There are boilers that run not only on solid fuel, but your “house in the village” may end up in a place where gas is not supplied, and there are power outages. In such a situation, a wood-burning boiler for heating is a real panacea. The main thing is to prepare firewood in advance - and you will be able to heat not only the house, but also the bathhouse or greenhouse. What are the advantages of such equipment and does it have any disadvantages, by what principle is the choice made, and what are the connection diagrams? Answers to these questions will be given throughout the article.

Organization of heating from a wood boiler

The design and principle of operation of a wood-burning boiler

Firewood belongs to the group of solid fuels and can be used on the same level as coal for heating residential buildings no higher than 2 floors, and is also well suited for organizing air heating in the house.

Installation of a wood-fired boiler. Photo source: rgagroup.ru

Wood-burning hot water boilers are conventionally divided into 2 types:

- non-volatile, operating with the natural draft of the chimney;

- supercharged, in which air is forced into the firebox.

The first ones use simple oven technology, with the only difference being that they have an internal water circuit. A large combustion chamber is located above the ash pit, separated from it by grates.

Air from the room is supplied to the combustion device through a damper in the ash pan, and then moves through the grate. The supply volume is adjusted by a thermostat that controls the temperature of the coolant in the water jacket of the boiler unit. The damper control is mechanical.

The exhaust gases formed in the combustion space at a high temperature move through the flame tubes of the internal heat exchanger and are cooled through the walls of the tubes by heating water.

Based on the structural elements of the boiler unit, flue gases are able to circulate several times through the flue pipes, effectively exchanging thermal energy with the water jacket.

Operating principle. Photo source: stroikabudet.ru

Giving up their heat, volatile substances formed from fuel combustion leave the heating boiler with flue gases using a flue exhaust system.

A non-volatile wood-burning boiler cannot boast of good efficiency, at most it is 70%.

The second version of the heat generator is the most productive; its efficiency can reach 75% due to forced air supply carried out by a supply fan.

Strapping scheme

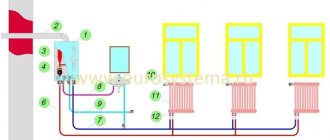

A typical connection diagram for boilers for heating with wood contains two basic units that allow it to operate reliably in heating systems of an individual home. This is a safety group and a water group with a three-way valve with a thermal head and a temperature sensor.

Unfortunately, due to its design features, this heating source cannot use modern automation and control systems. The boiler's piping along the water circuit of the heating network and the exhaust of flue gases is carried out according to the counterflow principle, that is, the media move towards each other.

Connection diagram with boiler

This design of wood-burning boilers for heating allows you to reduce the temperature of the flue gases. But, as evidenced by the real efficiency of wood-burning boilers, this does not happen very well.

To increase the efficiency of the entire thermal circuit, it is recommended to include an indirect hot water boiler with a water tank. It allows you to reduce the temperature of exhaust gases and additionally heat hot water, at the same specific fuel consumption.

Criterias of choice

The Kupper boiler is characterized by an optimal price/quality ratio.

When choosing a boiler, it is worth considering the following indicators:

- Heated area. Approximate efficiency calculations are performed using the formula 1 kW = 10 sq.m. For example, in the central part of Russia, heating a house with an area of 150 sq.m requires a device with a power of 15 kW. For colder regions, a more powerful unit is needed. To heat a similar house in Siberia, it is worth taking a device with 30 percent more power. When connecting a second water circuit for DHW, you need to add another 15–20 percent to the final value.

- Material. Cast iron equipment can last 35 years and has the best thermal and technical performance. But such units are unstable to mechanical damage and weigh a lot. Steel devices are cheaper, they are not afraid of shocks, but their service life is on average 10–15 years less.

- Firewood loading type. More often, devices are manufactured that provide for lateral fuel supply. But there are also top-loading models. A similar design is used in gas generator boilers. The main advantage of the solution is the ability to pre-dry the firewood, which increases the heating efficiency.

