Designing a private house at the very first stages involves choosing a heating system. It consists of many factors that need to be taken into account. Heating a house with a diesel boiler is beneficial, for example, when there is no gas supply on the site and is not even planned in the near future. This heating option turns out to be the most acceptable in many respects. Let's take a closer look.

Diesel boilers for heating

Advantages

Let's start right away by considering the winning aspects (we'll discuss those that aren't so good later) that characterize heating a country house with diesel fuel. This question is relevant for many owners of private housing, because diesel fuel is not cheap; frankly speaking, a lot of it is required for the heating season.

The rating of this equipment in European countries is quite high, thanks to its advantages. Let's list the main ones.

The efficiency of the equipment under discussion is high, reaching 95% under the following conditions:

- correct installation of the boiler;

- furnace installations in accordance with all rules and regulations;

- high-quality insulation of the house;

- installation of double-glazed windows;

- proper storage of fuel reserves;

- using high-quality fuel;

- timely maintenance;

- competent choice of equipment power, manufacturer, model.

The efficiency can reach up to 98% when using a condensing type boiler, but more on that later.

- Wide range of model range, manufacturers, power characteristics, etc.

- Economical consumption of electrical energy.

- Environmental friendliness, which is a fairly current trend in modern European society. When burned, almost no harmful substances or gases are formed.

- High level of safety compared to gas boilers.

- Autonomous, automatic operation that does not require constant human intervention.

- Inertia is not typical for the design of diesel boilers (unlike solid fuel analogues). Productivity decreases immediately.

- Liquid fuel takes up much less storage space than solid fuel (peat, firewood, coal).

- Possibility to use used engine oils, which are cheaper. At the same time, the issue of recycling waste material, which is completely burned in a diesel unit, is resolved. Again, a reference to environmental friendliness.

Review of manufacturers

There are many manufacturers of diesel boilers. There are domestic ones, from near and far abroad. There are so many offers that it is difficult to choose. In this case, it is customary to focus on the most popular ones.

Diesel boilers Kiturami (Kiturami)

Convenient for heating cottages and houses with irregular residence. They operate autonomously and use a tubrocyclone burner - one of the latest developments that saves fuel. It is possible to control both the room temperature and the coolant temperature; a self-diagnosis system is built-in.

The power of boilers using Kiturami diesel fuel is from 10.5 to 34 kW, fuel consumption is from 1.13 liters/hour to 4.3 liters/hour. There are dual-circuit models, with a possible supply of hot water from 3.8 liters/min to 20 liters/min.

Diesel boilers Kiturami (Kiturami)

Buderus boilers

The Buderus company produces diesel boilers made of steel and cast iron. Cast iron boilers of the Logano G model (Logan) are popular. There are powers from 25 kW to 95 kW. In another line there are more powerful ones up to 1200 kW.

They run on standard diesel fuel or fuel with low sulfur content. They are interesting because in the Unit modification, the burners optimize the fuel mixture, achieving almost complete combustion of gas, which reduces soot formation and emissions. These units have simple controls and easy setting of the required operating parameters. It may be interesting to expand the functionality of the automation by installing additional modules (you do not need to change the automation unit as a whole, but just purchase an additional unit that provides the functions you are interested in).

Boilers "Buderus" on diesel fuel

Buderus Logano S steel boilers are produced only in industrial capacities - from 450 kW of power. These industrial units can operate on two types of fuel - gas and liquid fuel.

Navien

Korean diesel boilers Navien (Navien) are made in the form of a rectangle. Their design is more similar to European ones. A distinctive feature is its small dimensions.

Boilers marked Navien KG have fuel preheated before being supplied to the nozzle. The pressurized fan supplies fuel at a sufficiently high pressure, which also ensures the effective removal of combustion products into the chimney. A stainless steel heat exchanger and a filter adapted for Russian fuel, which has replaceable cartridges for easy and quick cleaning or replacement. The control panel is Russified, the automation is protected by a special microcircuit at the input, which allows the boiler to operate without failures with network parameters of 230 V ±30%.

