsible or soldered. The dismountable plate contours are combined using elastic rubber gaskets. To ensure the tightness of the channels, it is necessary to tighten them with metal ties. The design includes two massive plates - fixed and movable. The first one has rods on which the plates are threaded. The more there are, the more heat is generated. The movable plate is installed last. Place nuts on the ties and tighten until tight. The advantage of collapsible plate circuits is that they can be disassembled, cleaned or removed unnecessary elements. The disadvantage is its heavy weight and size.

Brazed heat exchangers are welded from plates in an argon atmosphere - this avoids corrosion in the welding areas. These circuits cannot be disassembled, so they are more difficult to clean than dismountable ones. Their advantage is their more compact size and relatively light weight.

Shell and tube

Shell and tube circuits are simpler in design, but less efficient, so they are made in larger sizes. Due to the significant consumption of materials, household gas boilers are equipped with such heat exchangers less and less often. But the design of shell-and-tube circuits is more reliable and can withstand severe loads during operation. Therefore, they are mainly equipped with industrial units.

These heat exchangers are a pipe in which many small tubes are laid. Heated water moves through them, which is then supplied to the taps.

Note! The efficiency of shell-and-tube heat exchangers is lower than that of plate analogues

Bithermic heat exchangers

Bithermic circuits consist of two pipes inserted into one another: hot water flows through the internal heat exchanger, and the heating system coolant flows through the external heat exchanger. Gas boilers with such a circuit design are more efficient; hot water in them heats up faster than in conventional analogues. However, bithermic heat exchangers also have disadvantages: they become clogged with salt deposits more quickly, which leads to their rapid failure. Therefore, if the choice fell on a unit equipped with a combined circuit, then you need to install a filter at the cold water inlet that will trap all salts and dirt. Otherwise, the heat exchanger will quickly become clogged with sediment and fail. It will not be possible to clean it as a separate circuit. You will have to buy a new bithermic heat exchanger, which is quite expensive.

Specifics of scrapping slabs

This method is most beneficial for those owners who can independently deliver the slabs to the collection point for metal products. At the same time, you can grab other metal debris (if any).

If you do not have your own transport, you can contact a company that removes scrap metal and pays for it. It is better to find a company with the most favorable financial conditions. As a rule, you pay for the product minus fees for the services of field specialists.

To successfully pull this off, you need to:

They come and take the device. They can dismantle it themselves. The owner receives money for such change.

There are some subtleties here too. When registering, you must correctly fill out the necessary documents. The client must prove his identity with a passport or other suitable document.

Specialists will inspect and check the slab and the type of metal using special equipment. They weigh her. The possible presence of hazardous impurities and other elements is detected. Based on the checks, the final price is formed.

The client receives payment directly on the day of delivery.

How much does it cost to sell a gas stove for scrap? Here a lot depends on its weight and content. For example, the standard weight of a small stove is 50 kg. Prices vary in different cities and companies. Usually this range is 3000 – 9000 rubles.

The price of a gas stove for scrap metal can be much less. Especially if it is a modest model in terms of weight and content.

Boilers with bithermic heat exchangers

The use of bithermal radiators in boiler systems is becoming increasingly widespread. Often, large manufacturers themselves develop model designs using their own components, including heat exchangers. One of the leaders in the segment is Immergas, which offers boilers with heat exchangers with 6 tubes. This design offers an advantage over 4 and 5 tube heat exchangers, since the expanded section can be located close to the burner flame. However, it is necessary to take into account the thermal power that will be provided by the 6-tube heat exchanger of the boiler. The bithermal operating principle in this case is capable of producing about 24 kW and this may be excessive for private houses and large country cottages. The companies Vaillant, Navien, and Protherm are also developing bithermal units. The products of these manufacturers are distinguished not only by their modern design, but also by their functionality. Engineers strive to provide models with the ability to smoothly adjust the flame, the option of cooling the heat exchanger, etc.

How much copper is in an old gas water heater?