- The ratio of the volume of the combustion chamber and the power indicators of the boiler - how many times during the day it is necessary to load fuel. For steel devices this value is on average 1.5–2.5 l/kW versus 1.1–1.4 l/kW for cast iron ones.

- Burn protection. An important characteristic, especially with open access to the boiler room. It is achieved through thermal insulation of the combustion chamber handles, other highly heated elements, protecting cases and grates.

- Additional functionality - automatic sensors, built-in storage boiler, remote control system. All this makes the operation of the heater more convenient. But some options require connection to an electrical power source, which deprives the unit of autonomy.

In addition to technical indicators, you will need to decide on the brand of wood-burning boiler and the cost. A good option in terms of price and functionality would be one of the modifications of the Kupper boiler. Their advantage is also their compactness, which allows the device to be placed in a small area.

Advantages and disadvantages

This type of heating has a significant list of advantages, in the first place of which is the economy of the heating option, which is caused not only by the lowest prices for wood fuel, but also by the low costs of installing and operating heating equipment.

The main advantages of boilers for heating with wood:

- Environmental Safety. Due to low emissions of harmful substances into the atmosphere.

- The technological simplicity of the boiler using wood and coal guarantees a long period of operation.

- The variability of the stove device, the possibility of using all types of solid fuel, for any premises, for example, for a wood-burning bathhouse.

- Energy independence.

- Possibility of heating large areas of 1000-1500 m2.

- Wide selection of types of units with a water circuit.

- The ability to create a water heating circuit with your own hands.

Disadvantages of solid fuel boilers:

- Need for additional fuel storage space.

- Low comfort levels and the need for constant care.

- High download frequency.

- Low level of automation and regulation.

Detailed installation instructions

Solid fuel units are characterized by high inertia (with the exception of pellet models) and a tendency to form condensation in the firebox. Long-term trouble-free operation of the equipment is possible subject to high-quality installation.

Masters adhere to the following sequence of actions:

- Preparing the premises (ventilation, lighting) and a platform made of non-combustible material.

- Installation of the boiler according to the project with vertical alignment of the body and maintaining the alignment of the chimney pipe.

- Construction of a thermally insulated combustion product exhaust system with a height of 5 m or more with a permissible number of turns of less than 3.

- Connection to the heating circuit (piping).

- Test run.

After installing the boiler, safety group devices are installed sequentially: pressure gauge, safety valve and air vent.

Types of wood boilers

A wood-burning boiler is a highly efficient heating equipment installed as a source of heat supply in autonomous systems in order to maintain sanitary and hygienic living conditions in houses of medium and small size.

These installations are equipped with special safety components to ensure safe operation. The units operate in the efficiency range from 70 to 80%.

There are quite a few modifications of boilers. Photo source: remoo.ru

Classification of solid fuel boilers:

- Classic direct combustion boilers. Despite the fact that they are significantly inferior to the latest devices in terms of operating time from 1 load, they are still popular due to their low price.

- Top combustion boilers are cylindrical in shape and equipped with a specialized telescopic air tube. Due to the fact that the combustion process also occurs at the top of the combustion chamber, a new portion of fuel can be added after the combustion of the previous layer.

- Bottom combustion boilers have a particularly well-thought-out and efficient design of mine boiler units with long-term combustion of the bottom layer. This makes it possible to fill the firebox with firewood at any time during operation.

- The pyrolysis device is a gas-generating wood-fired boiler with 2 combustion chambers. In the first, primary combustion takes place with a deficiency of oxygen, which triggers the process of pyrolysis and gas generation. The second is for complete combustion of synthesis gas. This design makes it possible to increase the operating time of the boiler with one filling of firewood.

- Pellet boilers are produced to operate on pressed or granulated wood waste and are equipped with a special hopper, from which fuel enters the combustion chamber using an auger.