That’s why Navien liquid fuel boilers are quite popular: manufacturers have taken into account many of the features of our country’s networks. Power from 13 kW to 40 kW, fuel consumption from 1.46 liters/hour to 4.65 liters/hour, hot water capacity - up to 22.9 liters/min

Diesel boilers Navien

Saturn

Saturn boilers are units from another Korean company. They run on diesel fuel and kerosene; manufacturers do not recommend using spent fuel. They are distinguished by the presence of a copper heat exchanger (pipe 20 meters long and 15 mm in diameter). They delight owners with quiet operation and minimal size. They can be placed in a living space. The power of Saturn diesel boilers is from 13.5 kW to 35 kW, fuel consumption is from 2.01 liters/hour to 4.54 liters/hour.

Liquid fuel boilers Saturn (Saturn)

When compared with Navien boilers, there is greater fuel consumption for heating with almost the same equipment power.

Liquid fuel boilers Ferroli

Ferroli produces dual-fuel boilers. They run on gas and/or liquid fuel. The body and heat exchanger are cast iron. The body is insulated with a layer of temperature-resistant material. The GN2 N model is available with power from 106 kW to 252 kW, weight from 360 kg to 780 kg.

Liquid fuel boilers Ferroli

Cast iron boilers of the GF N model operate on solid and liquid fuels. The power of boilers in this line ranges from 12.7 kW to 27.5 kW. Equipped with an overheating protection system and a safety valve, you can burn both large and small pieces of wood in the firebox and switch it to “liquid fuel” mode. These models are single-circuit only (they do not heat water).

In principle, from these brands you can choose equipment for any conditions and needs, and there are still more than a dozen of them on the market, and maybe more than one hundred. So arm yourself with patience and choose. Good luck!

Flaws

Now let’s look at the points that hold back buyers in their desire to purchase a diesel heating device:

- In the first place is the high price of fuel material. This makes using the equipment expensive. It is justified only by the absence of a gas pipeline near the land plot. Connecting gas communications from afar will be an even more expensive undertaking.

- Diesel fuel contains impurities that clog the nozzle and reduce pump performance. In this case, the installed cleaning filters quickly become clogged with paraffin. Without timely maintenance, the boiler will not operate at its full possible capacity with the same amount of fuel.

- The need for specially equipped fuel storage.

- The need for stable power supply. If situations with power outages are expected, it is better to acquire a stabilizer.

- Strong smell and noise require the installation of a separate isolated room or building.

- Thickening of the heating material under the influence of temperatures below +5⁰ C, which forces the pump to work in increased mode.

How to choose a boiler for heating a private house?

If you still choose a diesel unit, its purchase should be based on the following factors:

- Type of burner. The best option is a replaceable burner powered by a diesel or, if necessary, a gas source. If there is a burner heating system, fuel consumption will be significantly reduced.

- Boiler productivity. It is calculated taking into account the volume of the room and the amount of diesel fuel used. As a rule, 1 kWh of energy is consumed per 10 m². For housing with an area of 150 m², it is necessary to purchase a boiler with a capacity of at least 15 kW, and preferably a little more, so that there is a reserve of power for extreme cold.

- Number of circuits. You need to decide how the water will be heated. Boilers are produced with already built-in boilers, or, for example, with a second circuit for an indirect water heater purchased separately.

- Firebox material. The steel body of the firebox is more economical, but not as wear-resistant and durable. The cast iron firebox is designed for 50 years of operation and is resistant to sulfur-containing condensate and corrosion. At the same time, it is susceptible to cracking due to temperature changes.

- Type of fuel material. The best option, of course, is to work on all types of fuel (diesel, waste oil, gas). But this option will be a very expensive purchase.

Advantages and disadvantages

Let's move on to analyzing this type of fuel. What to expect from him?

Advantages

- The mentioned ability to control the boiler without human intervention is a huge plus. For a city dweller accustomed to comfort, the need to chop wood and light the boiler several times a day will turn life in nature into real hard labor. Here you can completely forget about the problems of heating your home.

