Gas equipment, even with scheduled preventive cleaning, may malfunction. But for every breakdown there is a reason, knowing which you can maximize the service life of boilers, saving a decent amount of money.

Before we look at the main types of faults in boilers, it is worth noting that any repair and scheduled maintenance work must be performed exclusively by specialists who have permission to provide these services.

The boiler does not ignite

No matter how funny it may sound, in 95% of all calls for technical assistance for the repair of gas equipment, this is the problem that people have most often. This is especially true for the first ignition after the boiler has been turned off for a long time.

Causes

Let's consider the reasons from the most trivial to serious breakdowns:

- There is no gas supply in the system: the valve on the pipe is closed or there is no gas directly in the room.

- The boiler is not plugged in: there is no spark, the flame cannot be lit, although there is a slight smell of gas.

- The hood is closed: the boiler gives a spark, there is ignition, but the flame goes out very quickly.

- The fuses on the electronic board have burned out: this often happens during sudden power surges in the network.

- Problems with the ionization electrode: it either moved away from the board or burned out completely.

It’s not difficult to determine “by eye” why a gas boiler won’t ignite, so before you hang up the service calls, first check yourself: have you done everything to light the boiler?

Briefly about the main thing

In order to know what needs to be done when the pressure drops and the gas boiler turns off, you need to have an idea of what malfunctions can lead to such a development of events. As a rule, the consumer of gas heating equipment faces the following series of problems:

- Fault with error code displayed.

- No indication.

- No ignition.

- The boiler does not operate in any mode.

In this case, the reasons can be both external and internal. The first includes insufficient fuel pressure, violation of smoke removal, violation of operating conditions, the second includes breakdown of electronics and individual components. Most often, the boiler turns off due to lack of ignition, a drop in coolant pressure and electronic failure. In each case, professional diagnostics are required to restore the unit’s operation.

Causes

In fact, there are not so many reasons for such a malfunction:

- The pump is not connected to the network: accordingly, the heating element quickly overheats, and water does not circulate through the system, but is concentrated in the boiler.

- The pump is connected to the network, but is faulty: water is not circulating or is circulating very slowly (slower than heating).

- Batteries are airy: A large amount of air has accumulated in the batteries, which by nature heats up faster than water.

- Malfunctions in the thermostat: the controller has burned out, or the wiring has oxidized.

Be sure to check the readiness of your own heating system for the first start-up. Lack of the required water level and pressure leads to an emergency shutdown of gas equipment.

The principle of operation of a gas burner

It consists of the following: air and fuel are mixed, and the combustion products must go through the entire combustion process.

We can conditionally distinguish three tasks in the operation of this element of the system:

- preparing air and fuel for combustion by determining temperature, speed and direction;

- mixing these elements;

- combustion, that is, oxidation of combustible elements with the help of oxygen, combustion due to the nozzle at the end point of the tube.

The reasons that the burner does not light up must be sought in the principle of its operation.

The burner itself is essentially a metal tube that is hollow inside and has several holes called nozzles. The gas burns in it, heading towards the combustion chamber. The mixture of combustion products is discharged outside. And if the air is collected by natural injection, then the gas is distributed and directed inside thanks to the system of indicated holes.

If the gas boiler does not ignite, it means that the combustion conditions are not met: there is no gas, no air is supplied, and combustion products do not come out. Understanding the cause of problems allows you to eliminate them in a timely manner and restore system operation. When lighting a gas boiler, be careful. This equipment requires special care.

How to solve a problem?

A list of things you can do yourself without calling a specialist:

- Fill the heating system with water: open the water supply tap or add water to the expansion tank to the mark on the pressure gauge recommended by the manufacturer.

- Unscrew the nuts on the batteries to release excess air. This must be done on each coolant separately until water begins to drip.

- Check the pump for proper operation. In some cases, increasing its power and speed helps. You can put your ear to the pump and hear whether it is working or not.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

The rest of the repair work related to assessing the performance of the thermostat and the central control board is the responsibility of the craftsmen.

This problem indicates the presence of weak draft in the exhaust system, or a malfunction of the central board that blocks the operation of gas equipment.

What devices use bimetal?

The scope of application of the bimetallic strip is extremely wide. Almost all devices where temperature control is necessary are equipped with bimetal-based thermostats. This is explained by the design simplicity and reliability of such relay systems. In our usual technology, thermostats are:

- In household heating appliances: stoves, ironing systems, boilers, electric kettles, etc.

- Heating systems: electric convectors, gas and solid fuel boilers with electronics.

- In electric packages there is automatic shutdown.

- In electronics in measuring instruments, as well as in pulse generators and time relays.

