What is a gas boiler AOGV? The abbreviation means that this is a gas water heating device, that is, a gas boiler for home or apartment heating systems. AOGV gas boilers differ from conventional boilers that are installed in individual heating systems in that they are completely energy independent (the ability to fully operate in autonomous mode, without connecting to the electrical network), are equipped with an automatic monitoring and control system (ACS), which can, without intervention, a person to control equipment modes, air draft controllers and flame strength in the wick.

Boiler room with gas unit AOGV

About company

Before the Great Patriotic War, the Zhukovsky Machine-Building Plant produced a variety of metal structures, and in the post-war period, equipment for aviation maintenance. It still produces similar equipment for the domestic and foreign markets.

The company also produces heating equipment. Today, over 30 options are produced with a power from 11 to 68 kW. The most popular modification of the Zhukovsky MZ is the AOGV boiler. The remaining series - AKGV and KOV - are in demand among Russian consumers. The company has diplomas and distinctions for the high quality of its products.

Foreign-made AGV

Foreign autonomous gas water heaters differ from their domestic counterparts in their higher cost, increased efficiency and dependence on electricity. The most popular are AGV brands BAXI, FERROLI, characterized by good visual qualities and the ability to fine-tune, as well as RINNAI and ANIERIA, which have ease of operation and reliability in their arsenal of advantages.

However, despite all the advantages of foreign units, domestic ones still have a significant advantage - complete energy independence. In addition, AGVs produced in the domestic space are much cheaper in themselves, and from the point of view of efficiency they are better.

Advantages of ZhMZ products

Any of the ZhMZ gas devices can operate independently of electrical networks - this allows you to expand the scope of their application. Advantages:

- Designed for the harsh Russian climate. Adapted to changes in water and pressure. Hardy, powerful, reliable, unpretentious.

- Can operate at very low pressure in gas and water supply systems.

- In severe frosts, they will ensure a comfortable temperature in the house.

- Highly reliable automation ensures high productivity of each unit and safe operation of all systems.

- Service life - 14 years or more. Warranty - 36 months.

- Capable of heating large areas.

- Some modifications can switch to liquefied gas.

Advantages of AOGV and management

When deciphering the abbreviation, the advantages of the units become clear, namely:

- Simple and easy control of the heating gas unit allows you to organize safe and affordable control of the coolant temperature within the specified parameters;

- All devices, parts and components are manufactured using high-precision technologies, but what is this in practice? This is an absolute guarantee of the safety and reliability of gas equipment operation. In addition, some models have manual gas shut-off and coolant temperature adjustment;

- All AOGV brands are non-volatile, that is, they are not tied to electrical networks and are completely autonomous;

- Piping in the heating system can be done with any pipes - polypropylene, cast iron, steel or metal-plastic;

- The heat exchanger (jacket) is usually made of copper, which ensures long service life;

- Pressure drops in the gas pipeline do not affect the stability of operation;

- A high degree of thermal protection ensures maximum heat transfer of the unit and the system as a whole.

Installation of AOGV is only advisable in private residential buildings, and not in apartments due to their high power and large size.

Design Features

- Fire adjustment is made in two ways: automatically and manually. The models differ not only in power, each of them has a certain range of capabilities.

- Some models have a pump to circulate water in the pipes. This allows you to effectively heat the room due to uniform heat distribution. Cheaper modifications do not have pumps, and water circulates according to the laws of physics. Therefore, when installing such boilers, the pipes are mounted at an angle.

- All modifications have an expansion tank. It allows you to achieve optimal pressure in the system, and if the liquid expands due to strong heating, it stores its excess.

Varieties

All boilers at the Zhukovsky Plant are floor-standing. There are three modifications:

- "Economy";

- "Universal";

- "Comfort".

In the first case, automation manufactured in the Russian Federation was used, in the other two - foreign ones. The brand presents only single-circuit versions - for heating buildings; double-circuit versions are not produced at ZhMZ.