Yes, it seems to me, and as far as I remember, the cat cried there. From personal experience, our old speaker burned down and we wanted to throw it in the trash, but then I decided to take it apart. In general, they didn’t accept the aluminum from there; the copper came out to about two kg

No specific marking is indicated, but one can speculate - copper is expensive nowadays, so why throw away something that could very well bring in money. There are different columns, but there are also those in which the radiator was made of copper (sometimes there is copper in the burners and there is also a reducer, which is brass) and its weight can reach up to 6 kilograms, in ordinary household ones - 4-5 (on average) kilogram. The “younger” the column is by date of issue, the less valuable the amount of such valuable metal in it is; it may turn out to be only a couple of kilograms or even less. So it’s better to look for the column markings on the Internet and find out how much there is. Otherwise, the result of the effort put into it may not be worth it.

Actually about 5 kg.

So drag and grab something valuable along the way

Copper is an extremely useful metal in Fallout 4 , which can be useful in making electrical appliances. Pay attention to the “junk”, among which you can find old household appliances and electrical appliances. Carefully walk around abandoned houses, in which you can find many things, disassembling which you will get copper.

Copper can be found in tiles and magnets, in telephones and fuses, as well as in power relay coils and magnifying glasses. The source of copper can be a shadowless lamp and a yellow table lamp, a vacuum lamp and various light bulbs, including broken ones. The Bunsen burner, sensor module and black box can all be used to mine copper.

Although the easiest way is to use the copper cheat code: 0006907C .

For copper plating of various parts at home, you can use the following technology:

Prepare electorolite with the following composition

Copper sulfate (copper sulfate) - 180-220 g/l

Sulfuric acid -40-60 g/l

The operating temperature of the electrolyte during copper plating is 18-25 degrees.

Pour electrolyte into a glass container.

Hang two copper plates (anode) in a container on copper wires.

Thoroughly clean the part intended for copper plating from oxides, degrease and hang it between copper plates. Assemble the electrical circuit shown below.

Connect the plus to the copper plates and the minus to the part. You can use a car battery as a power source. The current should be 1-4 A/dm kV during copper plating

In folk medicine, “medicinal coppers” have been used for a long time. Believe it or not. But it has been absolutely scientifically proven that a lack of copper in the body causes headaches and fatigue. Probably copper (in microdoses) has a positive effect on the state of the nervous system. That is why “coppers” began to be used in folk medicine. For example, for osteochondrosis (pain in the spine), coins are placed along the entire spine (from neck to tailbone); some claim that such a “procedure” helps relieve pain.

At first, copper coins of Russia were used until 1917, but it turned out that coins made of pure copper had too many side effects (pure copper oxidizes quickly and these brown or green oxides are by no means so useful). Through trial and error, we came to the following conclusion: it is better to use 5 and 3 kopeck coins of the USSR up to and including 1957. They were minted from aluminum bronze (and bronze is an alloy of copper and tin), these coins are “long-lasting” and practically do not oxidize.

Naturally, coins for treatment must be prepared: washed in vinegar (table), then in soda or saline solution. For varicose veins of the legs, first make “honey compresses” (at night), and during the day several coins are placed on the varicose nodes. If tests show that there is a copper deficiency in the body, then simply place 5-7 coins on the dry skin of the hands or feet for a while (“sick people” assure that the body itself takes everything it needs, and at the end of the procedure - coins they just fall off on their own). The body is “fed” in this way for about a week.

Thermal conductivity of substances has several mechanisms.

- The first mechanism is the transfer of heat by changing the energy of vibrations of the molecules and atoms of the substance itself - the so-called. "thermal fluctuations"

- The second mechanism is heat transfer by free carriers - conduction electrons.

There are also convection mechanisms, if the substance is in the liquid or gaseous phase, they improve heat transfer..

Metals have the maximum thermal conductivity known now.. It is those same conduction electrons that are actually common to the entire body that determine high conductivity for electric current, and they also determine high thermal conductivity.. The explanation for this is that electrons have little inertia, are not connected in a lattice and can have large kinetic energy and can easily transfer it to the lattice.. But this is a very simplified explanation, the exact explanation is within the framework of solid state theory, and it is associated with quantum processes, which are quite difficult to understand, here the concept of a quantum of thermal vibrations of the lattice is introduced - phonon ..

Purpose

Heat exchanger is a device for transferring heat from one medium to another. Cold transfer is not possible. Even in a refrigerator, the heat exchanger takes away excess heat rather than transferring cold. The coldest substance is warmer than absolute zero. Transmission occurs through insulating material. Rules:

- The insulating material must be a thermal conductor.