Rating of the best models

The choice of boiler modification is determined by the type of building being heated, its purpose, operating features, and architectural parameters. Craftsmen give preference to equipment with greater functionality, reliability, and energy efficiency, produced by a company that undertakes warranty obligations regarding long-term trouble-free operation of the equipment.

"Teplodar Cooper Praktik-14", 14 kW

The energy-independent single-circuit model is designed for heating rooms up to 140 m². Firewood, coal, and peat briquettes can serve as fuel. The floor-standing boiler with mechanical control has a steel heat exchanger and an open combustion chamber. The arguments in favor of its choice are: equipping with a heating element, simplicity and reliability of control, and the manufacturer’s use of high-quality materials.

"Teplodar Kupper Praktik-14" is intended for heating premises.

"Teplodar Kupper OK 20" with pellet burner, 20 kW

A universal model for heating buildings up to 180 m² is equipped with a rotary damper, a thermometer, an electric heating block, and a screw. It is possible to switch to pellets or gas after replacing the burner. The permissible operating pressure in the system is up to 2 atm. Traction is adjustable within 30-100%. There is a turbocharger and a heating element control panel. Warranty period - 3 years.

"Vesuvius Elbrus-10", 10 kW

The boiler is installed in residential and industrial buildings with an area of up to 100 m² at a pressure in the circuit of up to 3 atm with forced or natural circulation. The housing has cast iron doors that ensure the tightness of the structure when closed. When designing the heat exchanger, easy access to the internal surfaces is provided to simplify their cleaning. The water jacket is insulated with basalt insulation.

"Vesuvius Elbrus-10" is a heating water boiler.

"Bourgeois-K T-50A-2K", 50 kW

A single-circuit pyrolysis boiler with an autodraft regulator is installed in domestic, industrial, and small-apartment buildings. Increased reliability is ensured by an all-welded body made of heat-resistant steel with increased resistance to corrosion.

Basalt is used for thermal insulation; the outer metal cladding has an additional protective coating. Efficiency - 82-89% (depending on the type of fuel).

"Bourgeois-K Modern-12", 12 kW

The Russian non-volatile solid fuel unit is made of certified steel 3 mm thick and is intended for heating residential and technical buildings. It can work on wood, pressed sawdust, coal. When fully loaded, the fuel will last for 8 hours. It is possible to additionally equip the boiler with automation. The model is easy to repair and clean, and is tested after assembly at a pressure of 4 atm.

"Bourgeois-K Modern-12" is a non-volatile solid fuel unit.

"Lemax Forward-16", 17 kW

A single-circuit unit is chosen for country houses, office and industrial buildings with an area of up to 160 m². Designed for use in systems operating at coolant temperatures up to 95 °C and pressures up to 2 atm. This is a steel non-volatile floor-standing boiler of a classic design with mechanical draft control and an efficiency of 75%. There is a possibility of vertical loading. The manufacturer guarantees high build quality.

Kentatsu Elegant-03, 17 kW

Cast iron floor convection model with an open combustion chamber. The equipment is energy independent and allows operation with natural or forced circulation. Can serve as the main or backup heat generator. Operates with 90% efficiency. The model is equipped with a thermomechanical power regulator and a thermometer, which helps to quickly obtain data on the operation of the unit. To reduce the concentration of harmful emissions and improve the completeness of fuel combustion, there is a secondary air supply regulator.

"Kentatsu Elegant-03" is a solid fuel cast iron boiler.

"Protherm Beaver 50 DLO", 39 kW

The argument in favor of choosing a model is its increased resistance to corrosion, thermal loads, pressure and temperature changes. There is a thermomanometer on the front panel; the draft is regulated by a damper on the chimney. The cast iron non-volatile boiler has a large combustion chamber. One load is enough for 6 hours of burning.

Zota BOX 8, 8 kW

The single-circuit steel floor-mounted model is designed for heating technical buildings (workshops, garages) with an area of up to 80 m². There is a cast iron hob for cooking or heating food. The heating element is optional.

“Zota BOX 8, 8 kW” is a solid fuel boiler for heating rooms.

