When choosing a pump from the Danish company Grundfos, you need to consider where it will be located, what optimal volume of water per day it should pump, at what ambient temperature the equipment can be operated and other characteristics. If the site needs water constantly, the requirements for the unit are the same, but if, for example, only on weekends in the summer season, the requirements are completely different.

To buy a reliable device with a price/quality ratio that satisfies all parameters, you need not only to study its technical characteristics, but also to read customer reviews and expert ratings.

This rating was compiled taking into account consumer opinions and includes only the best Grundfos pumps.

Which Grundfos pumps are best for underfloor heating?

In order to choose the right Grundfos pump for pumping coolant in heated floors, it is necessary to take into account that the manufacturer has released several models of equipment specifically designed for this purpose

It is worth paying attention to the following modifications:

- Grundfos UPS circulation pumps for water floor heating are popular due to their low cost and good technical characteristics. The disadvantages include a mechanical change in the speed of the pump, lack of adaptation, depending on the actual consumption of thermal energy. For premises with an area of no more than 100 m², the optimal solution would be to purchase a model from the UPS 25-60 series.

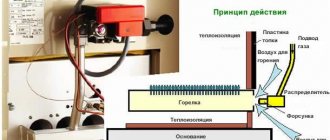

Grundfos Alpha2 circulation electric pumps with an electronic control unit for the underfloor heating system, with frequency control of pressure in the water circuit. The regulator automatically adjusts the operation of the pumping equipment, changing the circulation intensity. As a result, power consumption drops almost by half, module efficiency increases and ease of use is ensured.

Depending on the chosen model, the cost of a Grundfos pump varies from 8 to 80 thousand rubles. The price is affected by performance, throughput, and type of control unit. The classification of pumps for underfloor heating includes the UPS series (UPSD, UPE, UPS Series 100 and 200) and Alfa, Alfa2, Magna.

How to properly connect a Grundfos pump to a heated floor system

The Grundfos module is mounted in a manifold for underfloor heating using special pipes. For convenience, the connectors are engraved with arrows indicating the installation direction. The first start of the module is performed only after the system is filled with coolant. Connection to the electrical network is made through the terminal box. The housing is installed strictly in a vertical position.

Grundfos pumping equipment is the optimal solution for multi-circuit heating systems. Technical parameters allow connection to solid fuel, liquid fuel and gas equipment.

Scope of application

Grundfos borehole pumps are used in the following areas:

- pumping water from wells and wells to dachas, low-power water supply and irrigation systems;

- pumping various liquid media into industrial tanks;

- increased pressure in the water supply system;

- use as work cycles in garages and gas stations;

- for sampling and restoration for environmental purposes;

- well submersible pumps of the SQ and SQE series are used for pumping water from wells and boreholes, open sources to residential sectors and irrigation systems.

Grundfos sewer pumps

Grundfos Unilift KP 150-A1 – submersible drainage pump

The Grundfos Unilift KP 150-A1 pump is a drainage unit with a housing and working parts made of stainless steel. Equipped with strainer, check valve, handle, float switch and 10 meter cable.

Can be installed both stationary and mobile. Pumps relatively clean and slightly contaminated liquid with t ≤ +50 °C. Characteristics: flow rate 9.0 m3/h, head 5.25 m, immersion depth 10 m, power consumption 0.3 kW.

Pros:

- automatic operation: using a float;

- ease of use: small dimensions (15×22 cm), light weight (6.3 kg), low noise level (up to 65 dB), significant diameter of inclusions (10 mm);

- protection against idling, overheating and overload;

- corrosion resistance: the device is made of stainless steel;

- no need for maintenance;

- reliability and durability (10 years).

Minuses:

- Flimsy fastening of the filter using a clamp: it may fall off upon impact;

- relatively high price: 13.2-15.4 thousand rubles.

Grundfos SEG.40.09.2.1.502 – submersible sewage pump

Pump Grundfos SEG.40.09.2.1.502 – fecal unit with a cutting mechanism. With a power of 0.9 kW, it pumps out 15.0 m3/h of liquid with temperatures up to +40 °C. Capable of diving to 10 m and lifting drains to 14.5 m.