- It should not allow one medium to pass into another, otherwise mixing will occur.

To increase the effectiveness of the first condition, the surface area is increased. For example, soldering plates perpendicular to the tubes. They try to make the walls of the insulating material thinner. Limits the pressure of the environment. The heat exchanger material affects heat transfer.

How much copper is in a geyser

Homo Immortalis

Group: Members Messages: 10289 Registration: 4/21/2004 From: V.Novgorod User No.: 746 Thanks said: 94

There is a heat exchanger from an old Russian gas water heater. Can you tell me where I can donate it and approximately how much they will give for it?

Maybe someone would like to pick it up and sell it at a higher price?

Post edited by ALX

— 26.1.2009, 14:11

Ambassadorial order I

Group: Members Messages: 1871 Registration: 9.2.2007 From: Novgorod the Great User No.: 26790 Thanks said: 2

90-90-16

Group: Members Messages: 13495 Registration: 1/16/2005 From: V. Novgorod User No.: 4121 Thanks said: 248

Ambassadorial order I

Group: Members Messages: 1871 Registration: 9.2.2007 From: Novgorod the Great User No.: 26790 Thanks said: 2

Homo Neanderthalensis

Group: Members Messages: 805 Registration: 2.9.2007 User No.: 32907 Thanks said: 4

Homo sapiens

Group: Members Messages: 1311 Registration: 1.11.2008 From: G.V.N.=) User No.: 50741 Thanks said: 1

Homo Immortalis

Group: Members Messages: 10289 Registration: 4/21/2004 From: V.Novgorod User No.: 746 Thanks said: 94

Is 50r cheap? That is, it’s better to let it lie around until the copper gets expensive? As far as I remember, 2 years ago an acquaintance rented out an exchanger for 800 rubles.

Ambassadorial order I

Group: Members Messages: 1871 Registration: 9.2.2007 From: Novgorod the Great User No.: 26790 Thanks said: 2

How to clean the heat exchanger of a gas boiler

To clean the heat exchanger from scale, mechanical, chemical and magnetic cleaning methods are used. The first option is performed using a cleaning rod and scraper.

Tools can be manual or electric. The chemical option involves the use of crustacean chemicals that can loosen and dissolve contaminants.

Algorithm for cleaning the heat exchanger from scale:

- Turn off the boiler.

- Prepare liquid for flushing heat exchangers of gas boilers according to the manufacturer’s recipe.

- After complete cooling, utility networks are disconnected from it and the water is drained.

- Remove the tie rods, move the pressure plate aside and then carefully remove each plate one by one. The work is carried out with gloves so as not to injure your hands.

- When working with acid, change gloves to rubber ones.

- Prepare a container for cleaning the plates so that they are completely covered with the working solution.

- The plates are immersed in the composition for 1 hour, after which the remaining deposits are removed under tap water using a brush.

- Assembly of the cleaned structure is carried out in the reverse order.

After washing the heat exchanger, check the tightness of the boiler under the operating pressure of the coolant. All utilities, gas and electricity are connected and the equipment is started for the first time after flushing.

If a leak is detected, it is necessary to tighten the nuts or install a new gasket on the heat exchanger.

Question about electric stove

Is there copper in an electric stove? This is a very pressing question for the owners of such devices in situations where they are deciding how best to hand over an electric stove that is no longer needed.

As a rule, the wires of such plates contain copper conductors. Such core material is required according to payday loans gallatin tn PUE criteria. Depending on the number of cores and their thickness, the potential benefit of delivering these products is determined. But this is still a very small benefit.

How much copper is in the electric stove itself? Not much either. It may be present in modest proportions in heating components. There may also be tungsten in there. The type of electric stove also matters. For example, small two-burner models may rarely have copper heaters.

Wall-mounted boilers with bithermic heat exchanger

Let's figure out what a bithermic heat exchanger is. From its name it is clear that we are talking about performing two different tasks inside one structure (this is heating water for heating and hot water supply).

This simple design allows you to use the internal area for hot water supply, and the external space for heating. Also, for better heat transfer, the outer pipe is equipped with plates that provide the greatest contact with combustion products.