"Zota Topol-32VK", 32 kW

The boiler is equipped with water-filled grates, it is possible to load horizontally or vertically. Autonomously works up to 12 hours. Ease of cleaning the heat exchanger is ensured by the presence of a removable damper.

The position of the blower valve on the ash pan is adjusted using a screw or a mechanical regulator.

It is allowed to equip with a heating element to increase the functionality of the boiler.

"Protherm Beaver 20 DLO", 19 kW

A solid fuel installation with a cast iron coil is designed to operate on coal, peat, and wood. The housing design allows for front loading for log lengths up to 550 mm. For insulation, inorganic wool with an aluminum foil coating is used. The manufacturer provides a 2-year warranty with the condition of professional service for the Beaver 20 DLO model after 1 year of operation.

"Protherm Beaver 20 DLO" is a floor-standing solid fuel boiler.

Stropuva S30, 30 kW

The long-burning model is chosen for heating buildings up to 300 m². The boiler operates on wood, coal, pellets with an efficiency of 85% at a coolant temperature of up to 75 ° C and a pressure in the circuit of up to 2 atm. The bookmark is enough for 30 hours of work. If briquettes are used, the battery life increases to 2-3 days. The equipment is energy independent.

Stropuva Mini S8, 8 kW

The single-circuit compact boiler is available in a basic classic configuration. It is designed for installation in workshops and garages with an area of up to 80 m². With a firewood length of up to 40 cm, the firebox can accommodate up to 37 kg. In this case, the installation will operate autonomously for up to 18 hours (provided that the wood is well dried).

“Stropuva Mini S8, 8 kW” is a long-burning boiler.

"Trayan T10", 10 kW

A long-burning double-circuit floor-standing boiler that can be used to produce hot water or organize an emergency cooling system. Heating power - from 40%. The air supply is regulated by an automatic damper. Efficiency - 82-85%. Additional equipment with heating element is possible. The coolant temperature can reach 95 °C at a pressure of up to 4.5 bar. To monitor operating parameters, the unit is equipped with a pressure gauge and thermometer.

"Trayan T15", 15 kW

A long-burning floor-standing boiler, powered by fuel briquettes, coal or wood, is characterized by economical consumption of materials due to their efficient two-stage combustion. The model is non-volatile. The design of the loading chamber allows for the loading of firewood up to 45 cm in length. It is possible to additionally equip the installation with an electric heater with a power of up to 9.5 kW.

"Trayan T15" is a long-burning floor-standing boiler.

Wood and electric boiler

Manufacturers of wood-burning boilers, to protect the interests of consumers, decided to modify them and eliminated the main drawback - a significant decrease in the temperature of the coolant in the system between firing sessions.

Electric heating was integrated into the system of electric wood-burning boilers, thus creating boilers with combined heating.

Such heat sources combine all the advantages of electric and wood heating in one device, in which consumers are very interested.

Units powered by wood and electricity also work well in tandem with an indirect heating boiler and can heat water at night according to the tariff metering, thereby making such a heating system extremely economical.

Calculation of water heating

First you need to calculate the system. First of all, it is necessary to remember that the need for heating will directly depend on factors such as heat loss through window and door openings, as well as through walls, floors and ceilings. Thus, to calculate the power of a heating boiler, you need to know the principle of operation of the system and the degree of heat loss by the finishing and design materials from which the house is made.

Those walls of a private house that are in direct contact with the external atmosphere conduct heat more efficiently. In this case, the degree of heat loss will increase with each temperature difference between the internal and external sides of the wall. The normal temperature is considered to be 20 °C.

When calculating water heating, this indicator should be summed up with the highest negative temperature characteristic of a particular area. When calculating heat loss, you need to calculate the exact area of the end (external) walls, door and window openings, ceilings, floors, and then multiply these data by the degree of heat loss for each square meter of a private house. After this, all results are summed up.