The design includes: cast iron body and motor connected by a clamp; adjustable impeller; horizontal flange outlet; stator temperature sensors. Automatically operates at a liquid depth of 0.25 m. Grinds particles Ø 10 mm.

Pros:

- huge productivity: 15.0 m3/h;

- corrosion resistance and reliability: durable stainless steel and cast iron are used;

- high efficiency: a chopper, an adjustable impeller, a cartridge shaft seal are available;

- automatic operation: a level relay is built into the design;

- overheating protection: temperature sensors are used;

- simple and easy procedures: settings, disassembly, assembly.

Minuses:

- large weight: 38.0 kg;

- very expensive: 66.4-72.5 thousand rubles.

Grundfos Sololift 2 C-3 – surface sewage installation

The Grundfos Solofit2 C-3 pump is a sewerage installation designed to connect 7 water intake points. Equipped with a plastic housing, dry motor, level switch, check and ventilation valves.

It works automatically depending on the depth of the liquid: at 65 mm it turns on, at 35 mm it turns off. Characteristics: flow rate 12.4 m3/h, head 8.5 m, power consumption 0.64 kW, wastewater temperature up to +90 °C.

Pros:

- automatic control using level relays;

- the presence of a cutting element and engine in a “dry” version;

- ease of installation: small size (width 16 cm) and light (6.6 kg); supplied assembled;

- high temperature of the pumped liquid: up to +60…+90 °C;

- no odors: ventilation with carbon filter;

- price corresponding to quality and performance characteristics: 19.9-24.4 thousand rubles.

Minuses:

- Over time, the float becomes clogged (sticks) and requires periodic cleaning;

- not for the toilet;

- noisiness.

Rating of popular models

Most often, this model is counterfeited by scammers, since it sells better.

The pump rating is based on a comparison of the technical indicators and operational capabilities of three models. In first place is the Grundfos UPS 25-60 (N) 180 product, which is a circulation unit with a cast iron body (this option is used only for heating). Its modification for hot water supply has a stainless steel body. All samples are equipped with a single-phase asynchronous motor, a speed switch and a special sleeve separating the rotor and stator.

The advantages include:

- permissibility of use in any type of circuits (closed and open);

- wear resistance and efficiency (consumption no more than 60 W);

- low noise level (up to 43 dB);

- compactness, low weight and overheating protection;

- ease of installation and maintenance;

- long service life.

The disadvantages of these products are the obsolescence of individual models and their high cost.

The second position is occupied by a Grundfos ALPHA2 25-40 180 , equipped with a built-in permanent magnet electric motor. The power consumed by this device from the network is 0.022 kW, and the productivity is 2.4 m3/hour. At an operating temperature of the coolant from +2 to +110 °C, the pressure created in the circuits is 4.0 meters.

The Alpha model is made of cast iron and has an increased service life

This product has a pure cast iron body and is equipped with an efficient wet rotor motor and ALPHA plug. Vertical or horizontal installation of the unit is allowed, which, after startup, is controlled via built-in electronics. All information about the possible operating modes of the device, its energy consumption and typical breakdowns is displayed on the display located on the front panel.

The positive aspects of this model include:

- Low power consumption (only 22 watts).

- Small dimensions (10x15x18 cm) and light weight (2.1 kg).

- Low noise level during operation (no more than 43 dB).

- Protection from corrosion (the body is made of stainless steel).

- The presence of the AUTOADAPT function, as well as the ability to select night or summer mode.

- Low level of heat loss (the housing is insulated with a protective casing).

- Possibility of setting fixed operating modes.

- Long-term warranty (up to 5 years).

The disadvantages of this product are the frequent malfunctions of the electronics, as well as the lack of special protection against dry running.

The third place is confidently occupied by the Grundfos UPA 15-90 (N) - a modern monoblock type unit, which has characteristics slightly worse than the previous model.

Specifications

It is best to consider the characteristics of pumps using a specific example. A good option is the pump for the Grundfos heating system UPS 25-40 - a popular unit that is very often chosen by owners of country cottages. The numbers in the name mean that the device’s pipes have a diameter of 25 mm, and the pressure value is 40 dm (4 m). This pump is perfect for one-story houses, and when using single-pipe wiring, it can even cope with heating a two-story building.