Operating principle

- The plates heat up as a result of fuel combustion and transfer heat to the coolant circulating inside the heating circuit. If hot water is not used for domestic needs, then the DHW circuit is closed.

- When you open a hot water tap, the heating circuit is blocked and the DHW circuit opens, as a result of which the coolant moving through the inner tube is heated. As soon as the hot water tap is closed, the DHW circuit will automatically close and the movement of coolant in the heating circuit will resume.

In other words, only one of the two circuits is always working, while the DHW water receives heat from the already heated water from the heating circuit. It is believed that boilers with bithermic heat exchangers are 15% cheaper than using separate heat exchangers. But in this case, the efficiency is slightly less (by about 2%).

Advantages of boilers with bithermic heat exchangers

- A simple design that does not require the installation of a three-way valve, which quite often breaks and needs to be replaced.

- Such boilers have more compact dimensions, since no additional space is required inside the housing to accommodate a second heat exchanger.

- Hot water flows immediately from the tap when opened, unlike using boilers with separate heat exchangers.

- Due to their simpler configuration, many models are cheaper than boilers with an additional heat exchanger.

Some people mistakenly believe that the water from the DHW circuit, located in the inner tube of the heat exchanger, still takes a significant part of the heat when only heating is required, and reduces the overall efficiency of the boiler. Practice shows that this is not the case, and there is no cause for concern.

Flaws

- Possibility of getting burned while taking a shower. When using a boiler with a bithermal heat exchanger, you need to be more attentive to the temperature of the hot water, especially if there are children in the house. This problem is most pressing when there is severe frost outside and the heating is working at full capacity. After turning on the hot tap, it is better to wait a little while the very hot water drains.

- The duration of operation of the boiler in DHW mode has some limitations. This point needs to be clarified by specialists who are well acquainted with the boiler model you are purchasing with a bithermal heat exchanger.

- It is undesirable to use a coolant with a high content of impurities, as this will lead to the formation of scale on the inner walls of the heat exchanger tubes. If the water you use is too hard, it will need to be softened, which is an additional cost. In our practice, there are cases where the owners of such boilers did not monitor the quality of water in the heating system, and the heat exchanger failed during severe frosts. You understand what serious problems this causes.

- Difficult maintenance. Bithermic heat exchangers are difficult to clean, even if this procedure is entrusted to professionals.

- Due to clogging of the heat exchanger, the efficiency of the boiler decreases every year.

Sooner or later there comes a time when the bithermal heat exchanger will have to be replaced. Costs can reach 30-40% of the cost of the boiler. Agree that these are quite large expenses. However, payment for work is not taken into account here.

Without any exaggeration, we can say that bithermic heat exchangers are disposable, since their cleaning does not give much results due to their specific design.

We can only recommend using such boilers in combination with special cleaning systems that reduce the amount of salts in the coolant.

An example of a boiler with a bithermal heat exchanger is the wall-mounted boiler Baxi Eco Four 24. It has compact dimensions (400x730x299 mm), relatively light weight (29 kg) and is recommended for installation in houses with an area of up to 240 m2.

Criterias of choice

The first difference between gas boilers is that, as a complete review of gas heating boilers shows, there are boilers with an open combustion chamber, and others with a closed combustion chamber. In boilers with an open combustion chamber, combustion products are thrown into the chimney due to the draft that is present in it. Oxygen, without which the combustion process is impossible, is taken from the room in which the boiler is located. Before choosing a gas heating boiler, you should consider that a boiler with an open chamber can only be installed in a room where there is good ventilation.

Gas heating boilers for apartments with a closed combustion chamber take in air through a coaxial chimney. Combustion products are also released through this chimney. Such a chimney is laid from the boiler to the street through the wall.

The coaxial chimney is a “pipe-in-pipe” type structure. Fresh air enters through the outer chimney pipe, and exhaust gases are discharged through the inner pipe. When choosing a gas heating boiler, you should know that in the case of boilers with a closed combustion chamber, air comes from the street, so such a boiler can be installed even in an unventilated room.

Coaxial chimney

Based on such criteria as exhaust gas removal, models of gas heating boilers can be divided into the following types: parapet, chimney and turbocharged.