Device

The efficiency of the equipment is 89%, which is quite good for domestic products. This productivity can be achieved due to the original design of the heat exchanger. The cast iron heat exchanger is equipped with turbulators. The burner is atmospheric, air comes from the room. Thanks to automation, continuous operation for a long time is ensured.

Heaters from the Zhukovsky Plant have a number of innovations that increase their environmental friendliness. Developers are trying to keep up with global trends, but still, domestic products are far from achieving the indicators of European and some Asian competitors. But Russian products have an undeniable advantage - a low price that satisfies all consumers.

Kinds

There are several design options for floor-standing single-circuit boilers. They differ from each other in various ways.

By type of combustion chamber:

- atmospheric (open) . The air directly surrounding the boiler is used, and the smoke is removed under the influence of natural draft. Such models are connected only to the central vertical chimney;

- turbocharged (closed) . To supply air and remove smoke, a coaxial type chimney is used (pipe in pipe), or two separate pipelines that perform the functions of intake and supply of air to the boiler and exhaust of flue gases.

According to heat exchanger material:

- steel. The most common option used on inexpensive models.

- copper. The coil-shaped design increases the path of liquid passing through the heating zone. Such units are installed in expensive models from top manufacturers;

- cast iron. Installed on powerful and massive units. Cast iron heat exchangers demonstrate high performance, efficiency, and are capable of developing large units of power. Used for units from 40 kW and above.

By heat transfer method:

- convection Conventional heating of the coolant in the flame of a gas burner;

- parapet. They are able to do without a heating circuit, being a kind of analogue of a conventional stove;

- condensation The coolant is heated in two stages - first in the condensation chamber, from the heat from the condensing flue gases, and then in the usual way.

NOTE!

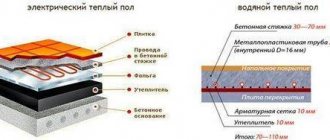

Condensing boilers are able to fully operate only with low-temperature systems (warm floors), or when the difference in temperature outside and indoors is no more than 20°. These conditions are not suitable for Russia.

About old-style boilers

AOGV is a later modification of the AGV brand. They, like their predecessors, do not have particularly high efficiency and do not have thermostat control. When gas was cheap, no one paid attention to low performance; today efficiency is one of the most important characteristics when choosing heating equipment. AGV models were distinguished by low-quality automation, which broke after one or two seasons of operation.

AGV and AOGV can work without automation: if it breaks down or is turned off on purpose, it will not interfere. When buying a heating boiler, you need to take care of a sufficient number of pipes - their diameter should not be less than two inches. If you take a smaller diameter, the circulation of the coolant may deteriorate - there will be additional costs for heating it.

What is the improvement?

The developers have made a number of improvements to the design:

- Glass thermometers were replaced with Italian, more modernized ones.

- German automation from Honeywell was installed.

- Piezo ignition.

- The appearance has improved thanks to the high-quality coating. The design has changed: the body can be round or rectangular. White color. Painting: powder.

How it all began

At one time, gas boilers of the AGV-80 or AGV-120 brand were used to heat a private house. This equipment had low productivity, but given the low cost of gas, this fact did not bother anyone.

AGV gas boilers for private homes were equipped with primitive automation, which failed in the first year of operation. However, the equipment functioned normally without it.

Installation of pipes for distribution is carried out outside around the perimeter of the house. However, this issue was not relevant at that time, and heat was supplied to the house in full. Pipes were used with a diameter of 2 inches, since a smaller diameter could cause the formation of air pockets that impede the natural circulation of the coolant.

After a slight modernization, gas boilers for heating AOGV and AOKGV appeared on the market, but this equipment was characterized by the same shortcomings (low performance and unreliable automation).

Despite this, boilers of this type have held up quite confidently on the market due to a serious advantage: the AGV heating stove operates without being connected to a power supply.