The technical characteristics of the Grundfos heating pump are as follows:

- The pump can operate in three modes at a power of 25, 35 and 45 W;

- The volume of pumped liquid is 3.5 m3/h;

- The distance between the edges of the pipes is 18 cm;

- Device weight – 2.6 kg;

- Power supply from a regular 220 V power supply.

The body of the device is made of cast iron, and the engine is made of aluminum. The material used to make the impeller and bearings is ceramic, and steel was used to create the rotor. The selection of materials was not made at random - their combination made it possible to achieve high strength of the device and the ability to withstand high temperatures.

Particularly worth mentioning are ceramic bearings, the use of which turned out to be a very successful solution. Even under severe operating conditions, these elements can last more than 10 years without complaints. In addition, ceramics are quite beneficial in terms of reducing the noise level that the Grundfos heating pump creates during operation.

In addition to the already mentioned option, you can also find pumps on sale equipped with a technopolymer impeller and a ceramic rotor. Of course, such devices are much more expensive, but the high cost in this case has a direct connection with quality - thanks to the materials used, the efficiency of the design and its durability increase.

On any good pump, the manufacturer must put an arrow that indicates the direction of rotation of the rotor and the movement of the coolant. This arrow is made specifically so that the technician installing the pump does not mix up the pipes and install the pump backwards.

The device package usually does not include fastening elements, so they must be purchased separately. After installing the pump, you need to wait about a day before starting it. However, if the Grundfos circulation pump for heating was previously in a warm room for the specified period, then this rule can be neglected - the whole point is that the pump can only be used at positive temperatures, and it must first “get used to” them .

Types of devices for heating systems

Grundfos pumps designed to operate as circulation pumps are divided into two main groups , the difference of which lies in the operating conditions of the drive motor rotor.

If only the pump impeller comes into contact with the pumped liquid, then this design is called “dry rotor”.

If the transported liquid contains both the impeller and the motor rotor, it is a pump with wet rotor characteristics.

Both types of construction have their own characteristics and areas of application.

Dry

The dry rotor is good high efficiency and high power. Pumps of this type are also little sensitive to the quality of the coolant and can easily tolerate contamination from suspended matter and fine abrasives. Operates at temperatures significantly higher than the permissible operating values of glandless rotor pumps.

Photo 1. Disassembled Grundfos circulation pump for a heating system, equipped with a dry rotor.

The disadvantages are a shorter service life, comparatively high cost, slightly larger size, the need for regular maintenance (lubrication), and high noise. For this reason, models with a dry rotor are best installed in a separate room. But at the same time, they are able to “pump up” large cottages or even apartment buildings.

Wet

The wet rotor is more compact, almost silent, and extremely durable when installed correctly. Does not require maintenance during operation, but is less productive, with a relatively low efficiency - no more than 50%.

With overall low power consumption (on average 6–100 W depending on power, mode and load), this characteristic is not decisive.

This type of pumping equipment is extremely sensitive to the quality of the pumped liquid, since it is both a lubricant and antifreeze for the rotor. Therefore, such devices cannot operate at temperatures above 115 degrees and require the installation of a mesh dirt filter in front of the pump.

Photo 2. Grundfos compact circulation pump with a wet rotor, sensitive to the quality of the pumped liquid.

Wet-type devices are widely used in individual heating and water supply systems as additional circulation pumps for the make-up line.

Features and benefits of pumps

The main advantages of Grundfos pumps are:

- The optimum ratio of price and quality,

- high energy efficiency of equipment,

- a huge selection that can satisfy any need.

- quite long service life,

- good technical support.

When choosing pumping equipment, the following technical parameters must be taken into account:

First you need to decide what type is needed. In total, there are three large groups: for wells, for heating, for drainage or sewerage. At Grundfos, designers have thought through in advance almost all possible problems that may arise in a particular area of operation. Therefore, when choosing equipment from this manufacturer, you get a unit that takes into account many years of experience.

Before ordering equipment, you need to decide what type of voltage will be used: single-phase or three-phase. For household pumps, single-phase pumps are mainly used; in industry, three-phase pumps are more commonly used.