- A parapet boiler is a unit with a closed combustion chamber in which exhaust gases are released naturally.

- A chimney boiler is a unit with an open combustion chamber.

- A turbocharged boiler is a boiler with a closed combustion chamber.

The release of exhaust gases in such boilers occurs forcibly. To exhaust exhaust gases, turbocharged gas heating boilers are equipped with a built-in fan.

Monothermic or bithermic

When the boiler is capable of operating only in heating mode, it is called single-circuit. But many modern models are also capable of operating in hot water supply (DHW) mode. Such boilers are called double-circuit boilers. Water can be heated in two ways: using a plate heat exchanger or bithermic.

The plate heat exchanger is installed separately from the main one and consists of two parts. When heating water passes through one part, it heats the second, which is connected to the water supply. This is a separate, more practical and reliable, but more expensive and less compact method.

The bithermal heat exchanger cannot be cleaned mechanically and is quite difficult to rinse. When scale forms, it clogs faster.

In order to save money and space, dual or bithermal heat exchangers were invented. Their operating principle is completely different. Structurally, this is one piece: a heat exchanger in a heat exchanger or a pipe in a pipe. Heating is usually carried out outside, and a hot water supply circuit is located inside.

Unfortunately, due to their design, bithermal heat exchangers have narrow passages that can quickly become clogged. But cleaning doesn’t always help, and it’s not so easy to do. The price of such heat exchangers is much higher. And you will still have to use water for a limited time, since there is a risk of burning through the metal. I believe that it is better to buy boilers with separate heat exchangers. They are more reliable.

Heat exchanger of a gas boiler in section. The use of contaminated coolant and lack of regular cleaning led to serious consequences: serious overheating and almost complete clogging.

Conclusion

People buy a boiler for more than one year. In the worst case, it should last several years

And since the heat exchanger is an important part of any boiler, its selection must be approached carefully. It is also worth remembering that this is one of the most expensive and difficult to replace spare parts.

It is better to monitor the correct operation of the equipment and service it annually than to pay extra money for repairs later.

The key point is the inside of the boiler

So, let's simulate the following situation. You wanted to buy a good wall-mounted gas boiler in a certain price segment. You have selected several key models for yourself, and now all that remains is to choose one, that very only model that will stand in your home and will not cause any trouble. Naturally, you want a boiler that is reliable and will serve for many years. To understand which heating boiler you should buy, you need to look into its insides. Remember, never choose a boiler based on its external characteristics. Almost all boilers are “freaks”. Rarely does a manufacturer manage to create an aesthetic model. Basically, these are unified devices that are no different from each other. And if you see a beautiful model, perhaps they are trying to show off your eyes. Remember: appearance is the last thing you need to pay attention to when choosing a good gas boiler for a private home. Its main function is high-quality heating of the home.

Gas boiler heat exchanger material: which is better

It surprises me when people don’t think about the material from which the heat exchanger in the boiler is made. After all, this is one of the most important elements of heating equipment. The efficiency, heating rate and, most importantly, service life depend on the material. In addition, they may contain a second circuit. So that you understand which heat exchanger is better, I want to talk about the advantages and disadvantages of each of them.

The first cast iron heat exchangers

Almost eternal, corrosion and scale resistant cast iron heat exchanger.

It was cast iron that was used to create the first coal and gas boilers. This is due to its anti-corrosion properties and service life of 30 to 50 years. And in general, cast iron has little effect on any chemicals. But as for the heat capacity, it is one of the highest. Therefore, even now, when many other types have appeared, cast iron heat exchangers continue to be in demand. They take longer to heat up, but also retain heat much longer after heating stops.

Unfortunately, they have more disadvantages. Firstly, it is huge weight and dimensions. Boilers with cast iron heat exchangers take up a lot of space, and it is not at all possible to hang them on the wall. Only the floor installation method, massive powerful boilers are demanding on the floor covering (their weight often exceeds 300-400 kg).

Secondly, they do not tolerate sudden temperature changes. But in heating, the return is always colder than the supply. Thirdly, in order to protect cast iron from these changes, they began to use special burners. And then heat capacity ceased to be an advantage. Therefore, in fact, the only advantage is a long service life.