The correct calculation of the location of the distribution boiler is very important, since the number of bends and the length of sections of the residential heating system in a private house will directly depend on this.

The most reliable and economical wood boilers

Firewood burns out pretty quickly. To prolong this process as long as possible, they achieve the process of smoldering fuel. For this purpose, special combustion structures have been made that allow working on one load for 4 hours or more.

The result was very inexpensive, popular boiler designs: Evan WARMOS-TK-12.0 and Lemax Forward-12.5.

Main characteristics of Evan WARMOS-TK-12.0:

- Brand country: Russia.

- Production - Russia.

- Heating capacity using wood is 9 kW.

- Boiler type: non-volatile.

- Number of circuits: single-circuit, heating.

- The firebox is open.

- Automation - by air.

- The metal of the heat exchanger is steel.

- Firewood burning time is 5 hours.

- Chimney – 114 mm.

- Dimensions – 620x440x930 mm.

- Weight – 250 kg.

- Warranty – 1 year.

- Price – 20,500 rub.

Main characteristics of Lemax Forward-12.5:

- Brand country: Russia.

- Production - Russia.

- Heating capacity using wood is 12 kW.

- Boiler type: non-volatile.

- Number of circuits: single-circuit, heating.

- The firebox is open.

- Automation - adjusting the level of air supply to the burner.

- The metal of the heat exchanger is steel.

- Firewood burning time is 4 hours.

- Chimney – 140 mm.

- Dimensions – 121x109x917 mm.

- Weight – 70 kg.

- Warranty – 3 years.

- Price – 16,500 rub.

Manufacturing a mine unit - procedure

The first stage of work is the assembly of the KDG body from blanks 4 mm thick. First, the side walls, door openings and vault cover are welded to the bottom of the homemade structure. Corners are mounted inside the resulting firebox. Grate bars are installed on them. The finished structure is welded along all existing seams. It must be sealed.

The second stage is the installation of a water circuit (it is 2 cm away from the body), assembled from 3 mm blanks, and welding pieces of steel strips to the side walls. The latter are necessary for attaching sheathing sheets to them. Important! The jacket does not cover the ash chamber. It starts at the level of the grate.

The third step is the installation of flame pipes in the boiler tank (in the upper part). They are mounted in openings that need to be made in the front and rear walls. The ends of the pipe products are hermetically welded. Then grate bars are made from the corners in the form of a grate and a door. Two rows of steel strip are attached to the latter from the inside, between which a narthex seal is placed - an asbestos cord. The grate bars additionally serve as an air diffuser, directed into the ash pan by a fan.

Special devices - fittings - are cut into the walls of the tank. They make it possible to connect the return and supply pipelines. An air duct is installed (a flange is immediately mounted on it to secure the fan) and a smoke exhaust pipe. The air duct is introduced into the ash compartment from the rear (approximately in the middle).

Embedded elements for installing the KDG casing and door hinges are welded to the body. The homemade unit is finished with insulation on top and on all sides. It is secured with a cord. The metal sheets are screwed to the heat insulator with self-tapping screws and the doors are installed.

The final work is connecting the control module on top of the boiler, installing a fan on the flange of the air pipe, and a temperature sensor under the insulation on the rear wall. The continuous burning unit is ready for use.

Wood boiler maintenance

Much to our chagrin, most owners of wood-burning boilers for heating a private home pay little attention to the operating features of the device.

Such boilers require high-quality maintenance. Photo source: hearth.com

However, a wood-burning boiler has its own differences in operation, which require certain operations:

- Preparing the chimney. Before putting such a unit into operation, it is necessary to inspect the gas duct and, if necessary, clean it of soot, and in the future it is recommended to perform this operation at least once every two months.

- The main points in boiler maintenance are loading firewood and cleaning the combustion chamber. In order to create oxygen access to the torch, when loading firewood, they are not stacked tightly.

- Cleaning is carried out using special devices included with the boiler.