- In thermal engines.

In industrial technology, bimetallic plates are installed in thermal relays designed to protect powerful electrical devices from temperature overloads: transformers, electric motors, pumps, etc.

How to solve a problem?

First, check if the hood is open and does it need cleaning? If this option does not help, then you should call a technician who will check all the systems and find out why the boiler is going out.

The situation is as follows: you filled the heating system with water, raised the pressure gauge values to the recommended values, started the boiler, but after a certain time you noticed that the radiators were cold and the boiler itself turned off. This is all due to the operation of the thermostat and protection, which shut off the gas supply if the pressure level in the heating system has reached its minimum.

The boiler blows out in a strong wind, what to do in this case

Mechanical heating boilers can go out due to being blown by strong winds. Any atmospheric phenomena - rain, high humidity, low atmospheric pressure, wind can affect draft, causing its excess or deficiency, and also cause reverse draft. Result: the boiler went out. What to do in this case?

The solution to the problem is as follows:

- You can install a special mushroom-umbrella on the edge of the pipe, which will protect the chimney from unwanted influences;

- Or you can increase the pipe itself if its length is not enough.

By the way, this is not the only problem that can arise with the chimney. In addition to blowing smoke, ice may form on the pipe. The reason for this phenomenon is condensation.

The fact is that moisture tends to accumulate and freeze over time, and then become so thick that it simply blocks the access to oxygen and the flame goes out and the boiler turns off.

However, it happens that it is very difficult to knock off ice build-ups and then you have to defrost them. You can purchase a disposable burner with a small can. To melt the ice, you need to light the burner and insert it into the cleaning hatch. When the pipe warms up, the boiler can be put into operation.

Causes

This picture appears in several cases:

- You forgot to add water to the expansion tank.

- They opened the water supply tap to the heating system, but forgot to fix it, and when the water in the central water supply was turned off, the water left on its own.

- There are various types of leaks that gradually reduce the water level in the system.

Again, you need to check exactly how the pressure gauge does its job. It is rare, but it happens that this device does not work correctly, blocking the operation of the entire heating system.

What models are there?

The main types of Lemax gas boilers are:

- Floor-standing models with steel or cast iron heat exchanger.

- Wall mounted solid fuel.

The solid fuel type of equipment is represented by two models:

- Wood stoves.

- Coal boilers.

Wall-mounted boilers are produced only as double-circuit boilers: they are capable of operating at pressures up to 3 bar. In all cases, Italian automation and circulation pumps are used. Wall-mounted models include a 6-liter expansion tank. This equipment is guaranteed for 2 years. Floor-mounted modifications equipped with steel heat exchangers are also in high demand. For their manufacture, high-strength metal with a thickness of 2 mm is used.

There are 5 models of steel boilers with different capacities:

- Lemax premium.

- Premium nova.

- Gazovik.

- Clever.

- Patriot.

The Premium nova model is considered the most advanced today. Thanks to automatic settings, the device can independently both start a Lemax gas boiler and set optimal operating parameters in the system. The Patriot series devices are characterized by the presence of a closed combustion chamber. They are produced exclusively as single-circuit ones, without the need for electrical power and a chimney. The presence of a 4 mm thick cast iron heat exchanger for the Leader and Wise units extends the service life by approximately 2 years. They are not afraid of various contaminants and the effects of corrosion.

Causes

The key reason is scale on the heat exchanger tubes, which significantly narrows their clearance. As a result, at the same gas flow rate, the heat transfer process is significantly reduced.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

Do not use tap water to fill the heating system. When it heats up, scale forms, which will have to be cleaned periodically. Softened water, which can be purchased in specialized stores, is better suited for these purposes.

Peculiarities

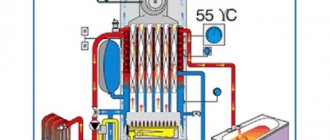

In order to turn on a gas boiler, you need to know its structure well, as well as its system features.

The first step is to consider the design of a standard AGV.

- Boiler equipped with an autonomous gas heater. This is a tank that is located in a casing.

- The pipe that is located inside this tank. Gas combustion occurs in it, due to which the water is heated. The combustion products that are formed inside come out through the chimney.

- Heating devices . For example, hot water flows into the heating circuit. Then it circulates through all the pipes. When the water cools, it is sent back to be warmed up. All this is a closed gravity heating system.

- Expansion tank , which is installed on top, above the gas boiler. It allows water, which expands when heated, to rise to the top.

- Pump . It is located behind the gas boiler, which allows you to efficiently pump water through the entire system. The speed of coolant movement throughout the system can be increased or decreased. All these processes are controlled using automation.