Steel

To get rid of the disadvantages of cast iron, they began to use steel heat exchangers. They are lighter, the equipment takes up less space, and the price is much lower. In addition, steel heat exchangers are not so afraid of temperature changes, so they are very suitable as a heating element. And if they break, they can be repaired. Of course, not all models, but many.

Why then do cast iron heat exchangers continue to be used if steel ones have so many advantages? The fact is that not everything is so smooth. After all, steel is susceptible to corrosion, and this is a huge disadvantage. Therefore, the service life is 2-3 times less, usually from 12 to 15 years

I would also like to draw your attention to the fact that steel can burn out. If you decide to choose a boiler with a heat exchanger made of this material, I advise you to find out in advance about the wall thickness

It should be 3 mm or more. Or better yet, 5 mm.

Copper

The best metal in terms of heat transfer characteristics is copper. Perhaps, we can name only one disadvantage of copper heat exchangers. This is their high price; copper heat exchangers are usually installed on models in the mid-price segment and above (from 45-50 thousand rubles). But there are a lot of advantages:

- compact dimensions;

- light weight;

- high efficiency;

- copper is practically resistant to corrosion;

- heats up and cools down quickly;

By the way, it is precisely because of the rapid heating that much less gas is wasted, so savings can be considered another advantage. As for the service life, manufacturers usually indicate 14-17 years, which corresponds to reality. This is slightly more than steel, but still much less than cast iron. But during this time you will be able to save much more on fuel.

Aluminum

Aluminum is also used as a material for the heat exchanger of a gas boiler. It was first used in condensation models, but I will talk about them a little later. Aluminum heat exchangers are also installed in conventional convection boilers. It would seem, why are they needed if copper copes well with its tasks? It's all about the price. To reduce the cost of production, in copper heat exchangers they try to reduce the wall thickness. There is no need to do this with aluminum. It is already several times cheaper than copper, and its heat transfer properties are also quite high.

It turns out that the aluminum heat exchanger is thicker than the copper one. And this is its huge advantage, because the service life increases. Practice has shown that aluminum is also less susceptible to oxidation. But on the Internet, opinions on this matter differ. Therefore, it is difficult to say exactly which heat exchanger is better.

Installation of floor-standing boilers

Before starting installation, you must select a room, taking into account all installation requirements. Double-circuit floor-standing boilers have a number of necessary parameters:

- at least 15 sq. m should be the area of the room in which the boiler will be installed;

- not 2.5 sq. m. should be the height of this room;

- window of suitable size;

- doorway at least 80 cm;

- free access to all systems and devices.

- the presence of a chimney that meets technical requirements.

A modern floor-standing gas boiler will not spoil the interior of your bathroom or kitchen

. Installation steps:

- preparing the foundation for the boiler;

- connecting the boiler to the chimney;

- connecting the boiler to the internal heating system;

- mandatory installation of a water purification filter;

- connecting the cold water supply to the boiler;

- connecting the gas pipeline to the boiler.

The choice of a floor-standing gas boiler is obvious if you have mains gas and a desire to save on heating and hot water supply. But do not forget that to install a boiler you must obtain a whole set of permits.

Before going to the store, it is best to make a list of criteria by which the model will be selected:

Construction of an energy-saving gas boiler

- Functionality

. Double-circuit water heaters operate on the principle of instantaneous water heaters. If this does not suit you, choose boilers with one circuit and additional connections for water heating devices. - Adaptation to domestic realities

. The pressure in the gas main and the voltage in our network do not always meet the standards. Therefore, it is better to choose a model that does not lose power even in extreme conditions. - Service maintenance

. First of all, pay attention to those brands whose service centers are located near your home. Thus, in case of breakdowns, repairs will be faster and cheaper. - After selecting and purchasing a boiler, leave all concerns related to its installation to specialists, because this is the only way to ensure a highly qualified approach to the work, take all necessary safety measures and carry out the installation in accordance with accepted standards.

Modern floor-standing gas boilers are a rather conservative and traditional thing. Over the years, they have not undergone major technological changes, which once again proves their reliability.