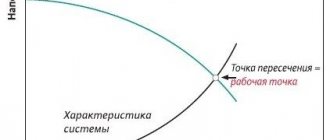

The main characteristic when choosing a pump is the graph of pressure versus flow. This graph shows how much water the pump will pump depending on the required pressure. The higher the pressure that needs to be maintained, the less water the pump can pump. When choosing equipment, the required operating point must be under its curve. It is also necessary to provide a margin of 20% for the supply.

Power is also an important parameter. It depends on the current and voltage. This parameter is taken into account when selecting pump protection, as well as when calculating the required cross-section of power supply cables. The higher the power, the greater the productivity.

When choosing pumps, it is also necessary to take into account geometric parameters and connection dimensions

Before placing an order, you must make sure that the selected equipment is suitable both in weight and dimensions.

Depending on the operating conditions, it is necessary to pay attention to the minimum and maximum permissible temperature of the pumped medium. There are cases when the wrong choice of range led to equipment failure

Also, when choosing from equivalent pumps, you need to choose the one with a higher efficiency rating

In the long term, such equipment will provide significant energy savings.

In order for the unit to work for a long time and without interruptions, it must be installed correctly. Installation of any equipment must be carried out strictly according to the attached installation instructions. Also, do not forget about installing automated control systems for pumps.

Such a system will protect your unit from power surges, from engine overheating, from the possibility of working without water, from water getting inside, etc., and will also allow you to control the process automatically, without human intervention.

Another condition for durability is proper operation. It is also written in the instructions

It is important to understand that if a pump unit protection system is installed, then you need to be alert when it is triggered. It is best to carry out a full cycle of equipment inspection. https://www.youtube.com/embed/0_9CFtB_0RE

Adviсe

The choice of a well pump must be taken with full responsibility. To do this, you need to know all the information about the well itself, which is presented in its passport. In particular, you need to pay attention to values such as:

- well flow rate is its productivity. This value indicates how much power can be used to pump liquid from a given source;

- borehole diameter is an important parameter when selecting a submersible unit. Today there are three standard diameters: 15.2, 13.3 and 10 cm;

- the dynamic fluid level shows at what depth of the well it is necessary to install the equipment;

- additional loads: distance of the pump to the storage tank, pressure level in the accumulator and others.

The pumping equipment set includes the following elements:

- a well pump with a cable connector in an impermeable sheath and the flat cable itself;

- Control block;

- pressure gauge for measuring pressure in the range from 0 to 10 bar;

- pressure tank with a capacity of 8 liters;

- pressure meter;

- stopcock;

- cable clamps.

The model range of Grundfos submersible units is presented in a wide range, so you can choose the optimal pump for any water supply system.

To make the right choice in favor of a specific device, it is recommended to consult a specialist.

Installation of pumping equipment should begin with checking the geometric parameters. The most important installation rule is to ensure that the device is oriented vertically.

Possible defects can be detected by checking the straightness and compliance of the well diameter with the dimensions of the pump.

You can use special templates - these are pipe elements with a diameter larger than the dimensions of the pumping unit, to determine possible distortions by lowering the template into the well.

During installation of the Grundfos downhole tool, the following tools will be required:

- special means for lifting the pump from the well;

- connecting parts;

- electrical wires and clamps;

- set of tools.

Initially, you need to connect the electrical wire, clean the ends of the cable and secure with solder. Along the edges of the electric motor there are sleeves into which the cable is inserted, and the connection points are treated with solder.

Before loading the pump into the well, you must read the equipment installation instructions. The manufacturer recommends filling the engine with fluid in advance.

The best option is water that has been filtered to eliminate the possibility of plaque formation.

If the electric motor is not filled with water, the pump can only be started several hours after immersion in water.

The pump is connected to the clamp in a strictly vertical position and lowered into the water column. The function of the clamp is to ensure the hanging position of the structure. The other end of the pipe is connected to the second clamp, continuing the immersion.

After starting the submersible pump, it is necessary to observe the operation of the equipment in order to promptly eliminate possible errors.

Source: https://stroy-podskazka.ru/vodosnabzhenie/nasosy/skvazhinnyj-grundfos/

Types of pumps

As for the variety of this type of pump, there are two most popular ones:

- Grundfos circulation pump for heating with a dry rotor. His photo is just below. Its peculiarity is that the motor practically does not touch the liquid it pumps. Often, such pumps are used in large systems where there is a need to pump large amounts of coolant;

- Glandless rotor pump. In such equipment, the rotor is located directly in the liquid. The main advantage of this design is that the air itself is removed when the pump starts.