Such heating devices have both disadvantages and advantages.

Among the advantages, the following points can be noted.

- AGVs are safe and reliable in operation, completely independent of electricity, and have the ability to install automatic locking.

- They consist of different types of water heaters. This includes both floor and wall structures.

- Such units are quite simple, easy to repair and maintain.

- They are not very expensive, and besides, such models are very economical.

Among the disadvantages, one can highlight the fact that this is a fairly voluminous equipment. Therefore, you need to build or allocate a separate room for it. The size of the AGV directly determines where it can be placed: some boilers can be placed against a wall or hung on it, in which case the boiler room can also be used as a storage room. A large heating device will occupy the entire room.

How to solve?

If the pump is working properly, but there is no heat in the house due to significant gas consumption, then you need to clean the heat exchanger. The procedure is performed only by specialists who use special liquids of high acidity.

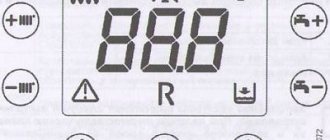

Incorrect errors on the screen

The boiler went out for some reason, and a code appeared on the display. Naturally, the first thought is to look at the instruction manual, but what to do if such a code is not there?

What is a bimetallic plate

An element that has the property of deforming (bending) in one direction under the influence of elevated temperature is called a bimetallic plate. From the name you can guess that the plate contains two metals. Each of them has its own coefficient of thermal expansion. As a result, when such a plate is heated, one component expands by a certain amount, and the second by another.

This leads to a bend, the shape of which depends on the difference in temperature coefficients. The rate of deformation is directly proportional to the change in temperature. When the plate cools, it returns to its original position. The plate is a monolithic compound and can work indefinitely.

Causes

Loud operation of the equipment is caused by the following possible reasons:

- There is a shortage of water in the heating system, the presence of airiness - you should definitely check the pressure gauge readings, and also bleed the air from each battery.

- The formation of scale in the coolant, which breaks off with temperature changes and contributes to overheating of the antifreeze.

If the boiler becomes noisy, do not ignore it, but immediately call a specialist to find and fix the problem.

Useful tips

To start the boiler, it is necessary to supply power and set the heating regulator to the required operating position. The presence of a weak hum indicates that the circulation pump has started working. Using a screwdriver, lightly unscrew the cover on the detected part. But this must be done before the water begins to flow. If liquid begins to seep out, screw the cap back into place. Such actions are performed several times and after this the air pockets will be completely removed from the system. The gurgling sounds will also disappear and the pump will run quietly.

How to solve?

Usually the problem is solved by cleaning the heat exchanger with special acid compounds. Secondarily, the condition of the heating system is assessed and excess air is removed from the radiators.

Jokes with gas equipment are bad, so all repair work should be carried out only by specialists in this industry. If you have the slightest suspicion that the boiler is not working as it was before, then you should not hesitate to call the experts.

Experts also recommend:

- Do not ignore the annual scheduled technical inspection of the serviceability of gas equipment. The technicians will clean the heat exchanger and look inside the boiler. If there are any malfunctions, they will be eliminated. This will maximize the life of the boiler and also protect your life from possible risks.

- Never repair a boiler yourself using manuals found on the Internet. This does not guarantee full serviceability of the equipment, which is fraught with negative consequences.

- Pay attention to the nuances of operating the model you choose. Don’t be lazy to study the documentation, which describes in detail the sequence of actions in a given situation.

In conclusion, it is worth noting that all problems in gas equipment sooner or later make themselves felt. Operation of faulty equipment can lead to a gas explosion, which is extremely dangerous to life. Observe all safety precautions and do not ignore the rules for operating gas equipment.

Solution

In order for the boiler to turn on normally after an emergency stop, it is necessary to fill all drainage elements with water - pipes and radiators. Just before this you need to look at the operating pressures in the system, their minimum and maximum. You can find them in the accompanying documentation for the device.

You can check the water level using a sensor installed on the panel.

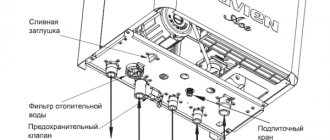

Pressure and temperature sensor

After this, the gas connection is checked: all hoses are connected, the tap is not closed. And you can start the system with the “network” button.

To unlock you will need to complete six steps:

- Set the heating temperature to maximum using the control knob.

- Abruptly turn off the temperature controller to zero.

- Repeat these steps 2-3 times.

- Leave the regulator at maximum temperature and wait until the system automatically unlocks and starts.

- Wait until the emergency stop light goes out.

- Set the required temperature mode.