- The price per kilowatt-hour of thermal energy obtained by burning main gas will, of course, be lower. However, gas pipelines are not available everywhere. The cost of connection with obtaining all permits in the Moscow region often reaches a million rubles, and the time frame can exceed a year.

Here everything is simple: just buy a boiler, install a container in the yard - and your home will be warm.

Power in rural areas is often provided by prehistoric equipment. Hence the power limitations.

Flaws

- Again, looking ahead: operating costs when heating with a solarium are VERY high and do not differ much from the costs when using bottled gas or electricity. In the latter case, we are, of course, talking about direct heating: ANY heat pump is much more economical.

- The boiler itself is somewhat more expensive than a gas analogue of identical power due to a more complex burner. Taking into account the need to purchase a container for storing diesel fuel (usually 4-10 m3) and installing a fuel line, equipment for diesel fuel will not be cheap.

- The burner of this type of heating device is VERY noisy due to the pressurization. Hence the conclusion: a solar boiler can only be installed in a separate room. Another argument in favor of this solution is the smell of diesel oil.

- All devices of this type are highly dependent on the quality of diesel fuel. Purchasing a cheap solarium can result in expensive boiler maintenance.

- The prospects are quite gloomy. Like all fuels produced from fossil raw materials, solar oil will only become more expensive over time.

- The container will take up quite a lot of space in your yard and will definitely not decorate the local area.

For quickly heating a small room, the stove in the photo is almost ideal.

How does a diesel boiler work for heating a private home?

Heating equipment with diesel fuel is a set of devices: the boiler itself, an automatic control system, a fuel unit.

The boiler consists of:

- Frame. Produced with combustion chambers:

- open type (communicates with the space of the room for air intake, requires installation of fresh air ventilation in the combustion chamber);

- closed type (chamber is insulated, air enters under pressure).

- Electric ignition unit. Generates a spark in the burner to ignite the supplied fuel.

- Burner. Depending on the method of air supply, there are:

- supercharged (air is supplied by a turbine);

- fan (fed by a fan).

Replacement burners are installed in combination boilers and require operation from different types of fuel, for example, diesel, gas.

Combination boiler diagram

The automatic control system is divided into blocks:

- working unit (responsible for maintaining a certain temperature of the medium, turning the unit on and off as necessary);

- emergency unit (safety control, emergency stop of equipment during an emergency).

The fuel unit includes:

- fuel tank;

- fuel pump (fuel supply to the burner from the tank);

- chimney (discharges combustion products outside).

Combined water heaters can be useful for a country house >>>

Features of work

Autonomous heating using diesel fuel has an operating principle identical to that of a turbocharged gas system. The air is forced by a fan and mixed with oil. This mixture is sent to the firebox and ignited using electric ignition. During the combustion process, all energy is transferred to the heat exchanger. Identity is present not only in the operating principle, but also in the equipment itself. The modern offer allows you to find dual-fuel installations that can run on both natural gas and diesel fuel. To change it, you only need to replace the burner.

The heating equipment operation process is fully automated. Fuel supply, ignition and fan rotation are carried out automatically using a thermostat.

Diesel boiler operation diagram

Heating equipment for a private house operates according to the following scheme:

- The fuel pump and the air supply system into the combustion chamber are driven.

- The pump pumps fuel from the storage tank into the combustion chamber. Here the fuel material is filtered and heated.

- The nozzle pressure increases to 10-16 atmospheres. This is enough to spray the fuel into a suspension.

- The electric ignition turns on.

- The atomized fuel mixes with the forced air and ignites from an electric spark.

- The thermal energy released during combustion is supplied to the heat exchanger, heating the coolant.

- The coolant circulates through heating appliances, warming the rooms of the house.

- If a condensing boiler is operating, the thermal energy of the released gases is also used for heating.

- The products of fuel combustion are discharged through the chimney outside the house.