Dry rotor pump

Advantages of Grundfos pumps

The Grundfos heating circulation pump has the following advantages:

- Small power, but high performance. The height of the building never reduces the performance of the device, since the water supplied by the pump to the pipeline always pushes the coolant in the opposite direction;

- Minimal energy losses occur only due to friction in the pipeline;

- Significant energy savings. This is explained by the fact that the pump maintains the desired temperature in autonomous mode;

- All modern systems of this type are equipped with special temperature controllers. You can set the desired temperature on this sensor and then the system will maintain it itself. The pump can quickly adjust to the desired mode and maintain the already set temperature;

- Circulation pumps for Grundfos heating systems are characterized by a simple design. If desired, you can install such a unit yourself without the involvement of knowledgeable specialists;

- The buyer can select the appropriate pump for a specific system. It should be noted that the price will depend on the configuration of the device. All this allows the buyer to significantly save his own money;

- A huge plus is the practicality and reliability of circulation pumps. There are no unnecessary functions and parameters;

- Possibility of purchasing through the online catalog from an official dealer thanks to the provided photos and videos of pumps.

Installation process

Features of Grundfos pumps

The Danish company Grundfos is a leader in the design of high-quality pumping equipment. It covers half the needs of the entire world market. This company is trusted by millions of people, as it has successfully established itself in the sales market of circulation pumps and equipment of this type.

Special requirements are always put forward for the equipment of this company due to the fact that such systems must operate continuously and autonomously. Also, a huge advantage of Grundfos pumping units is high-quality warranty service.

Typically the warranty period is twenty-four months from the date of purchase. Instructions are included with all pumps.

An open heating system is the best choice for a country house - read about it here.

About the manufacturer

Grundfos is a Danish brand whose head office is located in Bjerringbro. The company was founded in 1945 as a machining and injection molding factory. After 22 years, the company received its modern name, and a leading profile was determined in its activities. Grundfos produces different types of pumps, a wide range of parts and components for them, and also offers for sale electric motors for servicing stations and control cabinets. Today the corporation is represented in 56 countries, including Russia.

The company's concept was to develop standards for pumping equipment. The company occupies a leading position in the efficiency, reliability and resource capacity of equipment. Grundfos produces both solutions for private households and products that ensure the life of industrial buildings and small settlements.

Selecting Equipment Based on Performance

The performance of the device is the volume of pumped liquid, as well as the flow rate at the lowest load. The higher the performance, the better. To calculate this parameter there is a formula: Q = N / (t 2 - t 1). In it, the flow rate is designated by the letter Q. As for the temperature of the liquid in the pipes, it is designated t1, but the power of the heating source (in this case, the heating boiler is meant) is N. The supply temperature is t2. This value is determined after the heating boiler.

When the calculation is carried out, t1 should be equal to the limit from +60 to +70 °C, while t2 varies from +90 to +95 °C. This formula allows you to select approximate pump parameters. For 10 m of the length of the circulation ring, the equipment pressure will be required, which is 0.6 m minimum. Today, thermal standards are known: to warm up 10 m2, 1 kW of power is required. If we take the thermal power of the radiator section (200 W), then for every 10 m2 you will need 5 sections. You also need to take a small supply of 2 sections.

What is needed for selection?

The main characteristics required when choosing any water pump include:

- operating flow , that is, the amount of water pumped per unit of time;

- the amount of pressure required , which is the pressure at the outlet of the pump.

The operating point is determined from the flow and pressure values in the program. To do this, select the most suitable operating schedule for the desired family of pumps, which has a point with the closest parameters.

How to choose a Grundfos circulation pump

I would like to note right away that it is quite difficult to independently make calculations and select a pump that is optimally suited to an individual heating system. Company consultants and special online calculators can help you make your choice. As practice shows, the decision to purchase the model you like is most influenced by:

Technical characteristics of Grundfos circulation pumps - you should pay attention to power, throughput and type of design.

It’s a good idea to make sure that you are purchasing an original device and not a fake.

Design features.

Cost and service life of the module.