- It is not recommended to completely clean the grate; a small amount of ash on the grate can serve as thermal insulation and, thereby, increase the service life of the boiler.

What will you need?

You will need a small set of tools, materials, diagrams, and design sketches of heating boilers.

Tools

The issue of tools is not as important as the level of skill of the master. The simple skills of a novice welder in a garage workshop will not be enough. Above average level required. The reason for the requirements is work at high temperatures and hot water pressure. If the welds are not of sufficient quality, leakage and rupture are likely.

When welding parts, it is recommended to use double seams. Increases the consumption of welding electrodes and wire for semi-automatic machines, but guarantees the absence of leaks or burnouts during long-term heating in winter. Seams are the weak spot of a homemade boiler.

The following tools will be required:

- Inverter welding machine

- Semi-automatic welding machine

- Angle Grinder

- High speed drill, metal drill set

- Devices for fixing parts during welding - clamps, clamps

- Welding table

- Welder mask

- Pneumatic spray gun

Materials

If you do not pay due attention to the quality of materials, the structure made as a result of many hours of labor will not live up to expectations and will fail after several days of use. Leaks in the water jacket appear more often, and the smoke circulation system begins to pass smoke through the welds.

Problems can only be avoided by using high-quality materials:

- Sheet steel of heat-resistant grades

- Seamless pipes

- Construction fittings

- Asbestos sheets, sealing cords

- Gas, water fittings, pressure gauges, bimetallic thermometers

- FOM tape

- Heat resistant paint

Project

A number of operating diagrams and sketches with dimensions of the most practical, technologically simple heating structures are presented.

Solid fuel boiler - diagram, main dimensions

Before choosing a design, you need to calculate the required power. Measured in kW, calculate 1 kW per 10 sq. meters of area.

Diagram with the dimensions of a simple heating boiler

Is it possible to do it yourself?

The device that uses wood fuel is very simple and it is quite possible to make a wood-burning boiler with your own hands for those who know how to handle basic plumbing tools and a welding machine.

A cauldron made by myself. Photo source: biser.enjob.ru

Step-by-step instructions for a homemade wood-burning boiler:

- A DIY wood-burning boiler is made from a 200 liter metal barrel. The lid is cut off and the side is welded. A piston with a diameter smaller than the container is made from a powerful blank or other weighting material. You can use components for pumping stations and cables.

- A hole is made in the cover to accommodate a 100 mm air duct. In height, it is arranged 20 cm above the level of the barrel.

- A 100 mm chimney outlet is installed on the side.

- The air duct is welded to the piston. A damper is installed on the top of it, regulating the volume of required air. Special ribs are welded to the bottom of the piston structure to compact the firewood.

Such homemade boiler units with a long-burning principle can operate for more than a day on one stack of firewood.

Installation Features

To install a wood-burning boiler, you need to prepare a solid foundation.

A heating boiler that runs on wood can be installed in any place if it meets technological and fire standards. A technical room with ceilings higher than 2.2 m and an area of 8–12 sq.m. is suitable for the boiler room. Supply and exhaust ventilation and light must be installed. Only non-combustible materials are suitable for interior decoration. You can install the boiler in the basement, but only if it is dry.

When installing you also need to consider:

- The wood-burning boiler is mounted on a solid foundation. When connecting a cast iron device, you will need to build a concrete base.

- To prevent accidental ignition during fuel loading, the wooden base in the direction of opening the firebox door is covered with a sheet of metal or asbestos cement.

- The unit is installed in a place where it will be convenient to maintain. All elements must be freely available.

- Firewood should be stored in an adjacent room.

- The installation of the chimney pipe is carried out following fire safety requirements during installation. All parts that heat up and pass through the floor slabs and roof are insulated. A spark arrester is installed at the outlet of the chimney.

If the design of the unit requires connection to the electrical network, use a voltage stabilizer and an uninterruptible power supply. The automation is connected from the panel via circuit breakers and RCDs. In general, installation is not difficult; it is quite possible to do it yourself.