Other advantages of a heating system using AGV include the following:

- If we compare imported equipment and AGV, we note the affordable cost of the latter option.

- In contrast to the AOGV and the gas boiler produced by domestic manufacturers, the efficiency of the AGV can be noted.

The listed characteristics help in deciding what is better: an AOGV or a boiler.

Nuances of operation

When using gas equipment from ZhMZ, you should know: the burner, when starting, creates noise - cotton. In some modifications it is minimized - it turns on more smoothly.

The chimney is installed outside the residential premises. The diameter of the chimney is 14 cm. Under its pipe there is a container for collecting soot, which needs to be cleaned from time to time.

Important! A household heating boiler can only be connected by gas service specialists - independent connection is excluded.

Floor-standing devices are installed in separate rooms, on the lower level of the building. The new equipment comes with instructions, connection diagram and technical data sheet.

SAFETY INSTRUCTIONS

Persons who have examined this passport are allowed to service the device.

Installation and operation of the devices must comply with the requirements of the “Rules for the design and safety of operation of hot water boilers, water heaters and steam boilers with excess pressure”, as well as the requirements of the “Safety Rules for Gas Distribution and Gas Consumption Systems. PB 12 - 529", approved by the State Mining and Technical Supervision of Russia.

The operation of the devices must be carried out in accordance with the “Fire Safety Rules for residential buildings, hotels, dormitories, administrative buildings and individual garages PPB - 01 - 03”.

Operation of the device is only permitted with properly functioning automatic safety and thermal control.

Gas safety automatics must provide:

- Reducing the gas supply when the water temperature in the heating system reaches the set value.

- Shutting off the gas supply to the main burner when the set heating temperature is exceeded.

- Turning off the gas supply to the device in the following cases:

- when the gas supply to the device is stopped (within no more than 60 seconds);

- in the absence of draft vacuum or in the boiler furnace (for a period of no less than 10 seconds and no more than 60 seconds);

- when the pilot burner flame goes out (within no more than 60 seconds).

When operating the device, the hot water temperature should not exceed 95 °C.

Prohibited:

- operate the device with the heating system partially filled with water;

- use other liquids instead of water as a coolant**;

- install shut-off and control valves on the supply line and pipeline connecting the heating system to the expansion tank;

- operate the device if there is a gas leak through the gas pipeline connections;

- use an open flame to detect gas leaks;

- operate the device if there is a malfunction of the gas network, chimney or automation;

- independently eliminate malfunctions in the operation of the device;

- make any design changes to the apparatus, gas pipeline and heating system.

When the device is not working, all gas valves: in front of the burner and on the gas pipeline in front of the device, must be in the closed position (the valve handle is perpendicular to the gas pipeline).

Any malfunctions when operating the device on gas must be immediately reported to the emergency service of the gas operating company.

If gas is detected in the premises, you should immediately stop supplying it, ventilate all premises and call emergency or repair services. Until the malfunction is eliminated, it is prohibited to light matches, smoke, or use

** It is allowed to use household coolant “Olga” (manufacturer: ZAO Organic Products Plant) according to the instructions for use. After a period of operation, the coolant must be drained and disposed of.

The manufacturer reserves the right to make changes to the design and appearance of the product. This technical documentation may differ from the description above; see the operating manual enclosed with each boiler upon purchase.

This page uses materials from the site

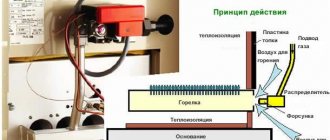

Principle of operation

The supply of cold water is carried out without forced circulation - by gravity. That is why the gas appliance is placed at the very bottom of the heating system. It happens that you even have to artificially lower its location.

The burner is ignited through the igniter. A prerequisite for combustion is draft. To control it, there is a special sensor. When the traction is lost, the gas supply automatically stops. If there is insufficient vacuum in the chimney or it is blown out by the wind, the gas is also turned off and the igniter goes out. The emergency situation is prevented.