General information about bithermic heat exchanger

Classic heat exchangers for boilers provide for the separation of heating chambers. That is, one chamber is intended for servicing heating circuits - usually the main one, and for hot water supply - a secondary radiator. This design has many advantages, however, against the backdrop of combined heating chambers, its weaknesses also become obvious. In this case, it would be incorrect to assume that in the second case the water is mixed - this principle does not allow a bithermic heat exchanger. What is this in terms of approach to water maintenance? This is the same radiator equipment, but with a common housing, which contains both chambers for heating the coolant and compartments for preparing domestic water. In bithermal systems, the principle of separating service areas of different environments also applies, but this applies specifically to the internal delimitation of chambers. While a standard split heat exchanger initially contains two different chambers.

Ways to solve the dilemma

When renovations are taking place in your kitchen, a stove replacement is planned, the question arises - where to put the old stove? The options are:

- Sale. The stove must be in good condition. You must have time to organize the sale. This includes placing ads, conversations, meetings with potential buyers, and showing them your product.

- Disposal to landfill. You can't just throw away the slab. This is not household trash. It must be disposed of correctly. Otherwise - a fine of about 50,000 for private individuals.

- Disposal. This matter is best left to professionals. Today there are many companies engaged in such matters. Of course, their services must be paid.

- Selling for scrap. This is the most acceptable option. You can also earn some income from it. It is necessary to know the specifics of such an event. One way or another, this is the best solution to the dilemma of where to sell your old electric or gas stove.

terms of Use

Experts advise choosing this radiator for use with hard water. At the same time, precipitation forms at the bottom of the device, they cause “boiling”. This promotes the activation of sediment formation, which may result in device failure and pipes becoming clogged.

To avoid such problems, you should not use heating in such modes that “boiling” may occur in the lower part of the device. It is recommended to use filters for cleaning and devices to reduce water hardness.

It is prohibited to use ethylene glycol as a coolant in a radiator, because the salts and sediments that it forms cannot be removed. The disadvantage of this type of boiler is the low power in the DHW operating system.

Initially, in the first four days, the hot water will have a temperature in the panel (up to 90 degrees). For this reason, it is necessary to make 1-2 places of the hot water supply system from steel.

They should be replaced in the future. Heating with a bithermal radiator is inexpensive, and their system is durable, but not powerful. If the water is very hard, the operation of the entire heating system may be disrupted.

Cleaning the Copper Heat Exchanger

As a result of many years of heating the coolant, layers form on the surface. They worsen the boiler's performance. If you ignore them for a long time, the unit may fail. To eliminate calcium and other inorganic substances, copper heat exchangers are washed with special chemicals or by supplying air under high pressure into the cavities.

This procedure must be carried out in accordance with the requirements of the heating equipment operating instructions. For this purpose, treatment systems are used that differ in the volume of liquid supplied and power. Some of them periodically change the direction of flow, which improves the quality of cleaning.

Copper plate heat exchangers cannot be disassembled for cleaning. They are washed with special solutions that are heated to a temperature of 60°C. After filling the cavity, the pump is switched on to circulation mode. Processing time ranges from 1 to 4 hours. Then the solution is passivated and neutralized using a reagent. The term “passification” means protecting the metal surface from oxidation.

Brass

Before using a brass heat exchanger, it is necessary to analyze the liquid with which the device will interact. Brass is used with fresh water without impurities and salts, otherwise the bundle of pipes will begin to rust and become unusable.

Despite the fact that the thermal and electrical conductivity of brass is lower than that of copper, it has a higher strength and corrosion resistance. Some brass alloys are resistant to sea water and superheated steam - their resistance to specific environments and conditions determines their scope of application. Moreover, brass is much cheaper than copper.

Stainless steel

Stainless steel heat exchangers have maximum resistance to corrosion and are used in systems with liquids whose chemical composition is not suitable for copper or brass. This can be water with high acidity, hardness, alkalinity, and a high concentration of sulfates. Stainless steel is used to produce pipes through which salt water with various impurities will flow.

In addition, stainless steel combines the advantages of cast iron and steel: it is durable, immune to temperature changes and has low inertia. It also does not emit metal ions that color and pollute water and is more affordable.

It is important to remember that the choice of material for a heat exchanger depends on certain parameters and is individual in each case. This issue should be approached with special care so that the heat exchanger lasts as long and efficiently as possible.

You might be interested in:

about products

Source