Types of diesel boilers for heating a private home

Diesel heating equipment differs in several respects. One of them is adjusting the power of the burners. In this case, boilers are:

- Single-stage (burner power is not adjustable, heating temperature is constant).

- Two-stage (burners operate in two positions).

- Modulating (wide range of burner performance adjustment).

In addition to heating the room, a diesel heating boiler for a private home often performs a water heating function. This is very convenient and allows you to significantly save on electricity. According to this indicator, heating systems are divided into:

- Single-circuit. They perform exclusively the function of heating the room.

- Dual-circuit. A double-circuit diesel boiler for heating a country house combines heating of rooms (first circuit) and heating of running water (second circuit). At the same time, there is a decrease in space heating by 20%.

- Double-circuit + built-in water heater. The second circuit is designed to heat water inside the boiler. This way you can significantly reduce your energy costs in winter.

Double circuit diesel boiler

Installation rules

It is best to call specialists to install the equipment, who will make the connection professionally. However, you can install a diesel heating boiler yourself. Its installation does not require special permission, as is the case with gas equipment. But there are separate requirements for installation, as well as arrangement of the combustion room:

- To install the heating boiler, it is necessary to provide a separate building. If this is not possible, at least a separate technical room, for example, in the basement of a house. The main condition for this is that there must be a separate exit to the outside.

- Ceilings in the equipment room are provided at least 2.5 m.

- The volume of a technical room or a separate building should not be less than 15 m².

- Experts strongly recommend installing fuel filters to extend the life of the equipment.

- For boilers with a power of 350 kV, a separate power supply line should be installed from a common circuit breaker.

- It is recommended to install away from doors and windows.

- Cladding of furnace walls with non-combustible finishing materials.

Fuel storage

An important issue when purchasing diesel equipment for heating a home is the method of storing fuel. You can use two options.

The first involves storing flammable liquids inside the boiler room. Moreover, the maximum volume that is allowed for storage is 800 liters. This is not enough; it will not be enough for the entire heating season, especially for regions with a long period of cold weather.

Installation diagram of the fuel tank

Therefore, the second option for storing fuel using an external container (4-10 tons) is still preferable. It is installed on the surface or dug into the ground. It is best to place it at a depth where the soil layer does not freeze, so that the diesel fuel does not thicken due to low ambient temperatures. Additionally, the container is insulated, as is the pipeline for supplying fuel to the combustion chamber.

It is preferable to choose stainless steel fuel containers.

When it is not possible to install gas communications for heating a country house, a diesel boiler can be a good alternative. Heating a private home with diesel fuel costs a lot of money, but it is much more economical than the option using electrical equipment.

Expenses

How to calculate diesel fuel consumption for heating during the season and, most importantly, your costs?

- For the center of the country, with good insulation of the house, you can take the approximate need for thermal energy as 1 kW per 10 m2. Yes, such a scheme is greatly simplified and gives rather mediocre accuracy; but an accurate calculation of the heat requirement is still beyond the scope of the article.

- As practice shows, burning a liter of diesel fuel produces about 10 kilowatt-hours of thermal energy. To provide heat to a house of 100 square meters during the peak of cold weather, we need to burn a liter every hour.

- Again, turning to practice - a correctly calculated heating installation ON AVERAGE operates at half the rated power. That is, if calculations showed that we need a 10-kilowatt boiler, then half the time it will operate at full power and half the time it will be idle. Therefore, in practice, the average fuel consumption will be halved and amount to 1/2 liter per hour.

A month is, as you can easily calculate, 720 hours. The instructions for further calculation are quite simple: we multiply hourly consumption by 720 and get 360 liters of diesel fuel per month, which at current prices will result in 32.5*360=11,700 rubles at the rate of 32.5 rubles per liter.

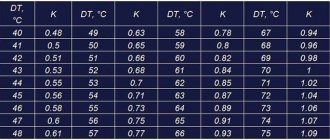

It is easy to judge the immediate prospects from the table of world fuel prices. We are still moving towards a market economy, which implies leveling prices at the general level.