The heating level of the coolant is controlled by a thermocouple. When the coolant heats up above the set value, the flow of fuel stops - the burner turns off. As soon as the coolant temperature reaches a critically low value, the gas begins to flow again and the burner lights up.

Such a control system cannot ensure a stable temperature in the room, but the equipment is able to function under any circumstances: without electricity, at low gas pressures, in severe frosts.

Automation system tasks

- Blocking when traction disappears.

- Switches off when the coolant heats up to a critical value and switches on when it cools down.

- Blocking gas flow at low or pulsating pressure, as well as in case of thermocouple failure.

The main advantage of AOGV is the possibility of use in gravity heating systems. Expansion tanks are installed in them, and circulation pumps are simply not needed. It is advisable to equip gravity flow systems with large volume radiators.

Operating principle

All AOGV boilers look like a single-circuit mechanism, which is equipped with an internal atmospheric burner. The maximum coverage of the heated surface in such boilers is ensured by the energy of the combustion gas. This happens thanks to special micro-torch burners.

At the bottom of the boiler, directly under the tank with the heat exchanger, there is a gas burner, with the help of which the water is heated. With a slight modernization of the device, it can be operated using liquefied gas.

The steel heat exchanger has a tubular configuration, which ensures high efficiency of the equipment. In the rear area of the gas boiler there are outlet and inlet fittings with a diameter of approximately 4 cm, intended for connecting a heat carrier. At the bottom of the device there is a return line, and at the top there is a so-called “direct” line.

The chimney has a diameter of about 120 mm and is connected to the top of the device.

The unit is controlled using a valve with electromagnetic properties and a thermostat lever. Sometimes boilers with piezo ignition or automatic start are produced. A thermocouple and a draft sensor are connected to the valve. The copper thermocouple controls the presence of fire at the igniter and is considered an important component of the boiler. The draft sensor is capable of shutting off the flow of gas if the draft decreases.

Model overview

Any AOGV is a single-circuit floor-standing device designed for heating a room. There is no second circuit in them. If you need hot water supply, you must connect an indirect heating boiler. Based on AOGV, AKGV is produced - they have a built-in heat exchanger for hot water supply.

The burner is designed for natural gas. To convert the device to liquefied gas, you will need to change it and need a special nozzle. The manufacturer produces heaters with power from 11 to 29 kW. You can choose a modification for heating an area from 45 to 250 m². The estimated cost of ZhMZ boilers is 18-23,000 rubles.

AOGV-11.6 Economy

Floor-standing version. Household versions - 11-29 kW. Features of version 11.6:

- Efficiency 90%

- Open camera.

- Heats 100 m².

- 11,600 W.

- One circuit.

- Mechanical control.

- Convection type.

- Weight - 45 kg.

AOGV-23.2-3 Comfort

- Efficiency 88%

- Open firebox.

- Heats 200 m².

- 23.2 kW.

- One circuit.

- Mechanical control.

- Convection type.

- Weight - 52 kg.

But 23 Universal can be made in two variations: single-circuit and double-circuit. The non-volatile device is equipped with imported automatic equipment. Works on any type of gas. Modest dimensions, light weight - an ideal solution for creating autonomous heating.

AOGV-17.4-3 Universal

AOGV 17 belongs to the convection type. Floor-standing version. Open firebox.

- Efficiency 88%

- Area - 140 m².

- Power - 17.4 kW.

- Weighs 49 kg.

The abbreviation stands for “Gas Water Heating Apparatus”. The Zhukovsky plant is not their only producer. They are released:

- JSC "Borinskoe" (Moscow region). It produces devices in an expanded power range; there are models for 5, 6, 7, 9 and 11 kW. Next: from 11 to 23 kW.

- CJSC "Rostovgazoapparat" Produces options 11.6-35 kW.

- There are also imported versions - Beretta (Italy).