Circulation pumps for Grundfos heating systems are offered in five basic versions. Selection of equipment requires the involvement of a specialist. Below are recommendations from professional installation teams and consultants.

How to distinguish a fake pump from an original Grundfos

Malfunctions of the Grundfos circulation pump are excluded if the original module is purchased. All breakdowns are mainly due to fakes. To avoid purchasing a low-quality surrogate, you should follow the following rules:

- You can purchase the model you like only in the official store of the company.

All products are certified and have permission from Rostechnadzor, as evidenced by the documentation provided in the kit. The original pumps have instructions in literate Russian.

Dimensions – it’s easy to distinguish a fake by using a ruler. Original products have an installation length of 18 cm. As a rule, the body of surrogates is 13 cm.

The speed switch in a mechanical pump is non-removable. The body is painted evenly and with high quality.

The pump consists of a rotor, stator, stainless sleeve, bearings. A specialist will be able to notice the differences.

Low cost. Factory products from a German brand cannot be cheap. As a rule, a counterfeit product is 2 times or more cheaper than the original.

How to calculate the required power of a Grundfos pump

The selection of a circulation pump is carried out according to several parameters:

- Heated area.

Throughput and height of the water column.

The choice of heating area is carried out in the following way:

- Determine the boiler performance. So, for a room of 200-250 m², you will need a 25 kW boiler.

It is believed that the throughput of the boiler per minute is equal to its productivity. Accordingly, a 25 kW boiler passes through itself 25 liters of coolant per minute or 1500 l/hour.

The pump is selected according to these parameters.

To facilitate the choice, the technical documentation of the pumping equipment immediately provides approximate parameters of the heated area.

Cost of Grundfos pumps

The average cost per unit of pumping equipment varies from 5 to 80 thousand rubles. The cost of the model is influenced by several factors:

- Technical characteristics of circulation pumps for heating of the Grundfos brand. Performance, the presence of a twin electric motor, and an automatic control unit - all this increases the cost of the model.

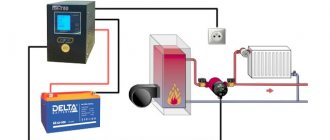

Additional equipment. After connecting the pump, the heating system becomes volatile and stops working after a power outage. To eliminate this drawback, you will need to connect an uninterruptible power supply. Installation to heated floors is carried out using a special mixing unit.

The high cost is justified when you consider that maintenance of circulation pumps for Grundfos heating systems is not required. The models will work throughout their entire service life without any complaints and will help to significantly save on electricity.

Service life of Grundfos pumps

The average service life of pumps is 7-9 years. Most models are covered by a 3-year factory warranty. Several factors directly influence the service life:

- Correct installation of the heating pump.

Coolant quality - it is allowed to use glycol-containing compounds with a maximum permissible antifreeze content of no more than 30%, in relation to the total volume. Water must be purified from impurities.

Date: September 25, 2022

Reviews, prices

As a rule, with the right choice of a well pump and its correct installation in accordance with its intended purpose, the equipment will last for several decades. Reviews of Grundfos products are mostly positive.

After using the pump for a long time, buyers concluded that the device works without any complaints or comments.

But buyers also mention the high cost of Grundfos pumping equipment, which is 2 times higher when compared with similar equipment from other manufacturers. The price range varies from 25,000 rubles. up to 40,000 rub.

But once they took the risk, they did not regret the money spent. In addition, the Grundfos pump comes with a power cable, which simplifies installation of the equipment.

The pump also does an excellent job of cleaning the sewer system, and can also be used for watering the garden.

- Nikolai Ilyich, 47 years old, Nikopol: Recently purchased a summer cottage with no centralized water supply. Therefore, the question arose of installing an autonomous highway. I chose the SBA 345av model. The device does its job perfectly. Works quietly. I'm happy with the purchase.

- Olga, 38 years old, p. Barmashevo: We bought a pump for watering our summer cottage. Model 3/35 and Grundfos works in summer. The pressure is sufficient. We installed it ourselves. No complaints.

- Grigory Nikolaevich Ilyin, 57 years old, Ternopil: I bought a device for watering vegetables and flower beds on the territory of a private house. The device operates quietly. Consumes little electricity. Everything is fine. Satisfied!