Zhukovsky MZ does not produce parapet boilers, but they can be found from other domestic manufacturers, for example, a device from the ROSS company. Parapet models have a closed combustion chamber, so they can be installed in an apartment. They do not require a separate room.

Example of a parapet device: ROSS AOGV-13P. This is a 2-circuit option. Heats up to 130 m². 13 kW. Efficiency - 90%.

The most popular manufacturers and their brief descriptions

The leading manufacturers of floor-standing single-circuit boilers are European companies, although domestic designs are optimal for Russian conditions.

The most famous companies are:

- Viessmann. A German company, one of the most famous and reliable companies producing thermal products;

- Protherm. A company from Slovakia that produces a wide range of heating boilers. ALL series are named after animals of different species;

- Buderus . “Daughter” of the world-famous concern Bosh, which fully characterizes the quality and reliability of the products;

- Vaillant. Another German company whose boilers are considered the highest quality and most reliable;

- Lemax. Russian manufacturer of energy-independent floor-standing gas boilers. When developing the project, all the features of working in difficult conditions were taken into account;

- Navien. Korean boilers that successfully combine high quality and affordable prices.

The list of manufacturers can be continued for a very long time. All currently operating companies care about the quality and reliability of their products, trying to surpass competitors and reach the maximum number of users.

Thermocouple check

In order to check the AGV-120 thermocouple, you should unscrew the union nut, which is located to the left of the solenoid valve. Then you need to turn on the igniter and use a multimeter to measure the value of the constant voltage at its contacts.

Removing the AGV-120 thermocouple Source tskl.ru

Possible faults

Other malfunctions, the occurrence of which is foreseen by the manufacturer and specified in the technical documentation for the unit, include a whole list. You can read its contents below.

Possible malfunctions of the AGV-120 Source 1-teplodom.ru

The pilot flame goes out

The reason may be that the core does not hold the armature. This happens due to the appearance of oxidation in the place where the magnetic valve connects to the thermocouple. To fix the problem, use a spanner to unscrew the nut connecting the magnetic valve and clean the contact washer under it. After that, return everything to its original place.

Another cause of malfunction is the accumulation of oxide on the poles of the core and the plane of the armature. In this case, you will need to tighten 2 screws, unfasten the plastic cap on the start button and the anchor. Gently wipe the surface with a soft, dry cloth, being careful not to damage the polished base of the assembly. Reassemble the unit in the reverse order of removal and install it in its original place.

Gas burner for AGV-120 Source chipmaker.ru

The third, most popular reason for the igniter to fade is the lack of voltage at the thermocouple tip. This happens due to burnt out contacts. Here you will need to change the node to a new, functional one. It is strictly prohibited to press or tie the start key to the magnetic valve.

The igniter smokes or is interrupted

This occurs due to clogged gas supply nozzles. The problem is solved by cleaning them. Work can be performed with the unit turned off and cooled down. The second and more effective method is to dismantle the unit and completely wash it.

Removed igniter AGV-120 Source images.ru

Specifications

The AGV-120 gas boiler was developed on the platform of the AGV-80 water heater, which became the first Soviet unit of this type. The device of the modified model was almost identical to its predecessor, but differed in technical characteristics, reflected in greater productivity and power. During many years of operation, both models have proven themselves to be positive.

As mentioned earlier, the name of the unit reflects the volume of the coolant reservoir - 120 liters. The manufacturer's technical documentation indicates 14 kW of thermal power, with a lower thermal performance of only 10 kW. This also affects the rate of heating of the water in the working volume. It will take at least an hour to heat up to 80°C. And this is subject to an optimally functioning system (high-quality gas, clean burner, igniter, unclogged heat exchanger and chimney).

Comparative technical characteristics Source prootoplenie.com

The boiler is designed for installation to heat rooms with an area of 75-85 m2. It is also capable of acting as a source of hot water supply with a temperature range from 30 to 95°C.